High-performance compact cylinders for robust force, efficiency & reliability in space-premium applications. Extremely short design, Ø12-Ø100mm bores, various strokes. Flexible mounting, often lightweight aluminum body. Integrated elastic cushioning (bumpers) absorbs impact, reduces noise & ensures smooth operation. Ideal for handling, clamping, robotics due to space efficiency.

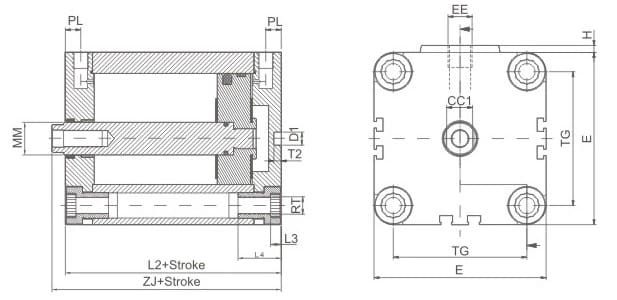

| حجم التجويف (مم) | D1 | E | هـ هـ | H | L2 | L3 | L4 | φMM | PL | RT | T2 | TG | ZJ | CC1 |

| 16 | 6 | 29 | M5 | 1 | 38 | 3 | 16 | 8 | 8 | M4 | 4 | 18 | 42.5 | 7 |

| 20 | 6 | 36 | M5 | 1.5 | 38 | 4 | 18 | 10 | 8 | M5 | 4 | 22 | 42.5 | 9 |

| 25 | 6 | 40 | M5 | 1.5 | 39.5 | 4 | 18 | 10 | 8 | M5 | 4 | 26 | 45 | 9 |

| 32 | 6 | 50 | G1/8 | 2 | 44.5 | 5 | 20 | 12 | 8 | M6 | 4 | 32 | 50.5 | 10 |

| 40 | 6 | 60 | G1/8 | 2.5 | 45.5 | 5 | 20 | 12 | 8 | M6 | 4 | 42 | 52 | 10 |

| 50 | 6 | 68 | G1/8 | 3 | 45.5 | 6 | 20 | 16 | 8 | M8 | 4 | 50 | 53 | 13 |

| 63 | 8 | 87 | G1/8 | 4 | 50 | 8 | 25 | 16 | 8 | M10 | 4 | 62 | 57.5 | 13 |

| 80 | 8 | 107 | G1/8 | 4 | 56 | 8 | 25 | 20 | 8.5 | M10 | 4 | 82 | 64 | 17 |

| 100 | 8 | 128 | G1/4 | 5 | 66.5 | 8 | 25 | 35 | 10.5 | M10 | 4 | 103 | 76.5 | 22 |

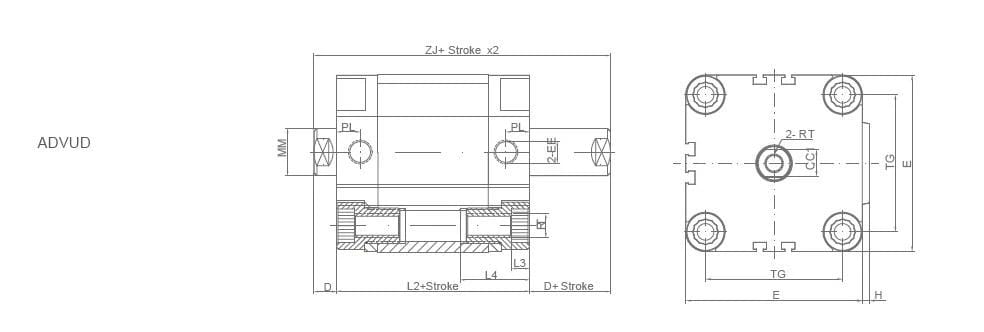

| التجويف (مم) | E | هـ هـ | H | L2 | L3 | L4 | مم | PL | RT | TG | ZJ | CC1 | D |

| 16 | 29 | M5 | 1 | 38 | 4 | 18.5 | 8 | 8 | M4 | 18 | 44 | 6 | 6 |

| 20 | 36 | M5 | 1.5 | 38 | 4 | 18.5 | 10 | 8 | M5 | 22 | 43.5 | 8 | 5.5 |

| 25 | 40 | M5 | 1.5 | 39.5 | 4 | 18.5 | 10 | 8 | M5 | 26 | 46 | 8 | 6.5 |

| 32 | 50 | G1/8 | 2 | 44.5 | 5 | 22 | 12 | 8 | M6 | 32 | 51.5 | 10 | 7 |

| 40 | 60 | G1/8 | 2.5 | 45.5 | 5 | 22 | 12 | 8 | M6 | 42 | 52 | 10 | 6.5 |

| 50 | 68 | G1/8 | 2.8 | 46.5 | 5 | 22 | 16 | 8 | M8 | 50 | 54.5 | 14 | 8 |

| 63 | 88 | G1/8 | 4 | 50 | 6 | 26 | 16 | 8 | M10 | 62 | 58 | 14 | 8 |

| 80 | 107 | G1/8 | 4 | 56 | 6 | 26 | 20 | 8.5 | M10 | 82 | 64 | 17 | 8 |

| التجويف (مم) | Z | E | هـ هـ | H | L2 | L3 | L4 | مم | PL | RT | J | TG | ZJ | CC1 | D | A |

| 16 | 13 | 29 | M5 | 1 | 38 | 4 | 18.5 | 8 | 8 | M4 | 6 | 18 | 63 | 6 | 6 | 6 |

| 20 | 15 | 36 | M5 | 1.5 | 38 | 4 | 18.5 | 10 | 8 | M5 | 6 | 22 | 64.5 | 8 | 5.5 | 6 |

| 25 | 15 | 40 | M5 | 1.5 | 39.5 | 4 | 18.5 | 10 | 8 | M5 | 6 | 26 | 67 | 8 | 6.5 | 6 |

| 32 | 18 | 50 | G1/8 | 2 | 44.5 | 5 | 22 | 12 | 8 | M6 | 6 | 32 | 75.5 | 10 | 7 | 6 |

| 40 | 18 | 60 | G1/8 | 2.5 | 45.5 | 5 | 22 | 12 | 8 | M6 | 6 | 42 | 76 | 10 | 6.5 | 6 |

| 50 | 20 | 68 | G1/8 | 2.8 | 46.5 | 5 | 22 | 16 | 8 | M8 | 7 | 50 | 80.5 | 14 | 8 | 6 |

| 63 | 20 | 88 | G1/8 | 4 | 50 | 6 | 26 | 16 | 8 | M10 | 7 | 62 | 84 | 14 | 8 | 6 |

| 80 | 25 | 107 | G1/8 | 4 | 56 | 6 | 26 | 20 | 8.5 | M10 | 8 | 82 | 95 | 17 | 8 | 6 |

| التجويف (مم) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| الإجراء | Double acting, single rod/double rod | |||||||||

| السوائل | Filtered compressed air | |||||||||

| مقاومة الضغط المضمونة | 1.5 ميجا باسكال | |||||||||

| التشغيل pressure range |

ADVU – -P-A | 0.12 ~ 1.0 ميجا باسكال | 0.1 ~ 1.0 ميجا باسكال | 0.08~1.0MPa | 0.06~1.0MPa | |||||

| ADVU – -P-A-S2 | 0.13~1.0MPa | 0.12 ~ 1.0 ميجا باسكال | 0.1 ~ 1.0 ميجا باسكال | 0.8~1.0MPa | ||||||

| درجة الحرارة المحيطة ودرجة حرارة السائل | -20~80 (No freezing) | |||||||||

| حجم المنفذ | M5 | G1/8″ | G1/4″ | |||||||

| Piston rod thread | Female thread | M4 | M5 | M6 | M8 | M10 | M12 | |||

| خيط ذكر | M8 | M10×1.25 | M12×1.25 | M16×1.5 | M20×1.5 | |||||

| وسادة | مصد مطاطي | |||||||||

| التجويف (مم) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| الإجراء | Double acting, single rod/double rod | |||||||||

| السوائل | Filtered compressed air | |||||||||

| مقاومة الضغط المضمونة | 1.5 ميجا باسكال | |||||||||

| التشغيل pressure range |

ADVU – -P-A | 0.12 ~ 1.0 ميجا باسكال | 0.1 ~ 1.0 ميجا باسكال | 0.08~1.0MPa | 0.06~1.0MPa | |||||

| ADVU – -P-A-S2 | 0.13~1.0MPa | 0.12 ~ 1.0 ميجا باسكال | 0.1 ~ 1.0 ميجا باسكال | 0.8~1.0MPa | ||||||

| درجة الحرارة المحيطة ودرجة حرارة السائل | -20~80 (No freezing) | |||||||||

| حجم المنفذ | M5 | G1/8″ | G1/4″ | |||||||

| Piston rod thread | Female thread | M4 | M5 | M6 | M8 | M10 | M12 | |||

| خيط ذكر | M8 | M10×1.25 | M12×1.25 | M16×1.5 | M20×1.5 | |||||

| وسادة | مصد مطاطي | |||||||||