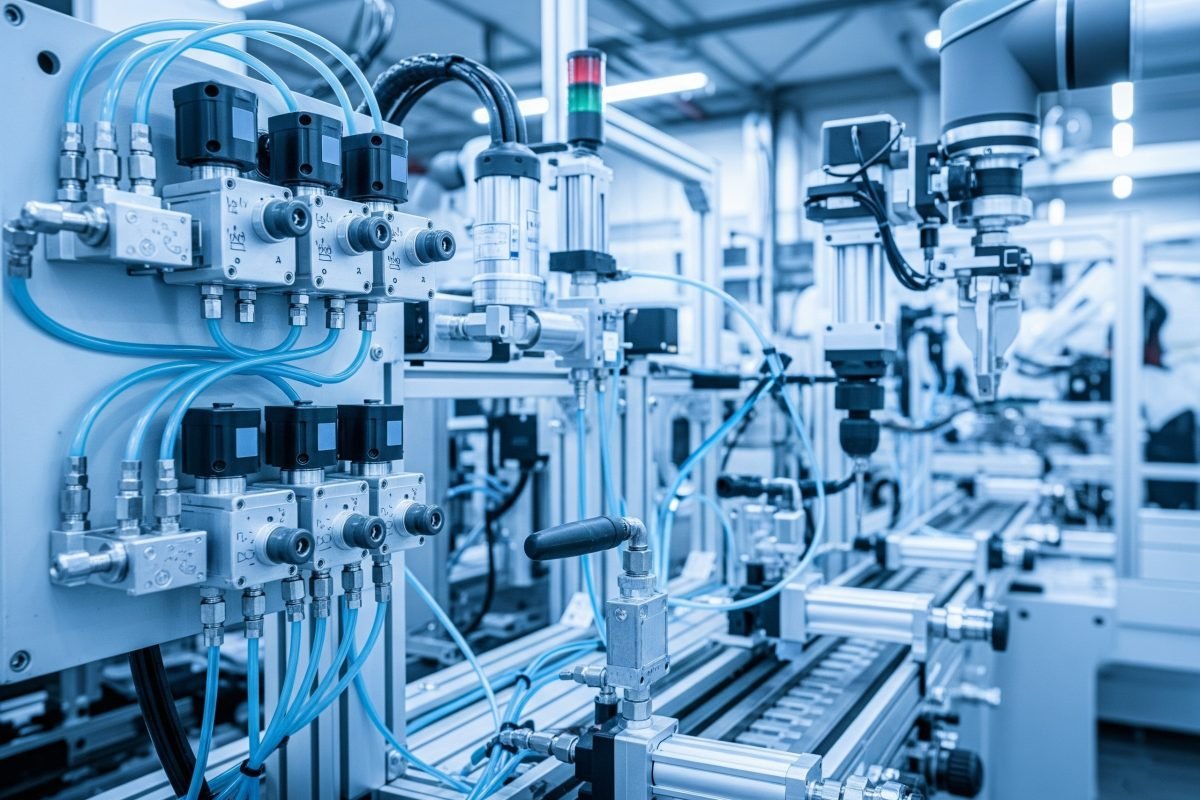

Ηλεκτρομαγνητικές βαλβίδες | Χρησιμοποιούν ηλεκτρικά σήματα για τον έλεγχο της ροής του αέρα για γρήγορο και ακριβή αυτοματισμό. Εξερευνήστε την πλήρη γκάμα ηλεκτρομαγνητικών βαλβίδων πιλοτικής και άμεσης δράσης. Ως βασικά εξαρτήματα ελέγχου σε πνευματικά συστήματα, μετατρέπουν ηλεκτρικά σήματα σε πνευματικές εντολές για να ενεργοποιούν γρήγορα και αξιόπιστα κυλίνδρους και άλλα εξαρτήματα. Αποτελούν την ιδανική επιλογή για την εκτέλεση σύνθετων ακολουθιών αυτοματισμού και εργασιών υψηλής συχνότητας. Επιλέξτε τώρα τη σωστή ηλεκτρομαγνητική βαλβίδα για την εφαρμογή σας.

Χρειάζεστε προϊόντα για το έργο σας;

Καταλαβαίνουμε ότι η προμήθεια μπορεί να είναι δύσκολη.

Συμπληρώστε τη φόρμα με τα συγκεκριμένα στοιχεία σας - μη διστάσετε να αναφέρετε ακόμη και μοναδικά ή δυσεύρετα εξαρτήματα - υποβάλετε την ερώτησή σας και λάβετε τις εξατομικευμένες λύσεις που αναζητάτε! Ξεχάστε τις γενικές προσφορές- ειδικευόμαστε στην κατανόηση των ακριβών αναγκών σας και στην παροχή αποτελεσμάτων που ταιριάζουν γάντι

Ξεκλειδώστε τον ανώτερο αυτοματισμό με τις ηλεκτρομαγνητικές βαλβίδες υψηλής απόδοσης. Σχεδιασμένες για ταχεία απόκριση και αξιόπιστη λειτουργία, οι ηλεκτρομαγνητικές βαλβίδες μας είναι η έξυπνη επιλογή για τον έλεγχο της ροής του αέρα στα πνευματικά σας συστήματα, εξασφαλίζοντας βέλτιστη αποδοτικότητα και παραγωγικότητα σε ποικίλες βιομηχανικές εφαρμογές.

Απολαύστε άμεσο έλεγχο με γρήγορους χρόνους εναλλαγής για ακριβή διαχείριση της ροής του αέρα και βελτιστοποιημένους ρυθμούς κύκλου.

Κατασκευασμένα με ανθεκτικά υλικά και στιβαρούς σχεδιασμούς για σταθερή απόδοση και παρατεταμένη διάρκεια ζωής, ελαχιστοποιώντας τον χρόνο διακοπής λειτουργίας.

Ευρεία γκάμα λειτουργιών (2 δρόμων, 3 δρόμων, 5 δρόμων), μεγεθών και επιλογών πηνίων για να ανταποκρίνονται σε ποικίλες απαιτήσεις βιομηχανικού ελέγχου.

Οι ηλεκτρομαγνητικές βαλβίδες είναι ηλεκτρομηχανικές συσκευές. Χρησιμοποιούν ηλεκτρικό ρεύμα μέσω ενός πηνίου (σωληνοειδούς) για να δημιουργήσουν ένα μαγνητικό πεδίο, το οποίο ενεργοποιεί ένα έμβολο ή ένα μηχανισμό με καρούλι. Η ενέργεια αυτή ανοίγει ή κλείνει τις θυρίδες της βαλβίδας, ελέγχοντας έτσι τη ροή του αέρα ή άλλων ρευστών σε ένα πνευματικό σύστημα.

Οι ενεργειακά αποδοτικοί σχεδιασμοί πηνίων μειώνουν τη χρήση ενέργειας και την παραγωγή θερμότητας, οδηγώντας σε εξοικονόμηση κόστους και μεγαλύτερη διάρκεια ζωής των πηνίων.

Κατασκευάζονται από αλουμίνιο υψηλής ποιότητας, ορείχαλκο ή ανοξείδωτο χάλυβα με ποιοτικές σφραγίδες για συμβατότητα με διάφορες συνθήκες λειτουργίας και μέσα.

Οι βελτιστοποιημένες εσωτερικές διόδους εξασφαλίζουν μέγιστη ροή (Cv) και ελάχιστη πτώση πίεσης, ενισχύοντας την απόδοση του συστήματος.

Διατίθενται σε διάφορες τάσεις πηνίου εναλλασσόμενου και συνεχούς ρεύματος (π.χ. 24VDC, 110VAC, 220VAC) για να ταιριάζουν στις ειδικές απαιτήσεις του συστήματός σας ελέγχου.

Π.χ., M5, 1/8″, 1/4″, 3/8″, 1/2″, κ.λπ., κρίσιμες για την ικανότητα ροής.

Π.χ., 2/2 NC, 3/2 NO, 5/2 μονό σωληνοειδές, 5/2 διπλό σωληνοειδές, 5/3 κεντροκλειστό.

Ελάχιστη και μέγιστη πίεση στην οποία μπορεί να λειτουργήσει αξιόπιστα η βαλβίδα.

Π.χ. 24VDC, 110VAC, 220VAC- κατανάλωση ισχύος σε Watt ή VA.

Δείχνει την ικανότητα της βαλβίδας να περνάει αέρα- υψηλότερο Cv σημαίνει μεγαλύτερη ροή.

Χρόνος που απαιτείται για την αλλαγή κατάστασης της βαλβίδας μετά την ενεργοποίηση/απενεργοποίηση.

Αλουμίνιο, ορείχαλκος, ανοξείδωτος χάλυβας ή μηχανικά πλαστικά, ανάλογα με τις ανάγκες της εφαρμογής.

Υποδεικνύει προστασία από την εισροή σκόνης και νερού, σημαντική για σκληρά περιβάλλοντα.

Για λεπτομερείς παραμέτρους, ανατρέξτε στα ατομικά εγχειρίδια του προϊόντος ή συμβουλευτείτε τους τεχνικούς μας εμπειρογνώμονες.

Ενεργοποίηση πνευματικών κυλίνδρων, έλεγχος πνευματικών εργαλείων και διαχείριση της ροής αέρα σε αυτοματοποιημένα μηχανήματα.

Χρησιμοποιείται στη διαλογή, την εκτροπή, το χειρισμό υλικών και σε διάφορα άλλα αυτοματοποιημένα στάδια παραγωγής.

Έλεγχος διαφόρων πνευματικών λειτουργιών σε συσκευές ανέγερσης κιβωτίων, γεμίσματος, σφράγισης, ετικετοποίησης και παλετοποίησης.

Ρύθμιση της ροής του αέρα σε διάφορες βιομηχανικές διεργασίες, όπως η χημική επεξεργασία, η επεξεργασία νερού και η παραγωγή ενέργειας.

Χρησιμοποιείται σε γραμμές συναρμολόγησης, ρομποτική, συστήματα βαφής και διάφορα πνευματικά εργαλεία.

Παρέχει ακριβή έλεγχο του αέρα για διάφορες λειτουργίες της μηχανής, όπως το τέντωμα του νήματος ή η παροχή μελανιού.

Πάντα να αποσυμπιέζετε και να απενεργοποιείτε το σύστημα πριν επιχειρήσετε οποιαδήποτε συντήρηση ή αντιμετώπιση προβλημάτων.

Ηλεκτρομαγνητικές βαλβίδες άμεσης δράσης: Το σωληνοειδές έμβολο ανοίγει ή κλείνει άμεσα το στόμιο της κύριας βαλβίδας. Δεν απαιτούν ελάχιστη πίεση λειτουργίας για να λειτουργήσουν.

Ηλεκτρομαγνητικές βαλβίδες με πιλότο: Χρησιμοποιήστε την πίεση της γραμμής του συστήματος για να βοηθήσετε στην ενεργοποίηση της κύριας βαλβίδας. Το σωληνοειδές ελέγχει ένα μικρό πιλοτικό στόμιο, το οποίο στη συνέχεια χρησιμοποιεί την πίεση της γραμμής για να μετακινήσει το έμβολο ή το διάφραγμα της κύριας βαλβίδας.

Η τάση του πηνίου πρέπει να ταιριάζει με την τάση που παρέχεται από το σύστημα ελέγχου σας. Οι συνήθεις βιομηχανικές τάσεις ελέγχου για τις ηλεκτρομαγνητικές βαλβίδες περιλαμβάνουν:

Η χρήση λανθασμένης τάσης μπορεί να προκαλέσει ζημιά στο πηνίο (εάν είναι πολύ υψηλή) ή να προκαλέσει την αποτυχία αξιόπιστης ενεργοποίησης της βαλβίδας (εάν είναι πολύ χαμηλή). Ελέγχετε πάντα τις προδιαγραφές εξόδου του συστήματος ελέγχου σας και το φύλλο δεδομένων της βαλβίδας. Επίσης, λάβετε υπόψη την κατανάλωση ισχύος (Watt για DC, VA για AC) για να διασφαλίσετε ότι το τροφοδοτικό σας μπορεί να αντέξει το φορτίο, ειδικά όταν ενεργοποιούνται ταυτόχρονα πολλές βαλβίδες.

Για μια ηλεκτρομαγνητική βαλβίδα 2/2 δρόμων (η οποία έχει δύο θύρες και δύο θέσεις - ανοικτή ή κλειστή):

Η επιλογή εξαρτάται από την απαίτηση ασφαλείας της εφαρμογής σας. Για παράδειγμα, αν θέλετε να αποσυρθεί ένας κύλινδρος ή να σταματήσει μια διαδικασία σε περίπτωση απώλειας ρεύματος, μπορεί να επιλέξετε μια βαλβίδα NC που ελέγχει την επέκταση και έναν κύλινδρο με ελατήριο.

Πολλές πνευματικές ηλεκτρομαγνητικές βαλβίδες γενικής χρήσης έχουν σχεδιαστεί ώστε να είναι συμβατές με λιπαντικό αέρα. Ωστόσο, είναι ζωτικής σημασίας να ελέγξετε τις προδιαγραφές του κατασκευαστή για τη συγκεκριμένη σειρά βαλβίδων που εξετάζετε.

Ανατρέξτε πάντα στην τεκμηρίωση του προϊόντος για οδηγίες σχετικά με τη συμβατότητα και τις απαιτήσεις λίπανσης.

Οι συνήθεις αιτίες βλάβης της ηλεκτρομαγνητικής βαλβίδας περιλαμβάνουν:

Το σωστό φιλτράρισμα του αέρα, η σωστή ηλεκτρική εγκατάσταση και η λειτουργία εντός των καθορισμένων παραμέτρων είναι το κλειδί για την πρόληψη των περισσότερων βλαβών.

Ζήστε τη διαφορά που μπορεί να κάνει η ακρίβεια, η ταχύτητα και η αξιοπιστία στις δραστηριότητές σας. Η εκτεταμένη γκάμα ηλεκτρομαγνητικών βαλβίδων μας έχει σχεδιαστεί για να ανταποκρίνεται στις πιο δύσκολες βιομηχανικές απαιτήσεις. Βρείτε σήμερα την ιδανική βαλβίδα για τις ανάγκες σας.