Le mini-cylindre pneumatique de la série CJ2 offre un design fin et léger, idéal pour les espaces compacts. Avec un cylindre en acier inoxydable et un mouvement de piston doux, il fournit un mouvement linéaire précis pour l'automatisation à petite échelle. Il est parfait pour l'assemblage électronique, la robotique et les machines industrielles légères où l'espace est limité.

| Alésage (mm) | 6 | 10 | 16 |

| Moyen de travail | Air | ||

| Modèle de mouvement | Double action/Simple action Type d'extrusion/Simple action Type d'emboutissage | ||

| Résistance à la pression garantie | 1,05Mpa(10,5kgf/cm2) | ||

| Pression maximale | 0,7Mpa(7,1kgf/cm2) | ||

| Pression minimale | 0,25Mpa(2,5kgf/cm2) | 0,15Mpa(1,5kgf/cm2) | |

| Plage de température de fonctionnement | -10~+70℃ | ||

| Plage de vitesse de fonctionnement | 50~750mm/s | ||

| Mise en mémoire tampon | Butoir en caoutchouc des deux côtés (standard) | ||

| Marge d'erreur de la course (mm) | +1.0 0 mm |

||

| Taille du port | M5×0.8 | ||

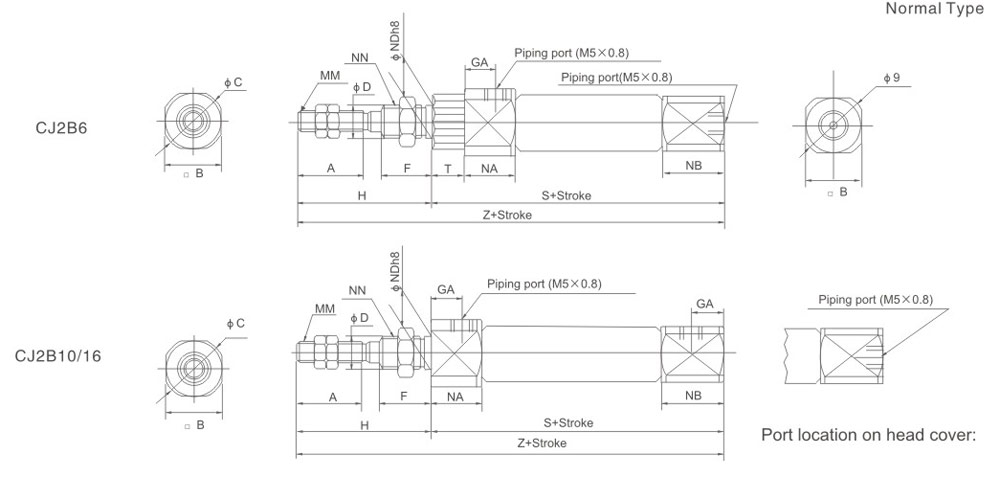

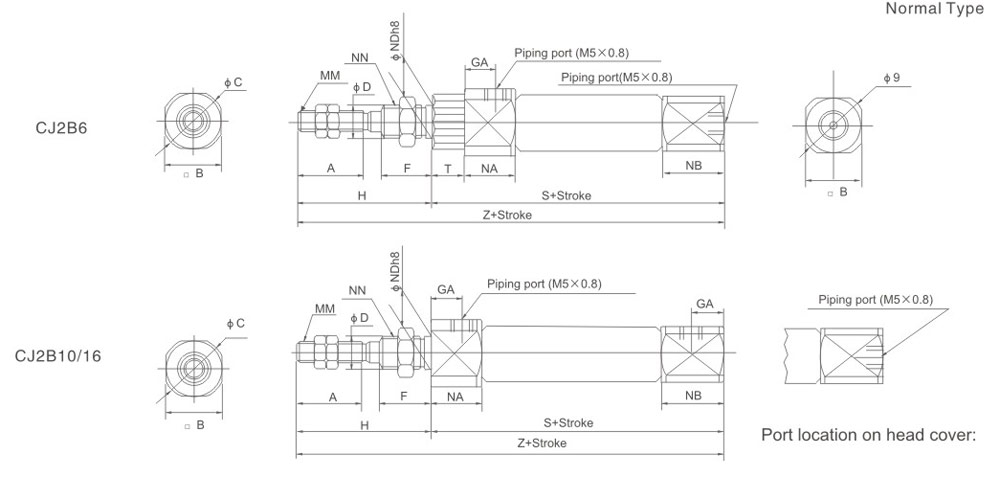

| Alésage(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

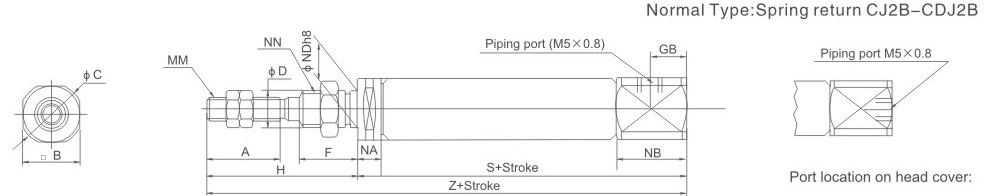

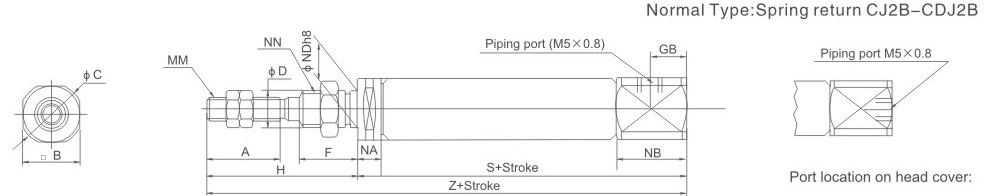

| Alésage (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Alésage (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |

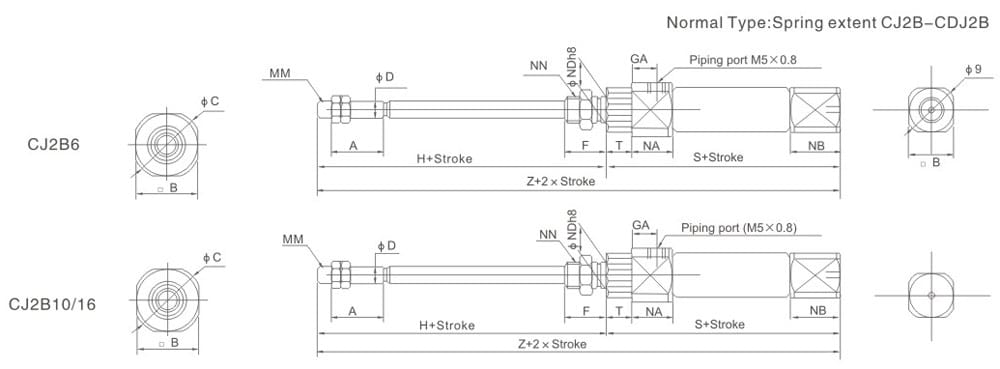

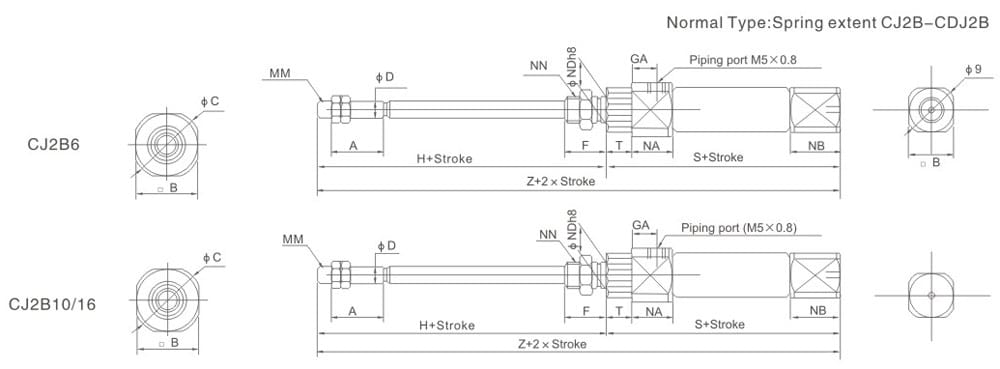

| Alésage(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

| Alésage (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Alésage (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |