Pneumatic technology plays an indispensable and critical role in modern automotive manufacturing, providing efficient and reliable power support and control solutions for various stages, from component production to final vehicle assembly. Leveraging its characteristics of cleanliness, safety, rapid response, and ease of maintenance, pneumatic systems are extensively integrated into automated production lines. Whether it's the precise gripping and positioning of components, the welding and riveting of body structures, or the tightening of various bolts, pneumatic actuators such as cylinders, air motors, and pneumatic grippers can complete tasks with extremely high repeatability and stability, significantly enhancing production efficiency and manufacturing quality. Furthermore, pneumatic tools, known for their light weight, durability, and wide force range, have become invaluable aids for workers on assembly lines, effectively reducing labor intensity.

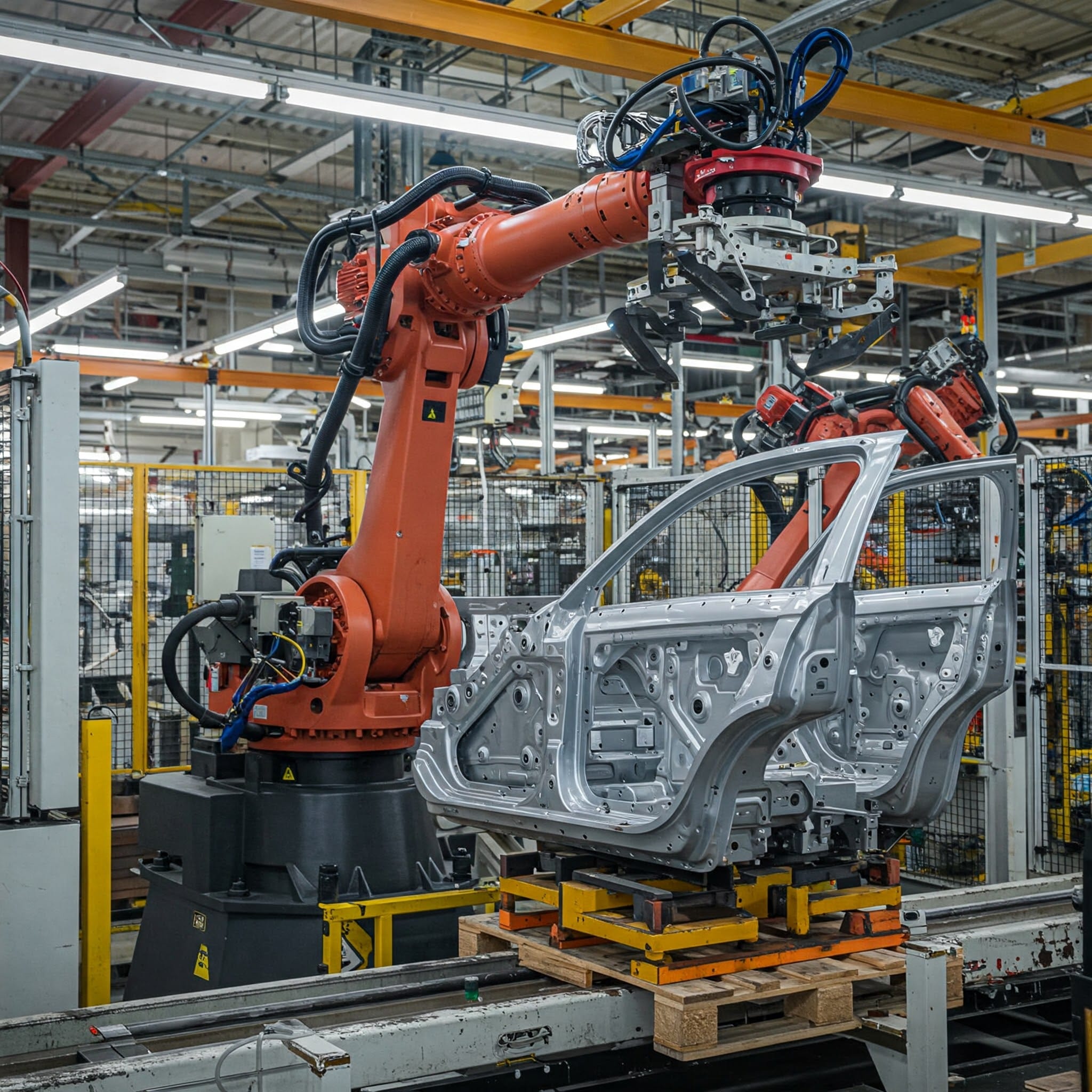

In specific application scenarios, the presence of pneumatic technology is ubiquitous. For instance, in the body shop, pneumatic welding guns and robotic pneumatic grippers are core to achieving rapid and precise body welding and handling. In the paint shop, pneumatic spray guns and paint delivery pumps ensure a uniform and fine paint finish. On the final assembly line, various pneumatic tightening tools, power-assisted manipulators, and material conveying systems guarantee the smooth and efficient flow of the assembly process. Moreover, pneumatic control valve terminals and precise air preparation units (such as filters, regulators, and lubricators) provide a solid foundation for the automated control of the entire production process and the stable operation of pneumatic components, collectively driving the automotive manufacturing industry towards greater intelligence and efficiency.