Silinder Tanpa Batang | Menghemat Ruang Instalasi & Mencapai Aktuasi Linear Langkah Panjang. Jelajahi silinder tanpa batang kami, yang dirancang khusus untuk ruang yang ringkas dan aplikasi langkah panjang. Desain bebas batang yang unik memaksimalkan efisiensi ruang dan menghilangkan risiko tekuk batang piston yang terkait dengan silinder tradisional, sehingga ideal untuk sistem gantry, penanganan material, dan jalur produksi otomatis. Temukan model Anda sekarang.

Butuh produk untuk proyek Anda?

Kami memahami bahwa mencari sumber daya bisa menjadi tantangan.

Isi formulir dengan item spesifik Anda - jangan ragu untuk mencantumkan komponen yang unik atau sulit ditemukan - kirimkan pertanyaan Anda, dan dapatkan solusi yang sesuai dengan yang Anda cari! Lupakan penawaran umum; kami mengkhususkan diri dalam memahami kebutuhan Anda dan memberikan hasil yang sesuai dengan keinginan Anda

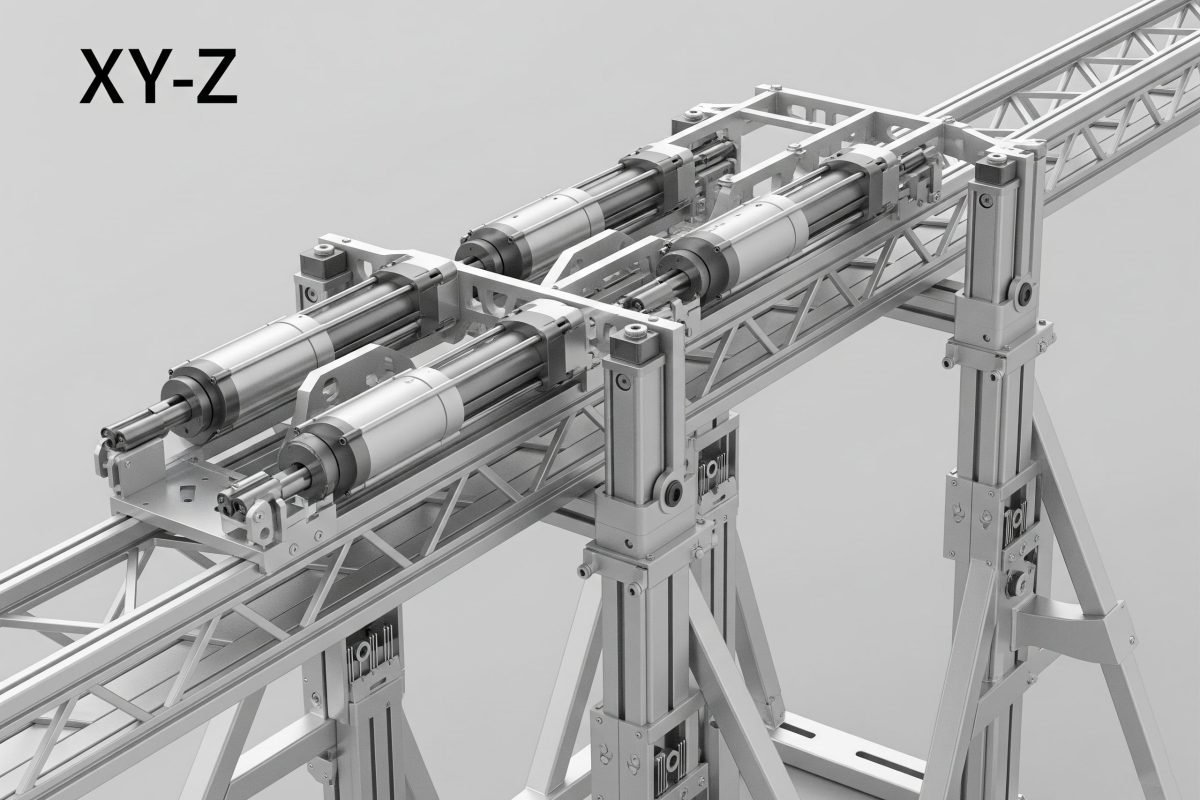

Silinder tanpa batang, dengan desain strukturalnya yang unik, menawarkan keuntungan yang signifikan dalam menghemat ruang pemasangan dan mencapai gerakan langkah panjang. Kami menyediakan berbagai jenis silinder tanpa batang untuk memenuhi beragam kebutuhan otomasi Anda, membantu meningkatkan kinerja sistem dan pemanfaatan ruang.

Tanpa batang piston yang menonjol, panjang pemasangan silinder tanpa batang hampir sama dengan langkah efektifnya, sehingga secara signifikan menghemat ruang pemasangan aksial.

Desain tanpa batang mencegah batang piston bengkok dan kendur dalam aplikasi langkah panjang, dengan mudah mencapai gerakan linier beberapa meter atau bahkan lebih panjang.

Beberapa silinder tanpa batang mengintegrasikan unit pemandu atau dapat dengan mudah digabungkan dengan pemandu eksternal, memungkinkannya menangani beban radial dan momen yang lebih besar untuk gerakan yang lebih halus.

Daya disalurkan melalui koneksi mekanis (seperti pita baja atau kabel) antara piston internal dan kereta eksternal. Mesin ini menawarkan kapasitas beban yang tinggi dan konstruksi yang kuat, cocok untuk berbagai aplikasi industri.

Piston internal dan eksternal digabungkan dengan gaya magnet yang kuat, memungkinkan transmisi daya bebas kebocoran. Ideal untuk aplikasi yang membutuhkan kebersihan tinggi atau di lingkungan yang korosif.

Memanfaatkan pusat permesinan CNC yang canggih dan jalur produksi otomatis, kami secara ketat mengontrol toleransi dimensi dan hasil akhir permukaan untuk menghasilkan fitting yang presisi dan konsisten.

Seri tertentu mengintegrasikan pemandu linier presisi tinggi atau menampilkan desain pemandu khusus, memastikan pergerakan kereta yang mulus, pemandu yang presisi, dan kapasitas beban/momen yang lebih tinggi.

Alur pemasangan sensor yang dioptimalkan, kompatibel dengan berbagai model sakelar magnetik, memfasilitasi pendeteksian posisi yang tepat dan kontrol otomatis bagi pengguna.

Kami menawarkan solusi yang disesuaikan berdasarkan kebutuhan khusus pelanggan, termasuk goresan khusus, opsi pemasangan, bahan tahan suhu tinggi/rendah, dan perlindungan lingkungan khusus.

Menentukan gaya keluaran silinder; pilih berdasarkan kebutuhan beban.

Pilih berdasarkan jarak tempuh linier yang diperlukan; silinder tanpa batang menawarkan pukulan yang sangat panjang.

Pertimbangkan beban langsung pada gerbong dan setiap momen yang diterapkan ke berbagai arah.

Pilih silinder yang memenuhi rentang kecepatan yang diperlukan oleh waktu siklus dan efisiensi aplikasi.

Pilihannya meliputi peredam kejut pneumatik, elastis, atau eksternal untuk meredam benturan pada akhir langkah.

Pilih aksesori pemasangan dan metode fiksasi yang sesuai berdasarkan struktur peralatan.

Tentukan apakah sakelar magnetik atau sensor lain diperlukan untuk deteksi posisi.

Pertimbangkan suhu, kelembapan, debu, sifat korosif, dll., untuk memilih bahan dan tingkat perlindungan yang sesuai.

Untuk parameter terperinci, silakan merujuk ke manual produk individual atau berkonsultasi dengan pakar teknis kami.

Digunakan di gudang otomatis dan jalur produksi untuk pengangkutan, pemosisian, dan penyortiran benda kerja secara horizontal atau vertikal.

Untuk gerakan linier langkah panjang dalam proses pengemasan seperti penyegelan, pelabelan, pembuatan karton, dan pembuatan palet.

Dalam jalur perakitan untuk elektronik, otomotif, dll., untuk pergerakan yang tepat, pemosisian komponen, dan perpindahan stasiun uji.

Digunakan untuk membuka dan menutup pintu pengaman, penutup pelindung pada peralatan otomatis, dan menggerakkan pintu geser besar.

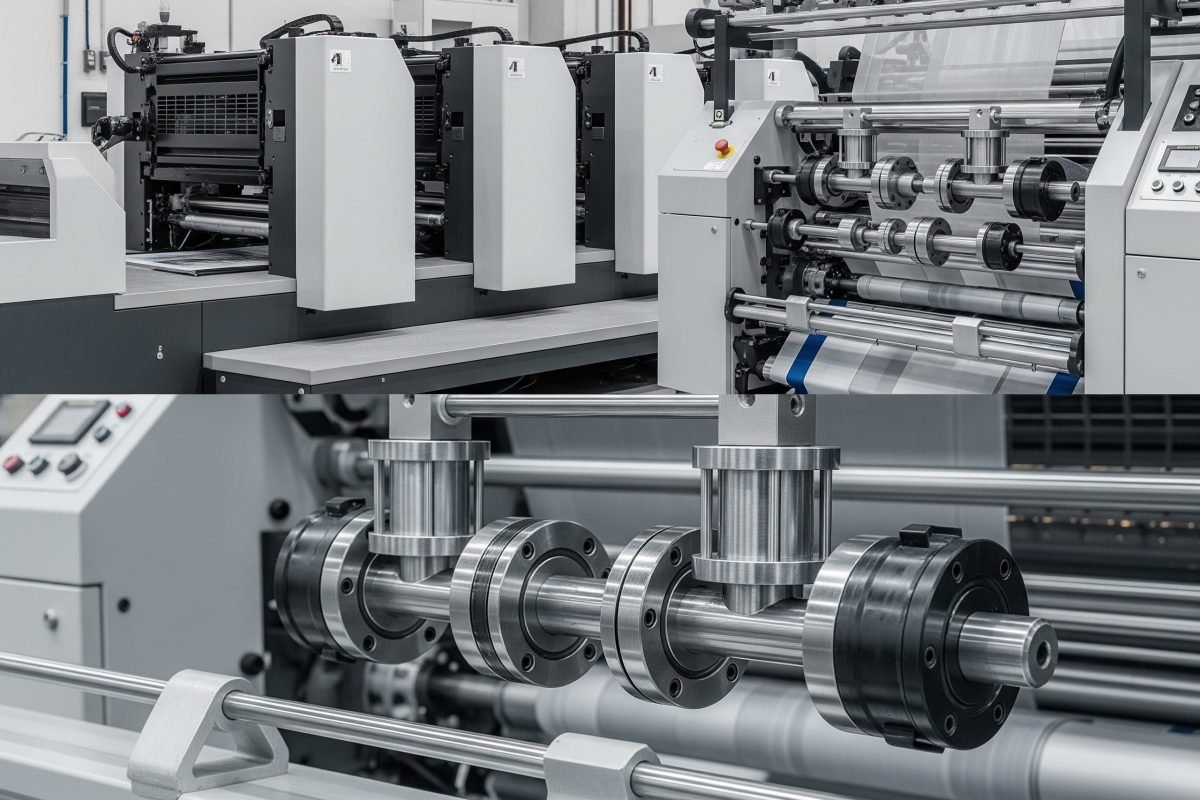

Untuk gerakan bolak-balik melintang pada mesin cetak dan mesin tekstil, seperti gerakan print head dan traksi kain.

Sebagai aktuator dalam sistem gerak multi-sumbu XYZ untuk pemosisian yang tepat pada rentang yang luas.

Selalu lepaskan pasokan udara dan daya serta lepaskan sisa tekanan sistem sebelum melakukan perawatan apa pun untuk memastikan keamanan.

Perbedaan utama terletak pada struktur dan karakteristik yang dihasilkan:

Pilihannya tergantung pada kebutuhan aplikasi tertentu:

Beban dipasang langsung pada gerbong eksternal. Pertimbangan utama meliputi:

Pemasangan beban yang tidak tepat dapat sangat memengaruhi kinerja dan masa pakai silinder tanpa batang.

Akurasi langkah (atau akurasi pemosisian ulang) silinder tanpa batang bervariasi menurut jenis, merek, dan model tertentu. Pada umumnya, silinder tanpa batang berkualitas tinggi dapat mencapai tingkat akurasi yang baik, misalnya, ± 0,1 mm hingga ± 0,5 mm atau lebih baik.

Faktor-faktor utama yang memengaruhi akurasi pukulan meliputi:

Untuk aplikasi presisi tinggi, disarankan untuk memilih silinder tanpa batang dengan unit pemandu berkinerja tinggi, yang dipasangkan dengan sistem kontrol dan sensor yang presisi.

Ya, banyak silinder tanpa batang dapat dipasang secara vertikal, tetapi diperlukan perhatian khusus:

Keselamatan adalah yang terpenting saat memasang silinder tanpa batang secara vertikal; selalu terapkan tindakan perlindungan yang memadai.

Seri silinder tanpa batang kami menawarkan solusi ideal untuk aplikasi langkah panjang dan peka ruang Anda. Jelajahi informasi produk terperinci sekarang, atau hubungi tim ahli pneumatik kami untuk mendapatkan dukungan pemilihan yang dipersonalisasi.