Silinder Pneumatik Mini Seri CJ2 menawarkan desain yang ramping dan ringan yang ideal untuk ruang yang ringkas. Dengan laras baja tahan karat dan gerakan piston yang halus, ini memberikan gerakan linier yang presisi untuk otomatisasi skala kecil. Sempurna untuk digunakan dalam perakitan elektronik, robotika, dan mesin industri tugas ringan di mana ruang terbatas.

| Lubang (mm) | 6 | 10 | 16 |

| Media Kerja | Udara | ||

| Pola Gerak | Aksi ganda / Tipe Ekstrusi Aksi Tunggal / Tipe Penarikan Aksi Tunggal | ||

| Ketahanan Tekanan yang Dipastikan | 1.05Mpa (10.5kgf/cm2) | ||

| Tekanan maksimum | 0.7Mpa (7.1kgf/cm2) | ||

| Tekanan minimum | 0,25Mpa (2,5kgf/cm2) | 0.15Mpa (1.5kgf/cm2) | |

| Kisaran Suhu Operasi | -10~+70℃ | ||

| Rentang Kecepatan Operasi | 50 ~ 750mm / s | ||

| Penyangga | Kedua sisi penyangga karet (Standar) | ||

| Margin Kesalahan Pukulan (mm) | +1.0 0 mm |

||

| Ukuran port | M5×0.8 | ||

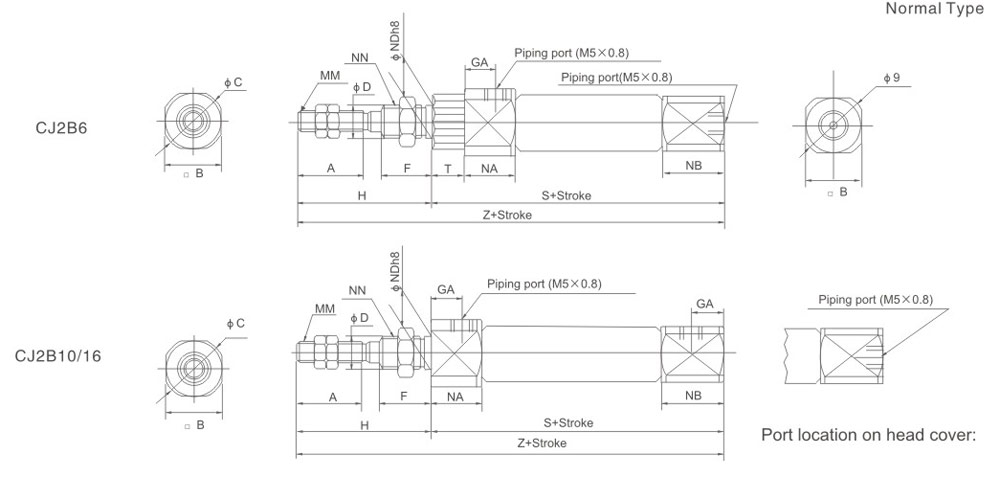

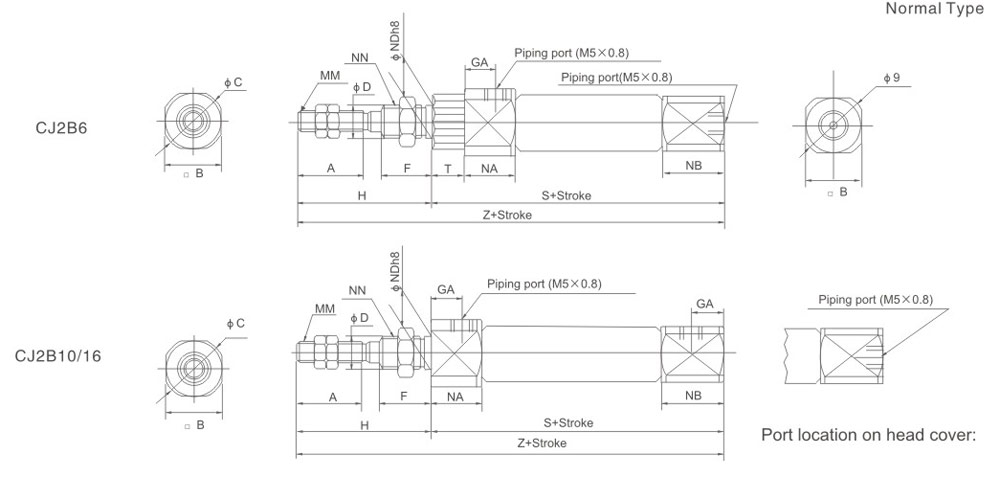

| Bore(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

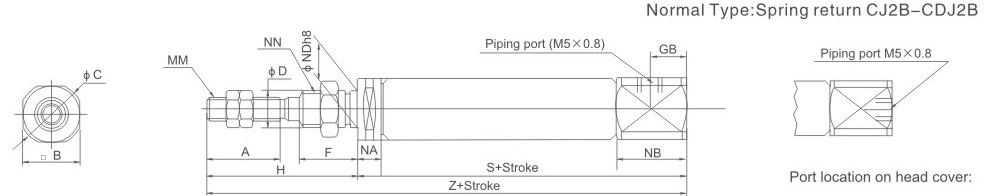

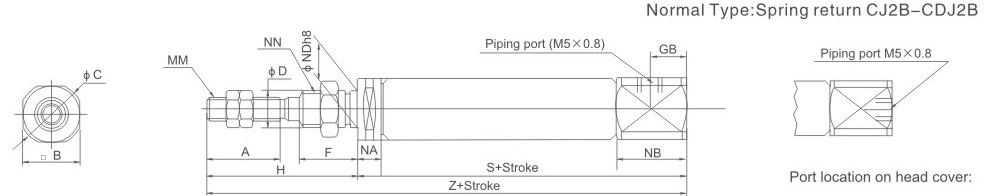

| Bore (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Bore (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |

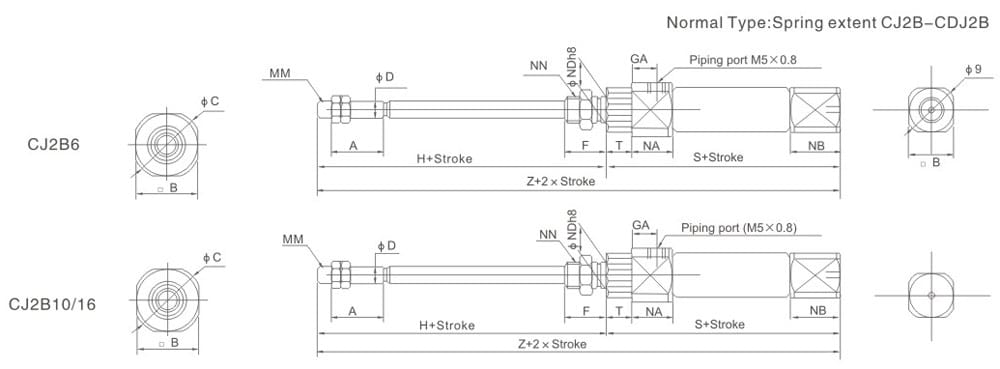

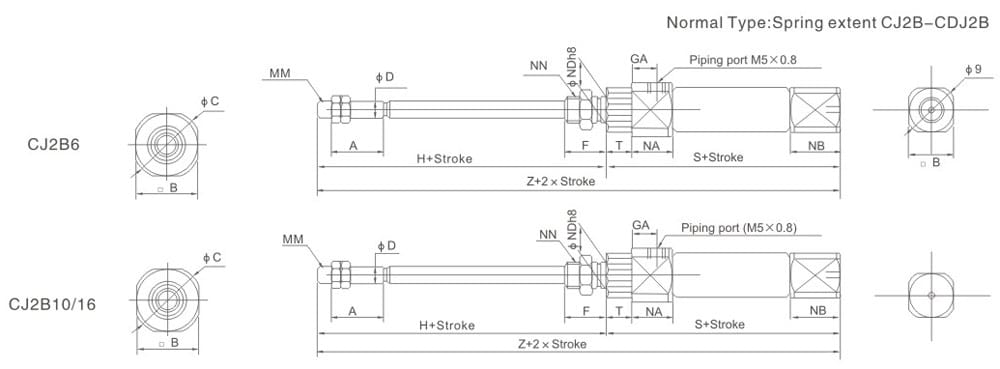

| Bore(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

| Bore (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Bore (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |