フィルターレギュレーター|不純物をろ過し、空気圧を安定させて下流の機器を保護します。 ろ過とレギュレーションを組み合わせた当社の精密ユニットをご覧ください。安定した正確な出力圧力を提供しながら圧縮空気を効果的に清浄し、デリケートな空気圧コンポーネントを保護し、スムーズなシステム運転を保証する理想的な製品です。今すぐ仕様を選択してください。

プロジェクトに必要な製品

私たちは、調達が困難であることを理解しています。

お問い合わせフォームに具体的な項目を入力し、ユニークな部品や入手困難な部品も遠慮なくご記入ください!お客様のニーズを正確に把握し、最適な結果をお届けします。

多用途のフィルタとレギュレータの組み合わせユニットで、空気圧システムを最適化します。これらのコンパクトな装置は、クリーンで正確に調整された圧縮空気を供給し、貴重な機器を保護し、操作の一貫性を高め、空気準備のセットアップを簡素化します。

必要不可欠な空気濾過と圧力調整を1つのユニットにまとめ、設置スペースを大幅に節約し、配管を削減します。

微粒子を含まないクリーンな空気を安定した圧力で正確に制御し、下流装置の性能を最適化します。

設置やメンテナンスが必要なコンポーネントが少ないため、セットアップにかかる時間が短縮され、長期的な運用コストが削減されます。

フィルタ・レギュレータ(FR)ユニットは、エアフィルタと圧力レギュレータを効率的に1つのコンパクトなハウジングにまとめたものです。圧縮空気はまずフィルター部に入り、固形粒子や凝縮した水分が除去されます。清浄化された空気はレギュレーターセクションに送られ、下流の空気圧機器に送られる前に、圧力が正確に制御され、希望の設定値に安定化されます。

高度なフィルターエレメントにより、水、油、粒子状物質の優れた除去を実現し、高品質の圧縮空気を保証します。

高感度ダイヤフラムと精密な調整機構により、出力圧力の変動が少なく安定した出力が得られます。

産業環境に耐える高品質材料で構成され、長寿命と信頼性を提供します。

凝縮水を目視点検できる透明ボウル、使いやすいドレン、簡単なフィルターエレメント交換。

例:G1/8、G1/4、G3/8、G1/2、G3/4、G1、NPTオプション。

標準レベル(例:5µm、25µm、40µm)、より微細なオプションあり。

調整可能な出力圧力範囲(例えば、0.05~0.85MPa)。

最大許容入口圧力。

指定圧力における定格風量(例:L/min、SCFM)。

ポリカーボネート(標準)または金属(より高い圧力/温度用)。

手動、半自動、または全自動ドレン。

内蔵または外部圧力計用のポートの有無。

詳細なパラメータについては、各製品のマニュアルまたは 技術専門家に相談する.

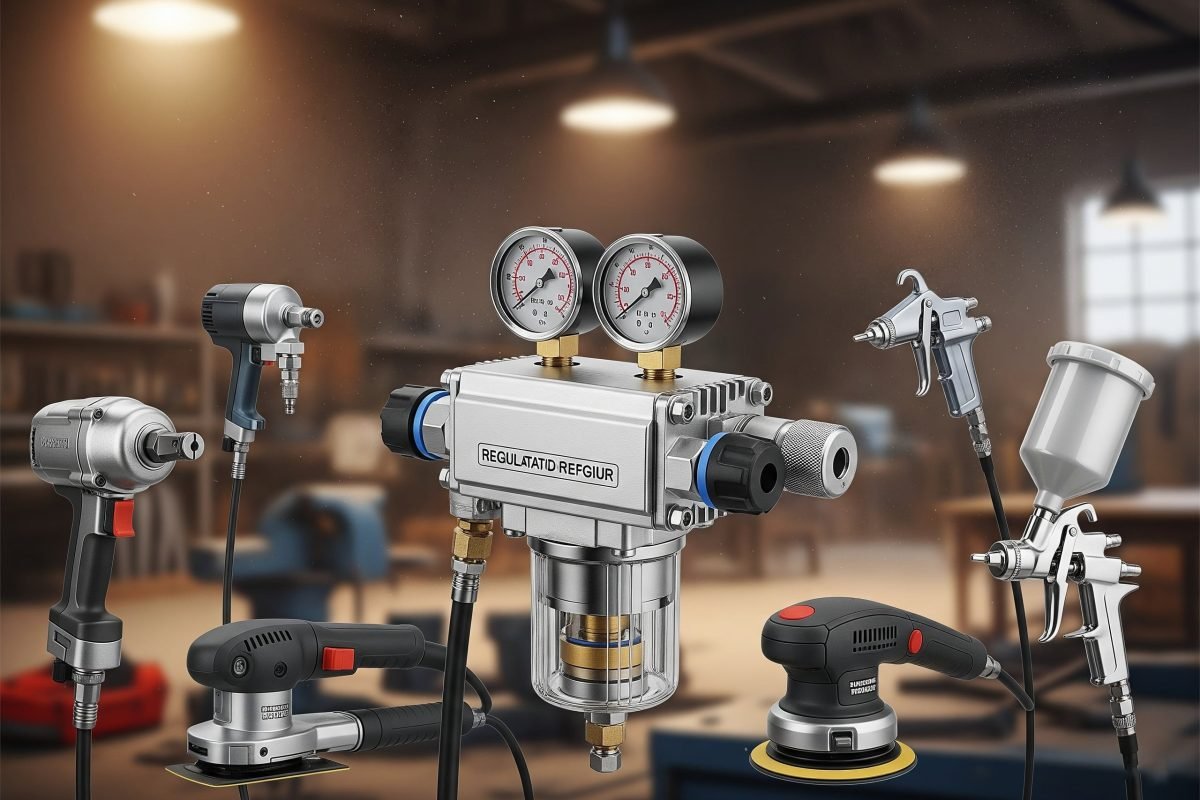

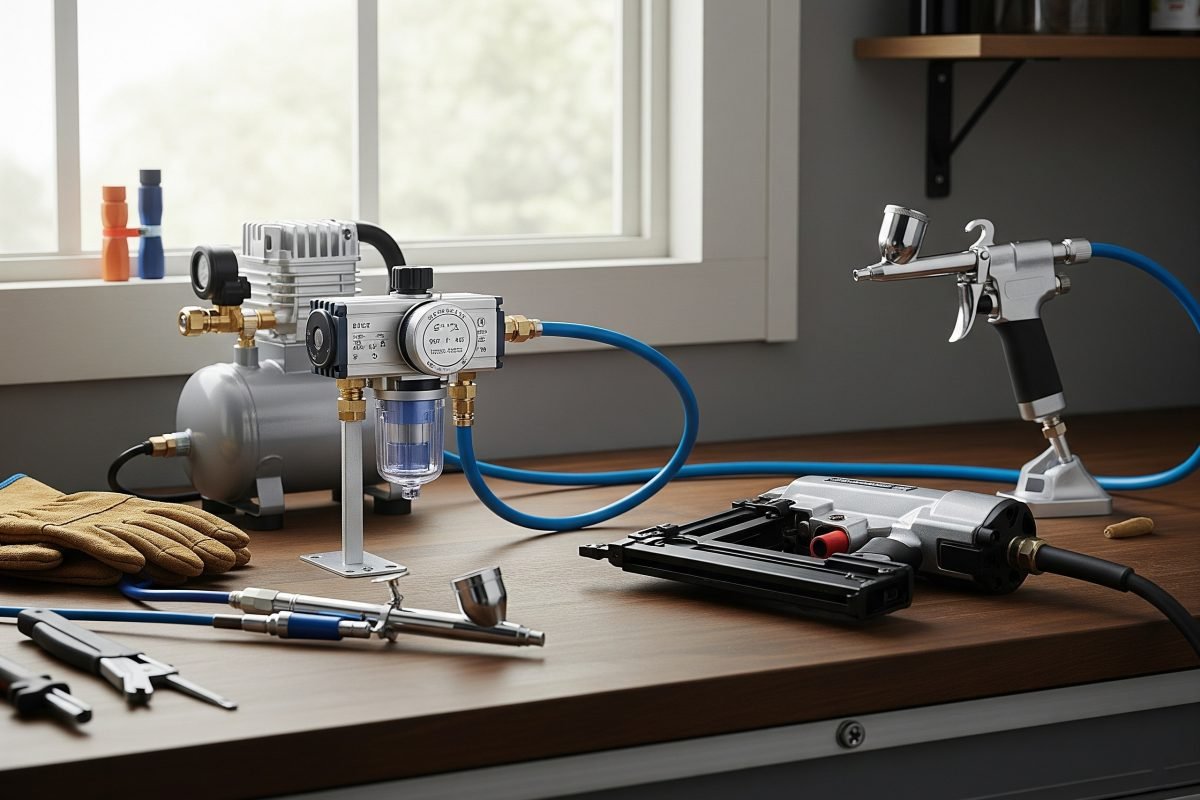

インパクトレンチ、グラインダー、サンダー、ネイルガン、スプレーガンにクリーンで安定した空気を供給し、最適な性能とツール寿命を実現します。

自動機械や組立ラインの空気圧シリンダー、回転アクチュエーター、グリッパーに調整空気を供給する。

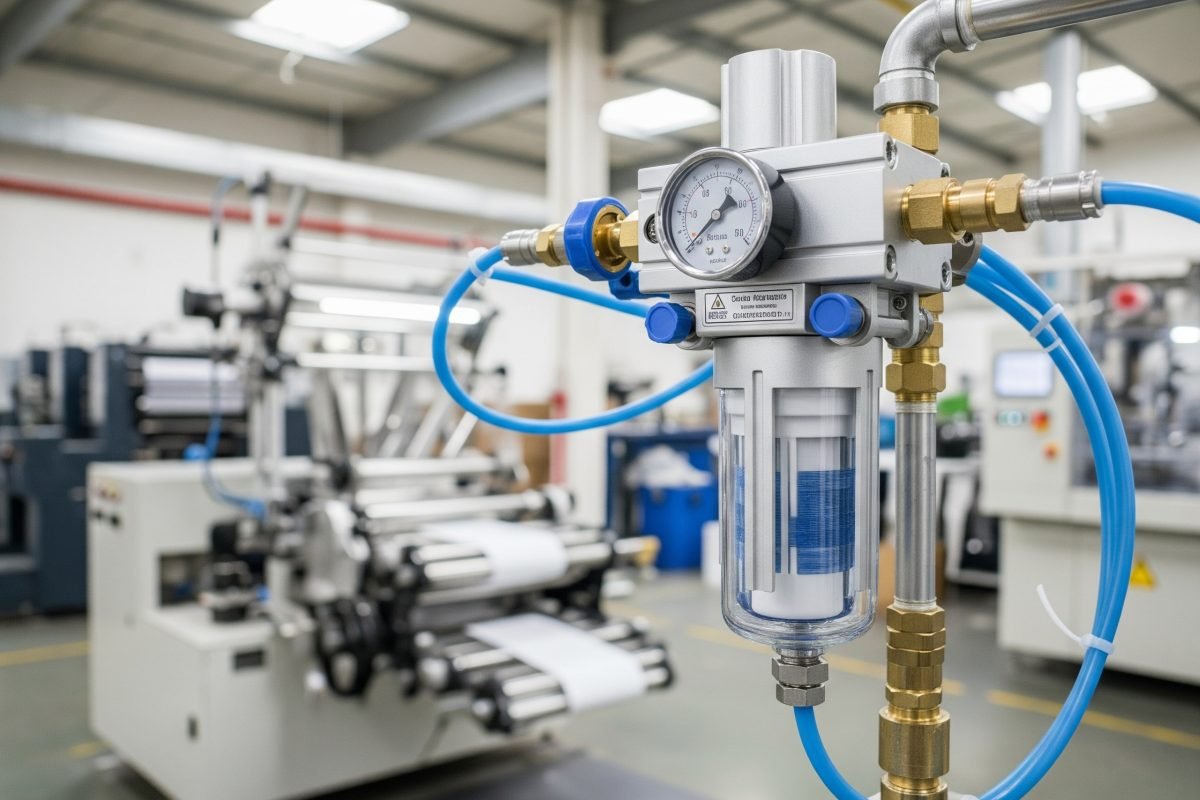

包装機械、印刷機、繊維機械、各種産業機器の空気圧システムを保護。

空気圧コンポーネントのテストや実験装置の操作に、正確に制御された空気を供給。

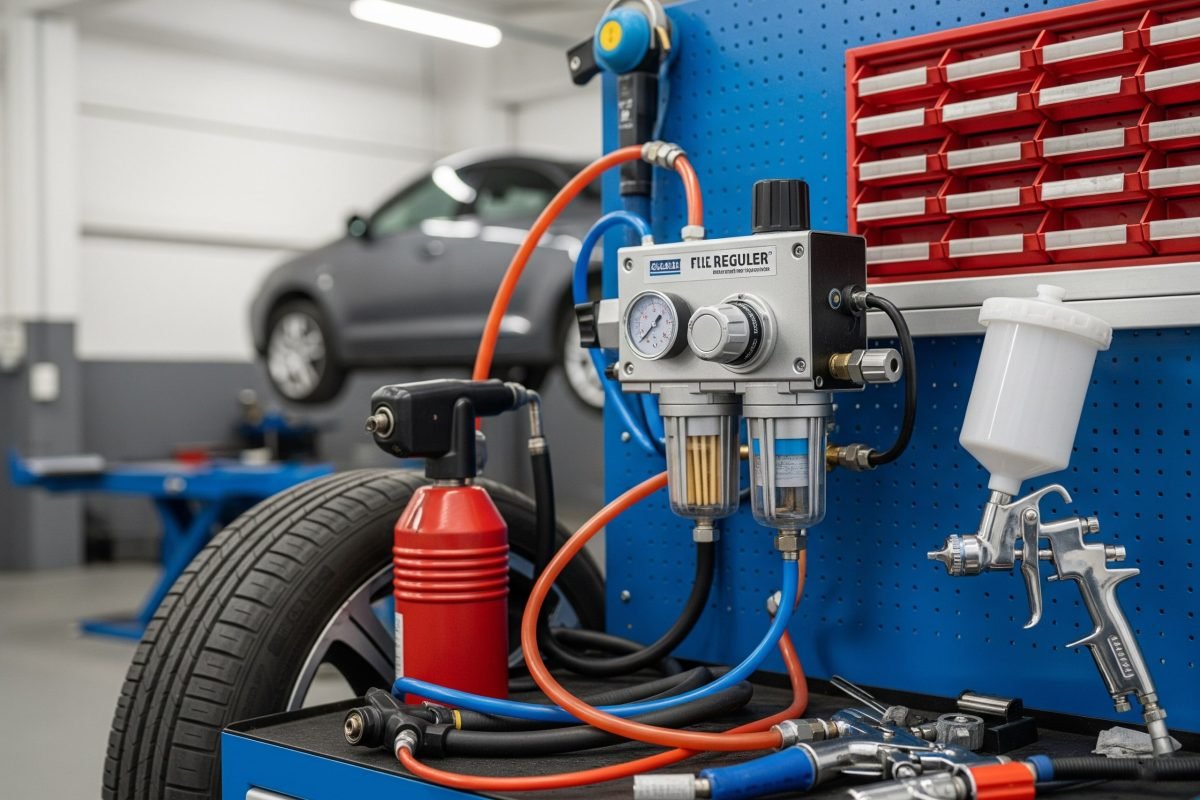

タイヤ空気入れ、ペイントスプレーガン、ガレージやサービスセンターのその他の空気圧ツール用の、清浄で調整された空気を確保する。

小型コンプレッサーやエアツールを使用する家庭用ワークショップに欠かせないコンパクトなユニット。

フィルタ・レギュレータ・ユニットのメンテナンスを行う前に、必ずシステムを減圧してください。

フィルターレギュレーター(FR)ユニットは、2つの重要な空気準備機能を1つのコンパクトな装置に統合したものです:

基本的には、クリーンで圧力制御された空気を空気圧部品に供給する。

ほとんどのフィルターレギュレーターには 調整ノブ を上に置く。圧力をかける:

エネルギーを節約し、部品の磨耗を減らすため、常にアプリケーションに必要な最小限の圧力に設定してください。

標準的なフィルターレギュレーターは通常 微粒子ろ過.一般的なFRユニットの最も一般的な濾過定格は以下の通りである:

これらのユニットはまた、サイクロン分離とバッフルによってバルク液水を除去する。しかし、通常、油エアロゾルや非常に微細なサブミクロン粒子は除去できない。オイル除去やより高純度の空気を得るには、標準のフィルター・セクションに加えて、あるいはその代わりに、別の合体フィルターや活性炭フィルターが必要となる。

はい、フィルターレギュレーター(FRユニット) ろ過と圧力調整のみ.空気流に潤滑油を加えることはない。

下流側の空圧部品(特定のエアツールや旧型のシリンダー設計など)が適切な動作と長寿命のためにオイルミスト潤滑を必要とする場合は、別の潤滑装置を追加する必要があります。 潤滑油 フィルターレギュレーターの下流にあるユニットを使用するか、または、複合型フィルターレギュレーターを使用する。 フィルター・レギュレーター・ルブリケーター(FRL) ユニット。

潤滑が必要なシステムでFRユニットを単独で使用すると、それらのコンポーネントがドライになり、摩耗の増加や早期故障につながる。

これは、レギュレーターが下流の過剰圧力をどのように処理するかを意味する:

汎用のフィルターレギュレーターの多くは、リリーフ型レギュレーターを採用している。

信頼性が高く効率的なフィルタレギュレータユニットで、空気圧機器を保護し、システムのパフォーマンスを向上させます。弊社の製品ラインナップをご覧いただくか、弊社のエアプレパレーションスペシャリストにお問い合わせください。