De mini pneumatische cilinder uit de CJ2-serie heeft een slank, lichtgewicht ontwerp dat ideaal is voor compacte ruimten. Met een roestvrijstalen cilinder en soepele zuigerbeweging levert deze nauwkeurige lineaire beweging voor kleinschalige automatisering. Perfect voor gebruik in elektronica-assemblage, robotica en lichte industriële machines waar de ruimte beperkt is.

| Droeg (mm) | 6 | 10 | 16 |

| Werkend Medium | Lucht | ||

| Bewegingspatroon | Dubbele actie/enkelvoudige actie Extrusietype/enkelvoudige actie Inblaastype | ||

| Verzekerde drukbestendigheid | 1.05Mpa (10.5kgf/cm2) | ||

| Max.druk | 0,7Mpa (7,1kgf/cm2) | ||

| Min.druk | 0,25Mpa (2,5kgf/cm2) | 0,15Mpa (1,5kgf/cm2) | |

| Bedrijfstemperatuurbereik | -10~+70℃ | ||

| Bereik bedrijfssnelheid | 50~750mm/s | ||

| Buffering | Beide zijden Rubberen buffer (Standaard) | ||

| Marge van Slagfout (mm) | +1.0 0 mm |

||

| Havengrootte | M5×0.8 | ||

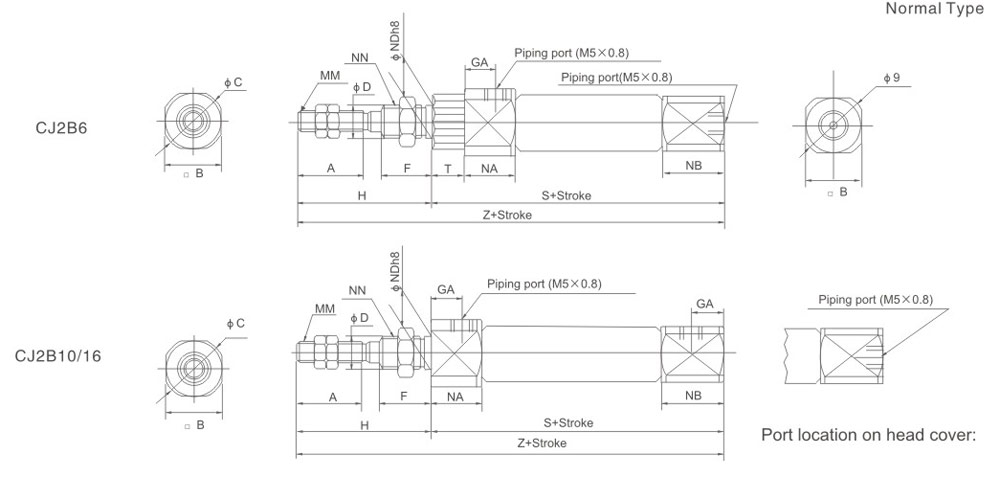

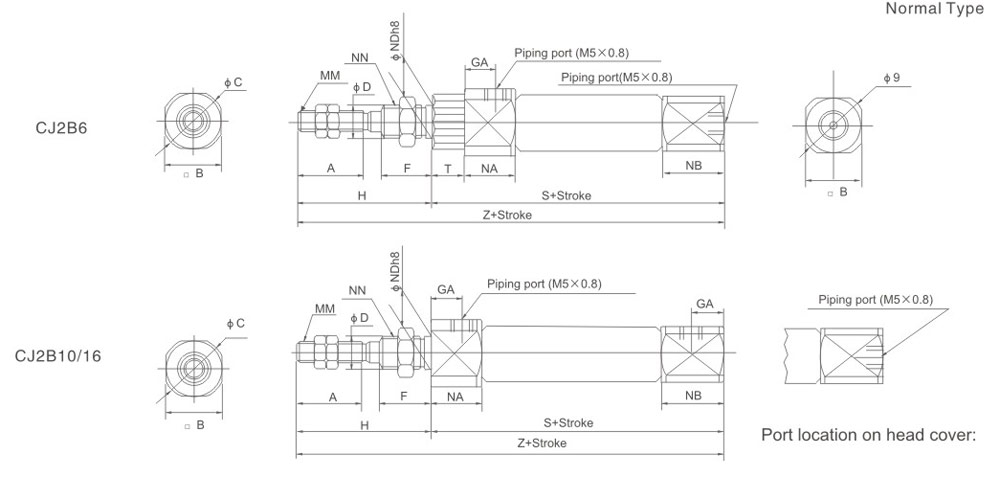

| Boring(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

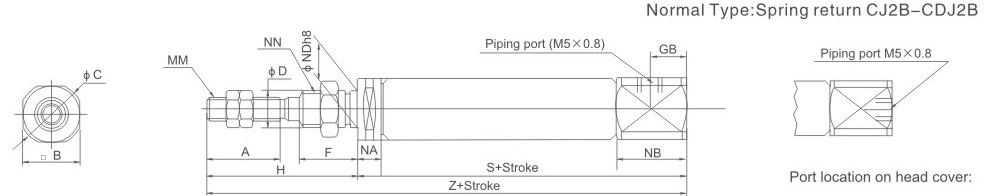

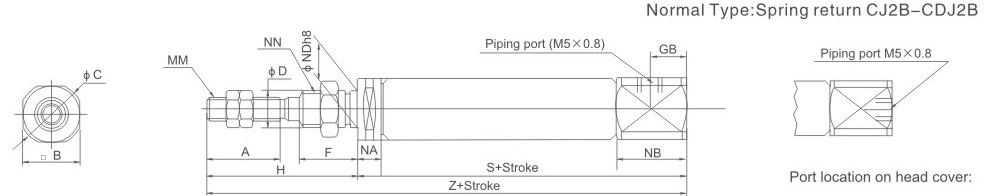

| Boring (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Boring (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |

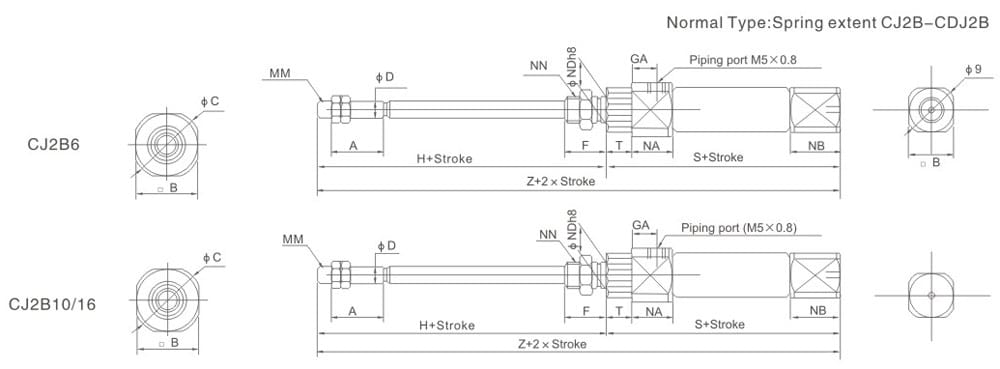

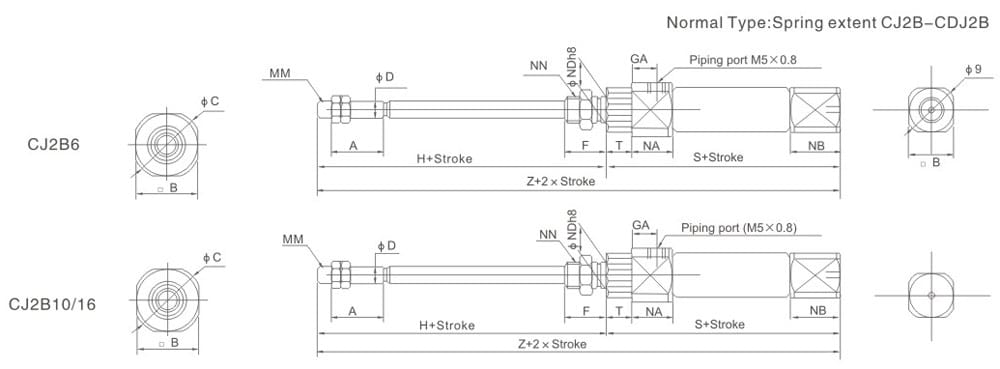

| Boring(mm) | A | B | C | D | F | GA | GB | H | MM | NA | NB | NDh8 | NN | S | T | Z |

| 6 | 15 | 12 | 14 | 3 | 8 | 14.5 | – | 28 | M3×0.5 | 16 | 7 | 6 | M6×1.0 | 49 | 3 | 77 |

| 10 | 15 | 12 | 14 | 4 | 8 | 8 | 5 | 28 | M4×0.7 | 12.5 | 9.5 | 8 | M8×1.0 | 46 | – | 74 |

| 16 | 15 | 18 | 20 | 5 | 8 | 8 | 5 | 28 | M5×0.8 | 12.5 | 9.5 | 10 | M10×1.0 | 47 | – | 75 |

| Boring (mm) |

A | B | C | D | F | GB | H | MM | NA | NB | NB b8 | *S | |||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | ||||||||||||

| 6 | 15 | 8 | 19 | 3 | 8 | – | 28 | M3×0.5 | 3 | 7 | 6 0 | 34.5 (39.5) | 43.5 (48.5) | 47.5 (52.5) | 61.5 (66.5) | – | – | – | – |

| 10 | 15 | 12 | 14 | 4 | 8 | 5 | 28 | M4×0.7 | 5.5 | 9.5 | 8 0 | 45.5 | 53 | 65 | 77 | – | – | – | – |

| 16 | 15 | 18 | 20 | 5 | 8 | 5 | 28 | M5×0.8 | 5.5 | 9.5 | 10 0 | 45.5 | 54 | 66 | 78 | 84 | 108 | 126 | 138 |

| Boring (mm) |

*S | *Z | ||||||||||||||

| 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | 5~ 15 | 16~ 30 | 31~ 45 | 46 ~ 60 | 61~ 75 | 76~ 100 | 101~ 125 | 126~ 150 | |

| 6 | 46.5 (51.5) | 55.5 (60.5) | 59.5 (60.5) | 73.5 (78.5) | – | – | – | – | 74.5 (79.5) | 83.5 (88.5) | 87.5 (92.5) | 101.5 (106.5) | – | – | – | – |

| 10 | 48.5 | 56 | 68 | 80 | – | – | – | – | 76.5 | 84 | 96 | 108 | – | – | – | – |

| 16 | 48.5 | 57 | 69 | 81 | 87 | 111 | 129 | 141 | 76.5 | 85 | 97 | 109 | 115 | 139 | 157 | 169 |