Every project manager I consult with faces the same challenge: pneumatic system integration projects consistently run over schedule and over budget. You’ve experienced the frustration of compatibility issues discovered too late, communication protocols that won’t talk to each other, and thermal management problems that arise only after installation. These integration failures create costly delays, finger-pointing between vendors, and systems that never achieve their performance targets.

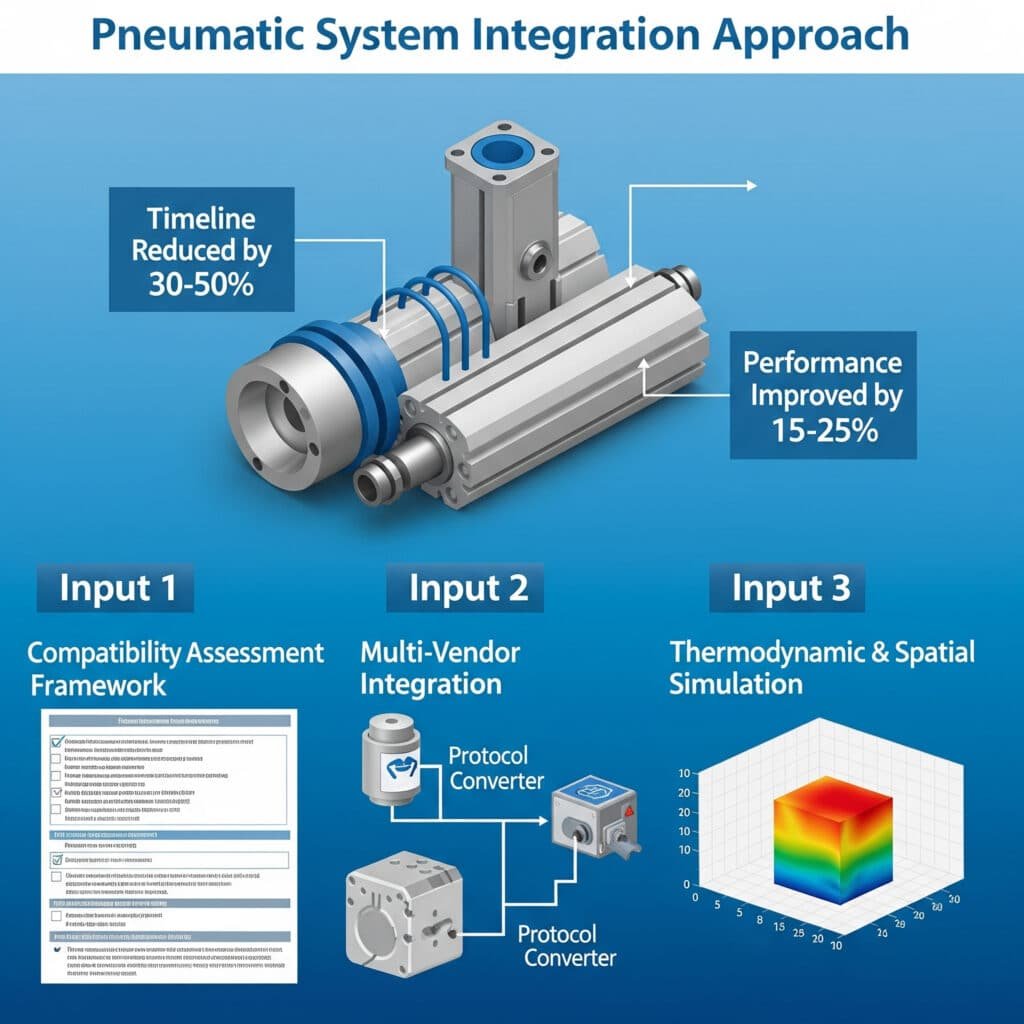

The most effective pneumatic system integration approach combines comprehensive turnkey compatibility assessment frameworks, strategic protocol converter selection for multi-vendor components, and advanced thermodynamic simulation for spatial layout optimization. This integrated methodology typically reduces project timelines by 30-50% while improving system performance by 15-25% compared to traditional component-by-component approaches.

Last quarter, I worked with a pharmaceutical manufacturer in Ireland whose previous pneumatic system integration project had taken 14 months and still had unresolved issues. Using our comprehensive integration methodology, we completed their new production line in just 8 weeks from design to validation, with zero post-installation modifications required. Let me show you how to achieve similar results for your next project.

Съдържание

- Turnkey Solution Compatibility Assessment Framework

- Multi-Brand Component Protocol Converter Selection

- Spatial Layout Thermodynamic Simulation Methodology

- Заключение

- FAQs About Pneumatic System Integration

How Do You Evaluate if a Turnkey Solution Will Actually Work in Your Environment?

Selecting the wrong turnkey solution1 is one of the most expensive mistakes I see companies make. Either the solution fails to integrate with existing systems, or it requires extensive customization that negates the “turnkey” benefits.

An effective turnkey compatibility assessment framework evaluates five critical dimensions: physical integration constraints, communication protocol alignment, performance envelope matching, maintenance accessibility, and future expansion capability. The most successful implementations score at least 85% compatibility across all dimensions before proceeding with implementation.

Comprehensive Turnkey Compatibility Assessment Framework

After evaluating hundreds of pneumatic system integration projects, I’ve developed this five-dimension compatibility framework:

| Compatibility Dimension | Key Assessment Criteria | Minimum Threshold | Ideal Target | Weight |

|---|---|---|---|---|

| Physical Integration | Space envelope, mounting interfaces, utility connections | 90% match | 100% match | 25% |

| Communication Protocol | Data formats, transmission methods, response times | 80% match | 100% match | 20% |

| Performance Requirements | Flow rates, pressure ranges, cycle times, precision | 95% match | 110% margin | 30% |

| Maintenance Accessibility | Service point access, component removal clearance | 75% match | 100% match | 15% |

| Future Expandability | Capacity headroom, additional I/O, space reserves | 50% match | 100% match | 10% |

Structured Assessment Methodology

To properly evaluate turnkey solution compatibility, follow this systematic approach:

Phase 1: Requirements Definition

Begin with a comprehensive definition of your needs:

Physical Constraints Documentation

Create detailed 3D models of the installation environment including:

– Available space envelope with clearances

– Mounting point locations and load capacities

– Utility connection points (electrical, pneumatic, network)

– Access pathways for installation and maintenance

– Environmental conditions (temperature, humidity, vibration)Performance Specification Development

Define clear performance requirements:

– Maximum and typical flow rates

– Operating pressure ranges and stability requirements

– Cycle time and throughput expectations

– Precision and repeatability needs

– Response time requirements

– Duty cycle and operating scheduleCommunication and Control Requirements

Document your control architecture:

– Existing control platforms and protocols

– Required data exchange formats

– Monitoring and reporting needs

– Safety system integration requirements

– Remote access capabilities

Phase 2: Solution Evaluation

Evaluate potential turnkey solutions against your requirements:

Dimensional Compatibility Analysis

Perform a detailed spatial analysis:

– 3D model comparison between solution and available space

– Mounting interface alignment verification

– Utility connection matching

– Installation path clearance validation

– Maintenance access evaluationPerformance Capability Assessment

Verify the solution meets performance needs:

– Component sizing validation for flow requirements

– Pressure capability throughout the system

– Cycle time analysis under various conditions

– Precision and repeatability verification

– Response time measurement or simulation

– Continuous duty capability confirmationIntegration Interface Analysis

Evaluate communication and control compatibility:

– Protocol compatibility with existing systems

– Data format and structure alignment

– Control signal timing compatibility

– Feedback mechanism appropriateness

– Alarm and safety system integration

Phase 3: Gap Analysis and Mitigation

Identify and address any compatibility gaps:

Compatibility Scoring

Calculate a weighted compatibility score:

1. Assign percentage match scores for each criterion

2. Apply dimension weights to calculate overall compatibility

3. Identify any dimensions below minimum thresholds

4. Calculate total compatibility scoreGap Mitigation Planning

Develop specific plans for addressing gaps:

– Physical adaptation options

– Communication interface solutions

– Performance enhancement possibilities

– Maintenance access improvements

– Expansion capability additions

Case Study: Food Processing Line Integration

A food processing company in Illinois needed to integrate a new pneumatic packaging system into their existing production line. Their initial selection of a turnkey solution appeared promising based on the vendor’s specifications, but they were concerned about integration risks.

We applied the compatibility assessment framework with these results:

| Compatibility Dimension | Initial Score | Issues Identified | Mitigation Actions | Final Score |

|---|---|---|---|---|

| Physical Integration | 72% | Utility connections misaligned, insufficient maintenance clearance | Custom connection manifold, component reorientation | 94% |

| Communication Protocol | 65% | Incompatible fieldbus system, non-standard data formats | Protocol converter addition, custom data mapping | 90% |

| Performance Requirements | 85% | Marginal flow capacity, pressure fluctuation concerns | Supply line upsizing, additional accumulation | 98% |

| Maintenance Accessibility | 60% | Critical components inaccessible without disassembly | Component repositioning, access panel addition | 85% |

| Future Expandability | 40% | No capacity headroom, limited I/O availability | Control system upgrade, modular design modification | 75% |

| Overall Compatibility | 68% | Multiple critical issues | Targeted modifications | 91% |

The initial assessment revealed that the selected turnkey solution would have required extensive modifications. By identifying these issues before purchase, the company was able to:

- Negotiate with the vendor for specific modifications

- Develop targeted integration solutions for identified gaps

- Prepare their team for the integration requirements

- Establish realistic timeline and budget expectations

Results after implementation with pre-planned modifications:

- Installation completed 3 days ahead of schedule

- System achieved full production capacity within 48 hours

- No unexpected integration issues encountered

- 30% lower integration costs than similar previous projects

Implementation Best Practices

For successful turnkey solution implementation:

Vendor Collaboration Strategy

Maximize compatibility through vendor engagement:

- Provide detailed environment specifications early

- Request compatibility self-assessment from vendors

- Arrange site visits for vendors to verify conditions

- Establish clear responsibility boundaries for integration

- Develop joint testing protocols for interface points

Phased Implementation Approach

Reduce risk through structured implementation:

- Begin with non-critical subsystems to validate approach

- Implement communication interfaces before physical installation

- Conduct off-line testing of critical interfaces

- Use simulation to verify performance before installation

- Plan for fallback options at each implementation phase

Documentation Requirements

Ensure comprehensive documentation for long-term success:

- As-built 3D models with actual clearances

- Interface control documents for all connection points

- Performance test results under various conditions

- Troubleshooting guides for integration-specific issues

- Modification records and rationale

Which Protocol Converter Actually Solves Multi-Brand Component Communication Problems?

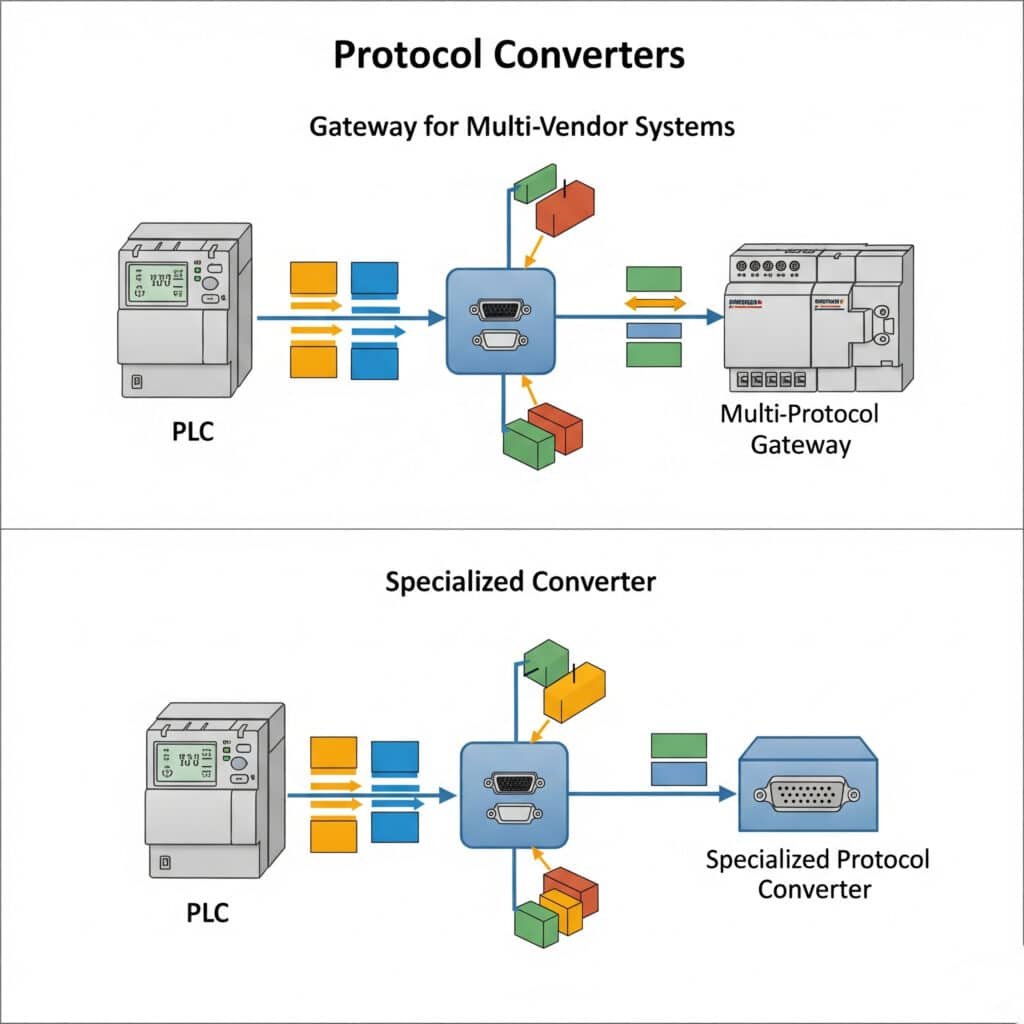

Integrating pneumatic components from multiple manufacturers creates significant communication challenges. Engineers often struggle with incompatible protocols, proprietary data formats, and inconsistent response characteristics.

The optimal protocol converter for pneumatic systems depends on the specific protocols involved, required data throughput, and control architecture. For most industrial pneumatic applications, gateway devices with multiple protocol support and configurable data mapping provide the best solution, while specialized converters may be required for proprietary protocols or high-speed applications.

Comprehensive Protocol Converter Comparison

After implementing hundreds of multi-vendor pneumatic systems, I’ve compiled this comparison of protocol conversion approaches:

| Converter Type | Protocol Support | Data Throughput | Configuration Complexity | Latency | Cost Range | Best Applications |

|---|---|---|---|---|---|---|

| Multi-Protocol Gateway | 5-15 protocols | Medium-High | Среден | 10-50ms | $800-2,500 | General industrial integration |

| Edge Controller2 | 8-20+ protocols | Висока | Висока | 5-30ms | $1,200-3,500 | Complex systems with processing needs |

| Protocol-Specific Converter | 2-3 protocols | Много висока | Нисък | 1-10ms | $300-900 | High-speed, specific protocol pairs |

| Software-Based Converter | Varies | Среден | Висока | 20-100ms | $0-1,500 | IT/OT integration, cloud connectivity |

| Custom Interface Module | Limited | Varies | Много висока | Varies | $2,000-10,000+ | Proprietary or legacy systems |

Protocol Conversion Requirements Analysis

When selecting protocol converters for pneumatic system integration, I use this structured analysis approach:

Step 1: Communication Mapping

Document all communication paths in the system:

Component Inventory

Create a comprehensive list of all communicating devices:

– Valve terminals and I/O blocks

– Smart sensors and actuators

– HMI and operator interfaces

– Controllers and PLCs

– SCADA and management systemsProtocol Identification

For each component, document:

– Primary communication protocol

– Alternative protocols supported

– Required and optional data points

– Update frequency requirements

– Critical timing constraintsCommunication Diagram

Create a visual map showing:

– All communicating devices

– Protocol used on each connection

– Data flow direction

– Update frequency requirements

– Critical timing paths

Step 2: Conversion Requirement Analysis

Identify specific conversion needs:

Protocol Pair Analysis

For each protocol transition point:

– Document source and destination protocols

– Identify data structure differences

– Note timing and synchronization requirements

– Determine data volume and frequency

– Identify any special protocol features requiredSystem-Wide Requirements

Consider overall system needs:

– Total number of protocol transitions

– Network topology constraints

– Redundancy requirements

– Security considerations

– Maintenance and monitoring needs

Step 3: Converter Selection

Match requirements to converter capabilities:

Multi-Protocol Gateways

Ideal when you need:

- Support for 3+ different protocols

- Moderate update speeds (10-100ms)

- Straightforward data mapping

- Central conversion point

Leading options include:

- HMS Anybus X-gateways

- ProSoft Protocol Gateways

- Red Lion Protocol Converters

- Moxa Protocol Gateways

Edge Controllers with Protocol Conversion

Best when you need:

- Multiple protocol support plus local processing

- Data preprocessing before transmission

- Complex data transformations

- Local decision making

Top choices include:

- Advantech WISE-710 Series

- Moxa UC Series

- Dell Edge Gateway 3000 Series

- Phoenix Contact PLCnext Controllers

Protocol-Specific Converters

Optimal for:

- High-speed applications (sub-10ms)

- Simple point-to-point conversion

- Specific protocol pair requirements

- Cost-sensitive applications

Reliable options include:

- Moxa MGate Series

- Anybus Communicator

- Hilscher netTAP

- Phoenix Contact FL Gateways

Case Study: Automotive Manufacturing Integration

An automotive parts manufacturer in Michigan needed to integrate pneumatic systems from three different vendors into a unified production line. Each vendor used different communication protocols:

- Vendor A: PROFINET3 for valve terminals and I/O

- Vendor B: EtherNet/IP for smart manifolds

- Vendor C: Modbus TCP for specialized equipment

Additionally, the plant management system required OPC UA communication, and certain legacy equipment used serial Modbus RTU.

Initial attempts to standardize on a single protocol were unsuccessful due to vendor limitations and replacement costs. We developed this protocol conversion strategy:

| Connection Point | Source Protocol | Destination Protocol | Data Requirements | Selected Converter | Rationale |

|---|---|---|---|---|---|

| Main PLC to Vendor A | EtherNet/IP | PROFINET | High-speed I/O, 10ms update | HMS Anybus X-gateway | High performance, simple configuration |

| Main PLC to Vendor B | EtherNet/IP | EtherNet/IP | Native protocol, no conversion | N/A | Direct connection possible |

| Main PLC to Vendor C | EtherNet/IP | Modbus TCP | Status data, 100ms update | Integrated in PLC | Software conversion sufficient |

| System to Legacy | Modbus TCP | Modbus RTU | Configuration data, 500ms update | Moxa MGate MB3180 | Cost-effective, purpose-built |

| Plant System Integration | Multiple | OPC UA | Production data, 1s update | Kepware KEPServerEX | Flexible, comprehensive protocol support |

Results after implementation:

- All systems communicating with update rates meeting or exceeding requirements

- 100% data availability across previously incompatible systems

- System integration time reduced by 65% compared to previous projects

- Maintenance staff able to monitor all systems from a single interface

Implementation Best Practices for Protocol Converters

For successful protocol converter implementation:

Data Mapping Optimization

Ensure efficient data transfer:

- Map only necessary data points to reduce overhead

- Group related data for efficient transmission

- Consider update frequency requirements for each data point

- Use appropriate data types to maintain precision

- Document all mapping decisions for future reference

Network Architecture Planning

Design the network for optimal performance:

- Segment networks to reduce traffic and improve security

- Consider redundant converters for critical paths

- Implement appropriate security measures at protocol boundaries

- Plan for sufficient bandwidth on all network segments

- Consider future expansion in network design

Testing and Validation

Verify conversion performance:

- Test under maximum load conditions

- Verify timing under various network conditions

- Validate data integrity across conversions

- Test failure scenarios and recovery

- Document baseline performance metrics

Maintenance Considerations

Plan for long-term support:

- Implement monitoring for converter health

- Establish backup and recovery procedures

- Document troubleshooting procedures

- Train maintenance staff on converter configuration

- Maintain firmware update procedures

How Can You Predict and Prevent Thermal Issues Before Installation?

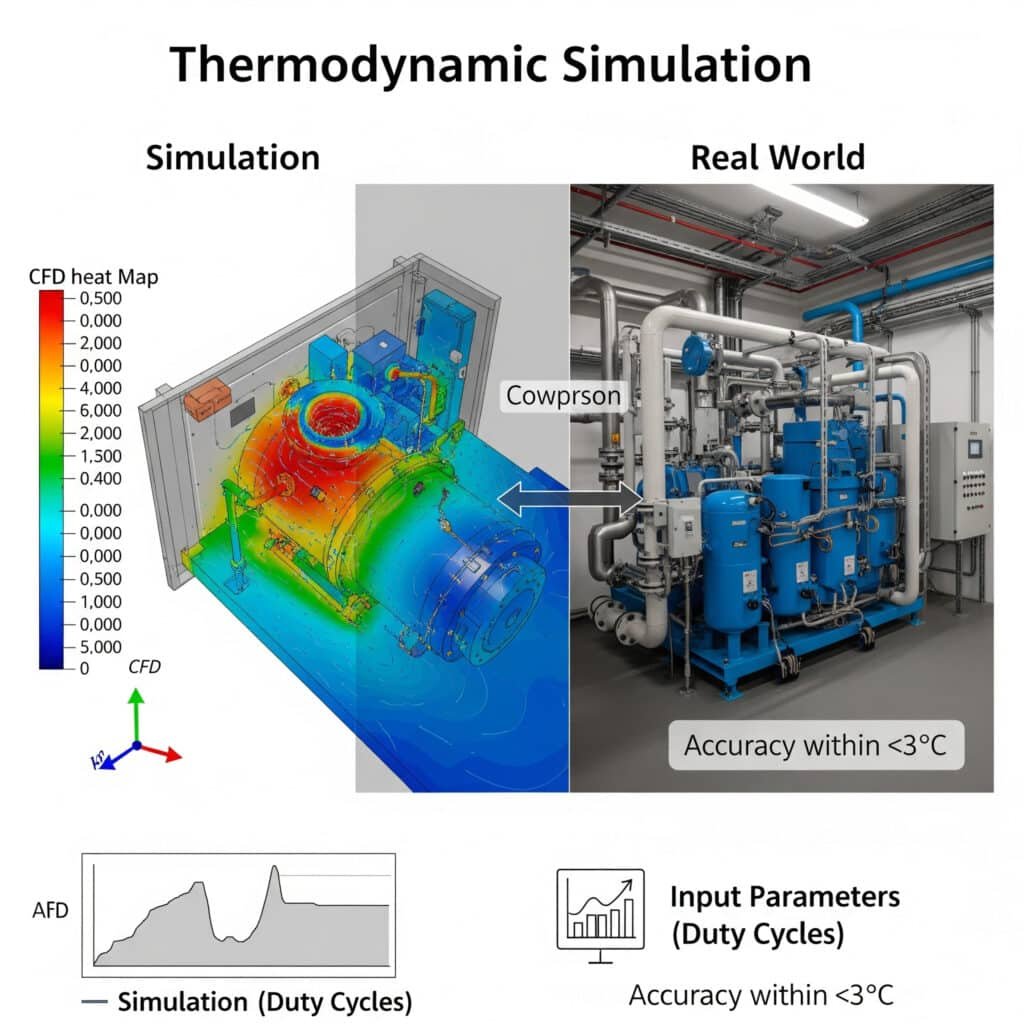

Thermal management is often overlooked in pneumatic system integration, leading to overheating components, reduced performance, and premature failures. Traditional “build and test” approaches result in expensive modifications after installation.

Effective thermodynamic simulation for pneumatic system layout combines computational fluid dynamics (CFD)4 modeling, component heat generation profiling, and ventilation path optimization. The most valuable simulations incorporate actual duty cycles, realistic ambient conditions, and accurate component thermal characteristics to predict operating temperatures within ±3°C of actual values.

Comprehensive Thermodynamic Simulation Methodology

Based on hundreds of pneumatic system integrations, I’ve developed this simulation methodology:

| Simulation Phase | Key Inputs | Analysis Methods | Outputs | Accuracy Level |

|---|---|---|---|---|

| Component Heat Profiling | Power consumption, efficiency data, duty cycle | Component-level thermal modeling | Heat generation maps | ±10% |

| Enclosure Modeling | 3D layout, material properties, ventilation design | Computational fluid dynamics | Air flow patterns, heat transfer rates | ±15% |

| System Simulation | Combined component and enclosure models | Coupled CFD and thermal analysis | Temperature distribution, hotspots | ±5°C |

| Duty Cycle Analysis | Operational sequences, timing data | Time-dependent thermal simulation | Temperature profiles over time | ±3°C |

| Optimization Analysis | Alternative layouts, cooling options | Parametric studies | Improved design recommendations | N/A |

Thermal Simulation Framework for Pneumatic Systems

To effectively predict and prevent thermal issues, follow this structured simulation approach:

Phase 1: Component Thermal Characterization

Begin by understanding the thermal behavior of individual components:

Heat Generation Profiling

Document heat output for each component:

– Valve solenoids (typically 2-15W per solenoid)

– Electronic controllers (5-50W depending on complexity)

– Power supplies (efficiency losses of 10-20%)

– Pneumatic regulators (minimal heat but can restrict flow)

– Servo drives (can generate significant heat under load)Operating Pattern Analysis

Define how components operate over time:

– Duty cycles for intermittent components

– Continuous operation periods

– Peak load scenarios

– Typical vs. worst-case operation

– Startup and shutdown sequencesComponent Arrangement Documentation

Create detailed 3D models showing:

– Exact component positions

– Orientation of heat-generating surfaces

– Clearances between components

– Natural convection pathways

– Potential thermal interaction zones

Phase 2: Enclosure and Environment Modeling

Model the physical environment that contains the components:

Enclosure Characterization

Document all relevant enclosure properties:

– Dimensions and internal volume

– Material thermal properties

– Surface treatments and colors

– Ventilation openings (size, position, restrictions)

– Mounting orientation and external exposureEnvironmental Condition Definition

Specify the operating environment:

– Ambient temperature range (minimum, typical, maximum)

– External air flow conditions

– Solar exposure if applicable

– Surrounding equipment heat contribution

– Seasonal variations if significantVentilation System Specification

Detail all cooling mechanisms:

– Fan specifications (flow rate, pressure, position)

– Natural convection pathways

– Filtration systems and their restrictions

– Air conditioning or cooling systems

– Exhaust paths and recirculation potential

Phase 3: Simulation Execution

Perform progressive simulation with increasing complexity:

Steady-State Analysis

Begin with simplified constant-condition simulation:

– All components at maximum continuous heat generation

– Stable ambient conditions

– Continuous ventilation operation

– No transient effectsTransient Thermal Analysis

Progress to time-varying simulation:

– Actual component duty cycles

– Startup thermal progression

– Peak load scenarios

– Cooling and recovery periods

– Failure mode scenarios (e.g., fan failure)Parametric Studies

Evaluate design variations to optimize thermal performance:

– Component repositioning options

– Alternative ventilation strategies

– Additional cooling options

– Enclosure modification possibilities

– Component substitution impacts

Phase 4: Validation and Optimization

Verify simulation accuracy and implement improvements:

Critical Point Identification

Locate thermal problem areas:

– Maximum temperature locations

– Components exceeding temperature limits

– Restricted air flow regions

– Heat accumulation zones

– Insufficient cooling areasDesign Optimization

Develop specific improvements:

– Component repositioning recommendations

– Additional ventilation requirements

– Heat sink or cooling system additions

– Operational modifications to reduce heat

– Material or component substitutions

Case Study: Industrial Control Cabinet Integration

A machine builder in Germany was experiencing repeated failures of pneumatic valve electronics in their control cabinets. Components were failing after 3-6 months despite being rated for the application. Initial temperature measurements showed localized hot spots reaching 67°C, well above the 50°C component rating.

We implemented a comprehensive thermodynamic simulation:

Component Characterization

– Measured actual heat generation of all electronic components

– Documented duty cycles from machine operation data

– Created detailed 3D model of the cabinet layoutEnvironmental Modeling

– Modeled the sealed NEMA 12 enclosure5 with limited ventilation

– Characterized the factory environment (ambient 18-30°C)

– Documented existing cooling provisions (single 120mm fan)Simulation Analysis

– Performed steady-state CFD analysis of the original layout

– Identified severe air flow restrictions creating hot spots

– Simulated multiple alternative component arrangements

– Evaluated enhanced cooling options

The simulation revealed several critical issues:

- Valve terminals were positioned directly above power supplies

- Ventilation path was blocked by cable trays

- Fan placement created a short-circuit air path that bypassed hot components

- Compact grouping of heat-generating components created a cumulative hot spot

Based on simulation results, we recommended these changes:

- Repositioned valve terminals to the upper section of the cabinet

- Created dedicated ventilation channels with baffles

- Added a second fan in push-pull configuration

- Separated high-heat components with minimum spacing requirements

- Added targeted cooling for the highest-heat components

Results after implementation:

- Maximum cabinet temperature reduced from 67°C to 42°C

- Even temperature distribution with no hot spots above 45°C

- Component failures eliminated (zero failures in 18 months)

- Energy consumption for cooling reduced by 15%

- Simulation predictions matched actual measurements within 2.8°C

Advanced Thermodynamic Simulation Techniques

For complex pneumatic system integration, these advanced techniques provide additional insights:

Coupled Pneumatic-Thermal Simulation

Integrate pneumatic performance with thermal analysis:

- Model how temperature affects pneumatic component performance

- Simulate pressure drops due to temperature-induced density changes

- Account for cooling effects of expanding compressed air

- Analyze heat generation from flow restrictions and pressure drops

- Consider moisture condensation in cooling components

Component Lifecycle Impact Analysis

Evaluate long-term thermal effects:

- Simulate accelerated aging due to elevated temperatures

- Model thermal cycling effects on component connections

- Predict seal and gasket performance degradation

- Estimate electronic component life reduction factors

- Develop preventive maintenance schedules based on thermal stress

Extreme Condition Simulation

Test system resilience under worst-case scenarios:

- Maximum ambient temperature with full system load

- Ventilation failure modes

- Blocked filter scenarios

- Power supply efficiency degradation over time

- Component failure cascade effects

Implementation Recommendations

For effective thermal management in pneumatic system integration:

Design Phase Guidelines

Implement these practices during initial design:

- Separate high-heat components both horizontally and vertically

- Create dedicated ventilation paths with minimal restrictions

- Position temperature-sensitive components in the coolest areas

- Provide 20% margin below component temperature ratings

- Design for maintenance access to high-heat components

Verification Testing

Validate simulation results with these measurements:

- Temperature mapping with multiple sensors

- Infrared thermal imaging under various load conditions

- Air flow measurements at critical ventilation points

- Long-duration testing under maximum load

- Accelerated thermal cycling tests

Documentation Requirements

Maintain comprehensive thermal design records:

- Thermal simulation reports with assumptions and limitations

- Component temperature ratings and derating factors

- Ventilation system specifications and maintenance requirements

- Critical temperature monitoring points

- Thermal emergency procedures

Заключение

Effective pneumatic system integration requires a comprehensive approach that combines turnkey compatibility assessment, strategic protocol converter selection, and advanced thermodynamic simulation. By implementing these methodologies early in your project lifecycle, you can dramatically reduce integration timelines, prevent costly rework, and ensure optimal system performance from day one.

FAQs About Pneumatic System Integration

What is the typical ROI timeframe for comprehensive system integration planning?

The typical ROI timeframe for thorough pneumatic system integration planning is 2-4 months. While proper assessment, protocol planning, and thermal simulation add 2-3 weeks to the initial project phase, they typically reduce implementation time by 30-50% and eliminate costly rework that averages 15-25% of total project cost on traditionally managed integrations.

How often do communication protocol issues cause project delays?

Communication protocol incompatibilities cause significant delays in approximately 68% of multi-vendor pneumatic system integrations. These issues typically add 2-6 weeks to project timelines and account for approximately 30% of all troubleshooting time during commissioning. Proper protocol converter selection and pre-implementation testing can eliminate over 90% of these delays.

What percentage of pneumatic system failures are related to thermal issues?

Thermal issues contribute to approximately 32% of pneumatic system failures, with electronic component failures being the most common (accounting for 65% of temperature-related failures). Valve solenoid burnout, controller malfunctions, and sensor drift due to overheating are the most frequent specific failure modes. Proper thermodynamic simulation can predict and prevent over 95% of these thermal-related failures.

Can existing systems be assessed using these integration methodologies?

Yes, these integration methodologies can be applied to existing systems with excellent results. Compatibility assessment can identify integration bottlenecks, protocol converter analysis can resolve ongoing communication issues, and thermodynamic simulation can diagnose intermittent failures or performance degradation. When applied to existing systems, these methods typically improve reliability by 40-60% and reduce maintenance costs by 25-35%.

What level of expertise is required to implement these integration approaches?

While comprehensive system integration methodologies require specialized expertise, they can be implemented through a combination of internal resources and targeted external support. Most organizations find that training their existing engineering team on assessment frameworks and working with specialized consultants for complex protocol conversion and thermal simulation provides the optimal balance of skill development and implementation success.

How do these integration approaches affect long-term maintenance requirements?

Properly integrated pneumatic systems using these methodologies typically reduce maintenance requirements by 30-45% over their operational lifetime. Standardized communication interfaces simplify troubleshooting, optimized thermal design extends component life, and comprehensive documentation improves maintenance efficiency. Additionally, these systems are typically 60-70% faster to modify or expand due to their well-planned integration architecture.

-

Provides a business definition of a turnkey solution, a type of project that is constructed so that it can be sold to any buyer as a completed product with no need for further modification or setup. ↩

-

Explains the concept of edge computing, a distributed computing paradigm that brings computation and data storage closer to the sources of data, improving response times and saving bandwidth, which is a key principle behind edge controllers. ↩

-

Offers a comparison of the major Industrial Ethernet protocols, such as PROFINET, EtherNet/IP, and Modbus TCP, detailing their differences in performance, topology, and typical applications. ↩

-

Describes the principles of Computational Fluid Dynamics (CFD), a powerful simulation tool that uses numerical analysis to model and visualize fluid flow, heat transfer, and associated phenomena within a defined system. ↩

-

Details the NEMA (National Electrical Manufacturers Association) enclosure type rating system, which defines standards for the degree of protection an enclosure provides against environmental hazards like dust, water, and oil. ↩