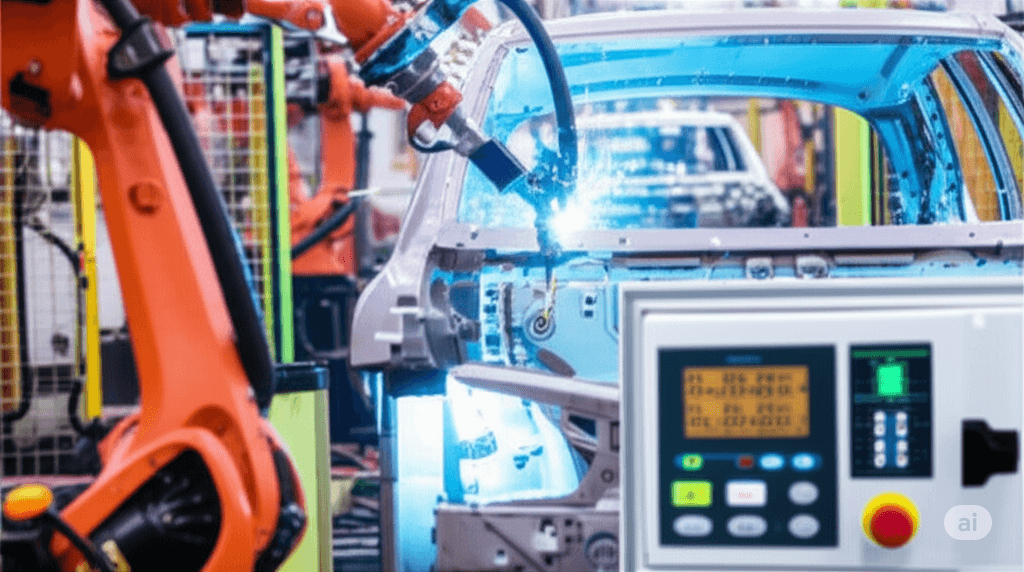

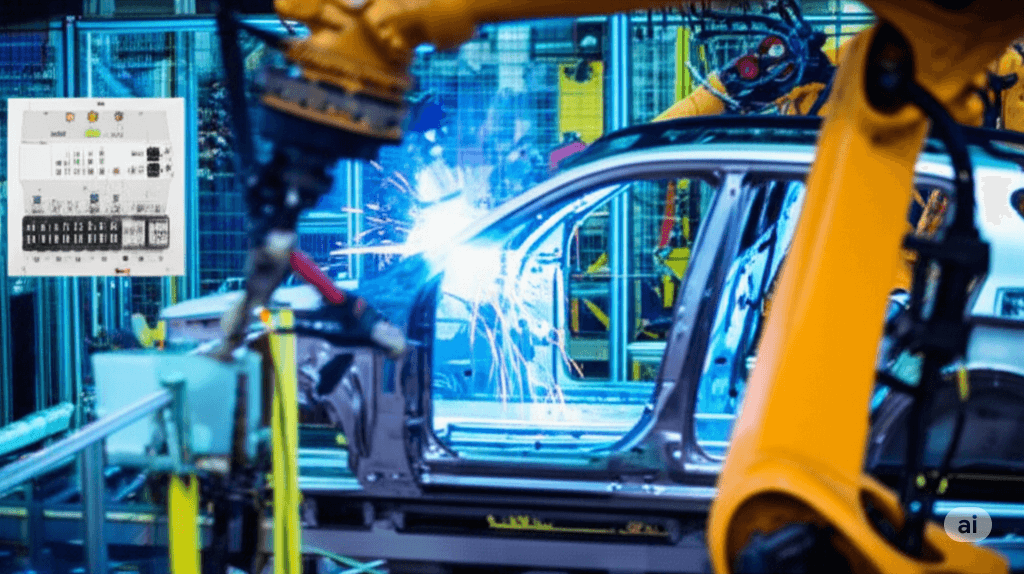

Welding robots are widely used in car body construction within the automotive manufacturing industry. These applications require robust solutions capable of positioning sheet metal parts with high precision and repeatability, supplying the production line with small components, and providing welding guns with compressed air and cooling water. Specifically for car body construction, Industry 4.0-capable components suitable for servo-pneumatic welding guns have been developed. Complete, application-specific solutions are available on the market to ensure a reliable supply of compressed air and cooling water for individual welding robots or entire welding lines. These systems are pre-tested, custom-tailored to the specific specifications of the body shop, and ensure a structured and bundled media supply, thereby guaranteeing the reliable reproducibility of welding points.

A representative product in this field is a valve terminal system, which includes an associated control terminal. This system integrates I/O modules, valve functionality, and safety functions compliant with the ISO 13849-1 standard into a single unit. Its functions include the exhausting of system components, reversing, and protection against unintentional restart. A high degree of functional integration and flexible connectivity to various common fieldbus systems make this type of automation solution a key component of decentralized intelligence in Industry 4.0 scenarios.

Designing and Developing.

We Engineer Pneumatic Excellence - Innovative, Versatile, Empowering.

Our dedicated pneumatic specialists focus on providing premium pneumatic products

to ensure optimal functionality for your systems.

Contact Us

Xuezhai Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province, China

© 2025. All Rights Reserved.Powered by Bepto