When your automated assembly line demands millimeter-perfect positioning without any rotational movement, standard cylinders simply can’t deliver the precision your operation requires, leading to misaligned parts and costly quality issues. Compact guide cylinders provide integrated anti-rotation guidance and precision positioning through dual-rod construction, linear bearing systems1, and rigid mounting configurations that eliminate rotational movement while maintaining exceptional accuracy in space-constrained applications.

Two weeks ago, I worked with Jennifer, a design engineer at an electronics manufacturing facility in North Carolina, whose compact PCB assembly stations were experiencing 15% rejection rates due to rotational drift in their standard pneumatic cylinders during precise component placement operations.

Obsah

- What Makes Guide Cylinders Essential for Anti-Rotation Applications?

- How Do You Select the Right Guide Cylinder Configuration?

- Which Mounting Options Maximize Precision in Compact Spaces?

- What Maintenance Practices Ensure Long-Term Accuracy?

What Makes Guide Cylinders Essential for Anti-Rotation Applications? 🎯

Understanding guide cylinder design principles is crucial for applications requiring precise linear motion without any rotational movement.

Guide cylinders eliminate rotation through integrated linear bearing systems, dual-rod configurations, or external guide rails that prevent any rotational movement while providing exceptional positioning accuracy, making them essential for precision assembly, testing, and material handling operations.

Anti-Rotation Technologies

Modern guide cylinders use several proven anti-rotation methods:

Dual-Rod Design

- Through-rod construction eliminates side loading

- Equal force distribution on both sides of piston

- Inherent anti-rotation without external guides

- Kompaktní půdorys for space-limited applications

Linear Bearing Integration

| Typ ložiska | Kapacita zatížení | Přesná vodováha | Údržba |

|---|---|---|---|

| Kulová pouzdra | Střední | ±0.002″ | Nízká |

| Roller guides | Vysoká | ±0.001″ | Střední |

| Plain bearings | Světlo | ±0.005″ | Minimální |

| Recirculating ball | Velmi vysoká | ±0.0005″ | Vysoká |

External Guide Rail Systems

External guides provide maximum rigidity:

- Kalené ocelové kolejnice for durability

- Precision ground surfaces pro bezproblémový provoz

- Adjustable preload pro optimální výkon

- Modulární konstrukce for custom configurations

Precision Advantages

Guide cylinders offer significant precision benefits:

- Opakovatelnost within ±0.001″ consistently

- No rotational drift během provozu

- Důsledné použití síly po celou dobu mrtvice

- Reduced wear on tooling and fixtures

Jennifer’s electronics facility was struggling with component placement accuracy because their standard cylinders allowed microscopic rotation that accumulated over thousands of cycles, causing placement errors that exceeded their ±0.05mm tolerance requirements. 🔧

Bepto’s Guide Cylinder Solutions

Our compact guide cylinders incorporate precision linear bearings and rigid construction to deliver exceptional anti-rotation performance in the smallest possible footprint.

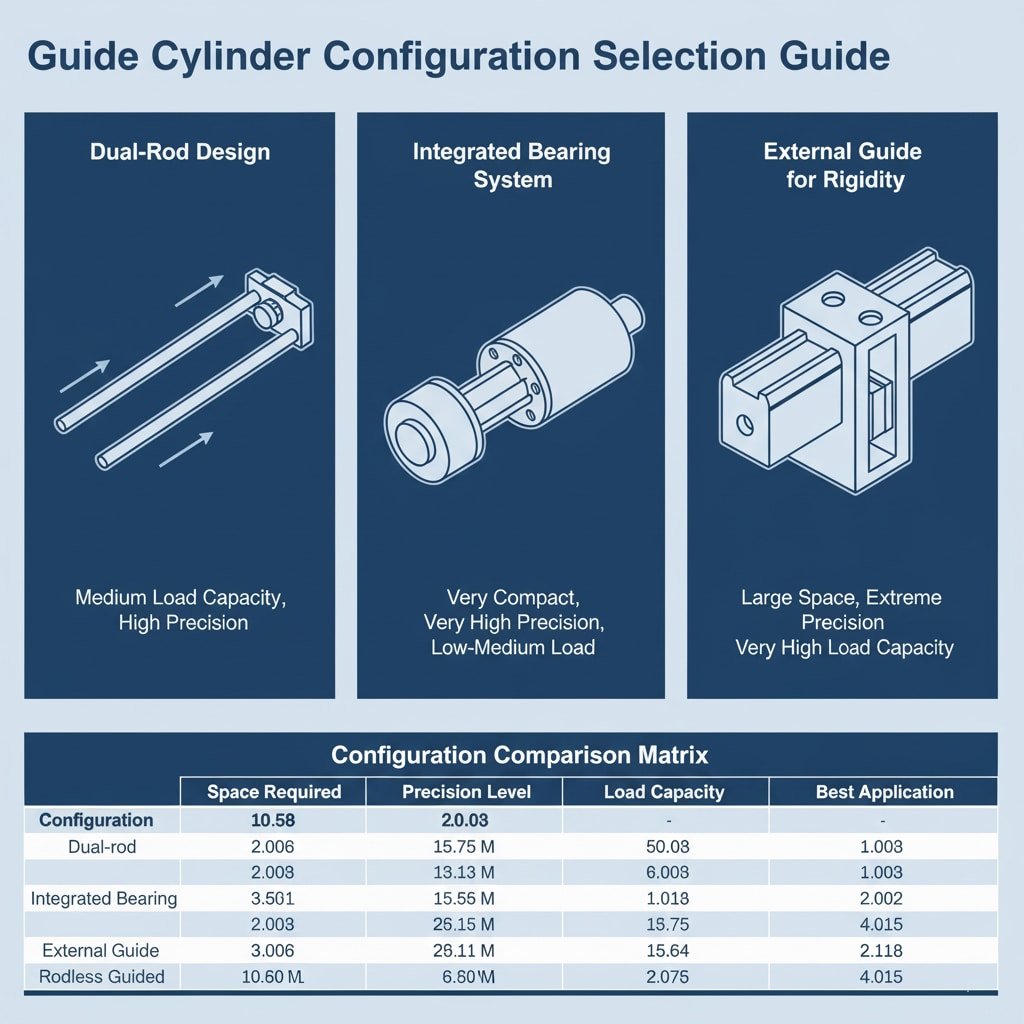

How Do You Select the Right Guide Cylinder Configuration? ⚙️

Proper configuration selection ensures optimal performance while meeting space constraints and precision requirements in demanding applications.

Select guide cylinder configuration based on load requirements, precision needs, and space constraints: choose dual-rod designs for balanced loading, integrated bearing systems for compact installations, and external guides for maximum rigidity in high-precision applications.

Configuration Comparison Matrix

| Konfigurace | Potřebný prostor | Přesná vodováha | Kapacita zatížení | Nejlepší aplikace |

|---|---|---|---|---|

| Dual-rod | Kompaktní | Vysoká | Střední | Assembly work |

| Integrated bearing | Very compact | Velmi vysoká | Low-medium | Elektronika |

| Externí průvodce | Velké | Extrémní | Velmi vysoká | Heavy precision |

| Rodless guided | Minimální | Vysoká | Vysoká | Manipulace s materiálem |

Požadavky na analýzu zatížení

Proper load analysis prevents premature failure:

Force Components

- Axial forces along cylinder centerline

- Boční zatížení perpendicular to motion

- Momentové zatížení2 creating rotational forces

- Dynamické síly from acceleration/deceleration

Load Capacity Guidelines

| Otvor válce | Maximum Side Load | Momentová kapacita | Typická aplikace |

|---|---|---|---|

| 1-2 inches | 50-100 liber | 200-500 in-lbs | Light assembly |

| 2-4 inches | 100-300 lbs | 500-1500 in-lbs | Medium work |

| 4-6 inches | 300-800 lbs | 1500-4000 in-lbs | Heavy positioning |

Precision Requirements Analysis

Different applications demand varying precision levels:

- Montáž elektroniky: ±0.001″ repeatability

- Výroba zdravotnických prostředků: ±0.0005″ accuracy

- Montáž automobilů: ±0.005″ positioning

- Všeobecný průmysl: ±0.010″ tolerance

Úvahy o životním prostředí

Operating environment affects configuration selection:

- Aplikace v čistých prostorách require sealed bearing systems

- High-temperature environments need special materials

- Corrosive atmospheres require stainless construction

- High-vibration areas need additional dampening

Bepto Configuration Expertise

Our engineering team provides comprehensive selection support including:

- Výpočty analýzy zatížení for your specific application

- Precision requirement verification through testing

- Optimalizace prostoru for compact installations

- Vlastní úpravy when standard options don’t fit

Which Mounting Options Maximize Precision in Compact Spaces? 🏗️

Strategic mounting selection and proper installation techniques are critical for achieving maximum precision in space-constrained applications.

Maximize precision in compact spaces using rigid base mounting with precision-machined surfaces, integrated mounting brackets that eliminate alignment errors, and modular mounting systems that provide adjustment capability while maintaining structural rigidity.

Mounting Style Comparison

| Typ montáže | Rigidity | Přesnost | Efektivita využití prostoru | Úprava |

|---|---|---|---|---|

| Fixed base | Vynikající | ±0.0005″ | Dobrý | Žádné |

| Adjustable base | Velmi dobré | ±0.001″ | Spravedlivé | Úplný |

| Boční montáž | Dobrý | ±0.002″ | Vynikající | Omezené |

| Integrovaný | Vynikající | ±0.0005″ | Vynikající | Minimální |

Precision Mounting Techniques

Critical mounting practices for maximum accuracy:

Příprava povrchu

- Machine mounting surfaces to 32 Ra3 or better

- Verify flatness within 0.0005″ across mounting area

- Use precision dowel pins for repeatable positioning

- Apply proper torque to all fasteners

Postupy vyrovnávání

- Establish reference datums4 using precision measurement tools

- Kontrola souběžnosti between mounting surface and motion axis

- Ověření kolmosti of all mounting surfaces

- Document alignment for future maintenance reference

Vibration Isolation

Minimize external vibration effects:

- Isolation pads between cylinder and mounting surface

- Rigid mounting structures to prevent deflection

- Dampening materials for high-vibration environments

- Proper fastener selection for dynamic loads

Compact Space Solutions

Maximize performance in limited space:

Integrated Mounting Systems

- Built-in mounting brackets eliminate separate hardware

- Precision-machined interfaces ensure perfect alignment

- Modular components for custom configurations

- Space-saving designs reduce overall footprint

Multi-Axis Integration

For complex positioning requirements:

- Stacked cylinder arrangements for X-Y positioning

- Rotary actuator integration for multi-axis motion

- Coordinated motion control for synchronized operation

- Compact controller integration for space savings

Jennifer’s facility implemented our integrated mounting system that reduced their assembly station footprint by 30% while improving positioning accuracy to ±0.02mm, well within their required tolerance. 📐

What Maintenance Practices Ensure Long-Term Accuracy? 🔧

Systematic maintenance procedures preserve precision performance and extend guide cylinder life in demanding applications.

Maintain long-term accuracy through regular bearing lubrication, precision alignment verification, wear pattern monitoring, and proactive seal replacement based on cycle counts rather than waiting for failure symptoms to appear.

Plán preventivní údržby

| Úkol údržby | Frekvence | Doba trvání | Potřebné nástroje |

|---|---|---|---|

| Vizuální kontrola | Týdenní | 15 minut | Eyes, flashlight |

| Lubrication check | Měsíční | 30 minut | Grease gun, manual |

| Precision verification | Čtvrtletně | 2 hours | Indikátory číselníku |

| Kompletní servis | Každoročně | 4-6 hodin | Full toolkit |

Critical Inspection Points

Focus maintenance attention on these key areas:

Linear Bearing Systems

- Check for smooth operation throughout full stroke

- Listen for unusual noises indicating wear

- Ověřte správné mazání at all bearing points

- Measure play or zpětná vazba5 in guidance system

Seal Condition Assessment

- Inspect for visible damage or deterioration

- Check for air leakage at all seal points

- Monitor operating pressure for consistency

- Replace seals proactively based on cycle counts

Precision Monitoring Techniques

Establish baseline measurements and track changes:

- Position repeatability testing monthly

- Straightness verification using precision straightedges

- Parallelism checks between cylinder and mounting

- Perpendicularity measurements at critical interfaces

Lubrication Best Practices

Proper lubrication is essential for long-term accuracy:

Výběr maziva

- High-quality bearing grease for linear guides

- Clean, dry air for pneumatic systems

- Kompatibilní materiály that won’t damage seals

- Appropriate viscosity for operating temperature

Application Procedures

- Clean all surfaces before lubricant application

- Use proper quantities – too much causes problems

- Distribute evenly through full range of motion

- Verify operation after lubrication service

Sledování výkonu

Track key performance indicators:

- Počty cyklů pro prediktivní údržbu

- Precision measurements v průběhu času

- Provozní tlak trendy

- Změny teploty během provozu

Bepto Service Support

We provide comprehensive maintenance support:

- Detailed maintenance manuals with step-by-step procedures

- Školící programy for your maintenance personnel

- Genuine replacement parts with guaranteed compatibility

- Technical support hotline for troubleshooting assistance

Závěr

Compact guide cylinders deliver the anti-rotation precision your applications demand – proper selection, installation, and maintenance ensure years of reliable, accurate performance in the most demanding environments. 🚀

FAQs About Compact Guide Cylinders

Q: What’s the minimum space requirement for installing a guide cylinder system?

Space requirements vary by configuration, but our most compact integrated bearing designs need only 20% more space than standard cylinders while providing superior anti-rotation performance. External guide systems require 50-100% more space but offer maximum precision.

Q: Can guide cylinders handle side loads without losing precision?

Yes, guide cylinders are specifically designed to handle side loads that would damage standard cylinders. Properly sized guide cylinders can handle side loads up to 50% of their axial force rating while maintaining precision positioning accuracy.

Q: How do I know if my application needs a guide cylinder versus a standard cylinder?

If your application requires positioning accuracy better than ±0.005″, involves any side loading, or cannot tolerate rotational movement, you need a guide cylinder. Standard cylinders are adequate only for simple push-pull operations without precision requirements.

Q: What’s the typical lifespan of linear bearings in guide cylinder applications?

With proper maintenance, quality linear bearings in guide cylinders typically last 2-5 million cycles depending on load conditions and operating environment. Our Bepto guide cylinders include premium bearings rated for extended life in industrial applications.

Q: Can guide cylinders be used in high-speed applications without losing accuracy?

Guide cylinders actually perform better at higher speeds than standard cylinders because the guidance system prevents deflection and vibration that degrades accuracy. However, proper cushioning and speed control are essential for maintaining precision at high velocities.

-

Learn about the different types of linear bearings and how they enable precise motion. ↩

-

Understand what a moment load is and how it creates rotational force on a component. ↩

-

A guide to understanding Ra (Roughness Average) values used to measure surface finish. ↩

-

Explore the concept of datums as reference points for precision measurement and alignment. ↩

-

Learn what mechanical backlash is and how it affects the precision of moving parts. ↩