Seal failures cost manufacturers over $2.3 million annually in unplanned downtime, with 65% of engineers selecting Buna-N seals for high-temperature applications where they fail within 6 months, while 40% choose expensive Viton seals for standard applications where cost-effective Buna-N would perform equally well for decades. ⚠️

Segel Buna-N menawarkan kinerja yang sangat baik dan hemat biaya untuk aplikasi pneumatik standar hingga 80 ° C dengan ketahanan kimia yang baik, sedangkan segel Viton memberikan kinerja suhu tinggi yang unggul hingga 200 ° C dan ketahanan kimia yang luar biasa tetapi dengan biaya 3-5x lebih tinggi, membuat pemilihan bahan sangat penting untuk mengoptimalkan kinerja dan ekonomi.

Just last week, I worked with Jennifer, a maintenance engineer at a plastics manufacturing plant in Ohio, whose pneumatic cylinders were failing every 3 months due to heat exposure. After switching from Buna-N to our Bepto Viton seal kits, her cylinders have operated flawlessly for over 8 months in 150°C environments. 🔥

Daftar Isi

- What Are the Key Chemical and Physical Properties of Buna-N vs. Viton?

- How Do Temperature Ranges Affect Seal Performance and Lifespan?

- Which Seal Material Offers Better Chemical Resistance for Your Application?

- When Should You Choose Buna-N vs. Viton Based on Cost and Performance?

What Are the Key Chemical and Physical Properties of Buna-N vs. Viton?

Understanding the fundamental material properties helps engineers select the optimal seal material for specific pneumatic cylinder applications.

Buna-N (Nitrile) offers excellent oil resistance, good mechanical properties, and cost-effectiveness with Shore A hardness1 of 70-90 and tensile strength2 up to 24 MPa, while Viton (Fluoroelastomer) provides superior chemical resistance, higher temperature capability, and exceptional durability with Shore A hardness of 75-95 and tensile strength up to 20 MPa.

Material Composition

Buna-N (NBR – Nitrile Butadiene Rubber):

- Synthetic rubber copolymer

- Acrylonitrile content: 18-50%

- Excellent oil and fuel resistance

- Good mechanical properties

- Cost-effective manufacturing

Viton (FKM – Fluoroelastomer):

- Fluorinated synthetic rubber

- High fluorine content (65-70%)

- Exceptional chemical inertness

- Superior thermal stability

- Premium performance material

Physical Properties Comparison

| Properti | Buna-N | Viton |

|---|---|---|

| Shore A Hardness | 70-90 | 75-95 |

| Tensile Strength | 10-24 MPa | 10-20 MPa |

| Elongation at Break | 200-600% | 150-300% |

| Set Kompresi3 | Bagus. | Luar biasa |

| Tear Resistance | Bagus. | Luar biasa |

| Abrasion Resistance | Bagus. | Sangat baik |

Permeability Characteristics

Gas Permeability (Lower is Better):

- Buna-N: Moderate permeability to gases

- Viton: Very low permeability, excellent gas barrier

- Air retention: Viton systems maintain pressure longer

- Leak rates: Viton reduces system air consumption

Pertimbangan Manufaktur

Buna-N seals are easier to manufacture with standard molding processes, while Viton requires specialized processing due to its chemical resistance. This affects both cost and availability, with Buna-N offering shorter lead times and broader supplier options.

How Do Temperature Ranges Affect Seal Performance and Lifespan?

Temperature exposure significantly impacts seal material performance, with each material having distinct operating ranges and failure modes.

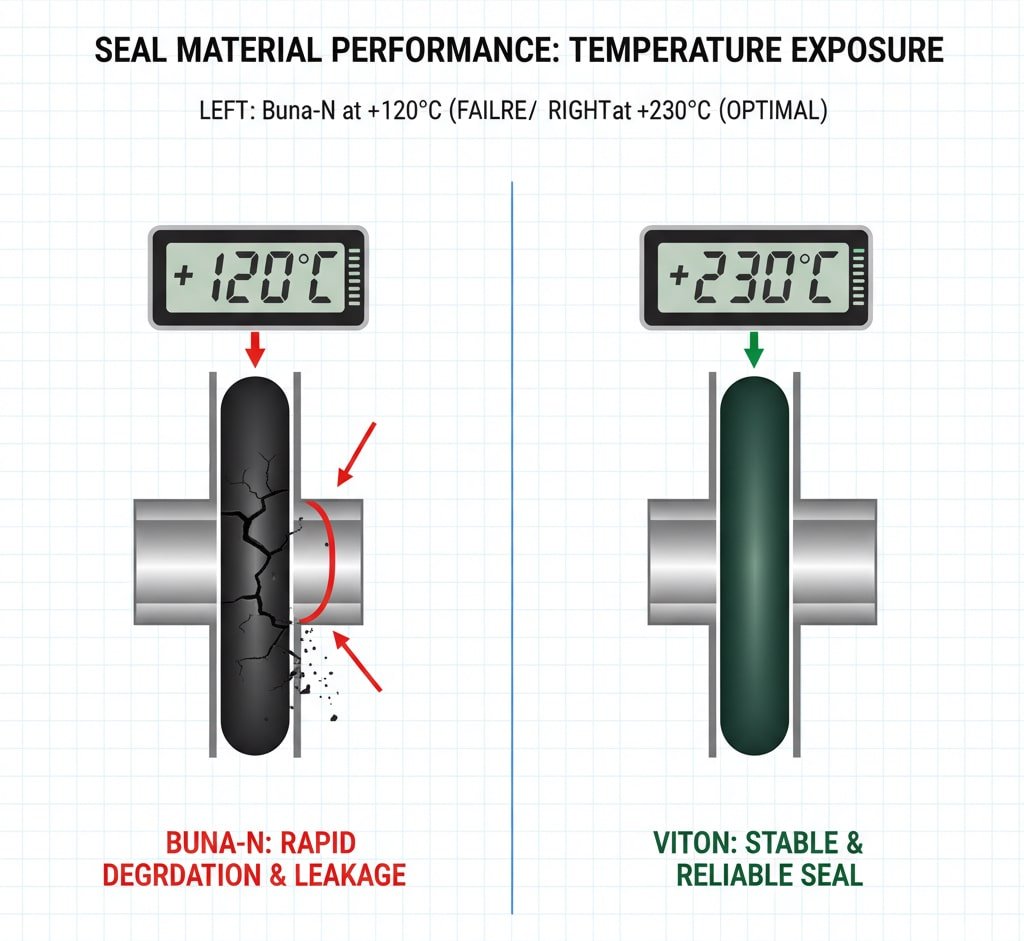

Buna-N performs optimally from -40°C to +100°C with acceptable performance to +120°C short-term, while Viton excels from -20°C to +200°C with continuous operation capability to +230°C, making temperature the primary selection criterion for high-heat applications where Buna-N experiences rapid degradation and hardening.

Operating Temperature Ranges

| Kisaran Suhu | Buna-N Performance | Viton Performance |

|---|---|---|

| -40°C to -20°C | Good (some stiffening) | Fair (limited flexibility) |

| -20°C to +20°C | Luar biasa | Luar biasa |

| +20°C to +80°C | Luar biasa | Luar biasa |

| +80°C to +120°C | Good (shortened life) | Luar biasa |

| +120°C to +150°C | Poor (rapid failure) | Luar biasa |

| +150°C to +200°C | Fails quickly | Bagus. |

| Above +200°C | Not suitable | Limited short-term use |

Temperature-Related Failure Modes

Buna-N High-Temperature Failures:

- Hardening and cracking above 100°C

- Hilangnya elastisitas leading to leakage

- Penuaan yang dipercepat reducing service life

- Set kompresi causing permanent deformation

Viton Temperature Advantages:

- Maintains flexibility at high temperatures

- Excellent heat aging resistance

- Minimal compression set even at 200°C

- Stable properties across wide temperature range

Service Life vs. Temperature

At 80°C continuous operation:

- Buna-N: 12-24 months typical service life

- Viton: 5-10 years typical service life

At 120°C continuous operation:

- Buna-N: 1-3 months before failure

- Viton: 2-5 years reliable operation

Thermal Cycling Effects

Repeated heating and cooling cycles affect materials differently:

- Buna-N shows good thermal cycling resistance up to 80°C

- Viton excels in thermal cycling applications up to 200°C

- Ketahanan terhadap kelelahan is superior with Viton in high-temperature cycling

Michael, a process engineer at a food processing plant in California, was replacing Buna-N seals monthly in steam-cleaning applications reaching 130°C. After upgrading to our Bepto Viton seal kits, his maintenance intervals extended to over 18 months, saving both downtime and replacement costs. 🍕

Which Seal Material Offers Better Chemical Resistance for Your Application?

Chemical compatibility determines seal longevity and system reliability, with each material offering distinct resistance profiles for different chemical environments.

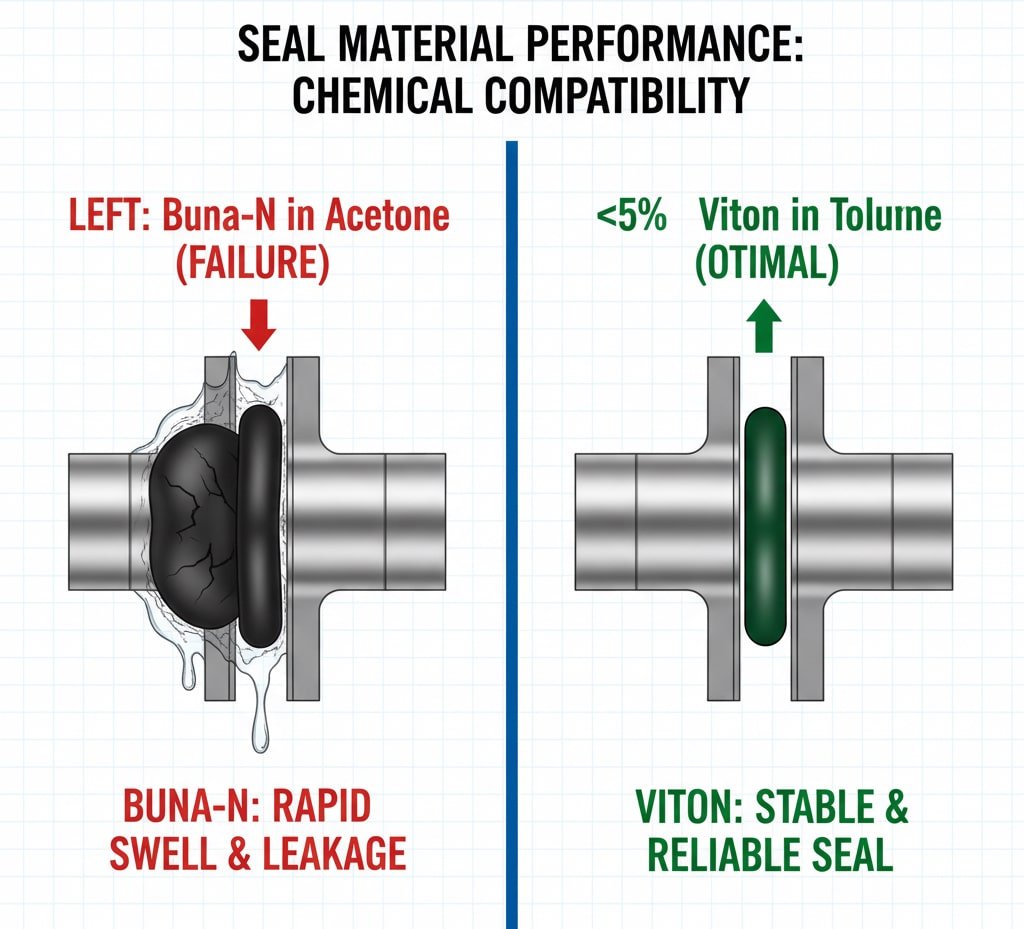

Buna-N provides excellent resistance to petroleum oils, hydraulic fluids, and aliphatic hydrocarbons4 but swells in aromatic solvents5 and ketones, while Viton offers superior resistance to acids, bases, oxidizers, and most chemicals except amines and high-pH solutions, making chemical exposure the critical selection factor for harsh environments.

Chemical Resistance Comparison

| Kelas Kimia | Buna-N Resistance | Viton Resistance |

|---|---|---|

| Petroleum Oils | Luar biasa | Bagus. |

| Hydraulic Fluids | Luar biasa | Bagus. |

| Aromatic Hydrocarbons | Miskin | Luar biasa |

| Ketones | Miskin | Luar biasa |

| Acids (Mineral) | Adil | Luar biasa |

| Bases (Caustic) | Miskin | Bagus. |

| Oxidizing Agents | Miskin | Luar biasa |

| Uap | Adil | Bagus. |

| Ozon | Miskin | Luar biasa |

Specific Chemical Applications

Buna-N Recommended For:

- Standard pneumatic systems with air/oil lubrication

- Hydraulic systems with mineral oils

- Fuel systems with gasoline/diesel

- General industrial applications

- Water-based systems

Viton Recommended For:

- Chemical processing environments

- High-temperature steam applications

- Oxidizing chemical exposure

- Aromatic solvent environments

- Aggressive cleaning chemical exposure

Swelling and Degradation

Volume Swell in Common Fluids (24 hours at 23°C):

| Cairan | Buna-N Swell | Viton Swell |

|---|---|---|

| Motor Oil | <5% | <10% |

| Bensin | <15% | <5% |

| Aseton | >100% | <5% |

| Methanol | <20% | <5% |

| Hydraulic Fluid | <10% | <15% |

Faktor Stres Lingkungan

UV and Ozone Resistance:

- Buna-N degrades rapidly under UV and ozone exposure

- Viton shows excellent UV and ozone resistance

- Aplikasi luar ruangan strongly favor Viton selection

- Indoor controlled environments allow Buna-N use

When Should You Choose Buna-N vs. Viton Based on Cost and Performance?

Economic considerations must balance initial seal costs against total system lifecycle costs, maintenance requirements, and performance reliability.

Choose Buna-N for standard pneumatic applications under 80°C with minimal chemical exposure where its 70% lower cost provides excellent value, while selecting Viton for high-temperature applications above 100°C, aggressive chemical environments, critical applications requiring maximum reliability, or systems where seal replacement costs exceed material cost differences.

Cost Analysis Framework

Initial Material Costs (Relative):

- Buna-N seals: Baseline cost (1.0x)

- Viton seals: 3-5x higher initial cost

- Volume pricing: Reduces cost differential

- Custom compounds: May increase costs further

Total Biaya Kepemilikan

| Faktor Biaya | Buna-N Impact | Viton Impact |

|---|---|---|

| Initial Seal Cost | Rendah | Tinggi |

| Frekuensi Penggantian | Lebih tinggi | Lebih rendah |

| Biaya Waktu Henti | Higher (more frequent) | Lower (less frequent) |

| Biaya Persediaan | Biaya unit yang lebih rendah | Biaya unit yang lebih tinggi |

| Biaya Tenaga Kerja | Higher (frequent service) | Lower (extended service) |

Panduan Seleksi Berbasis Aplikasi

Choose Buna-N When:

- Operating temperatures consistently below 80°C

- Standard pneumatic system applications

- Petroleum oil or hydraulic fluid exposure only

- Cost optimization is primary concern

- Easy maintenance access available

- Non-critical applications tolerating downtime

Choose Viton When:

- Operating temperatures above 100°C

- Chemical processing environments

- Critical applications requiring maximum uptime

- Difficult maintenance access locations

- Long-term reliability is essential

- Total cost of ownership optimization needed

Bepto Seal Solutions

At Bepto, we offer comprehensive seal kits for both materials:

Buna-N Seal Kits: Cost-effective solutions for standard applications with complete seal sets, O-rings, and gaskets designed for easy field replacement.

Viton Seal Kits: Premium performance seals for demanding applications, available in various durometer ratings and custom compounds for specific chemical compatibility.

Dukungan Teknis: Our engineering team provides chemical compatibility charts, temperature ratings, and application-specific recommendations to ensure optimal seal selection.

Lisa, a plant manager at a chemical processing facility in Texas, was spending $15,000 annually replacing Buna-N seals in her acidic environment. After switching to our Bepto Viton seals, her annual seal costs dropped to $8,000 despite the higher material cost, thanks to 5x longer service life. 🧪

Kesimpulan

Seal material selection requires balancing temperature requirements, chemical exposure, and economic factors, with Buna-N offering cost-effective performance for standard applications and Viton providing superior performance for demanding environments.

FAQs About Pneumatic Cylinder Seal Materials

Q: How much longer do Viton seals last compared to Buna-N in high-temperature applications?

In applications above 100°C, Viton seals typically last 5-10 times longer than Buna-N seals. At 150°C, Buna-N may fail within weeks while Viton operates reliably for years.

Q: Can I use Buna-N seals in food-grade applications?

Yes, food-grade Buna-N compounds are available and widely used in food processing. However, for high-temperature cleaning cycles above 100°C, Viton may be more suitable.

Q: What’s the temperature limit where I should switch from Buna-N to Viton?

The crossover point is typically around 100°C continuous operation. Above this temperature, Viton’s longer service life often justifies its higher initial cost.

Q: Do Viton seals work in low-temperature applications?

Viton has limited low-temperature flexibility below -20°C. For applications below -30°C, specialized low-temperature Buna-N compounds often perform better.

Q: How do I determine chemical compatibility for my specific application?

Contact our technical team with your specific chemical exposure details. We provide detailed compatibility charts and can recommend the optimal seal material and compound for your application requirements.

-

Learn how the Shore A durometer scale is used to measure the hardness and indentation resistance of flexible elastomers. ↩

-

Understand the definition of tensile strength and how this material property relates to a seal’s durability under force. ↩

-

Understand the concept of compression set and how this permanent deformation affects long-term sealing performance. ↩

-

See a chemical comparison of aliphatic hydrocarbons (like methane and propane) and their properties. ↩

-

Explore what aromatic solvents (like Toluene and Xylene) are and why they are aggressive toward certain rubbers. ↩