Pendahuluan

Garis perakitan otomatis Anda meleset dari target penempatan sebesar 0,5 mm, dan bagian yang ditolak menumpuk. 🎯 Anda telah mengkalibrasi sensor posisi tiga kali, tetapi ketidakkonsistenan tetap berlanjut. Penyebab tersembunyi bukan sistem kontrol Anda—melainkan hysteresis segel dinamis, fenomena gesekan yang menyebabkan kesalahan penempatan yang tidak terduga, yang mengakibatkan kerugian ribuan dolar bagi produsen setiap hari akibat limbah dan perbaikan ulang.

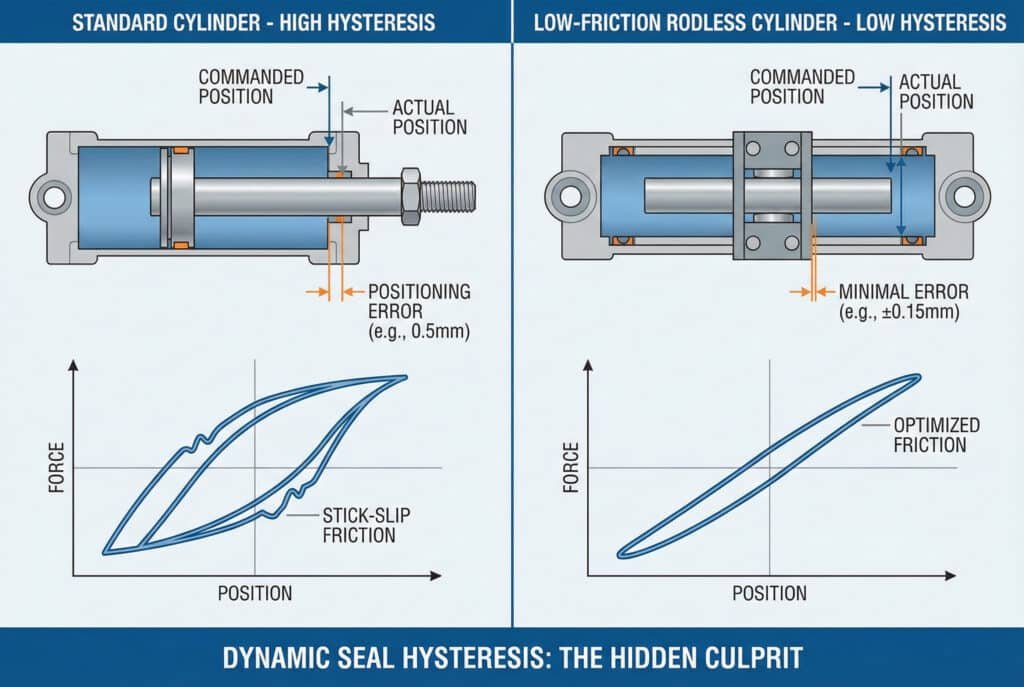

Histeresis segel dinamis adalah keterlambatan yang disebabkan oleh gesekan antara posisi silinder yang diperintahkan dan posisi aktual silinder yang disebabkan oleh perilaku tergelincir tongkat1, variasi gaya lepas, dan gesekan yang bergantung pada kecepatan pada bahan segel—histeresis ini menyebabkan kesalahan posisi sebesar 0,2–2,0 mm pada silinder pneumatik standar, sehingga desain segel, pemilihan bahan, dan optimasi pelumasan menjadi kritis untuk aplikasi yang memerlukan ketepatan lebih dari ±0,5 mm dalam sistem perakitan presisi, pengujian, dan pengukuran.

Bulan lalu, saya bekerja sama dengan Kevin, seorang insinyur kontrol di pabrik perakitan elektronik di Illinois, yang mengalami masalah penempatan komponen yang tidak konsisten dalam aplikasi pick-and-place. Kesalahan penempatan komponennya berkisar antara 0,3-0,8 mm meskipun menggunakan encoder beresolusi tinggi. Setelah menganalisis sistemnya, kami menemukan bahwa histeresis segel pada silinder standar yang digunakannya adalah akar masalahnya. Beralih ke silinder tanpa batang Bepto bergesekan rendah dengan geometri segel yang dioptimalkan mengurangi kesalahan penempatan menjadi ±0,15 mm, mengurangi tingkat penolakan sebesar 73%. 📊

Daftar Isi

- Apa Itu Histeresis Segel Dinamis dan Mengapa Hal Itu Mempengaruhi Akurasi Penempatan?

- Bagaimana Desain dan Bahan Segel yang Berbeda Mempengaruhi Perilaku Histeresis?

- Apa Saja Dampak Kuantitatif Histeresis Segel pada Sistem Penempatan Presisi?

- Strategi desain apa yang dapat meminimalkan histeresis segel pada silinder tanpa batang?

Apa Itu Histeresis Segel Dinamis dan Mengapa Hal Itu Mempengaruhi Akurasi Penempatan?

Memahami fisika kesalahan penempatan yang disebabkan oleh gesekan sangat penting untuk mencapai presisi dalam sistem otomatis. 🔬

Histeresis segel dinamis terjadi ketika gaya gesek bervariasi secara non-linier dengan kecepatan dan arah, menyebabkan keterlambatan antara tekanan input dan posisi output—lebar lingkaran histeresis (perbedaan antara kurva gaya-pergeseran saat memperpanjang dan menarik kembali) biasanya berkisar antara 5-15% dari total gaya stroke pada silinder standar, menyebabkan kesalahan yang bergantung pada posisi yang menumpuk dalam sistem loop tertutup dan mencegah pencapaian ketepatan sub-milimeter tanpa algoritma kompensasi atau desain segel bergesekan rendah.

Mekanisme Gesekan dan Histeresis pada Segel

Bayangkan histeresis segel seperti perbedaan antara mendorong kotak berat di lantai dengan menariknya kembali. Gesekan tidak sama dalam kedua arah karena interaksi permukaan, deformasi material, dan efek arah. Pada segel pneumatik, ketidakseimbangan ini bahkan lebih mencolok.

Ketika silinder mengembang, bibir segel tertekan ke arah satu sisi pada tabung. Ketika silinder mengerut, segel mengalami deformasi yang berbeda, menghasilkan karakteristik gesekan yang berbeda pula. Hal ini membentuk lingkaran histeresis—representasi grafis yang menunjukkan bahwa gaya yang diperlukan untuk menggerakkan silinder tidak hanya bergantung pada posisi, tetapi juga pada arah dan riwayat kecepatan.

Fenomena Stick-Slip dan Gaya Lepas

Aspek paling problematis dari histeresis segel adalah perilaku stick-slip. Saat diam, segel mengembangkan pembatasan2 Itu 20-50% lebih tinggi daripada gesekan dinamis selama pergerakan. Ketika tekanan meningkat untuk mengatasi gaya lepas ini, silinder tiba-tiba “melompat” ke depan, melampaui posisi target.

Gerakan slip-stick ini menghasilkan profil gerakan bergerigi alih-alih gerakan halus. Dalam penempatan presisi, hal ini manifes sebagai:

- Overshoot ketika mulai dari keadaan diam

- Penetapan osilasi di sekitar posisi target

- Kesalahan penempatan yang bergantung pada arah (posisi akhir yang berbeda saat mendekati dari arah yang berlawanan)

Di Bepto, kami telah mengukur gaya lepas pada silinder standar dengan rentang 15-35N untuk silinder berdiameter 40mm, sementara desain bergesekan rendah yang dioptimalkan kami mengurangi nilai ini menjadi 5-12N—penurunan sebesar 60-70% yang secara signifikan meningkatkan konsistensi penempatan.

Mengapa Sistem Pengendalian Tidak Dapat Sepenuhnya Mengkompensasi

Banyak insinyur menganggap bahwa pengendalian posisi loop tertutup dengan umpan balik dapat menghilangkan efek histeresis. Meskipun umpan balik membantu, hal itu tidak dapat sepenuhnya mengatasi fisika dasar. Sistem pengendalian mendeteksi kesalahan posisi dan menerapkan koreksi, tetapi histeresis menyebabkan:

Zona matiKesalahan posisi kecil yang tidak menghasilkan cukup gaya untuk mengatasi gesekan statis.

Siklus batasGetaran di sekitar target saat sistem secara bergantian mengatasi dan melepaskan gesekan.

Kesalahan yang bergantung pada kecepatan: Akurasi penempatan yang berbeda pada kecepatan pendekatan yang berbeda

Saya telah berkonsultasi pada puluhan proyek di mana para insinyur menghabiskan berbulan-bulan untuk menyesuaikan pengendali PID, hanya untuk menemukan bahwa batasan fundamentalnya adalah gesekan histeresis pada segel, yang tidak dapat dihilangkan dengan penyesuaian perangkat lunak sebanyak apa pun. Solusinya memerlukan penanganan sumber mekanisnya—segel itu sendiri.

Bagaimana Desain dan Bahan Segel yang Berbeda Mempengaruhi Perilaku Histeresis?

Geometri segel dan sifat material secara fundamental menentukan besarnya histeresis dan kinerja penempatan. ⚙️

Histeresis segel bervariasi secara signifikan tergantung pada desain: Segel U-cup dengan sudut bibir yang tajam menghasilkan gaya histeresis 40-60N pada silinder berdiameter 50mm, sementara desain bergesekan rendah yang dioptimalkan dengan sudut bibir yang dangkal dan bahan PTFE mengurangi histeresis menjadi 10-20N—pilihan bahan (polyurethane vs. PTFE vs. karet) memengaruhi rasio gesekan statis-dinamis (1,3-2,0x) dan perilaku gesekan yang bergantung pada kecepatan, dengan PTFE menawarkan karakteristik gesekan yang paling konsisten di seluruh rentang kecepatan untuk aplikasi penempatan presisi.

Geometri Segel dan Distribusi Tekanan Kontak

Sudut bibir segel dan lebar kontak secara langsung menentukan besarnya gaya gesek dan magnitudo histeresis. Segel U-cup tradisional menggunakan sudut bibir 15-25° untuk memastikan penyegelan yang andal, tetapi hal ini menyebabkan tekanan kontak yang tinggi dan gesekan.

Segel U-cup standar (Sudut bibir 25°):

- Tekanan kontak tinggi (2-4 MPa)

- Keandalan penyegelan yang sangat baik

- Gaya gesek tinggi (40-60 N untuk lubang berdiameter 50 mm)

- Lingkaran histeresis besar (kesalahan posisi ±0,5-1,0 mm)

Segel yang dioptimalkan dengan gesekan rendah (Sudut bibir 8-12°):

- Tekanan kontak sedang (0,8-1,5 MPa)

- Perekat yang baik dengan permukaan yang halus

- Gaya gesek rendah (10-20 N untuk lubang berdiameter 50 mm)

- Lingkaran histeresis kecil (kesalahan posisi ±0,1-0,3 mm)

Di Bepto, kami telah mengembangkan profil segel eksklusif yang mengoptimalkan keandalan penyegelan dengan gesekan minimal. Silinder tanpa batang kami menggunakan desain multi-lip, di mana segel utama menangani penahanan tekanan sementara elemen gesekan rendah sekunder meminimalkan histeresis.

Pengaruh Sifat Material terhadap Perilaku Gesekan

Bahan segel yang berbeda menunjukkan karakteristik gesekan dan perilaku histeresis yang sangat berbeda:

| Bahan Segel | Perbandingan Gesekan Statis/Dinamis | Sensitivitas Kecepatan | Gaya Histeresis (lubang 50 mm) | Aplikasi Terbaik |

|---|---|---|---|---|

| NBR (Nitril) | 1,8–2,0 kali | Tinggi | 45-65 derajat utara | Biaya rendah, tidak presisi |

| Poliuretan | 1,5–1,8 kali | Sedang | 30-50 N | Industri umum |

| PTFE (Perawan) | 1,2–1,4 kali | Rendah | 8-15 N | Pemosisian presisi |

| PTFE yang diisi | 1,3–1,5 kali | Rendah | 12-20N | Kinerja yang seimbang |

| PU yang diisi grafit | 1,4–1,6 kali | Sedang-Rendah | 20-35° LU | Efisiensi biaya dengan presisi tinggi |

Struktur molekul PTFE menghasilkan gesekan yang sangat konsisten di berbagai rentang kecepatan. Berbeda dengan elastomer yang menunjukkan gesekan yang sangat bergantung pada kecepatan (gesekan meningkat seiring dengan kecepatan), PTFE mempertahankan gesekan yang hampir konstan dari 1 mm/s hingga 1000 mm/s—hal ini sangat penting untuk penempatan yang dapat diprediksi.

Kurva Stribeck dan Regim Pelumasan

Perilaku gesekan segel mengikuti Kurva Stribeck3, yang menggambarkan tiga mode pelumasan:

Pelumasan batas (kecepatan sangat rendah):

- Kontak logam-ke-logam melalui lapisan pelumas

- Gesekan tertinggi

- Dominan pada kecepatan penempatan (<10 mm/s)

Pelumasan campuran (kecepatan sedang):

- Dukungan lapisan pelumas parsial

- Perilaku gesekan transisi

- Sebagian besar aplikasi penempatan beroperasi di sini.

Pelumasan hidrodinamik (kecepatan tinggi):

- Pemisahan lapisan pelumas sepenuhnya

- Gesekan terendah

- Jarang tercapai pada silinder pneumatik

Lebar zona pelumasan batas menentukan histeresis penempatan. Bahan dengan sifat pelumasan batas yang lebih baik (PTFE, campuran yang diperkuat grafit) mempertahankan gesekan yang lebih rendah pada kecepatan penempatan, sehingga mengurangi histeresis.

Pengaruh Suhu terhadap Histeresis

Gesekan segel tidak konstan dengan suhu—gesekan tersebut berubah secara signifikan saat sistem memanas selama operasi. Segel poliuretan standar menunjukkan pengurangan gesekan sebesar 30-40% dari 20°C hingga 60°C, yang menyebabkan pergeseran posisi saat suhu sistem stabil.

Saya bekerja sama dengan Sarah, seorang insinyur peralatan pengujian di Michigan, yang sistem pengukuran presisinya menunjukkan akurasi penempatan yang berbeda antara pagi dan sore hari. Segel silinder standar yang digunakannya sensitif terhadap suhu, menyebabkan variasi penempatan sebesar 0,4 mm saat sistem memanas. Kami menggantinya dengan silinder Bepto yang stabil terhadap suhu, menggunakan segel PTFE, dan konsistensi penempatannya meningkat menjadi ±0,12 mm terlepas dari suhu operasi. 🌡️

Apa Saja Dampak Kuantitatif Histeresis Segel pada Sistem Penempatan Presisi?

Memahami dampak numerik dari histeresis membantu Anda menentukan teknologi silinder yang sesuai dengan persyaratan akurasi Anda. 📈

Histeresis segel menyebabkan kesalahan penempatan yang dapat diukur: silinder standar dengan gaya histeresis 40-50N menunjukkan ketepatan ±0,5-1,2 mm pada tekanan 8 bar, sementara desain bergesekan rendah dengan gaya histeresis 10-15N mencapai ketepatan ±0,1-0,3 mm—kesalahan ini bergantung pada panjang stroke (0,1-0,2% stroke tipikal), variasi tekanan (perubahan tekanan ±10% menyebabkan perubahan posisi ±0,15 mm), dan arah pendekatan (repetibilitas dua arah 2-3 kali lebih buruk daripada satu arah), menjadikan histeresis sebagai faktor pembatas dalam aplikasi yang memerlukan akurasi lebih baik dari ±0,5 mm.

Magnitude dan Skala Kesalahan Posisi

Hubungan antara gaya histeresis dan kesalahan posisi mengikuti pola yang dapat diprediksi. Untuk diameter silinder dan tekanan operasi yang tertentu, kesalahan posisi berbanding lurus secara aproximatif dengan gaya histeresis:

Kesalahan Posisi ≈ (Gaya Histeresis / Gaya Pneumatik) × Panjang Stroke

Untuk silinder dengan diameter dalam 50 mm pada tekanan 8 bar (gaya efektif ≈ 1570 N) dengan stroke 400 mm:

- 40N histeresisKesalahan ≈ (40/1570) × 400 mm = 10,2 mm kesalahan potensial

- Kesalahan aktual dengan peredaman±0,6–1,0 mm (peredaman sistem mengurangi batas maksimum teoretis)

Hal ini menjelaskan mengapa silinder dengan diameter lubang yang lebih besar sering menunjukkan akurasi posisi relatif yang lebih baik—gaya pneumatik meningkat seiring dengan luas lubang (D²), sementara gesekan segel meningkat secara kasar seiring dengan diameter lubang (D), menghasilkan hubungan skalabilitas yang menguntungkan.

Repeatabilitas Dua Arah vs. Repeatabilitas Satu Arah

Salah satu spesifikasi paling penting untuk penempatan presisi adalah kemampuannya untuk kembali ke posisi yang sama saat mendekati dari arah yang berlawanan. Histeresis secara langsung menentukan spesifikasi ini:

Keterulangan satu arah (selalu mendekati dari arah yang sama):

- Silinder standar: ±0,3-0,6 mm

- Silinder bergesekan rendah: ±0,1-0,2 mm

- Bepto presisi tanpa batang: ±0,05-0,15 mm

Kemampuan pengulangan dua arah (datang dari arah mana pun):

- Silinder standar: ±0,8-1,5 mm (2-3 kali lebih buruk)

- Silinder bergesekan rendah: ±0,2-0,4 mm (dua kali lebih buruk)

- Bepto presisi tanpa batang: ±0,1-0,25 mm (1,5-2 kali lebih buruk)

Denda dua arah berasal langsung dari histeresis—posisi bergantung pada arah pendekatan akibat ketidakseimbangan gesekan. Aplikasi yang memerlukan akurasi dua arah harus menentukan silinder dengan histeresis minimal.

Sensitivitas Tekanan dan Keseimbangan Gaya

Ketepatan penempatan juga bergantung pada stabilitas tekanan. Histeresis menciptakan “daerah mati” di mana perubahan tekanan kecil tidak menghasilkan gerakan karena tidak mampu mengatasi gesekan statis. Lebar daerah mati ini adalah:

Tekanan Zona Mati ≈ Gaya Lepas / Luas Piston

Untuk silinder dengan diameter lubang 50 mm (luas ≈ 1963 mm²) dan gaya lepas 25 N:

Batas Kematian ≈ 25 N / 1963 mm² = 0,013 MPa = 0,13 bar

Ini berarti variasi tekanan di bawah 0,13 bar tidak akan menghasilkan gerakan—silinder “terkunci” pada posisinya. Untuk penempatan presisi, hal ini menyebabkan:

- Persyaratan pengaturan tekanan: Diperlukan ±0,05 bar atau lebih baik untuk penempatan yang konsisten.

- Batasan resolusiTidak dapat mencapai resolusi penempatan yang lebih baik daripada batas mati yang setara.

- Menyelesaikan masalah waktuSistem berosilasi dalam rentang mati sebelum stabil.

Persyaratan Aplikasi di Dunia Nyata

Berbagai aplikasi memiliki tingkat toleransi yang berbeda terhadap kesalahan yang disebabkan oleh histeresis:

Aplikasi presisi tinggi (±0,1-0,2 mm diperlukan):

- Perakitan dan pengujian elektronik

- Penempatan komponen optik

- Pengukuran dan pemeriksaan presisi

- SolusiSistem segel PTFE, desain bergesekan rendah, kontrol loop tertutup

Aplikasi dengan presisi sedang (±0,3-0,5 mm dapat diterima):

- Operasi rapat umum

- Pengelolaan material dengan toleransi yang ketat

- Kemasan dan penandaan

- Solusi: Segel poliuretan yang dioptimalkan, silinder standar kualitas

Aplikasi dengan presisi rendah (±1,0 mm+ dapat diterima):

- Pengelolaan material dalam jumlah besar

- Penjepitan dan pemasangan fixture

- Otomatisasi umum

- SolusiSilinder standar yang memadai

Di Bepto, kami membantu pelanggan memilih teknologi silinder yang sesuai dengan kebutuhan aktual mereka. Memilih silinder presisi dengan spesifikasi berlebihan hanya akan membuang-buang uang, sementara memilih dengan spesifikasi yang terlalu rendah dapat menyebabkan masalah kualitas dan biaya perbaikan.

Strategi desain apa yang dapat meminimalkan histeresis segel pada silinder tanpa batang?

Mencapai penempatan presisi memerlukan pendekatan desain terintegrasi yang mengatasi gesekan pada setiap tingkatan. 🎯

Mengurangi hysteresisi segel memerlukan strategi desain yang multifaset: geometri bibir segel yang dioptimalkan dengan sudut kontak 8-12°, bahan PTFE atau PTFE yang diisi dengan rasio gesekan statis/dinamis di bawah 1,4x, permukaan silinder yang dihaluskan dengan presisi (Ra 0,2-0,4 μm) untuk mendukung pelumasan batas, pelumas sintetis dengan viskositas yang sesuai (ISO VG 32-68), dan fitur desain mekanis seperti kereta yang dipandu dan penyesuaian beban awal—pada silinder tanpa batang, konfigurasi segel ganda dengan penyeimbangan tekanan lebih lanjut mengurangi gaya gesekan bersih sambil mempertahankan integritas segel.

Rekayasa Profil Segel yang Dioptimalkan

Di Bepto, kami telah berinvestasi secara signifikan dalam optimasi profil segel menggunakan analisis elemen hingga dan pengujian empiris. Profil segel presisi kami mencakup:

Sudut bibir yang dangkal (8-12° vs. standar 20-25°):

- Mengurangi tekanan kontak sebesar 40-60%

- Menjaga kedap udara melalui persyaratan finishing permukaan yang presisi.

- Membutuhkan permukaan laras dengan tingkat kehalusan Ra 0,3-0,5 μm (dibandingkan dengan Ra 0,8-1,2 μm untuk standar).

Konfigurasi multi-lip:

- Segel utama: Penahanan tekanan (gesekan sedang dapat diterima)

- Segel sekunder: Penghapus bergesekan rendah (tekanan kontak minimal)

- Segel tersier: Pencegahan kontaminasi (eksternal)

Desain yang seimbang tekanan:

- Menutup bibir segel dengan penyeimbangan tekanan

- Gaya gesek bersih berkurang sebesar 30-50%

- Terutama efektif pada silinder tanpa batang dengan penyegelan dua sisi.

Optimasi Permukaan dan Pelumasan

Permukaan laras memiliki pengaruh kritis terhadap pelumasan batas dan histeresis. Kami menentukan pengasahan presisi untuk mencapai:

Kekasaran permukaanRa 0,2-0,4 μm (dibandingkan dengan standar Ra 0,8-1,2 μm)

Pengasahan dataran tinggi4Membuat reservoir mikro untuk penahanan pelumas.

Finishing arahTanda pengasahan sejajar dengan arah gerakan

Digunakan bersama pelumas yang sesuai:

Pelumas sintetis (standar kami di Bepto):

- Rentang viskositas ISO VG 32-68

- Sifat pelumasan batas yang sangat baik

- Kinerja yang stabil pada berbagai suhu

- Kompatibel dengan bahan segel

Metode aplikasi:

- Pelumasan awal di pabrik untuk semua permukaan geser

- Port pelumasan berkala (untuk silinder tanpa batang dengan stroke panjang)

- Sistem pelumasan otomatis untuk aplikasi kritis

Fitur Desain Mekanik

Selain segel itu sendiri, desain mekanis mengurangi efek histeresis:

Sistem panduan presisi:

- Bantalan bola linier atau bantalan rol

- Memisahkan dukungan beban dari gaya pneumatik

- Mengurangi beban samping pada segel (penyebab gesekan utama)

Penyesuaian beban awal kereta:

- Memungkinkan optimasi kompresi segel

- Menyeimbangkan keandalan penyegelan dengan gesekan

- Dapat disesuaikan di lapangan untuk kompensasi keausan

Kekakuan pemasangan:

- Pemasangan kaku mengurangi ikatan yang disebabkan oleh defleksi.

- Penyesuaian yang tepat menghilangkan beban samping.

- Sangat penting untuk aplikasi dengan stroke panjang

Saya baru-baru ini membantu Michael, seorang pembuat mesin di Wisconsin, mengatasi masalah penempatan yang persisten pada aplikasi silinder tanpa batang dengan stroke 2 meter. Silindernya menunjukkan variasi penempatan 2-3 mm akibat ikatan segel yang disebabkan oleh defleksi. Kami merancang ulang sistem pemasangan dengan dukungan intermediet dan beralih ke silinder tanpa batang presisi Bepto kami dengan panduan yang dioptimalkan. Kesalahan penempatan berkurang menjadi ±0,25 mm sepanjang stroke penuh—peningkatan 10 kali lipat. 🔧

Integrasi Kontrol Lingkaran Tertutup

Untuk presisi maksimal, optimasi mekanis harus dikombinasikan dengan kontrol cerdas:

Umpan balik posisi:

- Enkoder linier (resolusi 5-10 mikrometer)

- sensor magnetostriktif5 (Resolusi 50-100 mikrometer)

- Memperbolehkan kompensasi untuk efek histeresis.

Algoritma kompensasi gesekan:

- Perkiraan gesekan berbasis model

- Kompensasi adaptif untuk keausan dan suhu

- Dapat mengurangi kesalahan penempatan sebesar 40-60%.

Profil tekanan:

- Penyesuaian tekanan yang bergantung pada kecepatan

- Mengurangi overshoot dan waktu penyelesaian

- Mengoptimalkan pendekatan ke posisi akhir

Di Bepto, kami menyediakan dukungan teknik aplikasi untuk membantu pelanggan mengintegrasikan silinder bergesekan rendah kami dengan sistem kontrol mereka. Kombinasi desain mekanis yang dioptimalkan dan kontrol cerdas menghasilkan kinerja penempatan yang mendekati sistem servo listrik dengan biaya yang jauh lebih rendah.

Perbandingan Biaya dan Kinerja

Ketepatan memiliki harganya, dan kuncinya adalah menyesuaikan teknologi dengan kebutuhan:

Silinder standar ($150-250):

- ±0,8–1,5 mm ketepatan pengulangan

- Cocok untuk aplikasi 70%

- Biaya awal terendah

Silinder bergesekan rendah ($250-400):

- ±0,3-0,6 mm ketepatan pengulangan

- Perbandingan terbaik antara biaya dan kinerja

- Pilihan presisi Bepto yang paling populer

Silinder ultra-presisi ($500-800):

- ±0,1-0,25 mm ketepatan pengulangan

- Segel PTFE, bantalan presisi, siap untuk umpan balik

- Hanya untuk aplikasi kritis

Keputusan harus didasarkan pada total biaya kepemilikan, termasuk biaya limbah, perbaikan, dan biaya kualitas. Untuk lini produksi yang memproduksi 10.000 bagian per hari, di mana kesalahan penempatan menyebabkan limbah 2% dengan biaya $5 per bagian, biaya kualitasnya adalah $1.000 per hari. Premi $300 untuk silinder presisi akan terbayar dalam hitungan jam, bukan bulan.

Kesimpulan

Histeresis segel dinamis merupakan musuh tersembunyi dalam penempatan presisi pada sistem pneumatik, yang menyebabkan kesalahan akibat gesekan yang tidak dapat sepenuhnya dihilangkan meskipun telah dilakukan penyesuaian kontrol. Dengan memahami mekanisme histeresis dan menerapkan desain segel yang dioptimalkan, bahan yang sesuai, serta solusi mekanis terintegrasi, akurasi penempatan dapat meningkat 5-10 kali lipat dibandingkan dengan silinder standar. Di Bepto, silinder tanpa batang kami mengintegrasikan puluhan tahun penelitian optimasi gesekan untuk memberikan kinerja penempatan presisi yang memenuhi persyaratan industri yang ketat sambil mempertahankan keunggulan biaya dan kesederhanaan aktuation pneumatik. 🌟

Pertanyaan Umum tentang Histeresis Segel Dinamis

Q: Apakah saya dapat mengukur hysteresis segel pada silinder yang sudah ada untuk mendiagnosis masalah penempatan?

Ya—lakukan uji gaya-pergeseran sederhana dengan perlahan-lahan memperpanjang dan mengembalikan silinder sambil mengukur gaya dan posisi, lalu plot hasilnya untuk memvisualisasikan lingkaran histeresis. Lebar lingkaran menunjukkan besarnya histeresis. Di Bepto, kami merekomendasikan uji diagnostik ini sebelum menentukan silinder pengganti, karena uji ini mengukur apakah histeresis benar-benar menjadi faktor pembatas atau apakah masalah lain (ketidakstabilan tekanan, masalah pemasangan) yang dominan.

Q: Bagaimana pengaruh keausan segel terhadap histeresis selama masa pakai silinder?

Keausan segel biasanya mengurangi hysteresisi pada awalnya (100.000-200.000 siklus pertama) saat segel “beradaptasi” dan tekanan kontak berkurang, kemudian hysteresisi secara bertahap meningkat seiring keausan yang menyebabkan pola kontak tidak teratur dan kerusakan permukaan. Segel yang dirancang dengan baik, seperti profil presisi Bepto kami, mempertahankan hysteresis yang stabil hingga 1-2 juta siklus sebelum terjadi degradasi signifikan, sementara segel standar mungkin menunjukkan peningkatan hysteresis sebesar 50-100% setelah 500.000 siklus.

Q: Apakah sistem penempatan pneumatik dengan hysteresisi rendah sebanding dengan sistem servo listrik?

Untuk aplikasi yang memerlukan ketepatan ±0,1-0,3 mm pada kecepatan sedang (<500 mm/s), silinder pneumatik yang dioptimalkan dengan kontrol loop tertutup dapat menyaingi kinerja servo listrik dengan biaya sistem 40-60% lebih rendah. Namun, servo listrik tetap unggul untuk aplikasi yang memerlukan ketepatan 1 m/s), atau profil gerakan kompleks. Kuncinya adalah menyesuaikan teknologi dengan persyaratan aktual daripada mengover-spesifikasikan servo listrik untuk aplikasi di mana pneumatik sudah cukup.

Q: Apakah saya dapat memasang segel bergesekan rendah pada silinder yang sudah ada untuk mengurangi histeresis?

Penggantian segel dapat membantu, tetapi terbatas oleh kondisi permukaan silinder dan geometri alur yang ada—segel bergesekan rendah memerlukan permukaan silinder dengan Ra 0,3-0,5 μm untuk berfungsi dengan baik, sementara silinder standar umumnya memiliki Ra 0,8-1,2 μm. Selain itu, dimensi alur segel harus sesuai dengan profil segel yang dioptimalkan. Dalam kebanyakan kasus, mengganti seluruh silinder dengan unit yang dirancang secara presisi seperti silinder tanpa batang bergesekan rendah Bepto kami memberikan kinerja yang lebih baik dan efisiensi biaya daripada mencoba retrofit.

Q: Bagaimana cara menentukan persyaratan hysteresisi saat memesan silinder presisi?

Tentukan ketepatan dua arah (bidirectional repeatability) daripada hanya “ketepatan”—mintalah “±0.3mm ketepatan dua arah sepanjang rentang penuh” daripada istilah yang tidak jelas seperti “ketepatan” atau “gesekan rendah.” Juga tentukan kondisi operasi (tekanan, kecepatan, laju siklus, rentang suhu) karena hal ini memengaruhi histeresis. Di Bepto, kami menyediakan data uji terverifikasi yang menunjukkan gaya histeresis yang diukur secara aktual dan ketepatan posisi untuk silinder presisi kami, memastikan Anda menerima kinerja yang didokumentasikan sesuai dengan persyaratan aplikasi Anda.

-

Pelajari tentang fisika dasar fenomena stick-slip dan bagaimana fenomena ini berkontribusi terhadap ketidakstabilan yang disebabkan oleh gesekan dalam sistem mekanik. ↩

-

Jelajahi definisi teknis gesekan statis (stiction) dan dampaknya terhadap gaya lepas yang diperlukan untuk penggerak pneumatik. ↩

-

Dapatkan pemahaman yang lebih mendalam tentang Kurva Stribeck dan bagaimana kurva tersebut mendefinisikan hubungan antara gesekan dan kondisi pelumasan pada segel geser. ↩

-

Pahami bagaimana proses honing plateau menciptakan reservoir mikro yang mengoptimalkan retensi pelumas dan mengurangi gesekan permukaan. ↩

-

Pelajari prinsip kerja sensor magnetostriktif dan mengapa sensor ini lebih disukai untuk umpan balik posisi beresolusi tinggi di lingkungan industri. ↩