Struggling with sluggish pneumatic cylinders that can’t keep up with your production demands? 🚀 Slow cylinder speeds create bottlenecks, reduce throughput, and force you to invest in oversized equipment just to meet basic performance requirements.

Quick exhaust valves dramatically increase cylinder speed by eliminating 背圧1 during the exhaust stroke, allowing compressed air to escape directly to atmosphere rather than flowing back through the main valve, resulting in speed improvements of 30-50% in most pneumatic applications.

Last week, I helped David, a production engineer from a Michigan automotive plant, whose assembly line rodless cylinders were operating too slowly to meet new production targets. 🏭

目次

- How Do Quick Exhaust Valves Work to Increase Cylinder Speed?

- What Are the Key Physics Principles Behind Quick Exhaust Valve Operation?

- How Much Speed Improvement Can You Expect from Quick Exhaust Valves?

- When Should You Use Quick Exhaust Valves in Your Pneumatic System?

How Do Quick Exhaust Valves Work to Increase Cylinder Speed?

Understanding the mechanics of quick exhaust valves reveals why they’re so effective at boosting pneumatic cylinder performance.

Quick exhaust valves use a spring-loaded diaphragm or poppet that automatically opens a direct exhaust path when cylinder pressure drops, bypassing the main directional valve and eliminating flow restrictions that normally slow down the exhaust stroke.

基本動作原理

Quick exhaust valves operate on a simple but ingenious principle that eliminates the primary bottleneck in pneumatic cylinder operation.

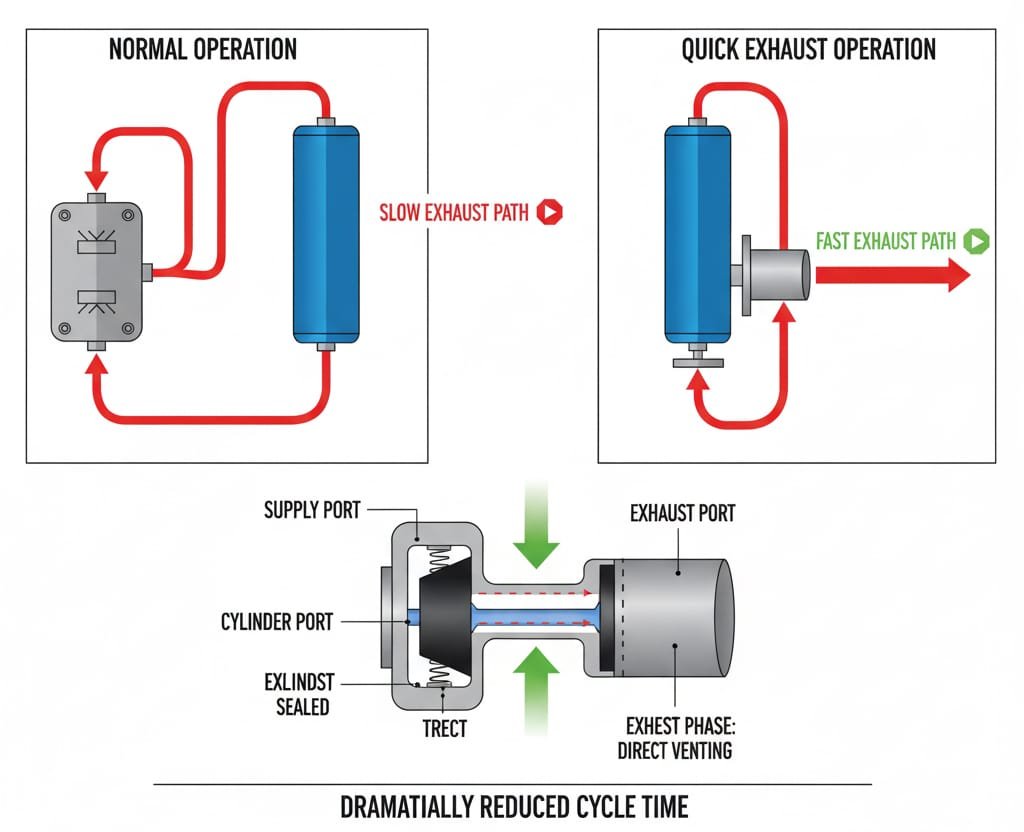

Normal vs. Quick Exhaust Operation

During normal operation without a quick exhaust valve, compressed air must travel from the cylinder, through connecting tubing, back through the directional valve, and finally to atmosphere. This creates significant flow restriction and back-pressure.

With a quick exhaust valve installed directly at the cylinder, the exhaust air takes a much shorter path directly to atmosphere, dramatically reducing flow resistance.

Internal Valve Mechanism

The valve contains a movable element (diaphragm or poppet) that responds to pressure differentials:

- Supply phase: Incoming pressure pushes the element against the exhaust port, sealing it

- Exhaust phase: When supply pressure drops, the element moves to block the supply port and open the exhaust

- Direct venting: Cylinder air escapes directly through the valve’s large exhaust port

I recently worked with Jennifer, a maintenance supervisor from a Texas packaging facility, whose rodless cylinders were limiting line speed on their high-speed cartoning equipment. Her original setup required air to travel nearly 6 feet back to the main valve manifold.

Our Bepto quick exhaust valve solution provided:

- Direct mounting: Valve installed right at the cylinder port

- Large exhaust capacity: 50% larger exhaust orifice than standard valves

- 即時対応: Zero delay in exhaust initiation

- スピードアップ: 40% faster cycle times on her packaging line

The improvement was immediately noticeable, allowing her to increase production by 25%. ✅

What Are the Key Physics Principles Behind Quick Exhaust Valve Operation?

The effectiveness of quick exhaust valves stems from fundamental fluid dynamics and thermodynamic principles.

Quick exhaust valves leverage ベルヌーイの原理2 and minimize pressure drop by reducing flow path length and eliminating restrictions, while also taking advantage of choked flow conditions3 that maximize mass flow rate through properly sized exhaust orifices.

Flow Dynamics and Pressure Drop

The physics behind quick exhaust valve performance involves several key principles that work together to maximize flow rates.

Pressure Drop Calculation

Pressure drop in pneumatic systems follows the relationship:

ΔP = f × (L/D) × (ρV²/2)

どこでだ:

- f = friction factor

- L = pipe length

- D = pipe diameter

- ρ = air density

- V = velocity

Flow Path Comparison

| 構成 | Path Length | Restrictions | Typical ΔP |

|---|---|---|---|

| Standard setup | 3-6 feet | Multiple fittings, valve | 15-25 psi |

| Quick exhaust | 2~4インチ | Minimal restrictions | 2-5 psi |

チョークド・フローの状態

When the pressure ratio across an orifice exceeds approximately 2:1, the flow becomes choked, meaning it reaches sonic velocity and maximum mass flow rate. Quick exhaust valves are designed to operate in this optimal flow regime.

Thermodynamic Considerations

As compressed air expands rapidly through the quick exhaust valve, it undergoes 断熱膨張4, which can cause significant temperature drops. This cooling effect actually helps increase air density and flow rates.

Volume Flow Rate Impact

The volumetric flow rate through an orifice is proportional to the pressure differential and orifice area. Quick exhaust valves typically feature orifices 2-3 times larger than the return path through a standard directional valve.

Robert, a design engineer from a California semiconductor equipment manufacturer, needed to understand the physics behind quick exhaust valves to justify the investment to his management team.

Our technical analysis showed:

- 流量係数5: 40% higher Cv rating than his existing setup

- 圧力回復: 85% faster pressure equalization

- 温度効果: 15°F temperature drop improving flow density

- Calculated improvement: Theoretical 45% speed increase confirmed by testing

The data convinced his team to standardize on Bepto quick exhaust valves across their entire product line. 📊

How Much Speed Improvement Can You Expect from Quick Exhaust Valves?

The performance gains from quick exhaust valves vary based on system configuration, but the improvements are typically substantial and measurable.

Most pneumatic systems see 30-50% speed improvements with quick exhaust valves, with the greatest gains occurring in applications with long tubing runs, small-bore connections, or high back-pressure conditions where flow restrictions have the most significant impact on cycle times.

Factors Affecting Speed Improvement

Several system variables determine how much benefit you’ll see from implementing quick exhaust valves.

Primary Influence Factors

- Tubing length: Longer runs see greater improvement (up to 60% gains)

- Tube diameter: Smaller tubes benefit more from bypass exhaust

- システム圧力: Higher pressures show more dramatic improvements

- Cylinder size: Larger cylinders with more air volume benefit most

Performance Improvement Matrix

| システム構成 | Expected Speed Gain | 代表的なアプリケーション |

|---|---|---|

| Short runs (<2 ft), large tubes | 15-25% | 小型機械 |

| Medium runs (2-6 ft), standard tubes | 30-45% | 組立ライン |

| Long runs (>6 ft), small tubes | 45-60% | Remote cylinders |

| High back-pressure systems | 50-70% | Multi-valve circuits |

Measurement and Validation

To accurately measure improvement, we recommend timing complete extend-retract cycles before and after installation. Use consistent pressure settings and load conditions for valid comparisons.

実際のパフォーマンス・データ

Based on our experience with hundreds of installations, here’s what customers typically see:

Speed Improvement by Industry

- 包装設備: 35-45% average improvement

- 組立オートメーション: 40-50% average improvement

- マテリアルハンドリング: 25-40% average improvement

- プロセス機器: 30-45% average improvement

Maria, who runs a custom machinery business in Ohio, was skeptical about our speed improvement claims until she tested our quick exhaust valves on her packaging machine prototypes.

Her test results showed:

- Baseline cycle time: 2.4 seconds per cycle

- With quick exhaust: 1.6 seconds per cycle

- Actual improvement: 33% speed increase

- 生産への影響: 50% more packages per hour

She now specifies Bepto quick exhaust valves on all her high-speed applications, giving her a competitive advantage in bidding. 🎯

When Should You Use Quick Exhaust Valves in Your Pneumatic System?

Strategic application of quick exhaust valves maximizes their benefits while avoiding unnecessary complexity in systems that won’t see significant improvement.

Use quick exhaust valves when you have long tubing runs, need maximum cylinder speed, operate at high cycle rates, or have back-pressure issues, but avoid them in applications requiring precise speed control or where exhaust air creates environmental concerns.

Ideal Applications for Quick Exhaust Valves

Certain pneumatic system characteristics make quick exhaust valves particularly beneficial.

High-Benefit Scenarios

- Remote cylinders: When cylinders are located far from the main valve

- 高速運転: Applications requiring maximum cycle rates

- 大型シリンダー: Systems moving significant air volumes

- 背圧条件: Circuits with restrictive exhaust paths

アプリケーション固有の考慮事項

製造アプリケーション

- 組立ライン: Faster part handling and positioning

- 包装設備: Higher throughput on filling and sealing operations

- マテリアルハンドリング: Quicker load transfer and sorting

- プレス業務: Faster ram return for increased productivity

When NOT to Use Quick Exhaust Valves

| Situation | 理由 | Alternative Solution |

|---|---|---|

| Precise speed control needed | Eliminates exhaust flow control | Use flow control valves |

| クリーンルーム環境 | Direct exhaust creates contamination | Use silencers or filters |

| 騒音に敏感な地域 | Loud exhaust noise | Install exhaust silencers |

| Very short tubing runs | Minimal benefit for added cost | Standard configuration |

インストールのベストプラクティス

For optimal performance, mount quick exhaust valves as close to the cylinder as possible. Use proper thread sealant and ensure the exhaust port is oriented away from personnel and sensitive equipment.

コスト・ベネフィット分析

Quick exhaust valves typically cost $15-50 each but can increase production throughput by 30-50%. In most applications, they pay for themselves within weeks through improved productivity.

Last month, I helped Thomas, a plant manager from a Wisconsin food processing facility, determine where to implement quick exhaust valves for maximum impact.

Our assessment identified:

- High-priority locations: 12 remote cylinders with 8+ foot tubing runs

- Medium-priority: 6 high-cycle applications on main production line s

- Low-priority: 15 short-run cylinders showing minimal benefit

- ROI calculation: $2,400 investment returning $8,000 annually in increased throughput

We implemented the high and medium priority applications first, achieving his target production increases within budget. 💰

結論

Quick exhaust valves provide significant speed improvements through simple physics principles, making them one of the most cost-effective pneumatic system upgrades available.

クイック排気バルブに関するFAQ

Q: Can quick exhaust valves be retrofitted to existing pneumatic systems?

Yes, quick exhaust valves can easily be added to most existing systems by installing them between the cylinder and supply tubing. Most installations require only basic fittings and take minutes to complete.

Q: Do quick exhaust valves affect cylinder extending speed or only retracting speed?

Quick exhaust valves primarily improve the speed of whichever stroke uses the port where they’re installed. For maximum benefit, install valves on both cylinder ports to improve both extending and retracting speeds.

Q: Will quick exhaust valves work with rodless cylinders?

Absolutely! Quick exhaust valves work excellently with rodless cylinders and often provide even greater speed improvements due to the larger air volumes typically involved in rodless cylinder applications.

Q: Do quick exhaust valves require regular maintenance?

Quick exhaust valves are generally maintenance-free devices with no moving parts exposed to contamination. However, we recommend annual inspection to ensure the exhaust ports remain clear and the internal mechanism operates freely.

Q: Can Bepto quick exhaust valves handle high-pressure applications?

Yes, our quick exhaust valves are rated for standard pneumatic pressures up to 150 psi and are designed to handle the rapid pressure changes inherent in high-speed pneumatic applications.

-

Learn how back-pressure impacts pneumatic system efficiency. ↩

-

Review the foundational physics of Bernoulli’s principle. ↩

-

Explore the concept of choked flow and sonic velocity in fluid dynamics. ↩

-

Understand the thermodynamic process of adiabatic expansion and cooling. ↩

-

See how Flow Coefficient (Cv) is used to measure valve performance. ↩