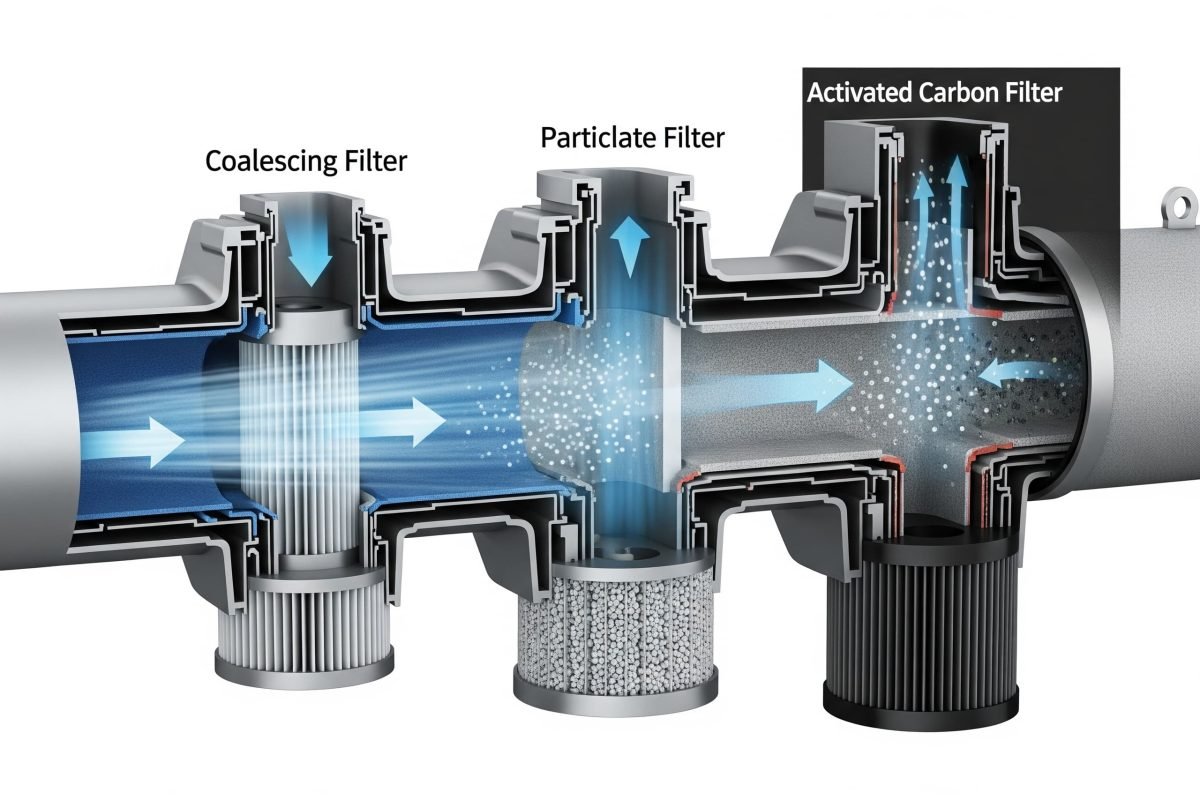

エアフィルター|水分、油分、微粒子を除去し、機器を保護します。 圧縮空気から汚染物質を的確に除去するために設計されたエアフィルタを幅広く取り揃えています。純粋な空気源を確保することは、繊細な空気圧コンポーネントを保護し、機器の寿命を延ばし、システム全体の効率を高めるために非常に重要です。お客様の用途に最適なフィルタを今すぐ見つけてください。

プロジェクトに必要な製品

私たちは、調達が困難であることを理解しています。

お問い合わせフォームに具体的な項目を入力し、ユニークな部品や入手困難な部品も遠慮なくご記入ください!お客様のニーズを正確に把握し、最適な結果をお届けします。

当社の手動バルブは、空気圧システムを直接、確実に制御できます。シンプルさ、耐久性、および正確な操作のために設計されたこれらのバルブは、オペレータの介入、システムの設定、隔離、または安全ロックアウトを必要とするアプリケーションに不可欠です。

バルブ、シリンダー、工具などの繊細な空圧部品を汚染物質による損傷から守り、動作寿命を延ばします。

きれいな空気は、コンポーネントのスムーズな動作を保証し、閉塞による圧力低下を低減し、エネルギー消費を最適化します。

部品の早期故障やシステムの誤作動を防ぐことで、当社のフィルターは、コストのかかる生産中断やメンテナンス費用を最小限に抑えるのに役立ちます。

優れた粒子捕捉、高い汚れ保持能力、低圧力損失のための高度なフィルターメディアを使用。

頑丈なポリカーボネート製または金属製のボウルは、視認性と耐衝撃性に優れたガード付きで、安全性と長寿命を保証します。

信頼性の高い手動、半自動、または全自動ドレンで、溜まった水と油を効果的に除去します。

素早く簡単にフィルターエレメントを交換できるよう設計されており、メンテナンスの時間と労力を最小限に抑えます。

フィルターが除去できる粒子のサイズ(例えば、40μm、5μm、1μm、0.01μm)。

例:G1/8、G1/4、G1/2、G1、NPTオプション。

所定の圧力でフィルターが処理できる最大風量(L/min、SCFMなど)。

入口圧力の最大値と最小値。

周囲温度と媒体温度の限界。

ポリカーボネート製または金属製。

手動、半自動、または全自動ドレン。

指定された流量におけるフィルターを横切る圧力損失。

詳細なパラメータについては、各製品のマニュアルまたは 技術専門家に相談する.

標準的な産業用オートメーションや機械のシリンダー、バルブ、工具を保護します。

繊細な測定装置、実験機器、分析機器に清浄な空気を確保する。

油分、水分、粒子を除去し、欠陥を防ぎ、高品質の仕上がりを保証する。

直接接触する用途や包装工程に、衛生的でオイルフリーの空気を供給します。

歯科器具、呼吸器、その他の医療用途に、清浄で乾燥した空気を供給。

活性炭を含む多段階ろ過により、作業員に安全で呼吸可能な空気を供給。

エアフィルターのメンテナンスを行う前に、必ずシステムの圧力を抜いてください。

コンプレッサーから直接圧縮された空気には、当然、水蒸気(凝縮する)、オイル(潤滑コンプレッサーやキャリーオーバーによる)、ほこり、パイプからのさび粒子、空気中の汚れなどの汚染物質が含まれています。除去されない場合、これらの汚染物質は次のような可能性があります:

適切なろ過は、投資を保護し、信頼性を確保し、製品の品質を維持するために不可欠です。

ミクロン・レーティングは 最小粒子径 フィルターエレメントが圧縮空気の流れから効果的に除去できるもの。1ミクロン(μm)は100万分の1メートルです。

必要なミクロン定格は、下流の空気圧コンポーネントの感度と、アプリケーションに必要な空気の質によって決まります。

フィルター・エレメントの交換間隔は、いくつかの要因に左右される:

一般的なガイドラインとして、パティキュレートフィルターの場合、交換は6~12ヶ月ごと、または圧力降下に基づいて行われます。合体フィルター・エレメントは寿命が短いことが多く、オイル除去効率を維持するためにスケジュール通りに交換することが重要です。推奨される交換スケジュールについては、必ず特定のフィルターのマニュアルを参照してください。

汚染物質の種類によってターゲットが異なる:

いや、そのためには 適切なタイプとグレードのエアフィルター お客様の特定の用途と下流装置の空気品質要件に対応します。

空気品質クラス(ISO 8573-1など)と機器の要件を理解することが、正しいろ過セットアップを選択する鍵です。

当社の優れた空気ろ過ソリューションで、お客様の貴重な空圧投資を保護し、業務を最適化します。当社の各種フィルタをご覧いただくか、当社の空気処理スペシャリストにお問い合わせいただき、お客様の空気品質のニーズに最適なソリューションをお探しください。