Incorrect piston area calculations cause 40% of pneumatic system underperformance issues, leading to insufficient force output, slow cycle times, and costly oversized equipment purchases. Efektywna powierzchnia tłoka w siłownikach dwustronnego działania jest równa pełnej powierzchni otworu podczas wysuwania i powierzchni otworu pomniejszonej o powierzchnię tłoczyska podczas cofania, przy czym obliczenia wymagają dokładnych pomiarów średnicy i uwzględnienia różnic ciśnień w celu dokładnego przewidywania siły. Yesterday, I helped David, an engineer from California, whose automated assembly line was running 30% slower than designed because he miscalculated piston areas and undersized his air supply system. 📐

Spis treści

- What Is Effective Piston Area and Why Does It Matter for Cylinder Performance?

- How Do You Calculate Piston Areas for Extension and Retraction Strokes?

- Which Factors Affect Piston Area Calculations in Real Applications?

What Is Effective Piston Area and Why Does It Matter for Cylinder Performance?

Understanding effective piston area is fundamental to proper pneumatic system design and performance optimization.

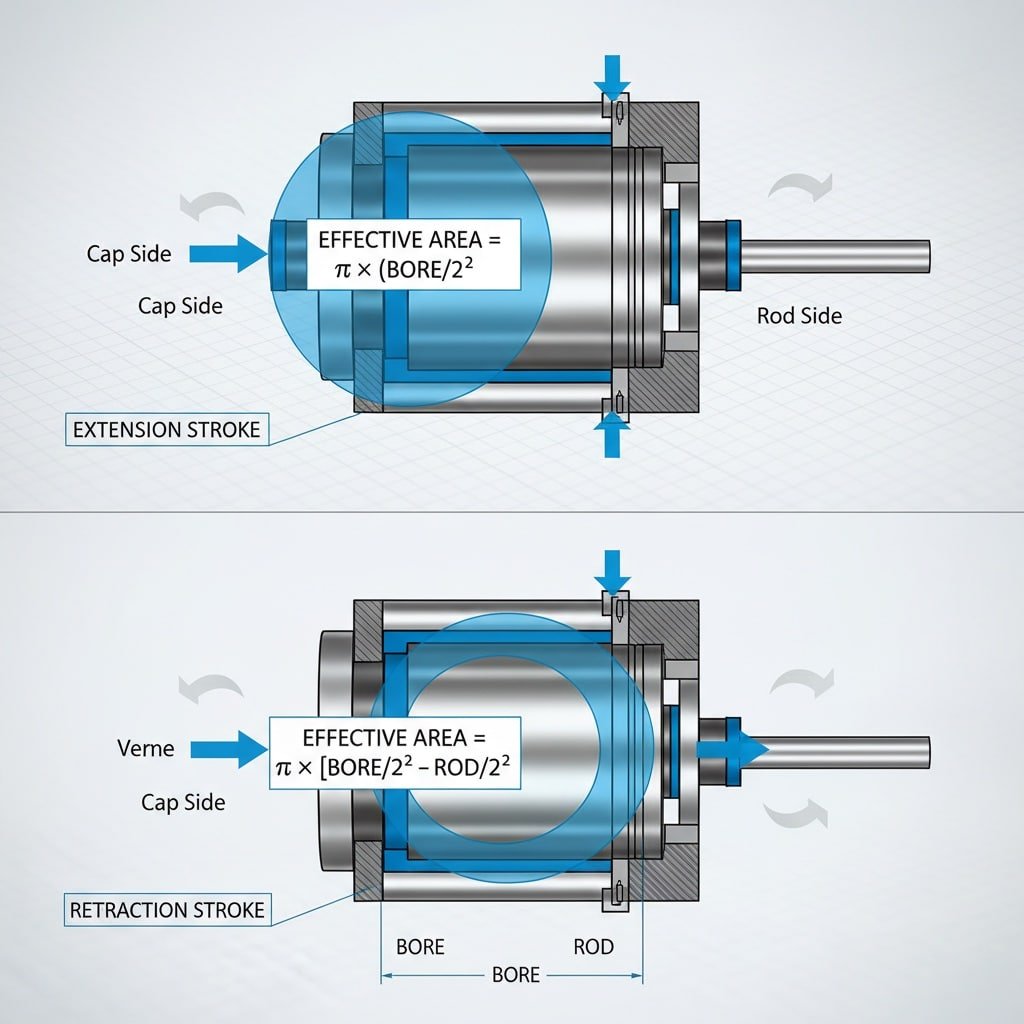

Effective piston area is the actual surface area of the piston that air pressure acts upon to generate force, which differs between extension and retraction strokes due to the rod occupying space on one side of the piston.

Basic Piston Area Concepts

Extension Stroke (Rod Extending):

- Full bore area receives air pressure

- Maximum force generation capability

- Rod side vents to atmosphere or return port

- Area = π × (bore diameter/2)²1

Retraction Stroke (Rod Retracting):

- Reduced effective area due to rod displacement

- Lower force output compared to extension

- Cap side vents while rod side receives pressure

- Area = π × [(bore diameter/2)² – (rod diameter/2)²]

Wpływ na wydajność

| Rozmiar cylindra | Extension Area | Retraction Area | Współczynnik siły |

|---|---|---|---|

| 2″ bore, 1″ rod | 3.14 in² | 2.36 in² | 1.33:1 |

| 4″ bore, 1.5″ rod | 12.57 in² | 10.81 in² | 1.16:1 |

| 6″ bore, 2″ rod | 28.27 in² | 25.13 in² | 1.12:1 |

Why Accurate Calculations Matter

Implikacje dla projektu systemu:

- Force output directly proportional to effective area

- Air consumption varies with piston area

- Cycle time depends on area-to-volume ratios

- Pressure requirements scale with area differences

Cost Considerations:

- Oversized systems waste energy and increase costs

- Undersized systems fail to meet performance requirements

- Proper sizing optimizes equipment investment

- Accurate calculations prevent expensive redesigns

David’s assembly line illustrates this perfectly. His initial calculations used full bore area for both strokes, leading to a 25% overestimate of retraction force. This caused him to undersize the air supply, resulting in slow retraction speeds that bottlenecked his entire production line. We recalculated using proper effective areas and upgraded his air system accordingly, restoring full design performance. 🎯

How Do You Calculate Piston Areas for Extension and Retraction Strokes?

Precise mathematical formulas ensure accurate force and performance predictions for double-acting pneumatic cylinders.

Extension area equals π × (D/2)² where D is bore diameter, while retraction area equals π × [(D/2)² – (d/2)²] where d is rod diameter, with all measurements in consistent units for accurate results.

Proces obliczania krok po kroku

Required Measurements:

- Cylinder bore diameter (D)

- Rod diameter (d)

- Operating pressure (P)

- Współczynnik bezpieczeństwa2 wymagania

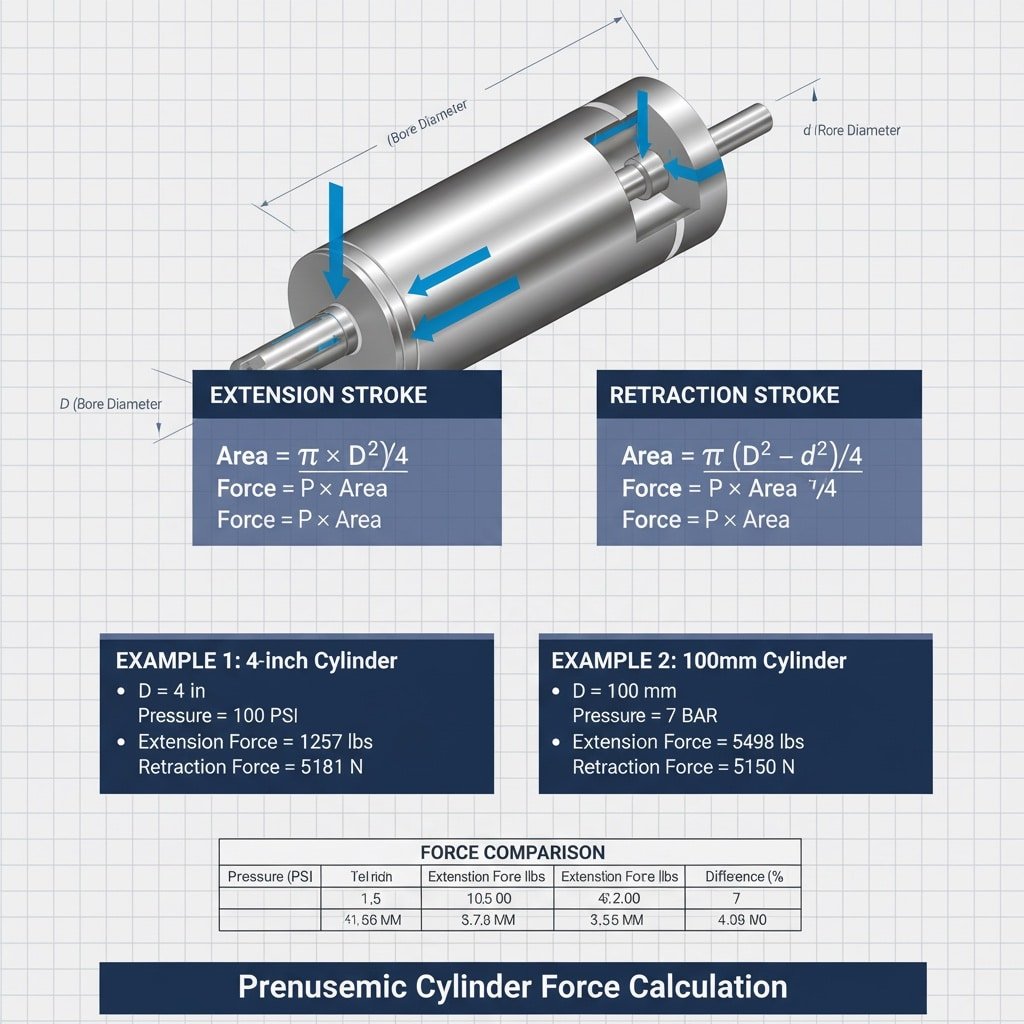

Extension Area Formula:

- A_extension = π × (D/2)²

- A_extension = π × D²/4

- A_extension = 0.7854 × D²

Retraction Area Formula:

- A_retraction = π × [(D/2)² – (d/2)²]

- A_retraction = π × (D² – d²)/4

- A_retraction = 0.7854 × (D² – d²)

Praktyczne przykłady obliczeń

Example 1: Standard 4-inch Cylinder

- Bore diameter: 4.0 inches

- Rod diameter: 1.5 inches

- Extension area: 0.7854 × 4² = 12.57 in²

- Retraction area: 0.7854 × (4² – 1.5²) = 10.81 in²

Example 2: Metric 100mm Cylinder

- Bore diameter: 100mm

- Rod diameter: 25mm

- Extension area: 0.7854 × 100² = 7,854 mm²

- Retraction area: 0.7854 × (100² – 25²) = 7,363 mm²

Force Calculation Applications

| Ciśnienie (PSI) | Extension Force (lbs) | Retraction Force (lbs) | Force Difference |

|---|---|---|---|

| 60 PSI | 754 lbs | 649 lbs | 14% reduction |

| 80 PSI | 1,006 funtów | 865 lbs | 14% reduction |

| 100 PSI | 1,257 lbs | 1,081 lbs | 14% reduction |

Rozważania zaawansowane

Spadek ciśnienia3 Effects:

- Line losses reduce effective pressure

- Flow restrictions affect dynamic performance

- Valve pressure drops impact actual force

- Temperature variations affect pressure delivery

Safety Factor Integration:

- Apply 1.5-2.0 safety factors to calculated forces

- Consider dynamic loading conditions

- Account for wear and performance degradation

- Include environmental factor adjustments

Maria, a machine designer from Oregon, was experiencing inconsistent clamping forces in her packaging equipment. Her calculations looked correct, but she hadn’t accounted for the 15 PSI pressure drop through her valve manifold. We helped her recalculate effective pressures and resize her cylinders accordingly, achieving consistent ±2% force repeatability across her entire production line. 💪

Which Factors Affect Piston Area Calculations in Real Applications?

Real-world applications introduce variables that significantly impact effective piston area performance and must be considered for accurate system design.

Manufacturing tolerances, seal friction, pressure losses, temperature effects, and dynamic loading conditions all influence actual effective piston area performance, requiring engineering adjustments to theoretical calculations for reliable system operation.

Manufacturing Tolerance Impact

Dimensional Variations:

- Bore diameter tolerance: typically ±0.002″

- Rod diameter tolerance: typically ±0.001″

- Surface finish effects on sealing

- Assembly clearance requirements

Tolerance Effect Analysis:

- 0.002″ bore variation = ±0.6% area change

- Combined tolerances can create ±1.2% force variation

- Quality control ensures consistent performance

- Bepto maintains ±0.001″ tolerance standards

Czynniki środowiskowe

Wpływ temperatury:

- Rozszerzalność cieplna4 changes dimensions

- Seal material temperature coefficients

- Air density variations with temperature

- Lubrication viscosity changes

Pressure System Variables:

- Supply pressure regulation accuracy

- Line pressure drops during operation

- Valve flow characteristics

- Air treatment system performance

Dynamic Performance Considerations

| Warunki pracy | Area Effectiveness | Wpływ na wydajność |

|---|---|---|

| Static holding | 100% | Pełna siła znamionowa |

| Slow movement | 95-98% | Seal friction losses |

| Wysoka prędkość działania | 85-92% | Ograniczenia przepływu |

| Dirty conditions | 80-90% | Zwiększone tarcie |

Bepto Engineering Advantages

Precyzyjna produkcja:

- Tighter tolerances than industry standards

- Enhanced surface finishes reduce friction

- Premium seal materials minimize losses

- Comprehensive quality testing protocols

Performance Optimization:

- Custom area calculations for specific applications

- Environmental factor analysis and compensation

- Dynamic performance modeling and validation

- Ongoing support for system optimization

Weryfikacja w świecie rzeczywistym:

- Field testing confirms theoretical calculations

- Performance monitoring identifies optimization opportunities

- Continuous improvement based on application feedback

- Technical support for troubleshooting and upgrades

Our precision manufacturing and engineering support help customers achieve 98%+ of theoretical performance in real applications, compared to 85-90% typical with standard components. We provide complete calculation services, application analysis, and performance validation to ensure your pneumatic systems deliver exactly the performance you need. 🔧

Wnioski

Accurate effective piston area calculations are essential for proper pneumatic system design, ensuring optimal performance, efficiency, and cost-effectiveness in double-acting cylinder applications.

FAQs About Effective Piston Area Calculations

Q: Why is retraction force always lower than extension force in double-acting cylinders?

Retraction force is lower because the rod occupies space on the pressure side, reducing effective piston area by the rod’s cross-sectional area. This typically results in 10-30% less force depending on rod-to-bore ratio.

Q: How do manufacturing tolerances affect piston area calculations?

Manufacturing tolerances can create ±1-2% variation in actual piston area, affecting force output proportionally. Bepto maintains tighter tolerances (±0.001″) compared to standard components (±0.002-0.005″) for more consistent performance.

Q: What safety factors should be applied to calculated piston areas?

Apply 1.5-2.0 safety factors to account for pressure losses, seal friction, and performance degradation over time. Critical applications may require higher safety factors based on risk assessment and regulatory requirements.

Q: How do pressure drops affect effective piston area performance?

Pressure drops don’t change physical piston area but reduce effective pressure, proportionally decreasing force output. A 10 PSI drop at 80 PSI operating pressure reduces force by 12.5%, requiring larger cylinders or higher supply pressure.

Q: Can Bepto provide custom piston area calculations for my specific application?

Yes, our engineering team provides free piston area calculations, force analysis, and system sizing recommendations for any application. We consider all real-world factors to ensure optimal performance and reliability.

-

Review the fundamental formula for calculating the area of a circle. ↩

-

Learn about the role of safety factors in mechanical engineering design and why they are critical. ↩

-

Understand the causes of pressure drop in pneumatic systems and how it impacts performance. ↩

-

Explore the principle of thermal expansion and its effects on mechanical components. ↩