Mechanical Button Control Valve | Mechanically Actuated to Control Air Flow for Automated Sensing & Positioning. Explore our range of mechanical button valves. They are actuated by contact with external machine elements, like cams or trips, to automatically shift the air flow path without manual intervention. Ideal for part detection, stroke limitation, and sequencing on production lines. Select the right mechanical valve for your automated process now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

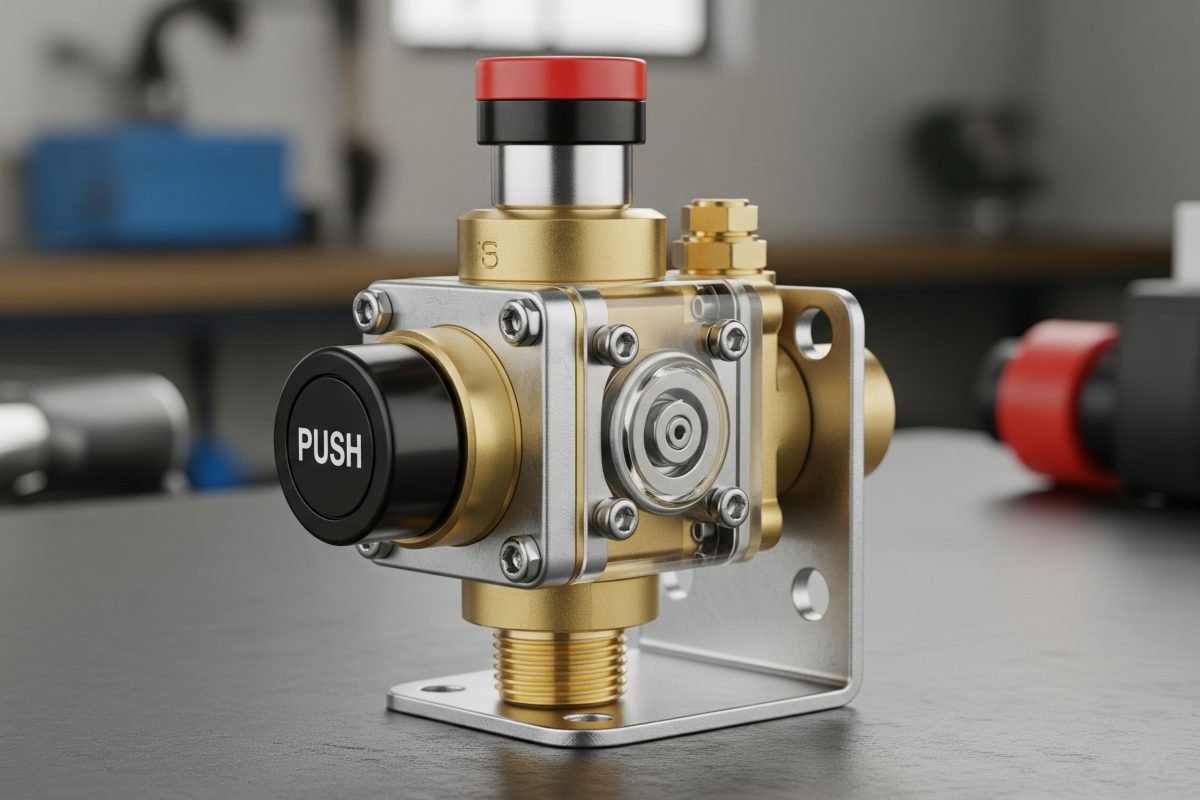

Experience direct and reliable pneumatic control with our range of mechanical button valves. Engineered for durability and ease of use, these valves provide positive manual actuation for a variety of industrial applications, ensuring safety and precise operation when you need it most.

Offers immediate, positive actuation via push buttons, knobs, or levers, providing operators with direct control over pneumatic circuits.

Built with durable materials and simple mechanisms for long service life and consistent performance, even in demanding industrial environments.

Perfect for manual overrides, emergency stops, and safety interlock circuits where direct operator intervention is required.

Mechanical button control valves are actuated by physical force applied to a button, lever, knob, or pedal. This direct mechanical action shifts the valve spool or poppet, redirecting airflow to control pneumatic actuators or system functions. They are valued for their simplicity and reliability, operating without the need for electrical power.

High-strength buttons, levers, and internal components designed for high cycle life and resistance to wear in industrial settings.

Many models feature clear detent positions, providing tactile feedback and ensuring the valve remains in the selected state until intentionally changed.

Including flush, extended, mushroom head (for E-stops), and shrouded buttons to suit different operational and safety needs.

Designed for easy panel mounting for control consoles or direct body mounting on machinery.

E.g., 3/2 NC, 3/2 NO, 5/2, 5/3 (detented or spring return).

Push button (various styles), lever, selector knob, roller, plunger.

Common sizes like M5, G1/8″, G1/4″.

Maximum pressure the valve can safely handle.

Indicates the valve’s air flow capacity.

Force required to actuate the button or lever.

Typically aluminum, brass, or durable plastics.

Panel mount (threaded neck) or body mounting holes.

For detailed parameters, please refer to individual product manuals or consult our technical experts.

Allowing operators to manually control parts of an automated system during setup, maintenance, or emergencies.

Used in two-hand control systems or as part of machine guarding to ensure operator safety.

Providing direct input for starting, stopping, or selecting functions in pneumatic machinery.

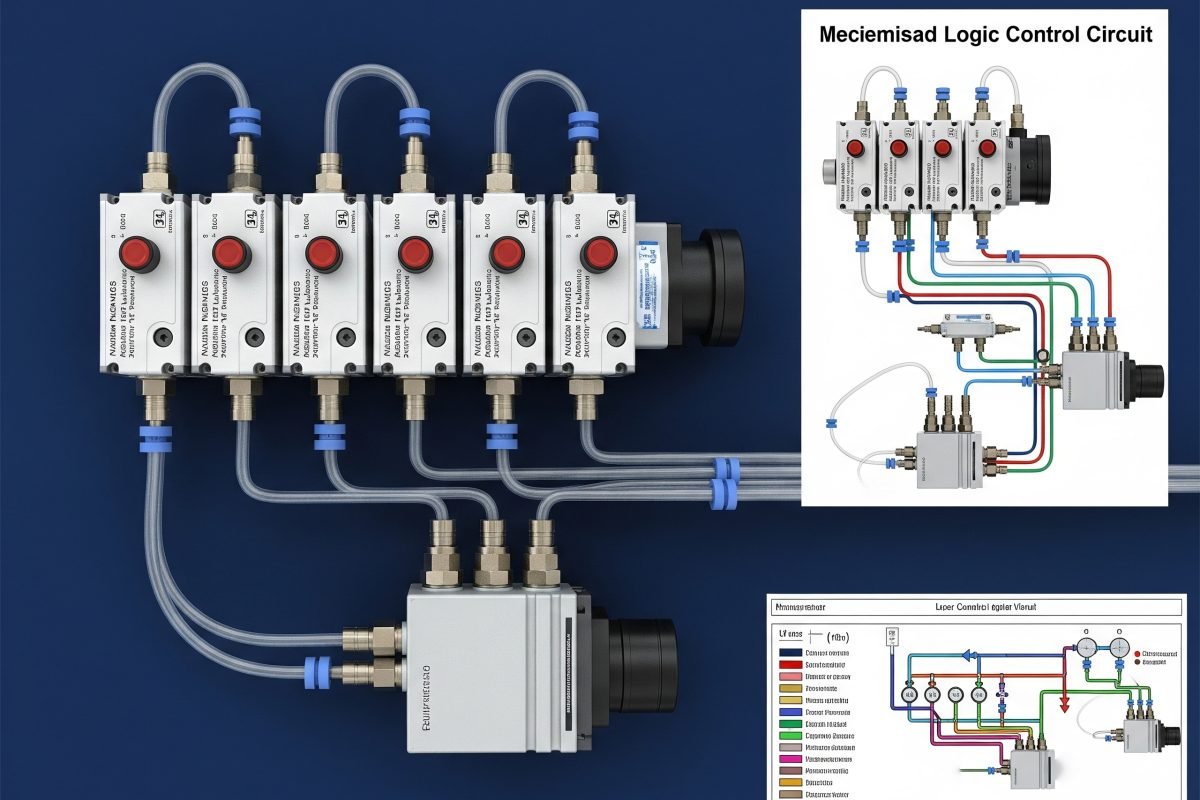

Used as input elements in purely pneumatic control systems where electrical signals are not desired.

For manual actuation of test sequences or clamping/unclamping operations on test rigs.

For basic on/off or directional control of small pneumatic devices and tools.

Always de-pressurize the pneumatic system before performing any maintenance or attempting to remove a valve.

The main advantage is simplicity and independence from electrical power. Mechanical button valves are actuated by direct physical force, making them:

This refers to how the valve maintains its position after actuation:

Choose based on whether you need the valve to stay actuated or return automatically.

The operating force required varies significantly depending on the valve’s design, size, internal spring strength (for spring return types), and the air pressure it’s working against.

Smaller valves or those with balanced spool designs generally require less force. Larger valves or those operating at higher pressures might need more force. Product datasheets usually specify the typical operating force or range for each model. For push buttons, this is often expressed in Newtons (N) or pounds-force (lbf).

While mechanical button valves are robust, their suitability for very high cycle rates depends on the specific design and application.

For extremely high cycle rates or fully automated processes, solenoid valves are generally preferred. Mechanical button valves excel in applications requiring deliberate manual input, safety functions, or where electrical control is not feasible.

Common mounting options for mechanical button control valves include:

The specific mounting options will be detailed in the product’s technical documentation.

For applications demanding reliable manual intervention and robust performance, our mechanical button control valves are the trusted choice. Explore our diverse range or contact our valve specialists to find the perfect solution for your needs.