Valves For Control And Regulation | Precisely Adjust Flow & Pressure to Optimize Processes. Explore our range of valves for precise control of flow, pressure, and direction. From simple on/off control to complex process modulation, our valves ensure your fluid systems achieve maximum efficiency and stability, making them ideal for chemical, water treatment, and HVAC industries. Find the right valve for your process needs now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

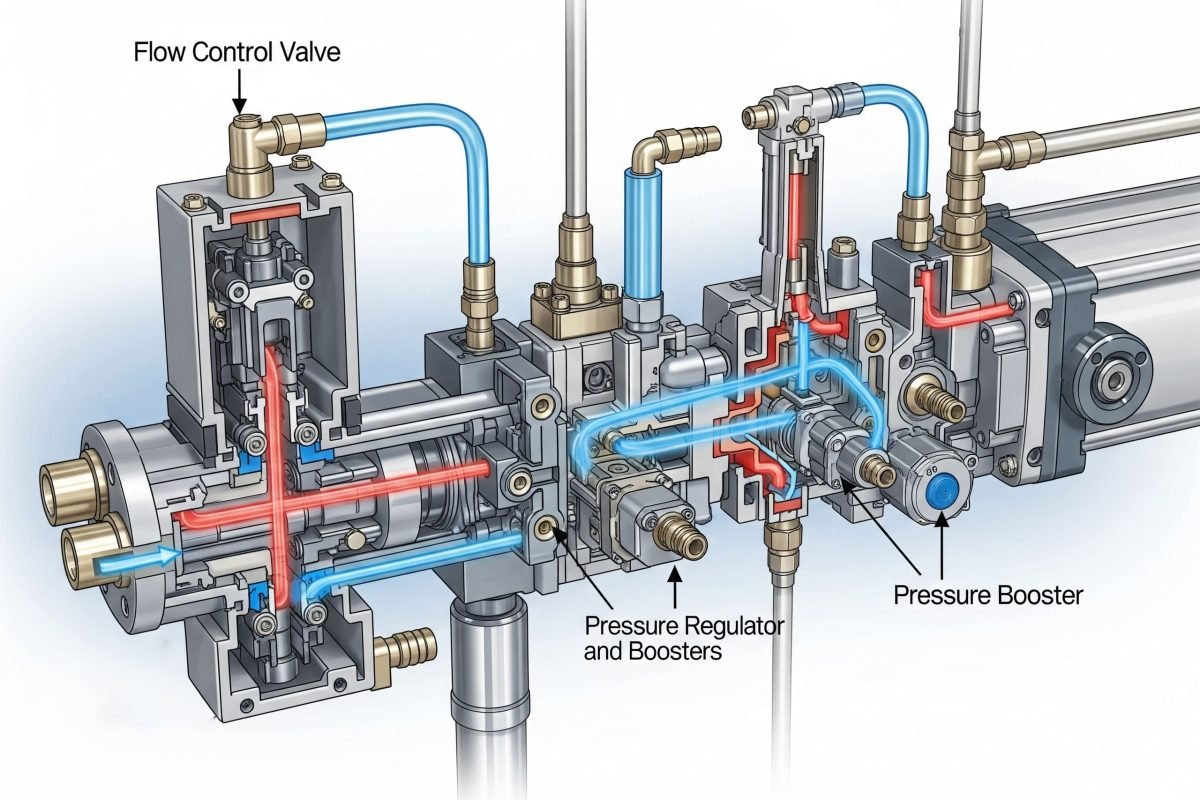

Achieve unparalleled precision and efficiency in your pneumatic applications with our specialized valves for control and regulation. From fine-tuning actuator speeds to ensuring system safety and optimizing air consumption, our valves provide the reliable performance your operations demand.

Enable fine adjustment of flow rates, pressure levels, and operational speeds for optimized performance of your pneumatic actuators and tools.

Maintain consistent operating parameters, protect sensitive components from overpressure, and ensure predictable system behavior.

Optimize air consumption, reduce energy waste, and extend the lifespan of your pneumatic components through precise control.

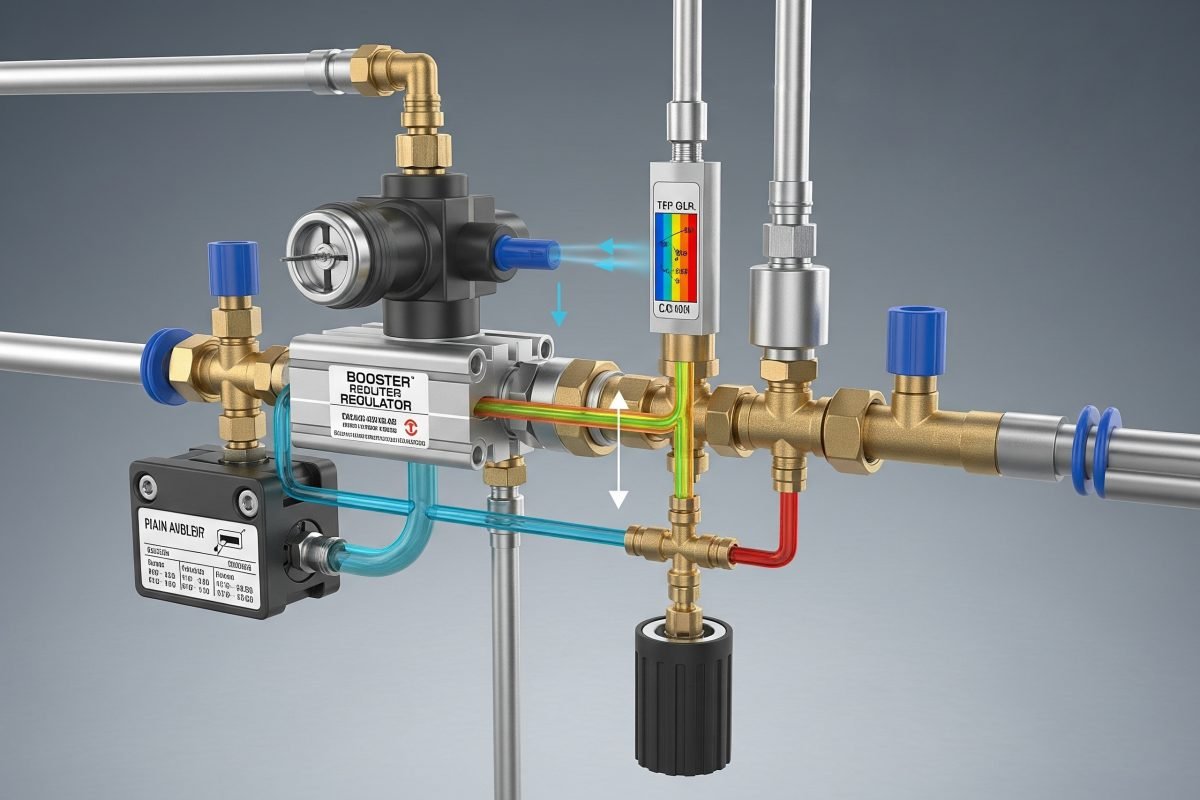

The VBA Series Booster Regulator amplifies your existing air pressure to achieve higher output pressures, ideal for applications requiring increased force or performance without upgrading your entire compressor system.

Increases shop air pressure up to 2 or 4 times.

No electrical input required, purely pneumatic operation.

Compact design with optional pressure gauge and silencer.

Building on the VBA series, the VBA-X3145 model is specifically engineered for reduced air consumption, offering an energy-efficient way to boost pressure for your critical applications while minimizing operational costs.

Significant reduction in air consumption compared to standard boosters.

Achieves desired output pressure with greater efficiency.

Contributes to lower energy costs and a greener footprint.

Precision-engineered needles, spools, or diaphragms allow for sensitive and repeatable adjustments of flow or pressure.

Constructed from high-quality brass, aluminum, stainless steel, or robust polymers for long life and compatibility with various industrial environments.

High-performance seals ensure minimal leakage and consistent operation across wide temperature and pressure ranges.

Designed for easy integration into pneumatic circuits, with various porting and mounting options.

Flow control, pressure regulator (standard or booster), check valve, quick exhaust, etc.

E.g., M5, G1/8, G1/4, NPT 1/2″.

Maximum inlet pressure and adjustable outlet pressure range.

Orifice size or flow coefficient indicating capacity.

For detailed parameters, please refer to individual product manuals or consult our technical experts.

Using flow control valves for speed, and pressure regulators (including boosters) for precise force management.

Employing booster regulators where specific components require higher pressure than the main airline supply.

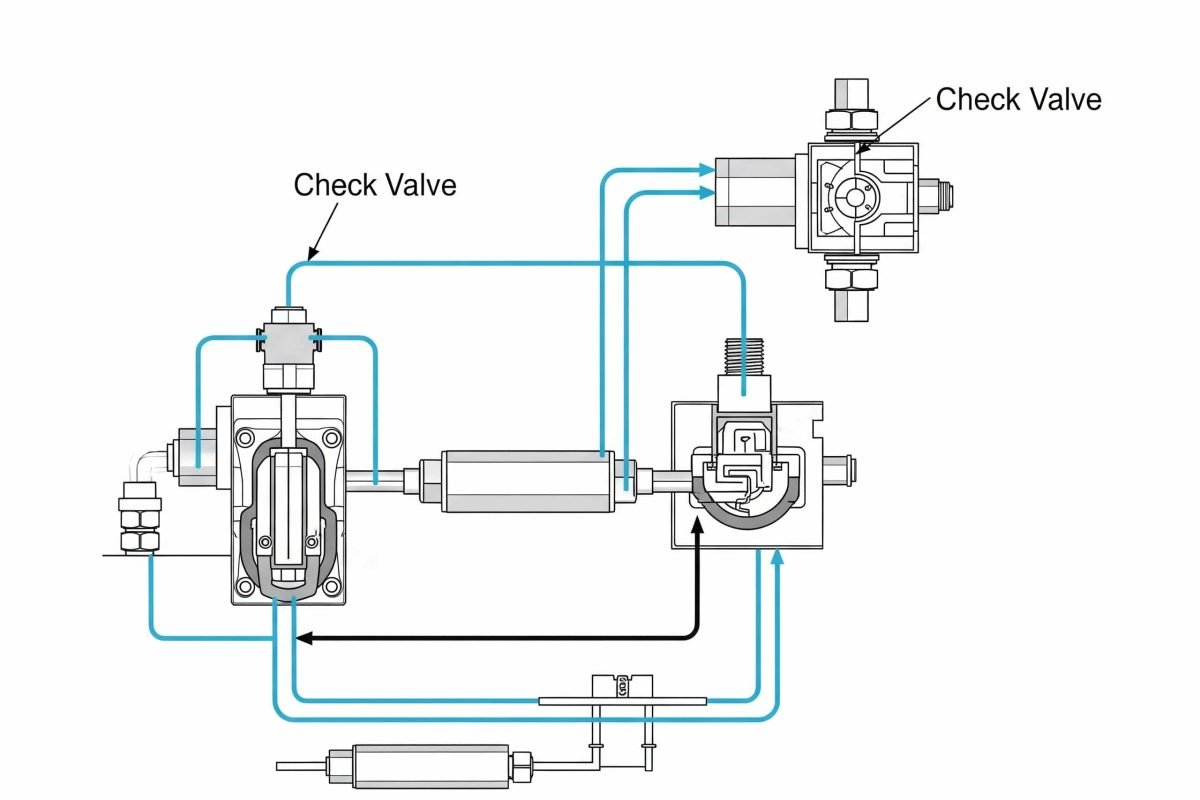

Using check valves to prevent backflow, or quick exhaust valves for rapid depressurization in safety circuits.

A pneumatic booster regulator is needed when a specific part of your pneumatic system requires a higher pressure than your main airline can provide. Instead of upgrading your entire compressor system, a booster can locally increase the pressure for:

The VBA-X3145 model is designed for energy efficiency. Its key benefits include:

To select the right flow control valve (often called a speed controller):

Our datasheets provide flow characteristics. If unsure, our technical team can assist.

Pressure Regulator: Reduces and maintains a constant downstream pressure, regardless of upstream fluctuations (as long as supply is higher). It controls output pressure for operation.

Pressure Relief Valve: A safety device that protects a system from overpressure. It opens to vent excess pressure if it exceeds a preset limit.

Use check valves to allow airflow in one direction only, for tasks like preventing backflow, maintaining pressure in a circuit segment, or in pneumatic logic circuits.

Achieve superior performance, efficiency, and safety in your automated processes. Explore our comprehensive range of valves, including advanced booster regulators, designed for precise control and regulation. Contact our specialists for expert advice and tailored solutions.