robust and reliable solutions for secure workholding in automated manufacturing and assembly processes. Engineered for consistent clamping force and durability in demanding industrial environments, these versatile cylinders ensure precise workpiece stabilization. Ideal for compact fixture designs and high-repetition clamping applications.

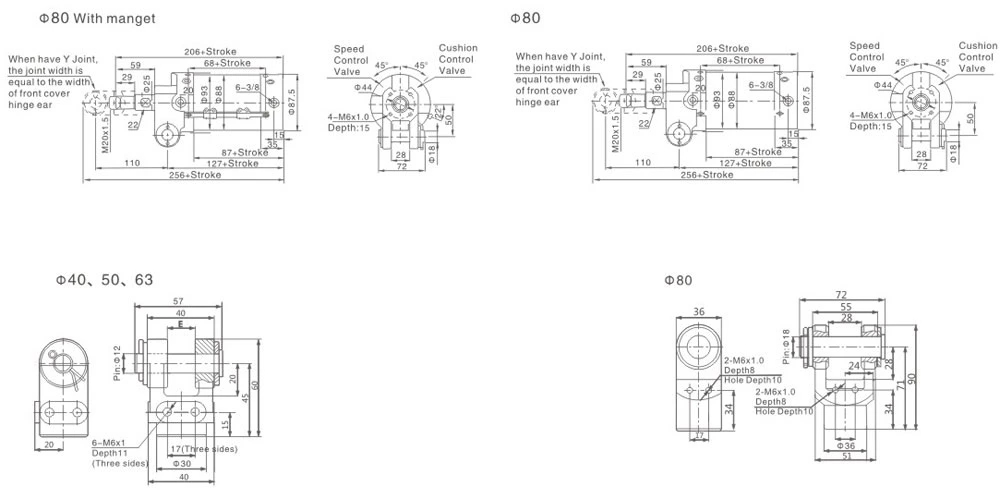

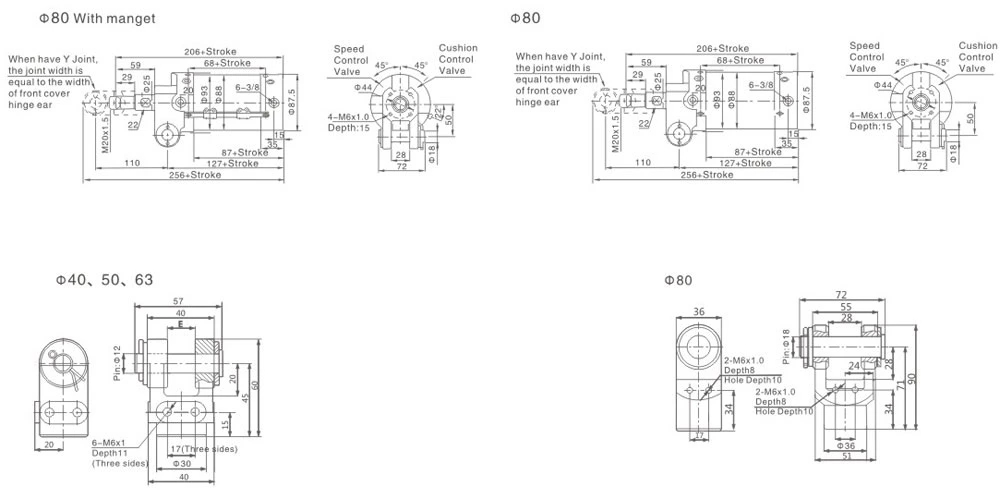

| Bore(mm) | 40 | 50 | 63 | 80 |

| Working Medium | Air | |||

| Ensured Pressure Resistance | 1.5Mpa(15kgf/cm2) | |||

| Mix. Working Pressur | 1.0Mpa(10kgf/cm2) | |||

| Min. Working Pressur | 0.1Mpa(1kgf/cm2) | |||

| Temperature Range | -5~60℃ | |||

| Piston Speed | 50~500mm/s | |||

| Air Buffer | Yes | |||

| Lubrication | No Need | |||

| Thread Tolerance | 6H | |||

| Stroke Tolerance | 1.5 | |||

| 0(mm) | ||||

| Speed Controller | Yes | |||

| Mounting Type | Double Ear Ring | |||

| Port Size | G1/4″ | G3/8″ | ||

| Bore(mm) | A | A1 | B | C | D | E | E1 | F | G | H | K | L | L1 | M | M1 | M2 | N | O | P | Q | R | V | V1 | W | W1 | W2 | X | Z | T | T1 | |

| XCKA | XCKB | ||||||||||||||||||||||||||||||

| 40 | 162 | 196 | 51 | 59 | 84 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 13 | 52 | 40 | 50 | 45 | 45295 | 9 | 21 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 20 | 47 | 54 | 24 |

| 50 | 165 | 199 | 51 | 65 | 87 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 12 | 60 | 40 | 50 | 55 | 45295 | 9.5 | 23 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 19 | 57 | 54 | 22 |

| 63 | 167 | 201 | 51 | 67 | 87 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 12 | 74 | 40 | 50 | 68 | 45295 | 9.5 | 23 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 19 | 70 | 54 | 22 |

| Model | Fit for Bore Size | E |

| XCKA50-Y | 40、 50、63 | 16.5 |

| XCKB50-Y | 40、 50、63 | 19.5 |

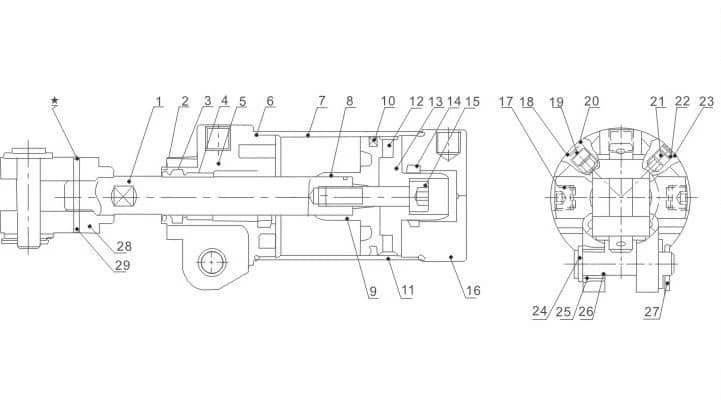

| NO | Designation | NO | Designation |

| 1 | Piston rod | 16 | Rear cover |

| 2 | Dust ring | 17 | Limit screw |

| 3 | Front cover 0-ring | 18 | O-ring |

| 4 | Slide bush | 19 | Speed control screw |

| 5 | Front cover | 20 | External reainer ring |

| 6 | O-ring | 21 | Cushion control screw |

| 7 | Aluminum tube | 22 | O-ring |

| 8 | Piston | 23 | External retainer ring |

| 9 | Piston rod O-ring | 24 | Gasket |

| 10 | Piston O-ring | 25 | Brass bush |

| 11 | Wear ring | 26 | PIN |

| 12 | Magnet | 27 | Split pin |

| 13 | Magnet base | 28 | Y |

| 14 | Cushion O-ring | 29 | Spring pin |

| 15 | Hexagon screw |

| Bore(mm) | A | A1 | B | C | D | E | E1 | F | G | H | K | L | L1 | M | M1 | M2 | N | O | P | Q | R | V | V1 | W | W1 | W2 | X | Z | T | T1 | |

| XCKA | XCKB | ||||||||||||||||||||||||||||||

| 40 | 162 | 196 | 51 | 59 | 84 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 13 | 52 | 40 | 50 | 45 | 45295 | 9 | 21 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 20 | 47 | 54 | 24 |

| 50 | 165 | 199 | 51 | 65 | 87 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 12 | 60 | 40 | 50 | 55 | 45295 | 9.5 | 23 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 19 | 57 | 54 | 22 |

| 63 | 167 | 201 | 51 | 67 | 87 | 97 | 35 | 3 | 11.5 | 16 | M16X1.5 | M6X1 | 12 | 74 | 40 | 50 | 68 | 45295 | 9.5 | 23 | 30 | 20 | 12 | 17 | 16.5 | 19.5 | 54 | 19 | 70 | 54 | 22 |

| Model | Fit for Bore Size | E |

| XCKA50-Y | 40、 50、63 | 16.5 |

| XCKB50-Y | 40、 50、63 | 19.5 |

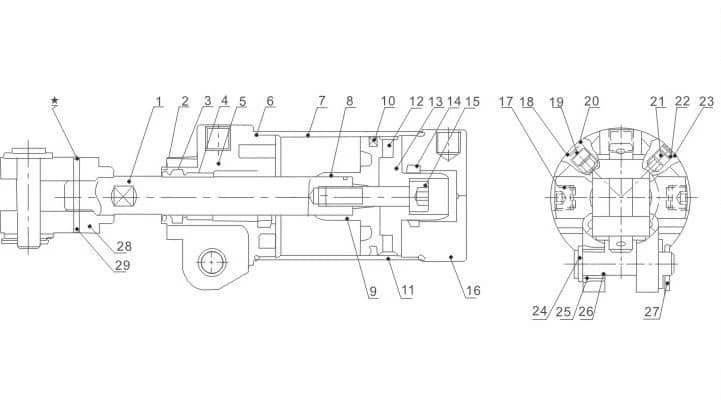

| NO | Designation | NO | Designation |

| 1 | Piston rod | 16 | Rear cover |

| 2 | Dust ring | 17 | Limit screw |

| 3 | Front cover 0-ring | 18 | O-ring |

| 4 | Slide bush | 19 | Speed control screw |

| 5 | Front cover | 20 | External reainer ring |

| 6 | O-ring | 21 | Cushion control screw |

| 7 | Aluminum tube | 22 | O-ring |

| 8 | Piston | 23 | External retainer ring |

| 9 | Piston rod O-ring | 24 | Gasket |

| 10 | Piston O-ring | 25 | Brass bush |

| 11 | Wear ring | 26 | PIN |

| 12 | Magnet | 27 | Split pin |

| 13 | Magnet base | 28 | Y |

| 14 | Cushion O-ring | 29 | Spring pin |

| 15 | Hexagon screw |