Manufacturing facilities lose millions annually due to unexpected pneumatic cylinder failures, with piston rod seal leaks causing 73% of all cylinder breakdowns, leading to costly production downtime, safety hazards, and emergency repairs that could have been prevented with proper failure analysis1. 💸

Piston rod seal leaks typically result from five primary root causes: improper installation techniques, contamination damage, excessive side loading, temperature extremes, and chemical incompatibility, with systematic failure analysis revealing that 85% of seal failures are preventable through proper selection, installation, and maintenance practices.

Last month, I worked with David, a maintenance engineer at a packaging facility in Ohio, whose production line was experiencing frequent seal failures every 2-3 months instead of the expected 2-year service life. Through our comprehensive failure analysis, we discovered contaminated air supply was the culprit. 🔧

Tabla de conținut

- What Are the Most Common Root Causes of Piston Rod Seal Failures?

- How Can You Identify Seal Failure Patterns Through Visual Inspection?

- Which Environmental Factors Accelerate Piston Rod Seal Degradation?

- What Preventive Measures Can Eliminate 90% of Seal Failures?

What Are the Most Common Root Causes of Piston Rod Seal Failures?

Understanding the primary failure mechanisms helps engineers prevent costly breakdowns and extend cylinder service life significantly.

The five most common root causes of piston rod seal failures are improper installation (32% of failures), contamination damage (28%), excessive side loading (18%), temperature-related degradation (12%), and chemical incompatibility (10%), with proper identification enabling targeted solutions that extend seal life from months to years.

Defecțiuni legate de instalare

Poor installation practices account for nearly one-third of all seal failures. Common mistakes include:

- Incorrect seal orientation: Installing seals backwards or upside down

- Damage during assembly: Nicking or cutting seals with sharp edges

- Improper lubrication: Insufficient or wrong lubricant type

- Over-compression: Excessive gland compression damaging seal geometry

Contaminare Daune

Contaminated air supply destroys seals through abrasive particles and moisture:

| Tipul de contaminant | Mecanismul de deteriorare | Timp tipic de defectare |

|---|---|---|

| Dirt/dust particles | Uzura abrazivă2 | 3-6 luni |

| Water/moisture | Seal swelling/degradation | 6-12 luni |

| Contaminarea cu ulei | Atac chimic | 2-8 luni |

| Particule metalice | Cutting/scoring | 1-3 luni |

Side Loading Issues

Excessive side loads cause premature seal wear and cylinder misalignment:

- Misaligned mounting: Creates constant side forces

- External loads: Improper load application

- Worn guide bushings3: Allow rod deflection

- Inadequate support: Insufficient external guiding

How Can You Identify Seal Failure Patterns Through Visual Inspection?

Visual inspection of failed seals reveals specific failure modes and their underlying causes.

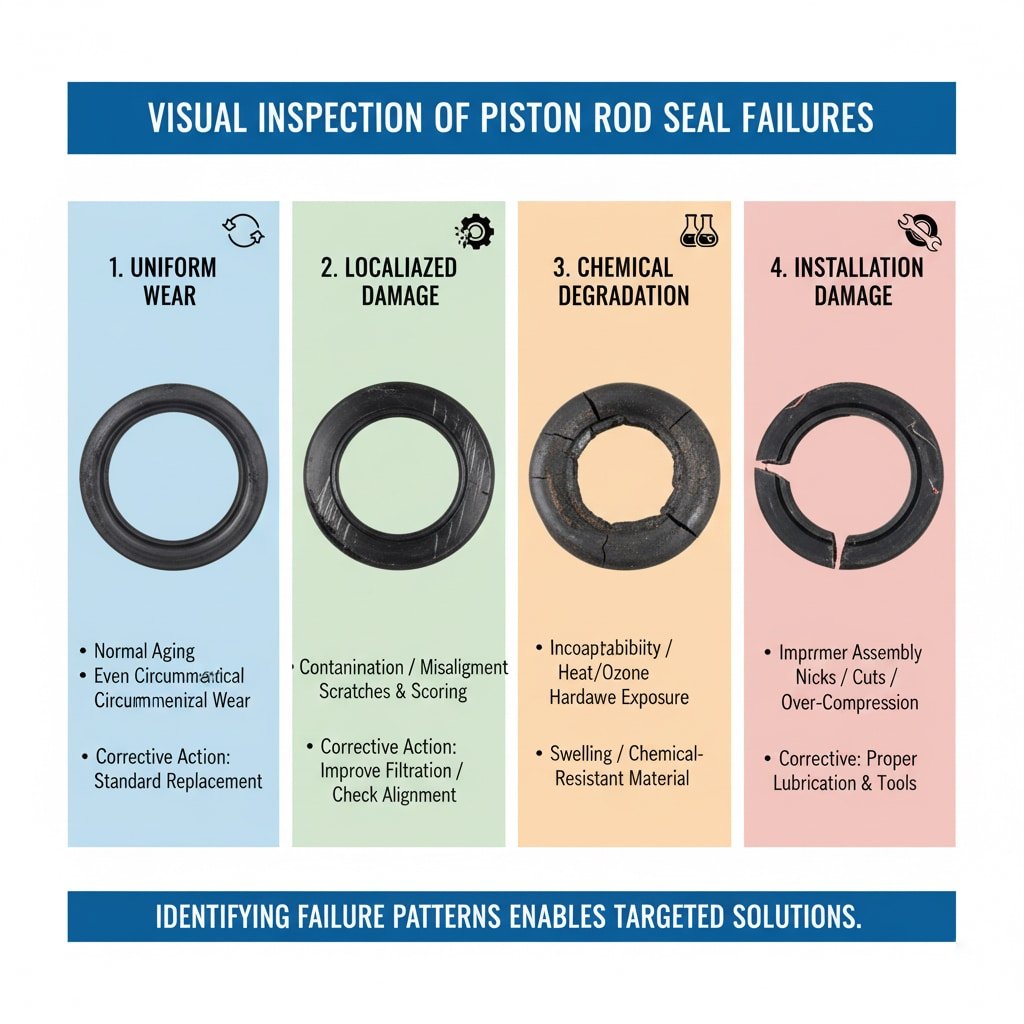

Visual inspection patterns include uniform wear indicating normal aging, localized damage suggesting contamination or misalignment, chemical degradation showing material incompatibility, and installation damage revealing improper assembly techniques, with each pattern pointing to specific root causes and corrective actions.

Analiza tiparelor de uzură

Different wear patterns indicate specific failure mechanisms:

| Wear Pattern | Root Cause | Corrective Action |

|---|---|---|

| Uniform circumferential | Uzură normală | Replace with same specification |

| Localized scoring | Contaminare | Improve air filtration |

| Asymmetric wear | Încărcare laterală | Check alignment/add guides |

| Cracking/hardening | Heat/ozone exposure4 | Use heat-resistant materials |

Material Degradation Signs

Chemical and environmental damage creates distinctive visual indicators:

- Swelling: Indicates chemical incompatibility

- Hardening: Shows heat or ozone exposure

- Color changes: Reveals chemical attack

- Surface cracking: Indicates temperature cycling

Sarah, a plant engineer in Michigan, sent us photos of her failed seals showing distinctive spiral scoring patterns. Our analysis revealed contaminated air lines, and after installing proper filtration, her seal life increased from 4 months to over 18 months. 📸

Which Environmental Factors Accelerate Piston Rod Seal Degradation?

Environmental conditions significantly impact seal performance and service life.

Critical environmental factors include temperature extremes causing material degradation, humidity promoting seal swelling and corrosion, chemical exposure leading to material incompatibility, and UV radiation5 breaking down polymer chains, with controlled environments extending seal life by 300-500%.

Efectele temperaturii

Temperature variations dramatically affect seal materials:

| Intervalul de temperatură | Impact on Seals | Materiale recomandate |

|---|---|---|

| Sub -20°C | Hardening, cracking | Low-temperature compounds |

| -20°C până la +80°C | Funcționare normală | Standard NBR/PU |

| +80°C până la +150°C | Îmbătrânire accelerată | Materiale rezistente la căldură |

| Peste +150°C | Rapid degradation | Specialized high-temp seals |

Compatibilitate chimică

Different seal materials have varying chemical resistance:

- NBR seals: Good oil resistance, poor ozone resistance

- Poliuretan: Excellent wear resistance, limited chemical resistance

- Fluorocarbon: Superior chemical resistance, higher cost

- PTFE compounds: Broad chemical compatibility, specialized applications

What Preventive Measures Can Eliminate 90% of Seal Failures?

Implementing comprehensive preventive measures dramatically reduces seal failure rates and associated costs.

Effective prevention strategies include proper seal selection for application conditions, correct installation procedures with appropriate tools, regular maintenance including air filtration and lubrication, environmental protection from temperature and chemical extremes, and systematic monitoring for early failure detection, collectively preventing 90% of premature failures.

Bepto Prevention Program

Our comprehensive approach includes:

- Analiza aplicațiilor: Matching seals to specific conditions

- Quality replacement parts: OEM-compatible seals at 40% cost savings

- Suport pentru instalare: Proper procedures and tools

- Maintenance guidance: Preventive care programs

Analiza cost-beneficiu

| Strategia de prevenire | Costuri de implementare | Failure Reduction | Economii anuale |

|---|---|---|---|

| Proper seal selection | Scăzut | 40-60% | $15,000-25,000 |

| Formare pentru instalare | Mediu | 60-80% | $25,000-40,000 |

| Air filtration upgrade | Mediu | 70-85% | $30,000-50,000 |

| Complete program | Înaltă | 85-95% | $50,000-80,000 |

Etape de implementare

- Conduct failure analysis on current seal failures

- Upgrade air treatment with proper filtration and drying

- Train maintenance staff on proper installation techniques

- Establish monitoring program for early failure detection

- Partner with reliable supplier for quality replacement parts

We help customers implement these preventive measures, often reducing their seal failure rates by over 90% while cutting replacement costs by 40% through our high-quality, cost-effective alternatives to OEM parts. 🎯

Concluzie

Systematic failure analysis of piston rod seal leaks reveals preventable root causes, enabling targeted solutions that extend service life and reduce costs significantly.

FAQs About Piston Rod Seal Failure Analysis

Q: How can I tell if my seal failure is due to contamination or normal wear?

Contamination damage shows localized scoring, pitting, or embedded particles, while normal wear appears as uniform circumferential wear patterns. Contamination failures typically occur much earlier than expected service life, often within 6 months instead of 2+ years.

Q: What’s the most cost-effective way to prevent seal failures?

Installing proper air filtration and drying equipment provides the highest return on investment, typically reducing failures by 70-85% while costing only $2,000-5,000 for most systems. This prevents contamination damage, the second-leading cause of seal failures.

Q: Can I use aftermarket seals instead of OEM parts?

Yes, high-quality aftermarket seals like our Bepto products offer identical performance to OEM parts at 40-60% lower cost. We provide exact dimensional matches and material specifications, often with improved designs based on failure analysis data.

Q: How often should I inspect piston rod seals?

Inspect seals monthly for external leakage signs and quarterly for detailed visual inspection during maintenance. Early detection of minor leakage allows planned replacement, preventing catastrophic failures and emergency downtime that costs 10x more than scheduled maintenance.

Q: What documentation should I keep for failure analysis?

Record installation dates, operating conditions, failure symptoms, and photos of failed seals. This data helps identify patterns and root causes, enabling targeted improvements. We provide failure analysis forms to help customers track and analyze their seal performance systematically.

-

Learn about the formal engineering process of Root Cause Failure Analysis (RCFA) used to identify and solve problems. ↩

-

Understand the mechanical process of abrasive wear and how hard particles damage surfaces. ↩

-

Explore the function of guide bushings in mechanical systems and how they prevent misalignment. ↩

-

Discover how ozone in the atmosphere can cause cracking and degradation in rubber seal materials. ↩

-

Read about the chemical process of photodegradation and how UV light breaks down polymer chains. ↩