Воздушные фильтры | удаляют влагу, масло и твердые частицы для защиты оборудования. Ознакомьтесь с нашим полным ассортиментом воздушных фильтров, предназначенных для точного удаления загрязнений из сжатого воздуха. Обеспечение чистого источника воздуха имеет решающее значение для защиты чувствительных пневматических компонентов, продления срока службы оборудования и повышения общей эффективности системы. Найдите идеальный фильтр для вашего применения прямо сейчас.

Нужна продукция для вашего проекта?

Мы понимаем, что поиск поставщиков может быть непростой задачей.

Заполните форму, указав конкретные позиции - не стесняйтесь указывать даже уникальные или труднодоступные компоненты, - отправьте запрос и получите именно те решения, которые вы ищете! Забудьте о типовых предложениях; мы специализируемся на том, чтобы понять ваши точные потребности и предоставить результаты, которые подходят как перчатка

Наш ассортимент ручных клапанов обеспечивает прямое и надежное управление пневматическими системами. Созданные для простоты, долговечности и точного управления, эти клапаны незаменимы для приложений, требующих вмешательства оператора, настройки системы, изоляции или защитной блокировки.

Защитите чувствительные пневматические компоненты, такие как клапаны, цилиндры и инструменты, от повреждений, вызванных загрязнениями, и продлите срок их службы.

Чистый воздух обеспечивает более плавную работу компонентов, снижает перепады давления, вызванные засорами, и оптимизирует потребление энергии.

Предотвращая преждевременный выход из строя компонентов и сбои в работе системы, наши фильтры позволяют свести к минимуму дорогостоящие перерывы в производстве и расходы на техническое обслуживание.

Использование передовых фильтрующих материалов обеспечивает превосходное улавливание частиц, высокую грязеудерживающую способность и низкий перепад давления.

Прочные чаши из поликарбоната или металла с защитой обеспечивают видимость и ударопрочность, гарантируя безопасность и долговечность.

Надежные ручные, полуавтоматические или полностью автоматические сливы для эффективного удаления собранной воды и масла.

Предназначен для быстрой и простой замены фильтрующего элемента, что сводит к минимуму время и усилия на техническое обслуживание.

Размер частиц, которые может удалить фильтр (например, 40 мкм, 5 мкм, 1 мкм, 0,01 мкм).

Например, варианты G1/8, G1/4, G1/2, G1, NPT.

Максимальный расход воздуха, который может выдержать фильтр при заданном давлении (например, л/мин, SCFM).

Максимальное и минимальное давление на входе.

Предельные значения температуры окружающей среды и среды.

Поликарбонат или металл; способность удерживать конденсат.

Ручной, полуавтоматический или полностью автоматический слив.

Потеря давления через фильтр при заданном расходе.

Подробные параметры см. в руководствах к отдельным изделиям или проконсультируйтесь с нашими техническими специалистами.

Защита цилиндров, клапанов и инструментов в стандартной промышленной автоматике и оборудовании.

Обеспечение чистого воздуха для чувствительных измерительных приборов, лабораторного оборудования и аналитических инструментов.

Удаление масла, воды и частиц для предотвращения дефектов и обеспечения высококачественной отделки.

Обеспечивает гигиеничный, безмасляный воздух для приложений с прямым контактом и упаковочных процессов.

Подача чистого, сухого воздуха для стоматологических инструментов, дыхательных аппаратов и других медицинских приложений.

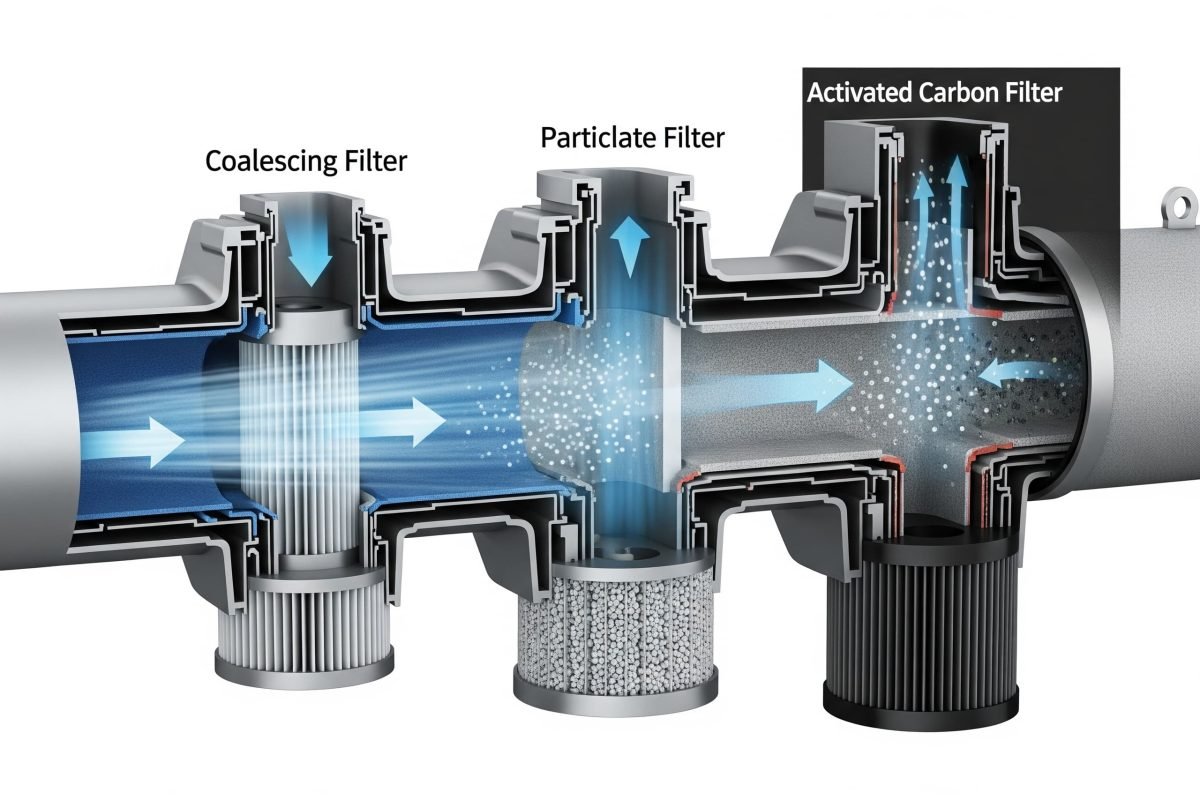

Многоступенчатая фильтрация, включая активированный уголь, обеспечивает безопасный воздух, пригодный для дыхания персонала.

Всегда снимайте давление в системе перед выполнением любого технического обслуживания воздушных фильтров.

Сжатый воздух, поступающий непосредственно из компрессора, естественно, содержит такие загрязнения, как водяной пар (который конденсируется), масло (из смазанных компрессоров или переносимое), пыль, частицы ржавчины из труб и воздушную грязь. Если не удалить эти загрязнения, они могут:

Правильная фильтрация необходима для защиты ваших инвестиций, обеспечения надежности и поддержания качества продукции.

Рейтинг микронов указывает на наименьший размер частиц которые фильтрующий элемент может эффективно удалить из потока сжатого воздуха. Один микрон (мкм) - это одна миллионная часть метра.

Необходимый микронный класс зависит от чувствительности пневматических компонентов, расположенных ниже по потоку, и требуемого качества воздуха для конкретного применения.

Интервал замены фильтрующего элемента зависит от нескольких факторов:

В качестве общего руководства для сажевых фильтров замена может производиться каждые 6-12 месяцев или в зависимости от перепада давления. Элементы коалесцирующих фильтров часто имеют более короткий срок службы и требуют своевременной замены для поддержания эффективности удаления масла. Всегда обращайтесь к руководству по эксплуатации конкретного фильтра для получения информации о рекомендуемых сроках замены.

Они направлены на различные типы загрязнений:

Нет, очень важно выбрать воздушный фильтр соответствующего типа и марки для конкретного применения и требований к качеству воздуха, предъявляемых к последующему оборудованию.

Понимание классов качества воздуха (например, ISO 8573-1) и требований вашего оборудования является ключевым моментом для выбора правильной системы фильтрации.

Защитите свои ценные инвестиции в пневматику и оптимизируйте работу с помощью наших превосходных решений по фильтрации воздуха. Ознакомьтесь с нашим ассортиментом фильтров или свяжитесь с нашими специалистами по очистке воздуха, чтобы найти идеальное решение для ваших потребностей в качестве воздуха.