High-cycle cylinder failures from thermal overload cost manufacturers millions in unplanned downtime and component replacement. Excessive heat generation leads to seal degradation, lubricant breakdown, and dimensional changes that cause catastrophic system failures during critical production runs.

Analys av termiska egenskaper hos högcykliska cylindrar innebär mätning av temperaturökning, värmeutveckling, värmeavledningskapacitet och materialets termiska gränser för att förutsäga prestandaförsämring, optimera kylstrategier och förhindra termiskt orsakade fel i krävande industriella applikationer.

Last month, I received an urgent call from Jennifer, a plant engineer at an automotive stamping facility in Detroit, whose high-speed transfer line was experiencing cylinder failures every two weeks due to thermal overload from 180 cycles per minute operation. 🔥

Innehållsförteckning

- What Are the Primary Heat Generation Sources in High-Cycle Cylinders?

- How Do You Measure and Monitor Cylinder Temperature During Operation?

- What Thermal Analysis Methods Predict Cylinder Performance and Failure Points?

- How Can Thermal Management Strategies Extend High-Cycle Cylinder Life?

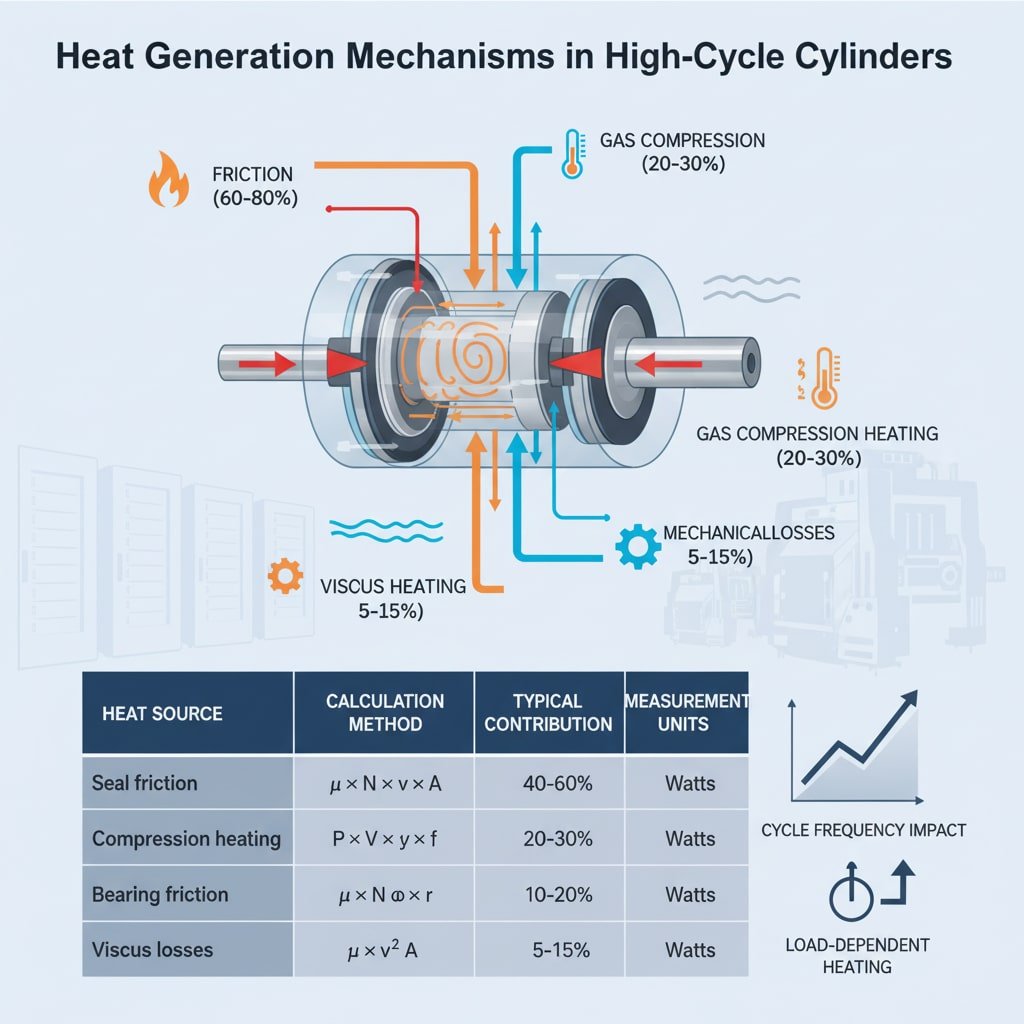

What Are the Primary Heat Generation Sources in High-Cycle Cylinders? 🌡️

Understanding heat generation mechanisms is essential for effective thermal management in high-cycle applications.

Primary heat generation sources in high-cycle cylinders include friction from piston seals and rod bearings, gas compression heating during rapid cycling, viscous heating in hydraulic systems, and mechanical losses from internal component movement, with friction typically contributing 60-80% of total heat generation.

Friction-Based Heat Generation

The dominant heat source in most high-cycle cylinder applications.

Friction Sources

- Kolvtätningar: Primary friction interface generating heat during stroke movement

- Stångens tätningar: Secondary friction source at cylinder head interface

- Lagerytor: Guide bushings and rod bearings create sliding friction

- Interna komponenter: Valve mechanisms and internal guides contribute friction losses

Compression and Expansion Heating

Thermodynamic effects from rapid gas compression and expansion cycles.

Gas Heating Mechanisms

- Adiabatic compression1: Rapid compression increases gas temperature significantly

- Expansion cooling: Gas expansion creates temperature drop during exhaust

- Tryckcykling: Repeated pressure changes generate thermal cycling effects

- Flödesbegränsningar: Valve and port restrictions create turbulent heating

Heat Generation Calculation Methods

Quantifying thermal energy production for analysis and prediction.

| Heat Source | Beräkningsmetod | Typiskt bidrag | Mätenheter |

|---|---|---|---|

| Friktion i tätning | μ × N × v × A | 40-60% | Watts |

| Compression heating | P × V × γ × f | 20-30% | Watts |

| Bearing friction | μ × N × ω × r | 10-20% | Watts |

| Viscous losses | η × v² × A | 5-15% | Watts |

Cycle Frequency Impact

How operating speed affects heat generation rates and thermal accumulation.

Frequency Effects

- Linjärt förhållande: Heat generation generally proportional to cycle frequency

- Thermal accumulation: Higher frequencies reduce cooling time between cycles

- Critical frequency: Point where heat generation exceeds dissipation capacity

- Resonanseffekter: Certain frequencies may amplify thermal generation

Load-Dependent Heating

How applied loads influence thermal characteristics and heat generation.

Belastningsfaktorer

- Seal compression: Higher loads increase seal friction and heat generation

- Bearing loads: Side loads create additional friction heating

- Pressure levels: Operating pressure directly affects compression heating

- Dynamiska belastningar: Varying loads create complex thermal patterns

Environmental Heat Sources

External factors that contribute to cylinder thermal loading.

External Heat Sources

- Omgivande temperatur: Surrounding environment temperature affects baseline

- Radiant heating: Heat from nearby equipment and processes

- Conduction heating: Heat transfer from mounting structures

- Solar heating: Direct sunlight exposure in outdoor applications

Jennifer’s automotive facility was experiencing severe thermal issues because their high-speed cylinders were generating over 800 watts of heat during peak production, far exceeding their cooling capacity. 🏭

How Do You Measure and Monitor Cylinder Temperature During Operation? 📊

Accurate temperature measurement is crucial for thermal analysis and performance optimization.

Cylinder temperature monitoring involves using thermocouples, infrared sensors, and embedded temperature probes at critical locations including cylinder head, barrel surface, and internal components, with data logging systems providing continuous monitoring and thermal trend analysis for predictive maintenance strategies.

Temperature Measurement Locations

Strategic placement of sensors for comprehensive thermal monitoring.

Critical Measurement Points

- Cylinder head: Highest temperature location due to compression heating

- Barrel surface: Mid-stroke position for average operating temperature

- Rod bearing: Critical seal interface temperature monitoring

- Avgasport: Gas temperature measurement for compression analysis

Sensor Technology Options

Different temperature measurement technologies for various applications.

Sensor Types

- Thermocouples2: Most common for industrial applications, wide temperature range

- RTD sensors: Higher accuracy for precision temperature measurement

- Infrared sensors: Non-contact measurement for moving components

- Embedded sensors: Built-in temperature monitoring for OEM applications

Data Acquisition Systems

Methods for collecting and analyzing temperature data from multiple sensors.

| Typ av system | Sampling Rate | Noggrannhet | Kostnadsfaktor | Bästa tillämpning |

|---|---|---|---|---|

| Basic logger | 1 Hz | ±2°C | 1x | Enkel övervakning |

| Industrial DAQ | 100 Hz | ±0.5°C | 3-5x | Processtyrning |

| High-speed system | 1000 Hz | ±0.1°C | 8-12x | Research analysis |

| Wireless sensors | 0.1 Hz | ±1°C | 2-3x | Fjärrövervakning |

Temperature Mapping Techniques

Creating comprehensive thermal profiles of cylinder operation.

Mapping Methods

- Multi-point measurement: Multiple sensors for spatial temperature distribution

- Termisk avbildning: Infrared cameras for surface temperature mapping

- Computational modeling: CFD analysis for internal temperature prediction

- Transient analysis: Time-based temperature variation measurement

Real-Time Monitoring Systems

Continuous temperature monitoring for process control and safety.

Monitoring Features

- Larmsystem: Temperature threshold warnings and shutdowns

- Trendanalys: Historical data for predictive maintenance

- Fjärråtkomst: Web-based monitoring and mobile alerts

- Data integration: Connection to plant SCADA and MES systems

Calibration and Accuracy

Ensuring measurement reliability and traceability for thermal analysis.

Krav på kalibrering

- Regular calibration: Periodic verification against reference standards

- Sensor drift: Monitoring and compensation for sensor aging effects

- Miljökompensation: Adjusting for ambient temperature variations

- Spårbarhet: NIST-traceable calibration for quality assurance

Säkerhetsöverväganden

Temperature monitoring for personnel and equipment protection.

Säkerhetsfunktioner

- Over-temperature protection: Automatic shutdown at dangerous temperatures

- Felsäker design: System response to sensor failures

- Explosion-proof sensors: Hazardous area temperature monitoring

- Emergency cooling: Automatic cooling activation at critical temperatures

What Thermal Analysis Methods Predict Cylinder Performance and Failure Points? 🔬

Advanced analysis techniques help predict thermal behavior and optimize cylinder design.

Thermal analysis methods include finite element analysis (FEA)3 for heat transfer modeling, computational fluid dynamics (CFD) for cooling optimization, thermal cycling analysis for fatigue prediction, and material degradation modeling to predict seal life and performance degradation under thermal stress conditions.

Finita element-analys (FEA)

Computer modeling for detailed thermal behavior prediction and optimization.

FEA Applications

- Heat transfer modeling: Conduction, convection, and radiation analysis

- Thermal stress analysis: Material expansion and stress prediction

- Temperature distribution: Spatial temperature mapping throughout cylinder

- Transient analysis: Time-dependent thermal behavior modeling

Beräkningsbaserad strömningsdynamik (CFD)

Advanced modeling for gas flow and heat transfer analysis.

CFD Capabilities

- Gas flow analysis: Internal gas movement and turbulence effects

- Heat transfer coefficients: Convective cooling effectiveness calculation

- Analys av tryckfall: Flow restrictions and their thermal effects

- Cooling optimization: Airflow and cooling system design optimization

Analys av termisk cykling

Predicting fatigue and degradation from repeated thermal stress.

| Analysis Type | Syfte | Key Parameters | Output |

|---|---|---|---|

| Spänningsanalys | Materialutmattning | Temperature range, cycles | Utmattningslivslängd |

| Nedbrytning av tätningar | Seal life prediction | Temperature, pressure | Service hours |

| Dimensional stability | Clearance changes | Termisk expansion | Performance drift |

| Material aging | Property changes | Time, temperature | Degradation rate |

Beräkningar av värmeöverföring

Fundamental calculations for thermal system design and analysis.

Beräkningsmetoder

- Conduction analysis: Heat flow through solid materials

- Convection modeling: Heat transfer to surrounding air or coolant

- Radiation calculations: Heat loss through electromagnetic radiation

- Thermal resistance: Overall heat transfer effectiveness

Performance Degradation Modeling

Predicting how thermal effects impact cylinder performance over time.

Degradation Factors

- Seal hardening: Temperature effects on elastomer properties

- Clearance changes: Thermal expansion affecting internal clearances

- Nedbrytning av smörjmedel: High temperature lubricant degradation

- Material property changes: Strength and stiffness variations with temperature

Predictive Maintenance Algorithms

Using thermal data to predict maintenance needs and prevent failures.

Algorithm Types

- Trendanalys: Statistical analysis of temperature trends over time

- Machine learning: AI-based prediction of thermal failure patterns

- Threshold monitoring: Simple temperature limit-based predictions

- Multi-parameter models: Complex models using multiple sensor inputs

Validation Methods

Confirming thermal analysis accuracy through testing and measurement.

Validation Approaches

- Laboratory testing: Controlled environment thermal testing

- Field validation: Real-world operation comparison with models

- Accelerated testing: High-temperature testing for rapid validation

- Comparative analysis: Benchmarking against known thermal performance

At Bepto, we use advanced thermal modeling software to optimize our rodless cylinder designs for high-cycle applications, ensuring maximum performance and reliability under demanding thermal conditions. 💪

How Can Thermal Management Strategies Extend High-Cycle Cylinder Life? ❄️

Effective thermal management significantly improves cylinder performance and service life.

Thermal management strategies include active cooling systems using forced air or liquid cooling, passive heat dissipation through enhanced surface area and heat sinks, material selection for improved thermal properties, and operational modifications like duty cycle optimization and pressure reduction to minimize heat generation.

Active Cooling Systems

Engineered cooling solutions for high-heat applications.

Cooling Methods

- Forcerad luftkylning: Fans and blowers for enhanced convective cooling

- Vätskekylning: Water or coolant circulation through cylinder jackets

- Värmeväxlare: Dedicated cooling systems for extreme applications

- Termoelektrisk kylning4: Peltier devices for precise temperature control

Passive Heat Dissipation

Design modifications to improve natural heat dissipation.

Passive Strategies

- Kylflänsar: Extended surface area for improved heat transfer

- Termisk massa: Increased material volume for heat absorption

- Ytbehandlingar: Coatings and finishes to enhance heat transfer

- Ventilation design: Natural airflow enhancement around cylinders

Material Selection for Thermal Management

Choosing materials with superior thermal properties for high-cycle applications.

| Material Property | Standard Materials | High-Performance Options | Förbättringsfaktor |

|---|---|---|---|

| Thermal conductivity | Aluminum (200 W/mK) | Copper (400 W/mK) | 2x |

| Heat capacity | Steel (0.5 J/gK) | Aluminum (0.9 J/gK) | 1.8x |

| Termisk expansion | Steel (12 μm/mK) | Invar (1.2 μm/mK) | 10x |

| Temperature resistance | NBR (120°C) | FKM (200°C) | 1.7x |

Operational Optimization

Modifying operating parameters to reduce thermal loading.

Strategier för optimering

- Duty cycle management: Planned rest periods for cooling

- Optimering av tryck: Reducing operating pressure to minimize heating

- Hastighetsreglering: Variable cycle rates based on thermal conditions

- Lastbalansering: Distributing thermal loads across multiple cylinders

Lubrication and Seal Management

Specialized approaches for high-temperature seal and lubrication systems.

Thermal Lubrication

- Smörjmedel för höga temperaturer: Synthetic oils for extreme temperature operation

- Cooling lubricants: Heat-absorbing lubricant formulations

- Tätningsmaterial: High-temperature elastomers and thermoplastics

- Smörjsystem: Continuous lubrication for cooling and protection

Systemintegration

Coordinating thermal management with overall system design.

Integration Aspects

- Styrsystem: Automated thermal management based on temperature feedback

- Säkerhetssystem: Thermal protection and emergency cooling activation

- Schemaläggning av underhåll: Thermal-based predictive maintenance programs

- Övervakning av prestanda: Continuous thermal performance assessment

Kostnads- och nyttoanalys

Evaluating thermal management investment versus performance improvement.

Ekonomiska överväganden

- Initial investering: Cost of cooling systems and thermal management equipment

- Rörelsekostnader: Energy consumption for active cooling systems

- Besparingar på underhåll: Reduced maintenance from improved thermal management

- Produktivitetsvinster: Increased uptime and performance from thermal optimization

Advanced Thermal Technologies

Emerging technologies for next-generation thermal management.

Future Technologies

- Material för fasförändring: Thermal energy storage for peak load management

- Micro-channel cooling: Enhanced heat transfer through micro-scale channels

- Smart materials: Temperature-responsive materials for adaptive cooling

- IoT integration: Connected thermal management systems with cloud analytics

Sarah, who manages a high-speed packaging line in Phoenix, Arizona, implemented our comprehensive thermal management solution and achieved 300% improvement in cylinder service life while increasing production speeds by 25%. 🚀

Slutsats

Comprehensive thermal analysis and management strategies are essential for maximizing high-cycle cylinder performance, preventing failures, and optimizing operational efficiency in demanding industrial applications. 🎯

FAQs About High-Cycle Cylinder Thermal Analysis

Q: What temperature rise is considered normal for high-cycle cylinder operation?

Normal temperature rise ranges from 20-40°C above ambient for standard applications, with high-performance cylinders tolerating up to 60°C rise under proper thermal management. Exceeding these ranges typically indicates inadequate cooling or excessive heat generation requiring system optimization.

Q: How often should thermal monitoring data be reviewed for predictive maintenance?

Thermal data should be reviewed daily for trending analysis, with detailed weekly reports for maintenance planning and monthly comprehensive analysis for long-term optimization. Critical applications may require continuous monitoring with real-time alerts for immediate response.

Q: Can existing cylinders be retrofitted with thermal management systems?

Yes, many existing cylinders can be retrofitted with external cooling systems, enhanced heat sinks, and temperature monitoring equipment. Our engineering team evaluates retrofit feasibility and designs custom thermal management solutions for existing installations.

Q: What are the warning signs of thermal-related cylinder problems?

Warning signs include gradually increasing operating temperatures, reduced cycle speeds, premature seal failures, inconsistent performance, and visible heat distortion or discoloration. Early detection through thermal monitoring prevents catastrophic failures and costly downtime.

Q: How do environmental conditions affect cylinder thermal management requirements?

High ambient temperatures, poor ventilation, and radiant heat sources significantly increase thermal management requirements, often necessitating active cooling systems. Our thermal analysis includes environmental factors to ensure adequate cooling capacity for all operating conditions.

-

Learn the thermodynamic principle of how gas temperature rises when compressed quickly without heat transfer. ↩

-

Understand the working principle (Seebeck effect) and types of these common industrial temperature sensors. ↩

-

Explore how FEA simulation is used to model heat transfer, convection, and thermal stress in engineering. ↩

-

Discover the solid-state physics behind Peltier devices and how they transfer heat using an electric current. ↩