Traditional pneumatic cylinder seals require constant lubrication, creating maintenance headaches and contamination risks in clean environments. Seal failures cause costly downtime while over-lubrication attracts dirt and accelerates wear. Self-lubricating seals incorporate embedded solid lubricants like PTFE1 eller graphite2 directly into the seal material, eliminating external lubrication requirements while providing superior wear resistance, extended service life up to 10 million cycles, and contamination-free operation ideal for food processing, pharmaceuticals, and precision manufacturing. Last week, I helped Jennifer, a maintenance manager from a pharmaceutical facility in New Jersey, eliminate her monthly seal replacement routine. Our Bepto self-lubricating seals have been running contamination-free for 18 months with zero maintenance! 🔧

Innehållsförteckning

- What Makes Self-Lubricating Seals Different from Traditional Pneumatic Seals?

- How Do Embedded Lubricants Work at the Molecular Level?

- What Are the Key Performance Advantages of Self-Lubricating Technology?

- Why Should You Upgrade to Bepto’s Advanced Self-Lubricating Seal Systems?

What Makes Self-Lubricating Seals Different from Traditional Pneumatic Seals?

Understanding the fundamental design differences helps you appreciate the revolutionary engineering behind maintenance-free operation.

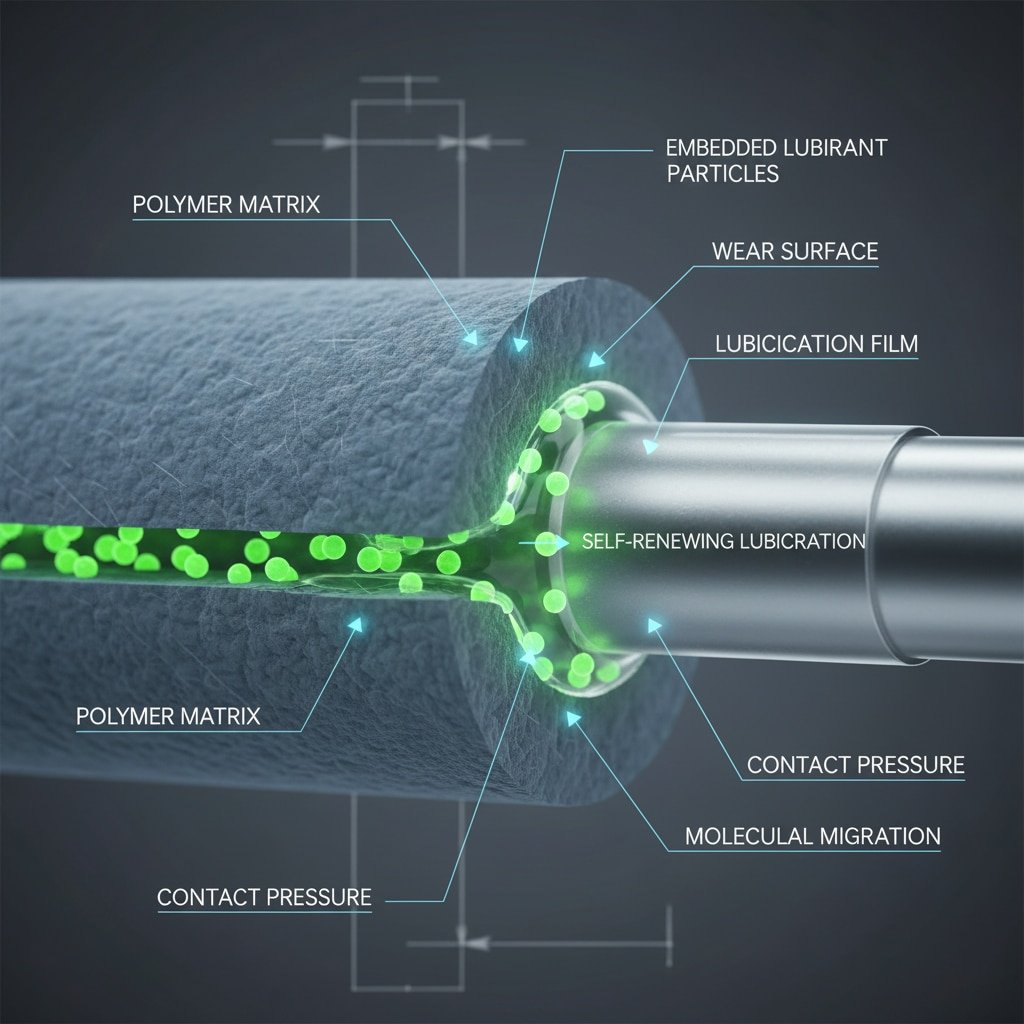

Self-lubricating seals integrate solid lubricant particles directly into the polymer matrix3 during manufacturing, creating a homogeneous material where lubricants are uniformly distributed throughout the seal cross-section – this eliminates dependency on external lubrication while providing continuous lubrication renewal as the seal wears.

Material Composition Breakthrough

Traditional seals rely on external oil or grease films that wash away or attract contaminants. Self-lubricating seals contain 15-25% solid lubricant particles embedded within the base polymer.

Lubricant Integration Methods

| Integration Type | Lubricant Material | Prestanda | Tillämpning |

|---|---|---|---|

| PTFE Filled | Polytetrafluoroethylene | Ultra-low friction | Höghastighetsapplikationer |

| Graphite Enhanced | Carbon graphite | Hög temperatur | Extrema förhållanden |

| MoS₂ Composite | Molybdenum disulfide4 | Tunga laster | Industrial duty |

| Multi-Component | Combined lubricants | Balanserad utveckling | Allmänt ändamål |

Structural Engineering

The molecular structure creates micro-reservoirs of lubricant that continuously migrate to the sealing surface, maintaining optimal lubrication throughout the seal’s service life.

Manufacturing Process Innovation

Advanced compounding techniques ensure uniform lubricant distribution while maintaining seal integrity and dimensional stability under pressure and temperature variations.

How Do Embedded Lubricants Work at the Molecular Level?

The microscopic engineering creates a self-renewing lubrication system that operates continuously without external intervention.

Embedded lubricant particles create micro-scale lubrication films through controlled migration to contact surfaces – as the seal experiences wear, fresh lubricant particles are exposed, maintaining optimal friction coefficients and preventing stick-slip-beteende5 throughout the entire service life.

Molecular Migration Mechanism

Solid lubricant particles migrate through the polymer matrix under mechanical stress and thermal cycling, continuously replenishing the lubrication film at critical contact points.

Surface Chemistry

The lubricant creates a molecular boundary layer that reduces direct metal-to-polymer contact, dramatically reducing wear rates and friction coefficients.

Wear Pattern Analysis

| Wear Stage | Traditional Seal | Self-Lubricating Seal | Fördel |

|---|---|---|---|

| Initial Break-in | High friction | Immediate lubrication | Smooth startup |

| Operating Period | Degrading performance | Konsekvent smörjning | Stable operation |

| End of Life | Rapid failure | Gradual wear | Predictable replacement |

Temperaturpåverkan

Self-lubricating materials maintain effectiveness across wider temperature ranges, with some formulations operating from -40°C to +200°C without lubrication breakdown.

Tryckrespons

Under high pressure, the embedded lubricants actually improve performance by creating denser lubrication films, unlike external lubricants that can be squeezed away.

Robert, a design engineer from Michigan, was struggling with seal failures in his high-cycle automation equipment. After switching to our self-lubricating seals, his maintenance intervals increased from monthly to annual while improving system reliability by 300%! 📈

What Are the Key Performance Advantages of Self-Lubricating Technology?

These advanced seals deliver measurable improvements in reliability, maintenance costs, and operational cleanliness.

Self-lubricating seals provide 5-10 times longer service life than traditional seals, eliminate 100% of lubrication maintenance, reduce friction by 60-80%, operate contamination-free in clean environments, and maintain consistent performance across millions of cycles – delivering substantial cost savings and improved system reliability.

Förlängd livslängd

The continuous lubrication renewal mechanism dramatically extends seal life, with many applications achieving 5-10 million cycles compared to 500,000-1,000,000 cycles for traditional seals.

Maintenance Elimination

| Underhållsuppgift | Traditional Seals | Självsmörjande | Kostnadsbesparingar |

|---|---|---|---|

| Lubrication Schedule | Weekly/Monthly | Never | 100% eliminering |

| Byte av tätning | Var 6:e-12:e månad | Every 3-5 years | 75% reducering |

| Contamination Cleanup | Regelbunden | Minimal | 90% reducering |

| Stilleståndstimmar | 24-48 hours/year | 4-8 hours/year | 80% minskning |

Performance Consistency

Self-lubricating seals maintain consistent friction coefficients throughout their service life, eliminating the performance degradation typical of externally lubricated systems.

Clean Environment Compatibility

Zero external lubrication makes these seals ideal for food processing, pharmaceutical manufacturing, and semiconductor fabrication where contamination is critical.

Energieffektivitet

Reduced friction translates to lower air consumption and reduced compressor loads, providing ongoing energy savings throughout the seal’s extended service life.

Why Should You Upgrade to Bepto’s Advanced Self-Lubricating Seal Systems?

Our proprietary seal technology delivers superior performance with guaranteed compatibility and comprehensive technical support.

Bepto’s self-lubricating seals feature proprietary multi-component lubricant systems, precision-engineered profiles for optimal sealing, and guaranteed 5+ million cycle life with 100% OEM compatibility – our proven technology reduces your total cost of ownership by 50-70% while eliminating maintenance headaches.

Proprietary Lubricant Technology

Our advanced formulations combine multiple lubricant types for optimal performance across diverse operating conditions, providing superior results compared to single-component systems.

Quality Assurance Program

Every seal batch undergoes rigorous testing including cycle life validation, friction coefficient measurement, and compatibility verification to ensure consistent performance.

Application Engineering Support

Our technical team analyzes your specific operating conditions to recommend optimal seal configurations, ensuring maximum performance and service life for your application.

Cost-Performance Comparison

| Funktion | OEM Self-Lubricating | Bepto-lösning | Fördel |

|---|---|---|---|

| Livscykel | 3-5 million | 5-10 million | 2x longer service |

| Kompatibilitet | Begränsade alternativ | Universal fit | Enkelt byte |

| Teknisk support | Grundläggande | Heltäckande | Complete solution |

| Kostnad | Premium-prissättning | 30-40% besparingar | Better value |

Retrofit Capability

Our self-lubricating seals directly replace existing seals in your current cylinders, providing immediate performance improvements without system modifications or downtime.

Our self-lubricating technology transforms your pneumatic systems from maintenance-intensive equipment to reliable, set-and-forget operations while delivering substantial cost savings. 💪

Slutsats

Self-lubricating seals represent the future of pneumatic cylinder technology, while Bepto’s advanced solutions deliver proven performance with unmatched value and comprehensive support.

FAQs About Self-Lubricating Seals

Q: How long do self-lubricating seals actually last compared to traditional seals?

A: Self-lubricating seals typically last 5-10 times longer than traditional seals, achieving 5-10 million cycles versus 500,000-1,000,000 cycles for conventional seals. Actual life depends on operating conditions and application requirements.

Q: Can self-lubricating seals operate in high-temperature applications?

A: Yes, advanced formulations operate reliably from -40°C to +200°C depending on the lubricant system. Graphite-enhanced seals handle the highest temperatures while PTFE-filled versions excel in moderate temperature ranges.

Q: Are self-lubricating seals compatible with all pneumatic fluids?

A: Most self-lubricating seals are compatible with standard compressed air, inert gases, and many process gases. Chemical compatibility should be verified for specific applications involving corrosive or reactive gases.

Q: How do I retrofit existing cylinders with self-lubricating seals?

A: Self-lubricating seals are designed for direct replacement of existing seals using standard groove dimensions. Simply remove old seals and install new ones – no modifications required to cylinders or systems.

Q: Why choose Bepto’s self-lubricating seals over OEM options?

A: Bepto offers 30-40% cost savings, longer service life guarantees, universal OEM compatibility, comprehensive technical support, and immediate availability versus long OEM lead times. Our proven technology delivers superior performance with better value.

-

Explore the properties of Polytetrafluoroethylene (PTFE), a fluoropolymer known for its extremely low coefficient of friction and chemical inertness. ↩

-

Discover the properties of graphite that make it an effective solid lubricant, especially its layered crystal structure and high thermal stability. ↩

-

Learn about the role of a polymer matrix, which acts as a binder to hold reinforcing fillers or particles together in a composite material. ↩

-

Understand the characteristics of Molybdenum disulfide (MoS₂), a solid lubricant known for its performance in high-load and vacuum applications. ↩

-

Explore the stick-slip phenomenon, a spontaneous jerking motion that can occur as two objects slide over each other, which advanced lubricants aim to prevent. ↩