Manufacturing engineers waste over $500,000 annually on wrong rodless cylinder selections, with 45% choosing mechanically coupled systems when magnetic coupling would eliminate seal wear, and 30% selecting magnetic systems for high-force applications where mechanical coupling provides superior strength and reliability. 😰

Manyetik olarak bağlanmış kolsuz silindirler 500N'a kadar hafif hizmet uygulamaları için sızdırmaz çalışma ve sorunsuz hareket sunarken, mekanik olarak bağlanmış sistemler doğrudan mekanik bağlantı ile 5000N'a kadar daha yüksek kuvvet kapasitesi sağlar ve seçimi kuvvet gereksinimlerine, çevresel koşullara ve bakım önceliklerine bağlı hale getirir.

Last month, I helped Robert, a design engineer at a food processing plant in Wisconsin, who was experiencing constant seal failures with his mechanically coupled cylinders in a washdown environment1. After switching to our Bepto magnetically coupled rodless cylinders, his system has operated leak-free for over 1,500 hours without maintenance. 🎯

İçindekiler

- What Are the Key Design Differences Between Magnetic and Mechanical Coupling?

- How Do Force Capabilities Compare Between These Two Technologies?

- Which Coupling Type Offers Better Reliability and Maintenance Benefits?

- When Should You Choose Magnetic vs. Mechanical Coupling for Your Application?

What Are the Key Design Differences Between Magnetic and Mechanical Coupling?

Understanding the fundamental design principles helps engineers select the optimal rodless cylinder technology for their specific requirements.

Magnetic coupling uses permanent magnets to transfer force through the cylinder wall without physical contact, eliminating seals and creating a completely enclosed system, while mechanical coupling employs a physical connection through a sealed slot with wipers and seals, providing direct force transmission but requiring maintenance of sealing components.

Manyetik Kaplin Tasarımı

Magnetic coupling systems use powerful nadir toprak mıknatısları2 arranged in opposing configurations:

Mekanik Kaplin Tasarımı

Mechanical systems use a physical connection through the cylinder wall:

| Tasarım Öğesi | Manyetik Kaplin | Mekanik Kaplin |

|---|---|---|

| Kuvvet Transferi | Magnetic field | Direct mechanical |

| Sızdırmazlık | Completely sealed | Slot with seals |

| İletişim | Temassız | Physical contact |

| Karmaşıklık | Simple, fewer parts | More complex assembly |

İnşaat Malzemeleri

Magnetic systems require:

- High-strength aluminum extrusion

- Rare-earth permanent magnets (Neodymium)

- Stainless steel magnetic carriers

- Precision-machined magnetic assemblies

Mechanical systems use:

- Aluminum or steel cylinder body

- Hardened steel coupling elements

- Specialized sealing materials

- Precision-machined slot geometry

Çalışma Prensipleri

Magnetic coupling relies on magnetic field strength that decreases with distance, creating natural overload protection but limiting maximum force. Mechanical coupling provides direct connection with unlimited theoretical force capacity but requires precise sealing to prevent contamination.

How Do Force Capabilities Compare Between These Two Technologies?

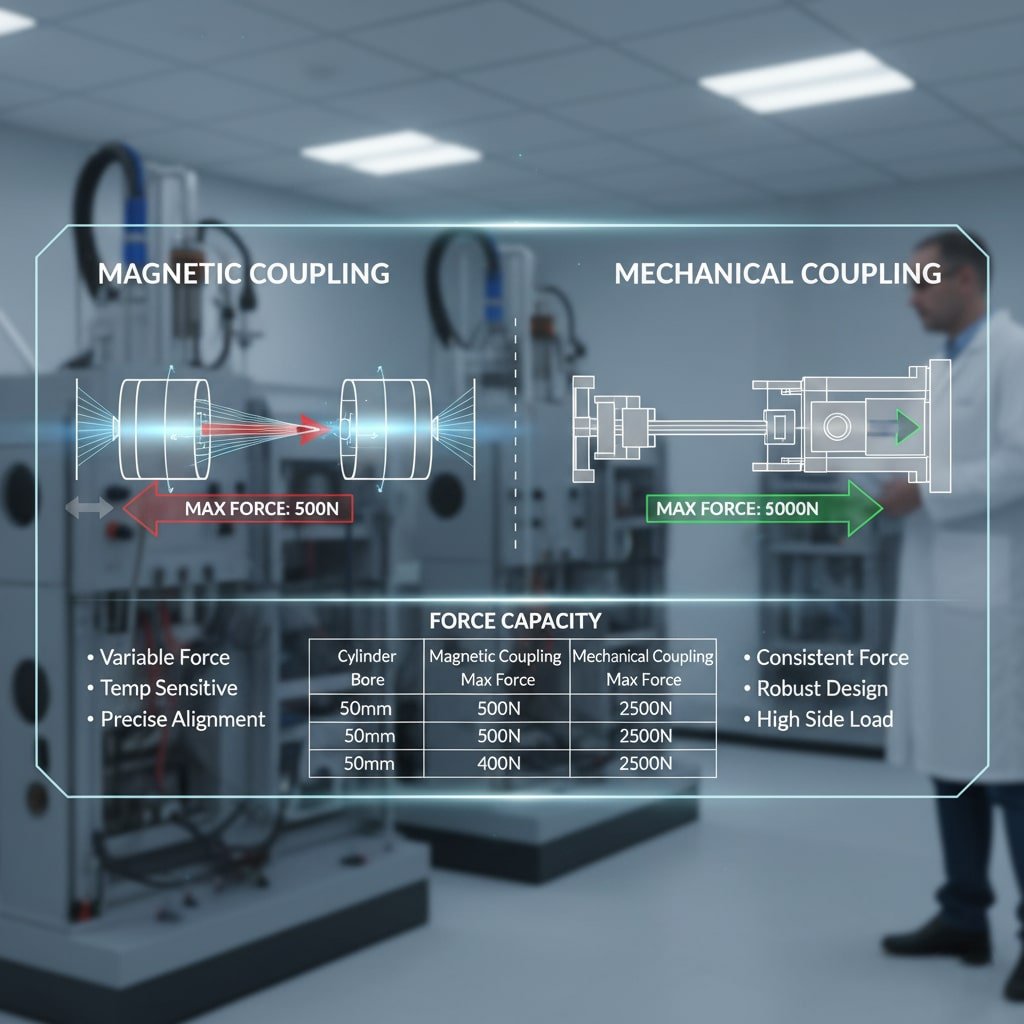

Force capacity represents the most critical performance difference between magnetic and mechanical coupling technologies.

Mechanical coupling delivers significantly higher force capacity up to 5000N due to direct physical connection, while magnetic coupling is typically limited to 500N maximum force due to magnetic field strength limitations, with mechanical systems also providing better force consistency across the full stroke length and superior resistance to yandan yükleme3.

Force Capacity Comparison

| Silindir Deliği | Magnetic Coupling Max Force | Mechanical Coupling Max Force |

|---|---|---|

| 25 mm | 150N | 800N |

| 32mm | 250N | 1200N |

| 40mm | 350N | 1800N |

| 50mm | 500N | 2500N |

| 63mm | N/A | 3500N |

| 80 mm | N/A | 5000N |

Kuvvet Tutarlılığı

Manyetik kaplin force varies with:

- Magnetic field strength degradation over time

- Temperature effects on magnet performance

- Air gap variations due to manufacturing tolerances

- Magnetic field interference4 from external sources

Mekanik kaplin provides:

- Consistent force throughout stroke length

- Minimal force variation with temperature

- Direct mechanical advantage

- Predictable performance characteristics

Yan Yük Direnci

Mechanical coupling excels in applications with side loading:

- Direct mechanical connection resists lateral forces effectively

- Guided systems can handle significant side loads

- Sağlam yapı withstands misalignment forces

Magnetic systems are more sensitive to side loading:

- Magnetic field distortion reduces coupling efficiency

- Limited side load capacity typically under 10% of axial force

- Precise alignment required optimum performans için

Sarah, a project manager at an automotive assembly plant in Michigan, initially chose magnetic coupling for a heavy-duty welding application. When forces exceeded 800N, the magnetic coupling began slipping. We replaced it with our Bepto mechanical coupling system, which has handled 1500N loads reliably for over 18 months. 🚗

Which Coupling Type Offers Better Reliability and Maintenance Benefits?

Maintenance requirements and reliability characteristics differ significantly between magnetic and mechanical coupling systems.

Magnetic coupling offers superior reliability with no wearing parts, leak-free operation, and maintenance-free performance for years, while mechanical coupling requires periodic seal replacement and slot cleaning but provides more predictable failure modes and easier field repair when maintenance is needed.

Bakım Gereklilikleri

Manyetik Kaplin Avantajları:

- Zero seal maintenance – completely enclosed system

- No wearing parts in the coupling mechanism

- Self-cleaning operation with no debris accumulation

- Uzun hizmet ömrü typically 5-10 years without maintenance

Mechanical Coupling Considerations:

- Periodic seal replacement every 12-24 months

- Slot cleaning required in dusty environments

- Wiper adjustment may be needed over time

- Predictable maintenance schedule allows planned downtime

Environmental Resistance

| Çevresel Faktör | Manyetik Kaplin | Mekanik Kaplin |

|---|---|---|

| Dust/Debris | Mükemmel | Good with proper sealing |

| Moisture/Washdown | Mükemmel | Fair, seals may leak |

| Kimyasal Maruziyet | Mükemmel | Depends on seal material |

| Sıcaklık Aralığı | Good (-20°C to +80°C) | Excellent (-40°C to +150°C) |

| Kirlenme | Immune | Susceptible through slot |

Arıza Modları

Magnetic coupling failures:

- Kademeli performans düşüşü as magnets weaken

- Sudden decoupling5 under overload conditions

- Difficult field diagnosis of magnetic field issues

- Complete unit replacement typically required

Mechanical coupling failures:

- Progressive seal wear with visible leakage

- Predictable wear patterns allow preventive maintenance

- Field-repairable with standard tools and parts

- Component-level replacement reduces costs

Cost of Ownership

While magnetic coupling has higher initial costs, total ownership costs often favor magnetic systems in clean, light-duty applications due to eliminated maintenance. Mechanical systems provide better value in high-force or harsh environment applications where their robustness justifies maintenance requirements.

When Should You Choose Magnetic vs. Mechanical Coupling for Your Application?

Selecting the optimal coupling technology requires careful consideration of application requirements, environmental conditions, and performance priorities.

Choose magnetic coupling for clean environments, light-duty applications under 500N, washdown requirements, maintenance-free operation priorities, and smooth motion needs, while selecting mechanical coupling for heavy-duty applications over 500N, harsh environments, high-precision positioning, side loading conditions, and applications requiring maximum force density.

Başvuru Kılavuzları

Magnetic Coupling Ideal Applications:

- Gıda ve içecek işleme

- İlaç üretimi

- Clean room environments

- Light assembly operations

- Packaging machinery (light products)

Mechanical Coupling Preferred Applications:

- Ağır imalat

- Otomotiv montajı

- Steel and metalworking

- High-precision machining

- Material handling (heavy loads)

Karar Matrisi

| Gereksinim | Magnetic Coupling Score | Mechanical Coupling Score |

|---|---|---|

| Force > 500N | ❌ Poor | ✅ Excellent |

| Leak-free operation | ✅ Excellent | ⚠️ Good |

| Bakım gerektirmez | ✅ Excellent | ❌ Poor |

| Yüksek hassasiyet | ⚠️ Good | ✅ Excellent |

| Sert ortam | ✅ Excellent | ⚠️ Fair |

| Maliyet duyarlılığı | ❌ Higher initial cost | ✅ Lower initial cost |

Bepto Solutions for Both Technologies

At Bepto, we offer both magnetic and mechanical coupling rodless cylinders to meet diverse application needs:

Magnetic Coupling Series: Our sealed magnetic systems provide maintenance-free operation with forces up to 500N, ideal for clean environments and washdown applications.

Mechanical Coupling Series: Our robust mechanical systems deliver forces up to 5000N with field-serviceable components, perfect for heavy-duty industrial applications.

Expert Application Support: Our engineering team helps customers select the optimal technology based on specific requirements, ensuring maximum performance and cost-effectiveness.

Tom, a maintenance supervisor at a chemical processing plant in Texas, was torn between technologies for a new conveyor system. After analyzing his 800N force requirements and corrosive environment, we recommended our Bepto mechanical coupling system with chemical-resistant seals. It’s been running trouble-free for 14 months in conditions that would challenge any system. 🏭

Sonuç

The choice between magnetic and mechanical coupling depends on force requirements, environmental conditions, and maintenance priorities, with each technology offering distinct advantages for specific applications.

FAQs About Rodless Cylinder Coupling Technologies

Q: What’s the maximum force available with magnetic coupling rodless cylinders?

Magnetic coupling systems are typically limited to 500N maximum force due to magnetic field strength limitations. For higher forces, mechanical coupling is the better choice.

Q: Do magnetic coupling cylinders require any maintenance?

Magnetic coupling systems are essentially maintenance-free with no seals to replace or wearing parts to service. They can operate for years without any maintenance requirements.

Q: Can mechanical coupling handle side loading better than magnetic coupling?

Yes, mechanical coupling systems handle side loading much better due to their direct physical connection and robust construction, while magnetic systems are sensitive to lateral forces.

Q: Which technology is better for washdown environments?

Magnetic coupling excels in washdown environments because it’s completely sealed with no external seals that can be compromised by high-pressure cleaning or chemicals.

Q: How do I know which Bepto rodless cylinder technology is right for my application?

Contact our technical team with your force requirements, environmental conditions, and performance needs. We’ll recommend the optimal coupling technology and provide detailed specifications for your specific application.

-

Learn about the IP (Ingress Protection) ratings that define equipment suitability for washdown and high-moisture environments. ↩

-

Discover what rare-earth magnets are, how they work, and why their high strength is essential for compact applications. ↩

-

Understand the definition of side loading (radial load) and how it can cause premature wear and failure in linear actuators. ↩

-

Explore the sources and effects of electromagnetic and magnetic field interference on sensitive components in industrial settings. ↩

-

Read about the process of magnetic decoupling, an inherent overload protection feature where the magnetic link breaks under excessive force. ↩