When your production line suddenly slows down, you might not immediately think about something as technical as port geometry. But here’s the reality: the shape and size of your pneumatic cylinder’s ports directly determine how quickly air flows in and out, affecting your entire operation’s speed and efficiency. 📈

Port geometry significantly impacts cylinder performance by controlling air flow rates during fill and exhaust cycles. Larger ports with optimized shapes can reduce cycle times by up to 40%, while poor port design creates bottlenecks that slow your entire system.

I recently worked with David, a production manager from a automotive parts facility in Michigan, whose assembly line was running 25% slower than expected. After analyzing his setup, we discovered that undersized exhaust ports were creating back-pressure, dramatically extending his cycle times.

İçindekiler

- How Does Port Size Affect Cylinder Speed?

- What Role Does Port Shape Play in Air Flow Dynamics?

- Why Do Exhaust Ports Matter More Than Fill Ports?

- How Can You Optimize Port Geometry for Maximum Performance?

How Does Port Size Affect Cylinder Speed? 🔧

Understanding port sizing is crucial for anyone serious about pneumatic system optimization.

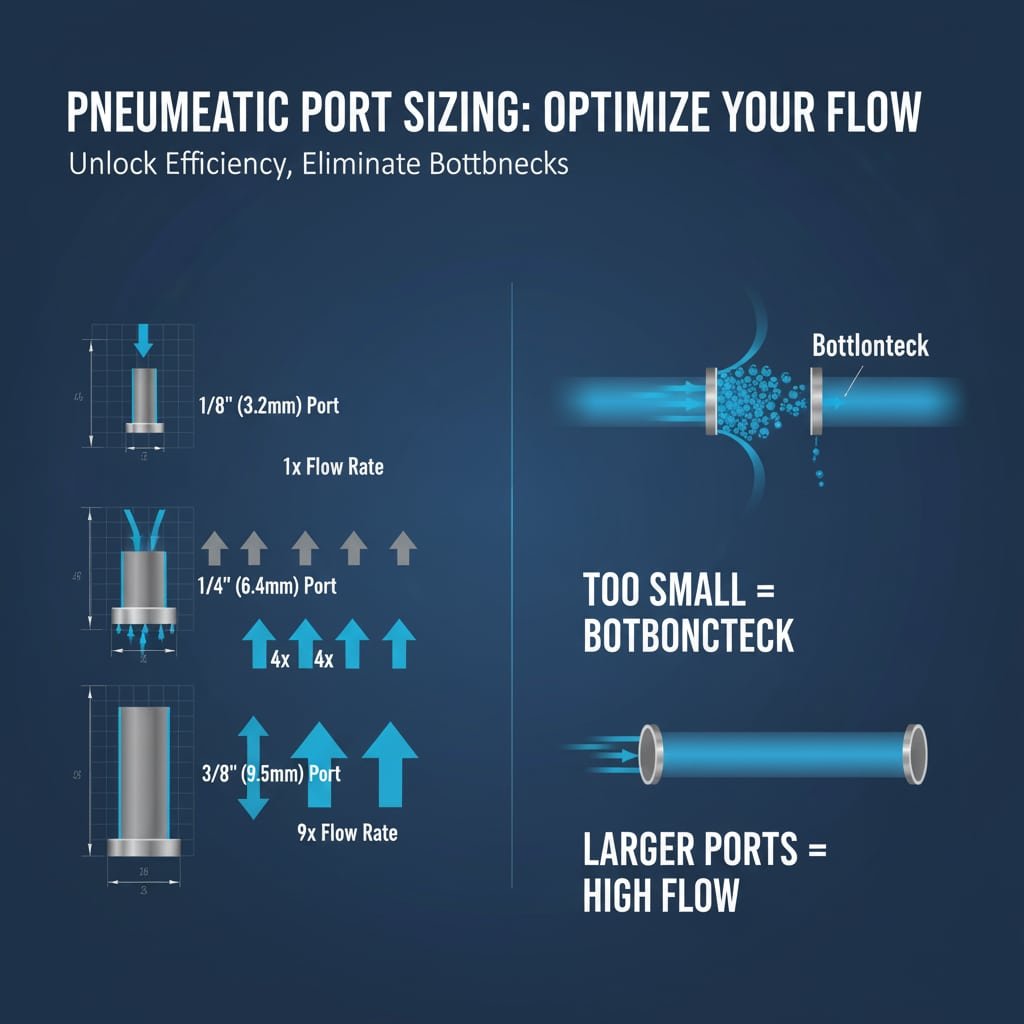

Larger ports allow higher flow rates, reducing fill and exhaust times proportionally. A port that’s too small creates a flow restriction that acts like a bottleneck, regardless of your air supply capacity.

The Physics Behind Port Sizing

The relationship between port diameter and flow rate follows basic fluid dynamics principles1. When air flows through a restriction, the flow rate is proportional to the cross-sectional area of the opening.

| Liman Çapı | Kesit Alanı | Relative Flow Rate |

|---|---|---|

| 1/8″ (3.2mm) | 0.0123 in² | 1x (taban çizgisi) |

| 1/4″ (6.4mm) | 0.0491 in² | 4x faster |

| 3/8″ (9.5mm) | 0.1104 in² | 9x faster |

Real-World Impact on Cycle Times

At Bepto, we’ve seen dramatic improvements when customers upgrade from standard 1/8″ ports to our optimized 1/4″ port designs. The difference isn’t just theoretical – it translates to measurable productivity gains.

What Role Does Port Shape Play in Air Flow Dynamics? 💨

Port shape is often overlooked, but it’s equally important as size for optimal performance.

Smooth, rounded port entrances reduce turbulence and basınç düşüşleri2 by up to 30% compared to sharp-edged ports. The internal geometry creates laminar flow patterns3 that maximize air velocity.

Comparing Port Geometries

Sharp-edged ports create vortices and turbulence as air enters, while chamfered or radiused entrances guide air smoothly into the cylinder. This seemingly small detail can significantly impact your system’s responsiveness.

The Venturi Effect in Cylinder Design

Our Bepto rodless cylinders incorporate venturi-shaped port transitions that actually accelerate air flow as it enters the cylinder chamber. This design principle, borrowed from aerospace engineering, ensures maximum fill rates even with modest air supply pressures.

Why Do Exhaust Ports Matter More Than Fill Ports? ⚡

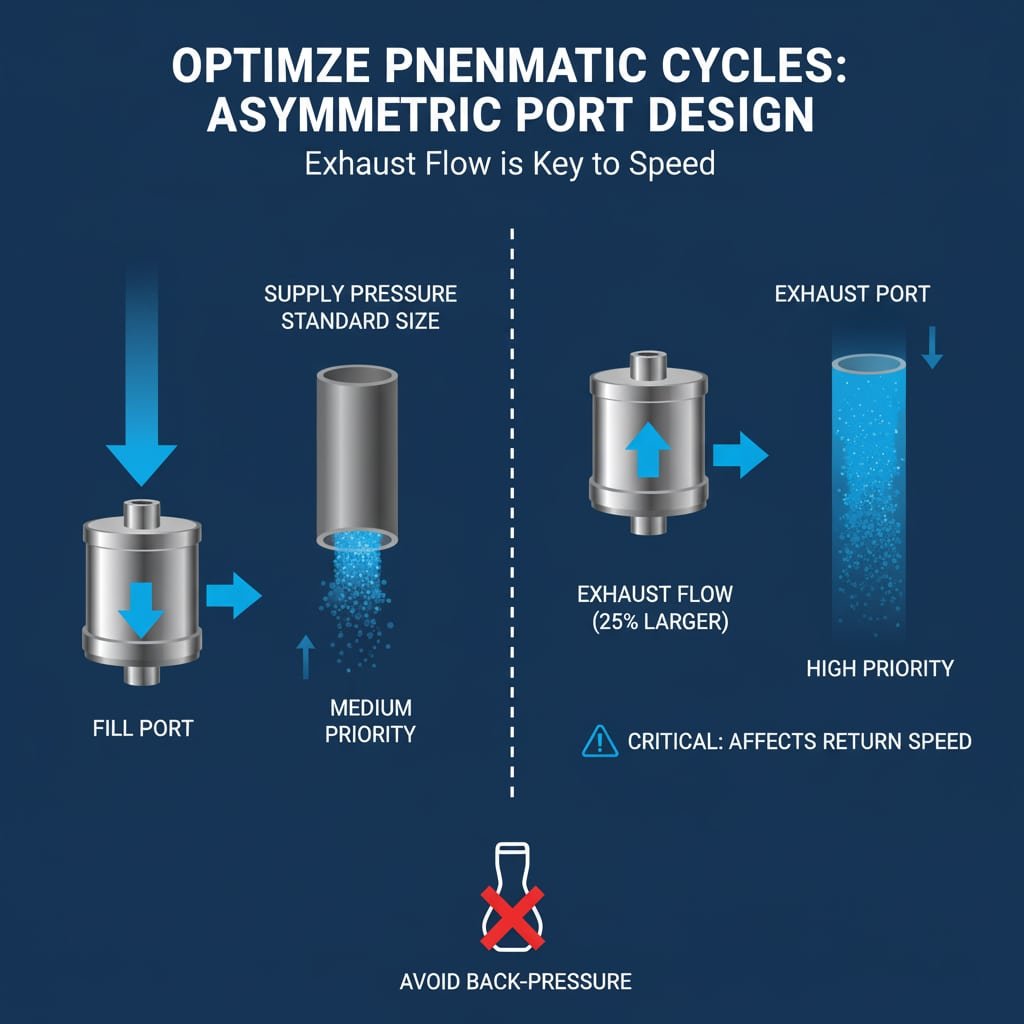

Most engineers focus on supply pressure, but exhaust flow often determines actual cycle speed.

Exhaust ports typically require 20-30% larger cross-sectional area than fill ports because compressed air must expand as it exits, requiring more space to maintain flow velocity.

The Back-Pressure Problem

Remember David from Michigan? His cylinders had adequate supply ports but undersized exhaust ports. The compressed air couldn’t escape quickly enough, creating geri basınç4 that slowed the return stroke dramatically.

Asymmetric Port Design Benefits

| Aspect | Fill Port | Exhaust Port | Sebep |

|---|---|---|---|

| Optimal Size | Standart | 25% larger | Air expansion during exhaust |

| Priority | Orta | Yüksek | Often the limiting factor |

| Basınç Düşüşü | Manageable | Kritik | Affects return speed |

How Can You Optimize Port Geometry for Maximum Performance? 🎯

Optimization requires balancing multiple factors specific to your application requirements.

The ideal port configuration depends on your cylinder bore size, operating pressure, and required cycle speed. Generally, exhaust ports should be 1.5x the diameter of supply ports, with smooth internal transitions.

Our Bepto Optimization Approach

When customers contact us for rodless cylinder replacements, we analyze their existing port geometry and recommend improvements. Our standard practice includes:

- Port sizing calculations based on bore diameter and pressure requirements

- Flow coefficient5 optimizasyon to minimize pressure drops

- Custom port machining when standard configurations don’t meet performance needs

Pratik Uygulama İpuçları

- Measure your current cycle times as a baseline

- Calculate required flow rates based on cylinder volume and target speed

- Size ports accordingly using proper flow equations

- Consider upgrading fittings to match optimized port sizes

Sarah, who manages a packaging facility in Ontario, saw her line speed increase by 35% simply by upgrading to our optimized port geometry – without changing any other system components.

Sonuç

Port geometry isn’t just a technical detail – it’s a critical factor that directly impacts your bottom line through cycle time optimization. 🚀

FAQs About Port Geometry and Cylinder Performance

Q: How much can proper port sizing improve my cycle times?

Optimized port geometry typically reduces cycle times by 25-40% compared to standard configurations. The exact improvement depends on your current setup and operating conditions, but the gains are usually substantial enough to justify the upgrade cost.

Q: Should I prioritize larger fill ports or exhaust ports?

Focus on exhaust ports first, as they’re typically the limiting factor in cycle speed. Exhaust ports should be approximately 25-30% larger than fill ports to accommodate air expansion during the exhaust stroke.

Q: Can I retrofit existing cylinders with better port geometry?

In most cases, yes. Our Bepto replacement cylinders are designed as direct drop-in replacements with optimized port configurations. We can often improve performance significantly without requiring any changes to your existing plumbing or mounting.

Q: What’s the relationship between operating pressure and optimal port size?

Higher operating pressures can partially compensate for smaller ports, but this approach wastes energy and creates unnecessary heat. It’s more efficient to optimize port geometry for your actual pressure range rather than over-pressurizing the system.

Q: How do I calculate the right port size for my application?

Port sizing involves calculating required flow rates based on cylinder volume, desired cycle time, and operating pressure. Contact our technical team at Bepto – we provide free port optimization analysis for potential rodless cylinder applications.

-

Learn about the fundamental physics of fluid dynamics and how they govern air flow and pressure in pneumatic systems. ↩

-

Understand what pressure drop is, how it’s caused by components, and why it reduces system efficiency. ↩

-

Explore the difference between smooth laminar flow and chaotic turbulent flow and its impact on air velocity. ↩

-

Read about the causes and effects of back-pressure, a resistance in the exhaust line that slows cylinder speed. ↩

-

Discover the concept of the Flow Coefficient (Cv), a standard rating of a component’s capacity to pass fluid. ↩