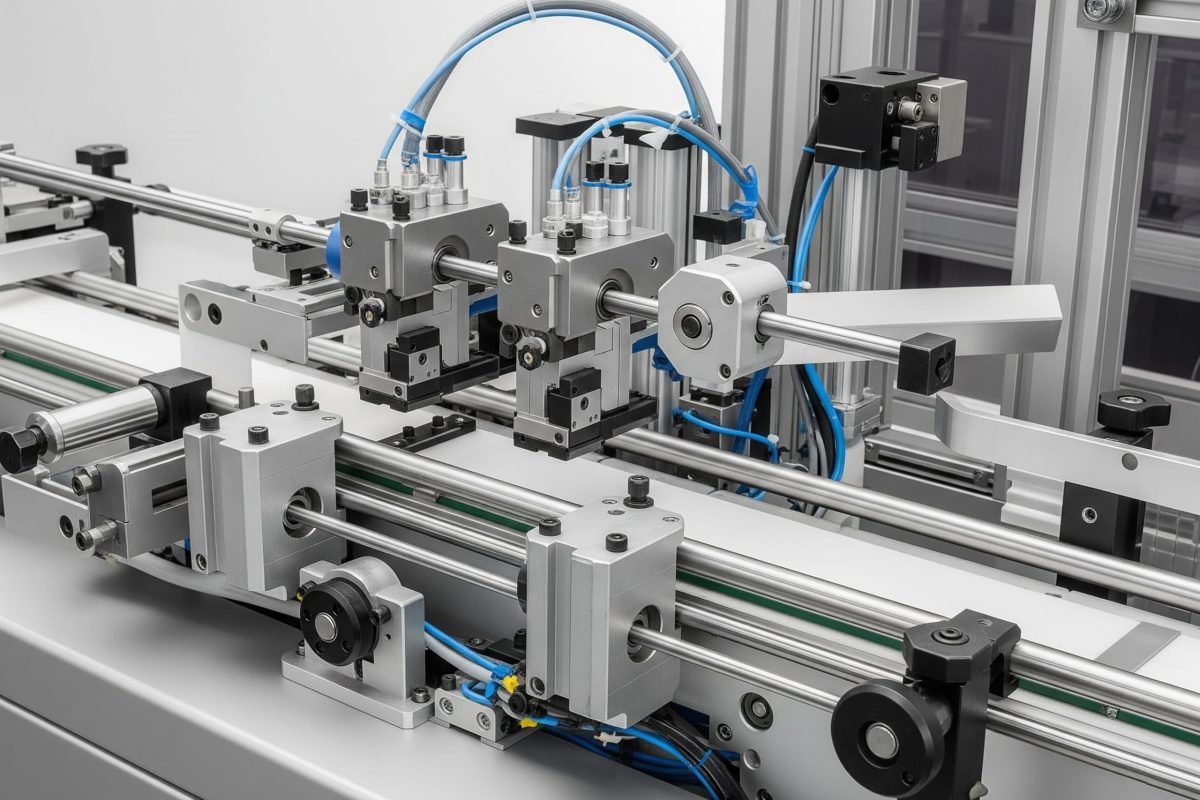

Kayar Silindirler | Hassas Doğrusal Hareket için Kararlı, Kılavuzlu Bir Platform Sağlar. Pnömatik bir aktüatör ile yüksek sertlikte bir kılavuz rayı tek bir kompakt ünitede birleştiren entegre kayar silindirlerimizi keşfedin. Yan yüklere ve momentlere karşı olağanüstü direnç sunarak alma ve yerleştirme, hafif işleme ve hassas konumlandırma görevleri için yüksek hassasiyetli, tekrarlanabilir hareket sağlarlar. Otomasyon ihtiyaçlarınız için ideal kayar tablayı şimdi bulun.

Projeniz için ürünlere mi ihtiyacınız var?

Kaynak bulmanın zor olabileceğinin farkındayız.

Formu özel öğelerinizle doldurun - benzersiz veya bulunması zor bileşenleri bile listelemekten çekinmeyin - sorgunuzu gönderin ve aradığınız tam olarak uyarlanmış çözümleri alın! Genel teklifleri unutun; ihtiyaçlarınızı tam olarak anlama ve size uygun sonuçlar sunma konusunda uzmanız

Mini silindir serimiz kompakt alanlar ve hafif uygulamalar için ustalıkla tasarlanmıştır. Küçük boyutları, hassas kontrolleri ve hızlı tepkileri ile elektronik, medikal ve küçük ölçekli otomasyon gibi endüstriler için ideal seçimdir ve daha hassas, daha verimli otomatik işlemler gerçekleştirmenize yardımcı olur.

Yerleşik lineer rulmanlar, bilyalı kılavuzlar veya kızak kılavuzları yüksek hassasiyet, sağlamlık ve hareket doğruluğu sağlar.

Sağlam kılavuz yapıları, önemli radyal yüklere ve momentlere dayanmalarını sağlayarak karmaşık kuvvetler altında kararlı çalışma sağlar.

Kompakt bir tasarım için silindir tahrik ünitesini ve kılavuz ünitesini mükemmel bir şekilde birleştirerek kurulum alanından tasarruf sağlar ve ekipman tasarımını ve montajını basitleştirir.

Seçilen yüksek kaliteli kılavuz malzemeler ve optimize edilmiş yapısal tasarım, yük altında kayar tablanın minimum deformasyonunu ve maksimum sertliğini sağlar.

Kılavuzların, taşıyıcıların, silindir gövdelerinin ve kılavuz ünitelerinin montaj hassasiyeti üzerindeki sıkı kontrol, hareket paralelliğini ve düzlüğünü garanti eder.

Çeşitli hızlar ve yükler altında darbe emme ihtiyaçlarına uyacak şekilde ayarlanabilir hava yastığı, hidrolik amortisörler veya kauçuk tamponlar sunar.

Standartlaştırılmış hava portları ve sensör montaj arayüzleri, çeşitli kontrol valfleri ve sensörlerle otomasyon sistemlerine kolay entegrasyonu kolaylaştırır.

Temel itme/çekme kuvvetini belirler, örn. Ø10, Ø16, Ø20, Ø25, Ø32, Ø40 mm.

Uygulama ihtiyaçlarına göre seçilen etkili hareket mesafesi; uzun stroklar özelleştirilebilir.

Kızak kılavuzu (örn. burç kılavuzu), yuvarlanma kılavuzu (örn. lineer yatak, bilyalı kılavuz).

Kayar tablanın eksenel ve radyal yük kapasitesi.

Kayar tablanın eğim, sapma ve yuvarlanma momentlerine dayanma kapasitesi.

Kayar tablanın hareketinin hassasiyetini ölçer.

Her iki uçta hava yastığı, kauçuk tamponlar veya harici hidrolik amortisörler.

Manyetik halka ve sensör montaj oluklarının mevcudiyeti.

Ayrıntılı parametreler için lütfen bireysel ürün kılavuzlarına veya tekni̇k uzmanlarimiza danişin.

Elektronik bileşenlerin ve küçük parçaların doğru hizalanması, preslenmesi ve sabitlenmesi.

Küçük malzemelerin hızlı ve hassas bir şekilde kavranması ve yerleştirilmesi için tutucular veya vantuzlarla birlikte kullanılır.

Dar alanlarda iş parçalarının kısa mesafeli, yüksek hassasiyetli taşınmasını ve konumlandırılmasını sağlar.

Boyutsal denetim, yüzey kontrolleri vb. işlemlerde hassas hareket için probların, sensörlerin veya optik lenslerin sürülmesi.

Baskı kafalarının ve etiketleme kollarının hassas konumlandırılması ve ileri geri hareketi için.

Numune işleme, sıvı işleme istasyonları, analitik cihazlar vb. alanlarda hassas hareket kontrolü için.

Doğru kurulum ve düzenli bakım, sürgülü silindirlerin uzun vadeli, yüksek hassasiyetli ve istikrarlı çalışmasının anahtarıdır.

Kayar silindirlerin ana avantajları entegrasyon ve kompaktlıklarında yatmaktadır:

Harici kılavuzlara sahip standart bir silindir benzer işlevleri yerine getirebilirken, sürgülü silindirler özellikle yüksek alan ve hassasiyet gereksinimleri olan uygulamalarda genellikle alan, kurulum kolaylığı ve genel performans açısından avantajlar sunar.

Bir kayar silindir seçerken yükün büyüklüğünü, yönünü ve uygulama noktasını dikkate almak çok önemlidir:

Özel çalışma koşullarınız için bu yük ve moment değerlerini hesaplamanız veya tahmin etmeniz gerekir. Ardından, ürün kataloğumuzdaki ilgili model için "İzin Verilebilir Yük ve Moment Tablosu "na bakın. Seçilen sürgülü silindir için izin verilen tüm değerlerin, uygun bir güvenlik marjı ile gerçek gereksinimlerinizden daha büyük olduğundan emin olun. Şüpheniz varsa, lütfen tekni̇k mühendi̇sleri̇mi̇ze danişin.

Kayar silindirlerin kılavuzlama hassasiyeti, kullanılan kılavuzun türüne, üretim hassasiyetine ve boyut özelliklerine bağlı olarak değişir. Genel olarak:

Spesifik hassasiyet parametreleri her modelin teknik özelliklerinde ayrıntılı olarak açıklanmıştır. Yüksek hassasiyetli uygulamalar için, yüksek dereceli yuvarlanma kılavuzlarına sahip kayar silindirlerin seçilmesi önerilir.

Evet, birçok sürgülü silindir dikey kurulumlarda kullanılabilir, ancak aşağıdakilere özellikle dikkat edilmelidir:

Kayar silindirleri dikey olarak monte ederken güvenlik çok önemlidir; her zaman yeterli koruyucu önlemleri uygulayın.

Kayar silindirin kılavuz parçasının yağlanması ve bakımı, hassasiyetini ve kullanım ömrünü sağlamak için çok önemlidir:

Her zaman ürün kılavuzundaki özel yağlama ve bakım talimatlarına uyun.

Kayar silindir serimiz, mükemmel kılavuzlama hassasiyeti, yüksek rijitliği ve kompakt yapısıyla otomasyon ekipmanınız için güvenilir doğrusal hareket desteği sağlar. Ürünlerimizi şimdi keşfedin veya profesyonel seçim tavsiyeleri ve özelleştirilmiş çözümler için pnömatik uzman ekibimizle iletişime geçin.

Tasarlama ve Geliştirme.

Pnömatik Mükemmelliği Tasarlıyoruz - Yenilikçi, Çok Yönlü, Güçlendirici.

Özel pnömatik uzmanlarımız birinci sınıf pnömatik ürünler sağlamaya odaklanır

sistemlerinizin optimum işlevselliğini sağlamak için.

Hakkında

Bize Ulaşın

Xuezhai Sanayi Bölgesi, Liushi Kasabası, Yueqing Şehri, Zhejiang Eyaleti, Çin

© 2025. Tüm Hakları Saklıdır.Powered by Bepto