Excessive cylinder deflection destroys seals, causes binding, and creates catastrophic failures that can injure operators and damage expensive equipment. Cylinder deflection in cantilevered mounts follows beam theory1 where deflection equals FL³/3EI – side loads and extended strokes create deflections that can exceed 5-10mm, causing seal failure and accuracy loss while generating dangerous stress concentrations at mounting points. Yesterday, I helped Carlos, a machine designer from Texas, whose 2-meter stroke cylinder suffered catastrophic seal failure due to 12mm deflection under load – our reinforced design with intermediate supports reduced deflection to 0.8mm and eliminated the failure mode. ⚠️

Зміст

- What Engineering Principles Govern Cylinder Deflection Behavior?

- How Do You Calculate Maximum Deflection for Your Mounting Configuration?

- Which Design Strategies Most Effectively Control Deflection Problems?

- Why Do Bepto’s Reinforced Cylinder Designs Deliver Superior Deflection Control?

What Engineering Principles Govern Cylinder Deflection Behavior?

Cylinder deflection follows fundamental beam mechanics with additional complexities from internal pressure and mounting constraints.

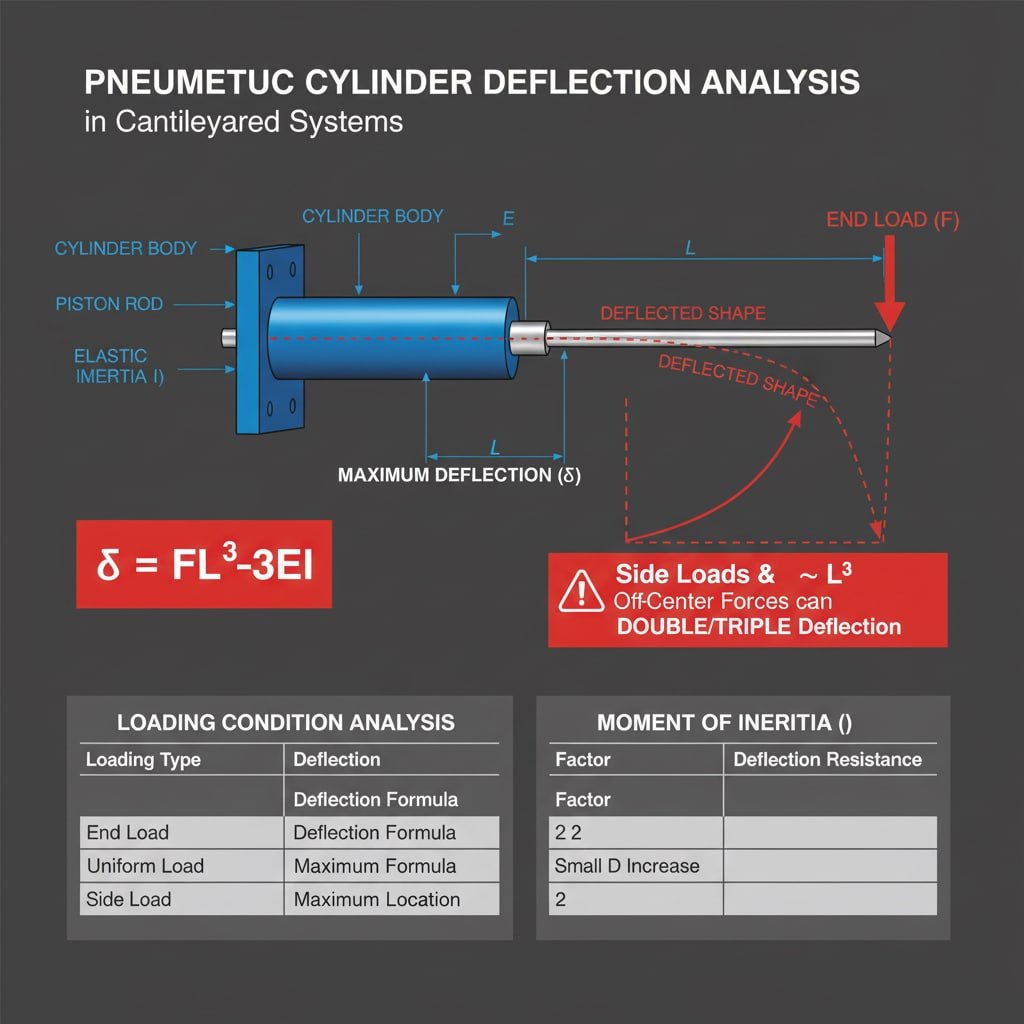

Cantilevered cylinders behave as loaded beams where deflection increases with the cube of length (L³) and inversely with момент інерції2 (I) – maximum deflection occurs at the rod end using δ = FL³/3EI, while side loads and off-center forces create additional bending moments that can double or triple total deflection.

Beam Theory Fundamentals

Cylinders mounted in cantilever configuration act as loaded beams with deflection governed by material properties, geometry, and loading conditions. The classic beam equation δ = FL³/3EI provides the foundation for deflection analysis.

Moment of Inertia Effects

For hollow cylinders: I = π(D⁴ – d⁴)/64, where D is outer diameter and d is inner diameter. Small increases in diameter create large improvements in deflection resistance due to the fourth-power relationship.

Loading Condition Analysis

| Loading Type | Deflection Formula | Maximum Location | Критичні фактори |

|---|---|---|---|

| End Load | FL³/3EI | Rod end | Stroke length, rod diameter |

| Uniform Load | 5wL⁴/384EI | Mid-span | Cylinder weight, stroke |

| Бічне навантаження | FL³/3EI | Rod end | Misalignment, mounting accuracy |

| Combined Load | Superposition3 | Змінна | Multiple force components |

Stress Concentration Factors

Mounting points experience Концентрація стресу4 that can exceed 3-5 times average stress levels. These concentrations create fatigue crack initiation sites and potential failure points.

Dynamic Effects

Operating cylinders experience dynamic loading from acceleration, deceleration, and vibration. These dynamic forces can amplify static deflection by 2-4 times depending on operating characteristics.

How Do You Calculate Maximum Deflection for Your Mounting Configuration?

Accurate deflection calculation requires systematic analysis of all loading conditions and geometric factors.

Deflection calculation uses δ = FL³/3EI for basic cantilever loading, where F includes axial force, side loads, and cylinder weight, L represents effective length from mount to load center, E is material modulus (200 GPa for steel), and I depends on rod diameter and hollow sections – safety factors of 2-3x account for dynamic effects and mounting compliance.

Force Analysis Components

Total loading includes:

- Axial cylinder force (primary load)

- Side loads from misalignment or off-center loading

- Cylinder weight (distributed load)

- Dynamic forces from acceleration/deceleration

- External loads from connected mechanisms

Effective Length Determination

Effective length depends on mounting configuration:

- Fixed-end mount: L = stroke length + rod extension

- Pivot mount: L = distance from pivot to load center

- Intermediate support: L = maximum unsupported span

Material Property Considerations

Standard values for steel cylinders:

- Modulus of Elasticity (E)5: 200 GPa

- Rod material: typically 1045 steel, chrome-plated

- Yield strength: 400-600 MPa depending on treatment

Приклад розрахунку

For a 100mm bore, 50mm rod, 1000mm stroke cylinder with 10,000N load:

Rod moment of inertia: I = πd⁴/64 = π(0.05)⁴/64 = 3.07 × 10⁻⁷ m⁴

Deflection: δ = FL³/3EI = (10,000 × 1³)/(3 × 200×10⁹ × 3.07×10⁻⁷) = 5.4 mm

This 5.4mm deflection would cause severe seal problems and accuracy loss!

Застосування коефіцієнта запасу міцності

Apply safety factors for:

- Dynamic amplification: 1.5-2.0x

- Mounting compliance: 1.2-1.5x

- Load variations: 1.2-1.3x

- Combined safety factor: 2.0-3.0x

Sarah, a design engineer from Michigan, discovered her 1.5m stroke cylinder had 8.2mm calculated deflection – explaining her chronic seal failures and 2mm positioning errors! 📐

Which Design Strategies Most Effectively Control Deflection Problems?

Multiple design approaches can significantly reduce cylinder deflection while maintaining functionality and cost-effectiveness.

Rod diameter increases provide the most effective deflection control due to fourth-power relationship with moment of inertia – increasing rod diameter from 40mm to 60mm reduces deflection by 5x, while intermediate supports, guided systems, and optimized mounting configurations provide additional deflection control options.

Оптимізація діаметра стрижня

Larger rod diameters dramatically improve deflection resistance. The fourth-power relationship means small diameter increases create large improvements in stiffness.

Rod Diameter Comparison

| Діаметр стрижня | Момент інерції | Deflection Ratio | Weight Increase | Вплив на витрати |

|---|---|---|---|---|

| 40 мм | 1.26 × 10⁻⁷ m⁴ | 1.0x (базова лінія) | 1.0x | 1.0x |

| 50 мм | 3.07 × 10⁻⁷ m⁴ | 0.41x | 1.56x | 1.2x |

| 60 мм | 6.36 × 10⁻⁷ m⁴ | 0.20x | 2.25x | 1.4x |

| 80 мм | 2.01 × 10⁻⁶ m⁴ | 0.063x | 4.0x | 1.8x |

Проміжні допоміжні системи

Intermediate supports reduce effective length and dramatically improve deflection performance. Linear bearings or guide bushings provide support while allowing axial motion.

Системи керованих циліндрів

External linear guides eliminate side loading and provide superior deflection control. These systems separate the guiding function from the actuating function for optimal performance.

Mounting Configuration Optimization

| Конфігурація | Deflection Control | Складність | Вартість | Найкращі програми |

|---|---|---|---|---|

| Basic Cantilever | Бідолаха. | Низький | Низький | Short strokes, light loads |

| Reinforced Rod | Добре. | Низький | Помірний | Medium strokes |

| Intermediate Support | Дуже добре. | Помірний | Помірний | Довгі штрихи |

| Guided System | Чудово. | Високий | Високий | Прецизійне застосування |

| Dual Rod | Чудово. | Помірний | Високий | Heavy side loads |

Alternative Cylinder Designs

Dual-rod cylinders eliminate cantilever loading by supporting both ends. Rodless cylinders use external carriages with integral guiding for superior deflection control.

Why Do Bepto’s Reinforced Cylinder Designs Deliver Superior Deflection Control?

Our engineered solutions combine optimized rod sizing, advanced materials, and integrated support systems for maximum deflection control.

Bepto’s reinforced cylinders feature oversized chrome-plated rods, optimized mounting systems, and optional intermediate supports that typically reduce deflection by 70-90% compared to standard designs – our engineering analysis ensures deflection remains below 0.5mm for critical applications while maintaining full performance specifications.

Advanced Rod Design

Our reinforced cylinders use oversized rods with optimized diameter-to-bore ratios that maximize stiffness while maintaining reasonable cost. Chrome plating provides wear resistance and corrosion protection.

Integrated Support Solutions

We offer complete systems including intermediate supports, linear guides, and mounting accessories designed specifically for deflection control. These integrated solutions provide optimal performance with simplified installation.

Engineering Analysis Services

Our technical team provides complete deflection analysis including:

- Detailed force and moment calculations

- Finite element analysis for complex loading

- Dynamic response analysis

- Mounting optimization recommendations

Порівняння продуктивності

| Особливість | Стандартний дизайн | Bepto Reinforced | Покращення |

|---|---|---|---|

| Діаметр стрижня | Standard sizing | Optimized oversizing | 2-4x larger moment of inertia |

| Deflection Control | Базовий | Розширений | 70-90% reduction |

| Варіанти кріплення | Обмежений | Всеохоплюючий | Complete system solutions |

| Analysis Support | Ні. | Complete FEA | Guaranteed performance |

| Термін служби | Стандартний | Розширений | 3-5x longer in deflection applications |

Матеріальні покращення

We use high-strength steel alloys with superior fatigue resistance for demanding applications. Special heat treatments and surface finishes provide enhanced durability under cyclic loading.

Забезпечення якості

Every reinforced cylinder undergoes deflection testing to verify calculated performance. We guarantee specified deflection limits with complete documentation and performance validation.

Приклади застосування

Recent projects include:

- 3-meter stroke packaging equipment (deflection reduced from 15mm to 1.2mm)

- Heavy-duty press applications (eliminated seal failures)

- Precision positioning systems (achieved ±0.1mm accuracy)

Tom, a maintenance manager from Ohio, eliminated monthly seal replacements by upgrading to our reinforced design – reducing deflection from 9mm to 0.7mm and saving $15,000 annually in maintenance costs! 💪

Висновок

Understanding and controlling cylinder deflection is critical for reliable operation in cantilevered applications, while Bepto’s reinforced designs provide superior deflection control with comprehensive engineering support for optimal performance.

FAQs About Cylinder Deflection and Control

Q: What deflection level is acceptable for pneumatic cylinders?

A: Generally, deflection should be limited to 0.5-1.0mm for most applications. Precision applications may require <0.2mm, while some heavy-duty applications can tolerate 2-3mm with appropriate seal selection.

Q: How does deflection affect cylinder seal life?

A: Excessive deflection creates side loading on seals, causing accelerated wear and premature failure. Deflection >2mm typically reduces seal life by 80-90% compared to properly supported installations.

Q: Can I calculate deflection for complex loading conditions?

A: Yes, but complex loading requires finite element analysis or superposition of multiple load cases. Our engineering team provides complete analysis services for complex applications.

Q: What’s the most cost-effective way to reduce deflection?

A: Rod diameter increases typically provide the best cost-to-performance ratio due to the fourth-power relationship. A 25% diameter increase can reduce deflection by 60-70%.

Q: Why choose Bepto’s reinforced cylinders over standard alternatives?

A: Our reinforced designs provide 70-90% deflection reduction, include comprehensive engineering analysis, offer integrated support solutions, and guarantee specified performance levels with extended service life in demanding applications.

-

Understand the fundamentals of Euler-Bernoulli beam theory, a cornerstone of engineering that describes how beams behave under bending loads. ↩

-

Explore the concept of Moment of Inertia, a geometric property that measures a cross-section’s resistance to bending or buckling. ↩

-

Learn about the principle of superposition, which states that for a linear system, the total effect of multiple loads is the sum of the effects of each load applied individually. ↩

-

Discover how stress concentrations occur at geometric discontinuities in a material, leading to localized high stresses that can initiate cracks and failure. ↩

-

Understand the Modulus of Elasticity (also known as Young’s Modulus), a fundamental property that measures a material’s stiffness or resistance to elastic deformation. ↩