préparation complète de l'air en 3 étapes pour une performance optimale du système. Faisant partie de la gamme XO, ces unités combinent la filtration (par exemple, 40µm), la régulation précise de la pression et la lubrification constante de l'huile (ISO VG32). Elles protègent les équipements pneumatiques en aval, améliorent l'efficacité et prolongent la durée de vie des composants dans diverses applications d'automatisation industrielle.

| Modèle | MINI | MIDI | MAXI | ||||||

| Vidange manuelle | Pression de travail:12bar,40μm | XOC-1/8-MINI | XOC-1/4-MINI | XOC-3/8-MINI | XOC-3/8-MIDI | XOC-1/2-MIDI | XOC-3/4-MIDI | XOC-3/4-MAXI | XOC-1-MAXI |

| Pression de travail : 7bar, 40μm | XOC-1/8-7-MINI | XOC-1/4-D-MINI | XOC-3/8-7-MINI | XOC-3/8-7-MIDI | XOC-1/2-7-MIDI | XOC-3/4-7-MIDI | XOC-3/4-7-MAXI | XOC-1-7-MAXI | |

| Pression de travail:12bar,5μm | XOC-1/8-5M-MINI | XOC-1/4-5M-MINI | XOC-3/8-5M-MINI | XOC-3/8-5M-MIDI | XOC-1/2-5M-MIDI | XOC-3/4-5M-MIDI | XOC-3/4-5M-MAXI | XOC-1-5M-MAXI | |

| Manomètre | 0~12bar | OMA-40-16-1/8 | OMA-50-16-1/4 | ||||||

| 0~7bar | OMA-40-10-1/8 | OMA-50-10-1/4 | |||||||

| Moyen | Air comprimé | ||||||||

| Caractéristiques de la structure | Filtre fritté avec séparateur d'eau;MINI/MIDI:MAXI:Régulateur à piston;Régulateur à membrane;Lubrificateur direct à densité constante | ||||||||

| Type de montage | Montage sur tube ou sur pied | ||||||||

| Position d'assemblage | Vertical ±5° | ||||||||

| Connexion | G1/8″ | G1/4″ | G3/8″ | G3/8″ | G1/2″ | G3/4″ | G3/4″ | G1″ | |

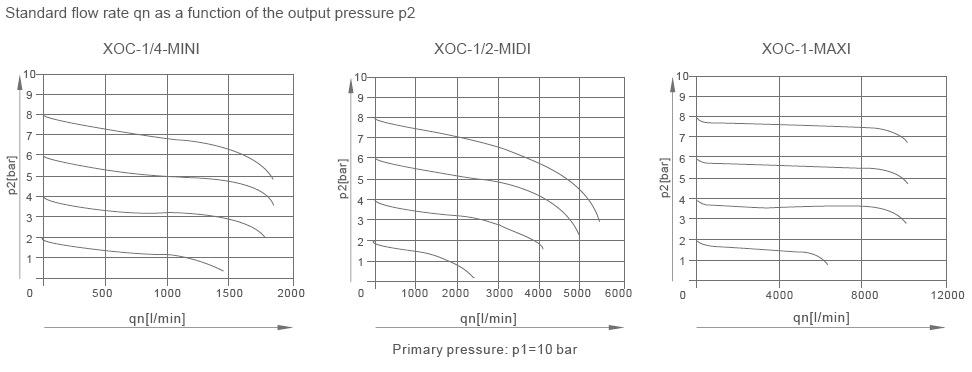

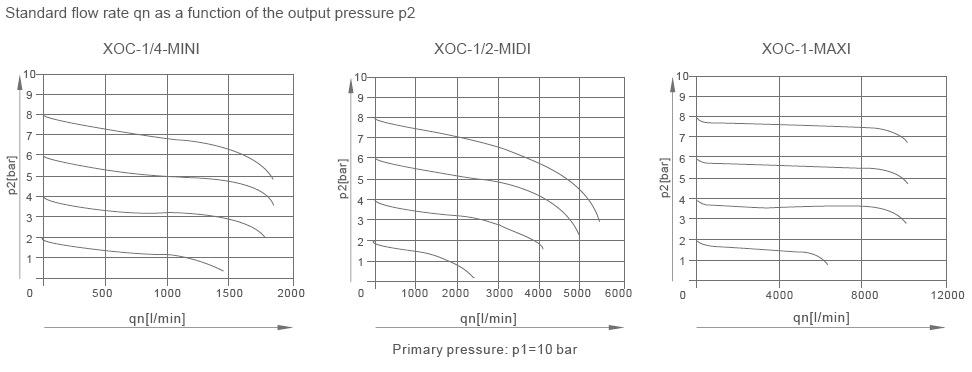

| Débit nominal standard | XOC-...(-A) | 700 | 1000 | 1200 | 2000 | 2600 | 2600 | 7000 | 8000 |

| XOC-...-7-(-A) | 800 | 1300 | 1500 | 2500 | 2800 | 2800 | 8500 | 8700 | |

| XOC-...-5M-(-A) | 600 | 850 | 1050 | 1700 | 1800 | 2100 | 6500 | 7200 | |

| Pression primaire | Purge manuelle du condensat | 1~16bar | |||||||

| Purge automatique des condensats | 1,5~12bar | ||||||||

| Pression de service | 0,5~12bar/0,5~7bar | ||||||||

| Min. Débit nominal standard | 3 L/min | 6 L/min | 10 L/min | ||||||

| Niveau de filtration | 40μm/5μm | ||||||||

| Capacité du liquide de condensation | 22ml | 43ml | 80ml | ||||||

| Plage de température | 0~60℃ | ||||||||

| Informations sur les matériaux | Boîtier:Zinc injecté;Bol de filtre et bol d'huile:PC;Protecteur de bol métallique:Alliage d'aluminium;Joint d'étanchéité:NBR;Bouton de réglage:POM | ||||||||

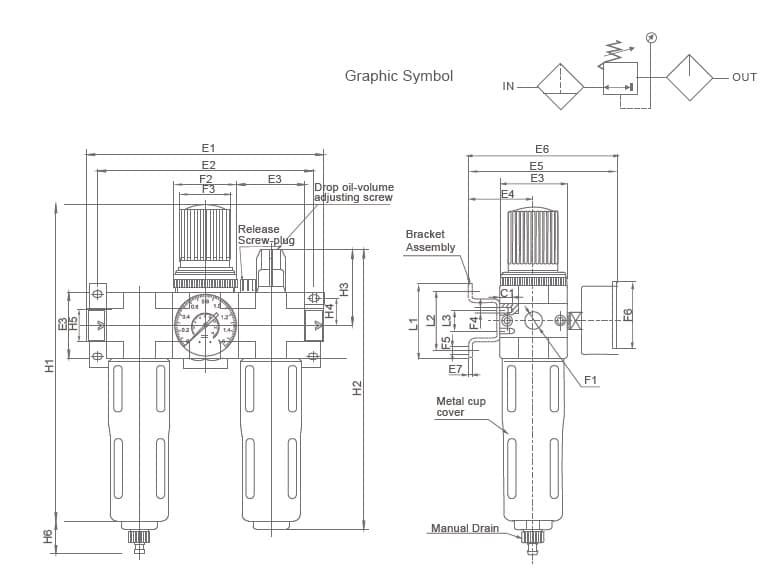

| Modèle | E1 | E2 | E3 | E4 | E5 | E6 | E7 | F1 | F2 |

| XOC-MINI | 143 | 132 | 40 | 39 | 76 | 95 | 2 | G1/8″,G1/4″,G3/8″ | M36x1,5 |

| XOC-MIDI | 193 | 180 | 55 | 47 | 93 | 112 | 3 | G3/8″, G1/2″, G3/4″ | M52x1,5 |

| XOC-MAXI | 247 | 220 | 66 | 53 | 104 | 124 | 3 | G3/4″,G1″ | M52x1,5 |

| Modèle | F3Ф | F4 | F5Ф | F6Ф | L1 | L2 | L3 | H1 | H2 | H3 | H4 | H5 | H6 |

| XOC-MINI | 31 | M4 | 4.5 | 41 | 44 | 35 | 11 | 194 | 169 | 69 | 17.5 | 20 | 15 |

| XOC-MIDI | 50 | M5 | 5.5 | 352 | 71 | 60 | 22 | 250 | 206 | 97 | 24.5 | 32 | 15 |

| XOC-MAXI | 50 | M5 | 5.5 | 53 | 71 | 60 | 22 | 272 | 226 | 80 | 24.5 | 32,40 | 15 |

Remarque : la couleur peut être personnalisée en fonction de vos besoins.

| Non | Nom | Matériau |

| 1 | Bride-IN | Alliage de zinc |

| 2 | Filtre + Régulateur | |

| 3 | Lubrificateur | |

| 4 | Bride - OUT | Alliage de zinc |

| 5 | Support | SPCC |

| 6 | Vis à tête cylindrique | S35C |

| 7 | Manomètre |

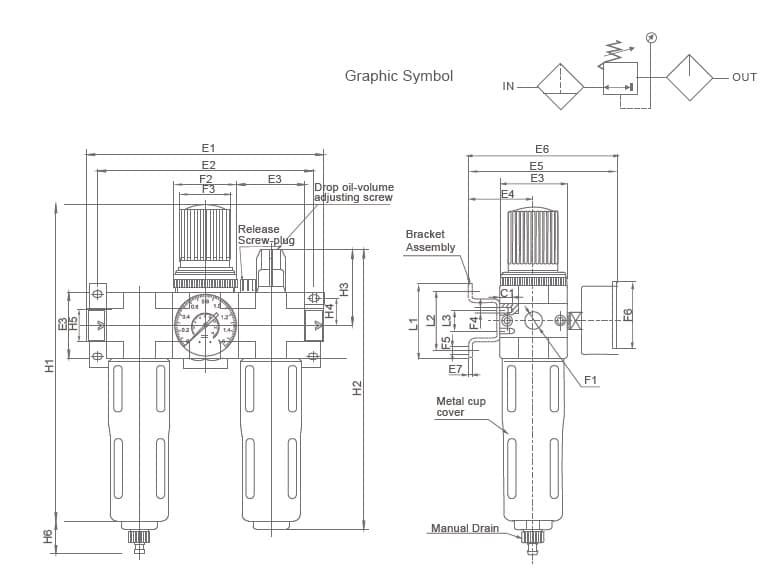

| Modèle | E1 | E2 | E3 | E4 | E5 | E6 | E7 | F1 | F2 |

| XOC-MINI | 143 | 132 | 40 | 39 | 76 | 95 | 2 | G1/8″,G1/4″,G3/8″ | M36x1,5 |

| XOC-MIDI | 193 | 180 | 55 | 47 | 93 | 112 | 3 | G3/8″, G1/2″, G3/4″ | M52x1,5 |

| XOC-MAXI | 247 | 220 | 66 | 53 | 104 | 124 | 3 | G3/4″,G1″ | M52x1,5 |

| Modèle | F3Ф | F4 | F5Ф | F6Ф | L1 | L2 | L3 | H1 | H2 | H3 | H4 | H5 | H6 |

| XOC-MINI | 31 | M4 | 4.5 | 41 | 44 | 35 | 11 | 194 | 169 | 69 | 17.5 | 20 | 15 |

| XOC-MIDI | 50 | M5 | 5.5 | 352 | 71 | 60 | 22 | 250 | 206 | 97 | 24.5 | 32 | 15 |

| XOC-MAXI | 50 | M5 | 5.5 | 53 | 71 | 60 | 22 | 272 | 226 | 80 | 24.5 | 32,40 | 15 |

Remarque : la couleur peut être personnalisée en fonction de vos besoins.

| Non | Nom | Matériau |

| 1 | Bride-IN | Alliage de zinc |

| 2 | Filtre + Régulateur | |

| 3 | Lubrificateur | |

| 4 | Bride - OUT | Alliage de zinc |

| 5 | Support | SPCC |

| 6 | Vis à tête cylindrique | S35C |

| 7 | Manomètre |