I cilindri standard forniscono un movimento lineare affidabile per l'automazione generale. Scoprite la nostra selezione completa di cilindri pneumatici standard, i cavalli di battaglia dell'automazione industriale. Costruiti per garantire affidabilità e versatilità, forniscono una forza di spinta/trazione costante per un'ampia gamma di applicazioni. Sono disponibili in vari stili di montaggio e alesaggi per adattarsi perfettamente ai requisiti del vostro sistema. Trovate subito il vostro cilindro ideale.

Avete bisogno di prodotti per il vostro progetto?

Sappiamo che l'approvvigionamento può essere impegnativo.

Compilate il modulo con i vostri articoli specifici (non esitate a elencare anche componenti unici o difficili da trovare), inviate la vostra richiesta e ottenete le soluzioni su misura che state cercando! Dimenticate le offerte generiche; siamo specializzati nel comprendere le vostre esatte esigenze e nel fornire risultati che calzano a pennello.

I cilindri senza stelo, grazie al loro esclusivo design strutturale, offrono vantaggi significativi in termini di risparmio di spazio di installazione e di realizzazione di movimenti a lunga corsa. Offriamo una varietà di tipi di cilindri senza stelo per soddisfare le diverse esigenze di automazione, contribuendo a migliorare le prestazioni del sistema e l'utilizzo dello spazio.

Progettati e prodotti rigorosamente secondo gli standard ISO e altri standard internazionali, assicurano l'universalità e l'intercambiabilità dei prodotti per una facile selezione e sostituzione.

Offriamo un'ampia scelta di misure di alesaggio, da piccole a grandi, e una ricca varietà di corse standard e personalizzate per soddisfare le diverse esigenze applicative.

Utilizzando guarnizioni di alta qualità e processi di lavorazione di precisione per garantire un funzionamento regolare del cilindro, una lunga durata e bassi tassi di guasto.

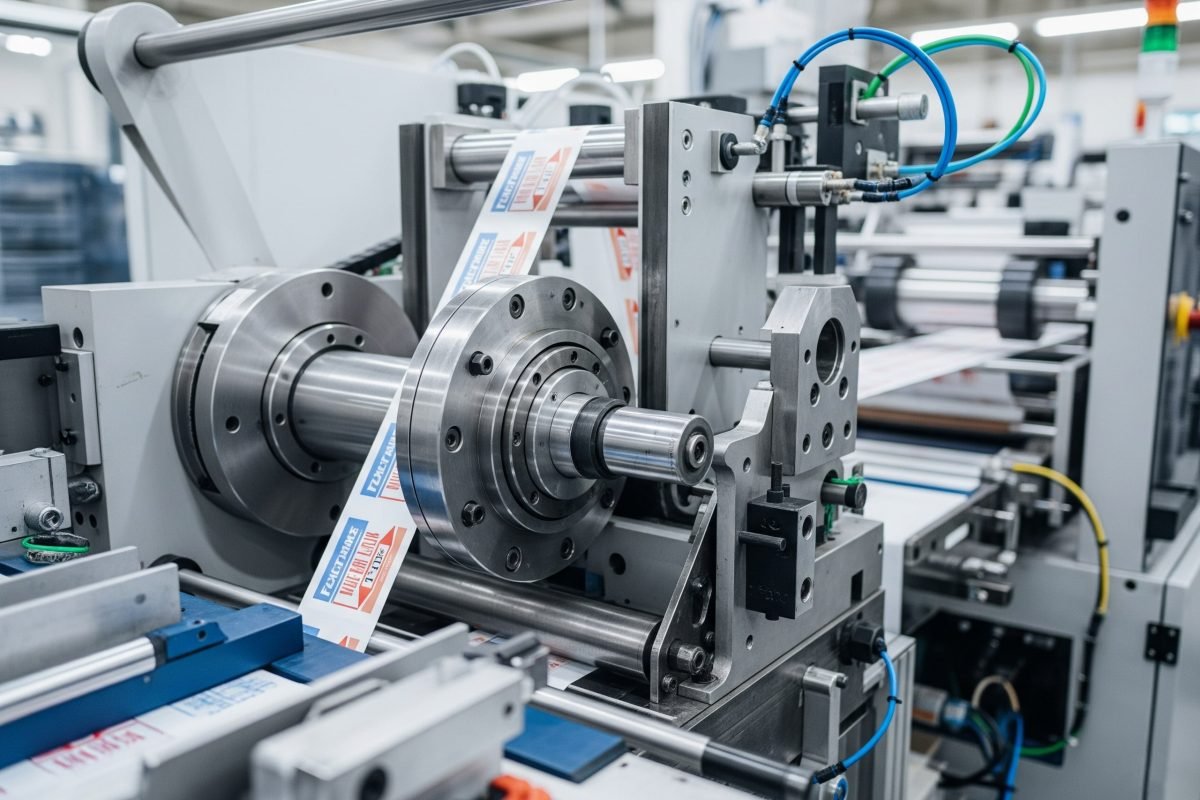

I cilindri standard sono generalmente costituiti da canna, pistone, stelo, tappi e guarnizioni. Il loro design maturo e il processo di produzione stabile li rendono uno degli attuatori pneumatici più utilizzati.

Utilizza guarnizioni a basso attrito e di lunga durata per ridurre la pressione di distacco, migliorare la velocità di risposta e prolungare la durata del cilindro.

Le boccole di guida dello stelo in alcuni modelli selezionati sono dotate di cuscinetti autolubrificanti, che riducono la necessità di manutenzione e garantiscono un funzionamento regolare a lungo termine.

Offrono ammortizzatori ad aria regolabili, paraurti in gomma fissi e altre opzioni per soddisfare le esigenze di assorbimento degli impatti a varie velocità e carichi.

Una gamma completa di accessori di montaggio standard, come staffe per i piedi, flange, ganci e clip a U, per un'installazione flessibile su varie apparecchiature.

Da Ø8 mm a Ø320 mm o più grandi, forza di uscita direttamente impattante.

Sono disponibili corse standard e corse non standard personalizzate su richiesta.

In genere 0,1~1,0 MPa; selezionare in base alla pressione effettiva della sorgente d'aria.

A doppio effetto (comune) o a semplice effetto (ritorno a molla/estensione).

Ammortizzazione ad aria regolabile su entrambe le estremità, paraurti in gomma o nessuna ammortizzazione.

Base, piede, flangia, clevis singola/doppia, trunnion centrale, ecc.

M5, G1/8, G1/4, G3/8, G1/2, ecc., in base alle dimensioni del foro.

Standard: -20℃~80℃; versioni ad alta/bassa temperatura personalizzabili.

Per i parametri dettagliati, fare riferimento ai manuali dei singoli prodotti o a consultate i nostri esperti tecnici.

Per varie azioni come spingere, tirare, sollevare, abbassare, bloccare e posizionare i pezzi.

Funzioni abilitanti come il trasporto dei materiali, l'etichettatura, la sigillatura degli astucci e la gestione della carta.

Servono come attuatori per i bracci robotici per eseguire movimenti di presa, manipolazione e altro.

Per il bloccaggio del pezzo, l'apertura/chiusura dello stampo, l'alimentazione degli utensili, ecc.

Utilizzati per il riempimento, lo smistamento e il trasporto (sono necessari modelli igienici).

Utilizzabile in quasi tutte le applicazioni che richiedono un movimento alternativo lineare.

L'installazione e la manutenzione corrette sono fondamentali per un funzionamento affidabile a lungo termine dei cilindri standard.

Per calcolare le dimensioni dell'alesaggio del cilindro si considerano in genere la forza di carico, la pressione di esercizio e il fattore di carico. La formula di base è:

Forza teorica in uscita dal cilindro (F) = Pressione (P) × Area effettiva del pistone (A)

Area effettiva del pistone (A) = π × (diametro dell'alesaggio D / 2)²

In pratica, la forza di uscita teorica dovrebbe essere superiore alla forza di carico. Spesso si considera un fattore di carico (ad esempio, 50%-70%), che significa F × Fattore di carico ≥ Carico effettivo. Per i cilindri a doppio effetto, l'area effettiva differisce per l'estensione e la ritrazione (l'area di ritrazione è ridotta dall'area dello stelo).

Si consiglia di fornire condizioni di carico dettagliate e pressione di esercizio, in modo che il nostro gli ingegneri tecnici possono assistere nella selezione.

Scopo: L'ammortizzazione del cilindro assorbe l'energia cinetica residua quando il pistone raggiunge la fine della corsa, riducendo l'impatto e la rumorosità, proteggendo il cilindro e l'attrezzatura e prolungando la vita utile. È particolarmente importante nelle applicazioni ad alta velocità o con carichi elevati.

Regolazione (per l'ammortizzazione regolabile):

La maggior parte delle nostre serie di cilindri standard supporta la personalizzazione di corse non standard. È possibile specificare l'esatta lunghezza della corsa richiesta per la propria applicazione.

Quando si personalizzano tratti non standard, tenere presente:

Per favore contattate il nostro team commerciale o tecnico con le vostre specifiche esigenze di corsa, valuteremo la fattibilità e vi forniremo una soluzione.

I cilindri standard, con materiali e design standard, sono adatti ad ambienti industriali generici. Per gli ambienti speciali, possiamo spesso fornire soluzioni personalizzate:

Al momento della richiesta, si prega di specificare le condizioni dell'ambiente operativo, in modo da poter consigliare o personalizzare i prodotti più adatti.

Quando si sceglie un interruttore magnetico per un cilindro standard, occorre considerare i seguenti punti:

È possibile consultare il catalogo degli accessori per cilindri o chiedete al nostro staff tecnico per le raccomandazioni di corrispondenza.

La nostra serie di cilindri standard, con la sua eccellente versatilità, affidabilità e convenienza, fornisce un supporto di potenza per diversi settori industriali. Esplorate subito i nostri prodotti o contattate il nostro team di esperti di pneumatica per una selezione professionale e un supporto tecnico.

Progettazione e sviluppo.

Progettiamo l'eccellenza pneumatica - innovativa, versatile, stimolante.

I nostri specialisti dedicati alla pneumatica si concentrano sulla fornitura di prodotti pneumatici di alta qualità.

per garantire la funzionalità ottimale dei vostri sistemi.

Circa

Contatto

Zona industriale Xuezhai, città di Liushi, Yueqing, provincia di Zhejiang, Cina

© 2025. Tutti i diritti riservati.Powered by Bepto