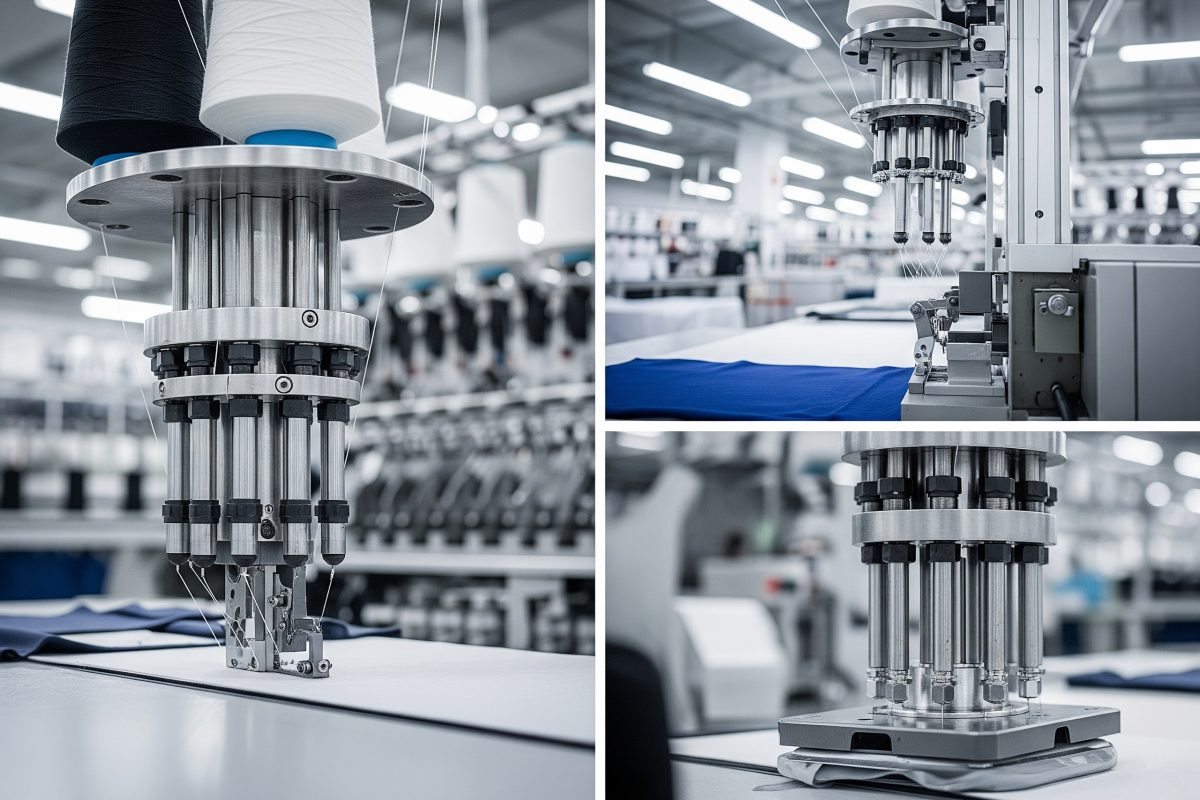

Mini Cylinders | Enable Precision Motion in Compact Spaces, Optimizing Small-Scale Designs. Explore our series of mini cylinders, engineered for applications where space is limited. Their lightweight, compact construction makes them the ideal actuators for high-precision tasks such as electronics assembly, medical devices, and fine-part handling, delivering excellent performance and reliability in the smallest of footprints. Find the right size for your application now.

Avete bisogno di prodotti per il vostro progetto?

Sappiamo che l'approvvigionamento può essere impegnativo.

Compilate il modulo con i vostri articoli specifici (non esitate a elencare anche componenti unici o difficili da trovare), inviate la vostra richiesta e ottenete le soluzioni su misura che state cercando! Dimenticate le offerte generiche; siamo specializzati nel comprendere le vostre esatte esigenze e nel fornire risultati che calzano a pennello.

Our mini cylinder series is expertly designed for compact spaces and lightweight applications. With their small size, precise control, and rapid response, they are the ideal choice for industries like electronics, medical, and small-scale automation, helping you achieve finer, more efficient automated operations.

Small bore sizes and a miniaturized overall design make them perfect for equipment and applications with extremely limited installation space.

Thanks to their small internal volume, air fills and exhausts quickly, giving mini cylinders excellent dynamic response characteristics and high operating frequencies.

High manufacturing precision enables accurate output of small strokes and forces, suitable for delicate and refined operational tasks.

Mini cylinders, often called pen cylinders or small cylinders, typically refer to cylinders with small bore sizes (e.g., from Ø4mm to around Ø25mm). They are the ideal choice for light loads, short strokes, and high-frequency operations.

Utilizing high-precision machining equipment and strict tolerance control to ensure dimensional accuracy and consistent operation.

Constructed with high-quality, wear-resistant materials for piston rods and seals, combined with optimized lubrication solutions to significantly extend service life.

Offering various derivative models such as guided, non-rotating, and double-rod versions to meet more complex application demands.

We provide fast and flexible customization services for special stroke lengths, mounting dimensions, or material requirements.

e.g., Ø4, Ø6, Ø8, Ø10, Ø12, Ø16, Ø20, Ø25 mm.

From a few millimeters to over a hundred, customizable.

Typically 0.1~0.7 MPa or 0.1~1.0 MPa.

Single-acting (spring return/extend), double-acting.

Usually elastic bumpers at both ends or no cushioning.

Small thread sizes like M3, M5, G1/8.

Optional magnetic piston for position sensing with magnetic switches.

Standard range, with high/low-temperature resistant versions customizable.

Per i parametri dettagliati, fare riferimento ai manuali dei singoli prodotti o a consultate i nostri esperti tecnici.

Chip pick-and-place, precision assembly of small components, test probe actuation, etc.

Sample handling, reagent dispensing, valve switching, small pump actuation, etc.

Desktop assembly machines, small sorting systems, educational lab equipment, etc.

For yarn switching, thread cutting, small pressing actions, and other delicate movements.

Auxiliary actions in packaging small items, labeling, sealing, etc.

Building small experimental platforms, robotic models, automated teaching demonstrations, etc.

Proper installation and adequate maintenance significantly extend the service life of mini cylinders.

Due to their small bore size, mini cylinders have a relatively small output force. For example, a Ø10mm mini cylinder at 0.5 MPa operating pressure has a theoretical output force (extending) of about 39 Newtons (approx. 4 kgf).

When selecting, calculate based on your actual load, motion type (push or pull), and required safety factor. It’s generally recommended that the cylinder’s theoretical output force be at least 1.5 to 2 times the actual load. For larger loads, consider cylinders with larger bores or other types of actuators.

Single-Acting Mini Cylinders: Have one air port; air pressure drives the piston in one direction, while a spring or external load returns it. Types include spring return (air extend, spring retract) and spring extend (air retract, spring extend).

Double-Acting Mini Cylinders: Have two air ports controlling both extension and retraction via air pressure.

Yes, due to their precise internal structure and small clearances, mini cylinders typically have higher air purity requirements than larger cylinders. Contaminants like moisture, oil, and dust in compressed air can easily cause valve spools to stick, seals to wear, or malfunctions.

Recommendations:

Clean air is key to the long-term, stable, and reliable operation of mini cylinders.

Standard mini cylinders (especially pen-type with round bodies) are primarily designed for axial loads. Due to their thin piston rods and limited guide length, their ability to withstand side loads or moments is very limited.

Significant side loads or moments can lead to:

For applications with side loads, it’s recommended to:

When selecting a magnetic switch for a mini cylinder, consider these points:

Due to size constraints, selecting and installing magnetic switches for mini cylinders can be more critical than for standard cylinders. Refer to our accessory selection guides or consult technical support.

Our mini cylinders, with their exceptional compactness, high precision, and rapid response, provide powerful support for your equipment miniaturization and performance enhancement. Explore our product series now, or contact our pneumatic expert team for professional selection advice and custom solutions.