Įvadas

Jūsų pneumatiniai cilindrai puikiai veikia esant pilnam slėgiui, tačiau, kai slėgis nukrinta žemiau 40 psi, jie staiga pradeda tekėti kaip sietai. Bandote įdiegti švelnaus paleidimo sekas arba kintamo slėgio kontrolę, tačiau standartinės sandarikliai tiesiog neišlaiko žemo slėgio. Jūsų procesas reikalauja švelnaus elgesio, tačiau cilindrai negali užtikrinti reikiamo tikslumo. Tai yra žemo slėgio sandariklių iššūkis. 🔧

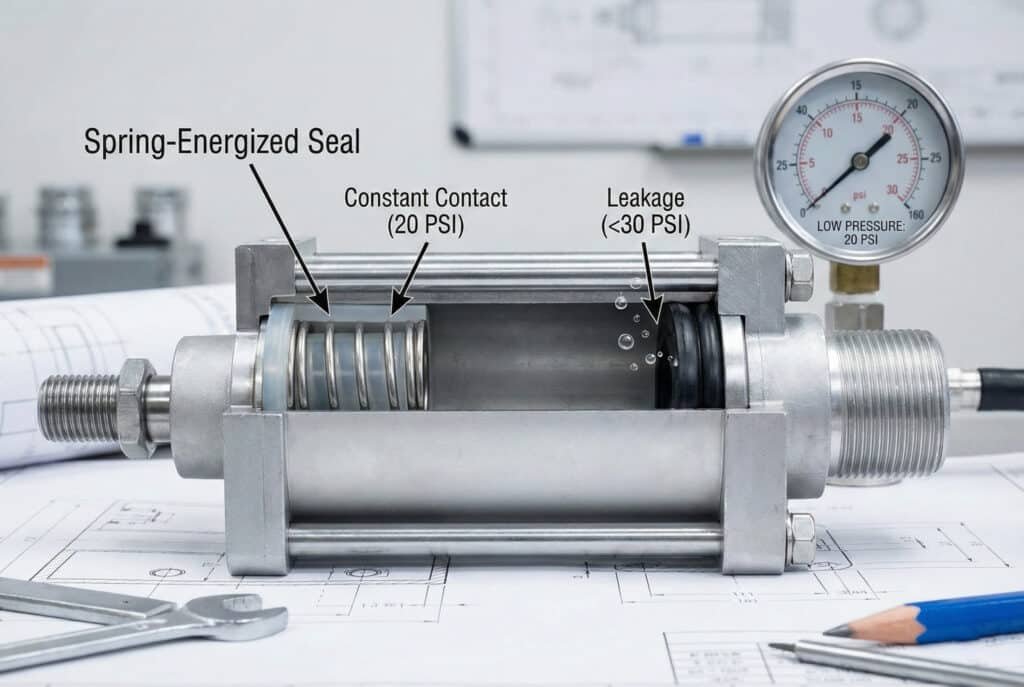

Pavaros spyruoklės sandarikliai išsprendžia žemo slėgio sandariklių gedimus, naudodami mechaninę spyruoklės jėgą, kad išlaikytų nuolatinį sandariklio kontaktą, nepriklausomai nuo sistemos slėgio. Nors standartiniai elastomeriniai sandarikliai visiškai priklauso nuo skysčio slėgio aktyvacijai ir gedžia esant mažesniam nei 30–40 psi slėgiui, pavaros spyruoklės konstrukcijos užtikrina patikimą sandarumą nuo vakuumo sąlygų iki 500+ psi, todėl jos idealiai tinka kintamo slėgio taikymams, minkšto paleidimo sistemoms ir procesams, kuriuose reikia švelniai elgtis su produktu.

Praėjusį ketvirtį dirbau su Marcusu, procesų inžinieriumi farmacijos tabletės dengimo gamykloje Masačusetse. Jo dengimo būgnai reikalavo tikslaus slėgio reguliavimo nuo 15 iki 80 psi, kad nebūtų pažeistos trapios tabletės, tačiau jo standartiniai cilindrų sandarikliai pernelyg praleisdavo slėgį šio intervalo apatiniame gale. Oro nuotėkis sukeldavo slėgio svyravimus, dėl kurių susidarydavo 8–12% dengimo defektų ir per mėnesį buvo atmesta daugiau nei $60 000 produktų. Jo OEM tiekėjas tvirtino, kad cilindrai atitinka specifikacijas, tačiau tai neišsprendė jo gamybos problemos. 💊

Turinys

- Kas yra spyruokliniai sandarikliai ir kaip jie veikia?

- Kodėl standartiniai sandarikliai neveikia esant žemam slėgiui?

- Kokios programos labiausiai naudoja spyruoklės energijos sandarinimo technologiją?

- Kaip pasirinkti ir įdiegti spyruoklinius sandariklius?

- Išvada

- Dažnai užduodami klausimai apie spyruoklinius sandariklius

Kas yra spyruokliniai sandarikliai ir kaip jie veikia?

Supratimas apie pagrindinius spyruoklinių sandariklių veikimo principus paaiškina, kodėl jie pranoksta standartinius modelius sudėtingose žemo slėgio sąlygose. ⚙️

Pavasario energija varomi sandarikliai jungia polimerinį sandarinimo elementą (paprastai PTFE1 arba poliuretano) su vidine metaline spyruokle, kuri užtikrina nuolatinę radialinę arba ašinę jėgą prieš sandarinimo paviršių. Spyruoklė išlaiko 2–5 psi ekvivalentinį kontaktinį slėgį nepriklausomai nuo sistemos slėgio, užtikrindama patikimą sandarinimą nuo visiško vakuumo (0 psi) per visą veikimo diapazoną, o mažos trinties polimerinis apvalkalas sumažina nusidėvėjimą ir pasipriešinimą.

Pagrindiniai dizaino komponentai

Pavasarinė energija varoma sandariklis susideda iš trijų svarbių elementų, kurie veikia harmoningai:

- Sandarinimo apvalkalas: PTFE, užpildytas PTFE arba poliuretano išorinis elementas, kuris liečiasi su sandarinimo paviršiumi

- Energizuojantis pavasaris: Nerūdijančio plieno ritė, konsolė2, arba V-spręžinė, užtikrinanti pastovią jėgą

- Plombos geometrija: Tiksliai apdirbtas profilis, optimizuotas šiai paskirčiai

Kaip veikia pavasario energizavimas

Skirtingai nuo slėgio aktyvuojamų sandariklių, kurie deformuojasi ir sukuria sandarinimo jėgą priklausomai nuo sistemos slėgio, spyruokliniai sandarikliai veikia mechaninio išankstinio įtempimo principu:

- Esant nuliui slėgiui: Tik spyruoklės jėga palaiko sandariklio kontaktą (paprastai 2–4 psi ekvivalentas)

- Esant žemam slėgiui (10–50 psi): Pavasario jėga ir minimalus slėgio aktyvavimas

- Esant aukštam slėgiui (50–500 psi): Kombinuotos spyruoklės ir slėgio jėgos užtikrina geresnį sandarumą

- Slėgio svyravimų metu: Pavasaris palaiko nuolatinį kontaktą, nepriklausomai nuo slėgio svyravimų.

Pavasario konfigūracijos tipai

| Pavasario tipas | Jėgos profilis | Geriausia paraiška | Slėgio diapazonas | Bepto prieinamumas |

|---|---|---|---|---|

| Sraigtinė ritė | Vienoda radialinė jėga | Bendrosios paskirties, stūmoklio sandarikliai | 0–300 psi | ✓ Standartinis |

| Konsolė | Kryptinė jėga | Strypų sandarikliai, vienkrypčiai sandarikliai | 0–200 psi | ✓ Standartinis |

| V-spręžinė | Didelė jėga, kompaktiškas | Erdvės ribotos taikomosios programos | 0–500 psi | ✓ Aukščiausios kokybės |

| Pasvirusi ritė | Kampinis jėgos vektorius | Kombinuotas radialinis/ašinis sandarinimas | 0–400 psi | ✓ Pasirinktinis |

Medžiagų deriniai

Apsauginės striukės medžiagos pasirinkimas lemia trintį, atsparumą nusidėvėjimui ir cheminį suderinamumą:

Virgin PTFE apvalkalai:

- Mažiausias trinties koeficientas (0,05–0,10)

- Puikus atsparumas cheminėms medžiagoms

- Temperatūros diapazonas: nuo -200 °C iki +260 °C

- Tinkamiausias: švarioms aplinkoms, didelės spartos taikymams

Pripildytos PTFE apvalkalai:

- Padidintas atsparumas dilimui (stiklo, anglies arba bronzos užpildai)

- Vidutinė trintis (0,08–0,15)

- Geresnis matmenų stabilumas

- Tinkamiausias: abrazyviniams sąlygoms, didelėms apkrovoms

Poliuretano striukės:

- Aukšta atsparumas dilimui

- Geras lankstumas esant žemai temperatūrai

- Temperatūros diapazonas: nuo -40 °C iki +100 °C

- Tinkamiausias: ekonomiškiems taikymams, vidutiniam slėgiui

„Bepto“ gamina spyruoklinius sandariklius iš visų trijų apvalkalo medžiagų, todėl galime optimizuoti jų veikimą pagal jūsų konkrečią be strypo cilindro taikymo sritį ir darbo sąlygas. 🎯

Kodėl standartiniai sandarikliai neveikia esant žemam slėgiui?

Slėgio aktyvuoto sandarinimo fizika atskleidžia pagrindinius apribojimus, kuriuos įveikia spyruoklinis energijos tiekimas. 📊

Standartinis elastomerinis3 sandarikliai (O-žiedai, U-taurės, V-pakavimo medžiagos) remiasi sistemos slėgiu, kad deformuotų sandariklio medžiagą ir sukurtų sandarinimo jėgą prieš jungiamuosius paviršius. Esant mažesniam nei 30–40 psi slėgiui, nepakankamas slėgis nesugeba įveikti sandariklio elastingumo pasipriešinimo, palikdamas tarpelius, pro kuriuos gali nutekėti oras. Šis nuo slėgio priklausomas sandarinimas sukuria “negyvos zonos”, kurioje neįmanoma užtikrinti patikimo sandarinimo naudojant įprastines konstrukcijas.

Slėgio aktyvinimo mechanizmas

Standartiniai pneumatiniai sandarikliai veikia pagal principą, vadinamą “slėgio aktyvacija”:

- Sistemos slėgis veikia ant plombos slėgiui veikiantį paviršių

- Hidraulinė jėga deformuoja elastomerą link sandarinimo paviršiaus

- Kontaktinis slėgis susidaro tarp sandariklio ir paviršiaus, sukurdamas sandariklį

- Sandarinimo efektyvumas yra tiesiogiai proporcingas sistemos slėgiui

Šis mechanizmas puikiai veikia esant įprastam darbinam slėgiui (60–150 psi), tačiau slėgiui mažėjant jo veikimas palaipsniui silpnėja.

Žemo slėgio gedimų zona

Štai kas atsitinka, kai slėgis sumažėja standartinių sandariklių konstrukcijose:

| Sistemos slėgis | Ruonių elgsena | Nuotėkio lygis | Veikimas |

|---|---|---|---|

| 100+ psi | Pilnas aktyvavimas, puikus sandarumas | <0,1 SCFM | Optimalus |

| 60–100 psi | Geras aktyvavimas, patikimas sandarumas | 0,1–0,3 SCFM | Geras |

| 40–60 psi | Dalinis aktyvavimas, ribinis sandarumas | 0,3–1,0 SCFM | Ribinis |

| 20–40 psi | Minimali aktyvacija, prastas sandarumas | 1,0–5,0 SCFM | Prastas |

| <20 psi | Nėra veiksmingos aktyvacijos | >5,0 SCFM | Nepavyko |

Realios pasekmės

Markuso farmacijos įmonėje Masačusetse mes išmatavome faktinius nuotėkio rodiklius visame jo slėgio diapazone:

- Esant 80 psi: 0.2 SCFM4 nutekėjimas (priimtinas)

- Esant 50 psi: 0,8 SCFM nuotėkis (ribinis)

- Esant 30 psi: 3,5 SCFM nuotėkis (sukeliantis slėgio nestabilumą)

- Esant 15 psi: 12+ SCFM nuotėkis (visiškas sandarumo gedimas)

Dėl šio per didelio nuotėkio esant žemam slėgiui buvo neįmanoma tiksliai reguliuoti slėgį, o tai tiesiogiai lėmė jo dangos defektus.

Papildomi žemo slėgio iššūkiai

Be paprasto nuotėkio, žemo slėgio veikimas sukelia daugybę problemų:

- Stick-slip5 judesys: Nenuoseklios atsiskyrimo jėgos sukelia trūkčiojantį judesį

- padėties nustatymo klaidos: Slėgio svyravimai trukdo tiksliai sustoti

- Didesnės oro sąnaudos: Kompresoriai veikia nuolat, kad kompensuotų nuotėkį.

- Sandariklio nusidėvėjimo pagreitis: Nepakankama tepimo plėvelė esant žemam slėgiui

- Sistemos nestabilumas: Slėgio grįžtamojo ryšio kilpos tampa nestabilios

Kodėl pavasario energizavimas išsprendžia šias problemas

Pavasario energija varomi sandarikliai pašalina slėgio priklausomybę, užtikrindami mechaninį išankstinį įtempimą:

Nuolatinė kontaktinė jėga: Pavasaris išlaiko 2–5 psi ekvivalentinį kontaktinį slėgį esant bet kokiam sistemos slėgiui, užtikrindamas patikimą sandarumą net esant nuliui slėgiui.

Nuo slėgio nepriklausomas veikimas: Sandarumo efektyvumas išlieka pastovus, nepriklausomai nuo to, ar sistemos slėgis yra 5 psi, ar 500 psi.

Sklandus judesys: Nuolatinė trintis esant bet kokiam slėgiui pašalina lipimo ir slydimo reiškinį ir užtikrina tikslų padėties nustatymą.

Kai įdiegėme „Bepto“ spyruoklinius PTFE sandariklius į „Marcus“ dengimo būgno cilindrus, nuotėkis esant 15 psi sumažėjo nuo 12 SCFM iki vos 0,15 SCFM – tai yra 98,75% sumažėjimas, kuris visiškai pašalino jo slėgio kontrolės problemas. 📉

Kokios programos labiausiai naudoja spyruoklės energijos sandarinimo technologiją?

Ne kiekvienam cilindrui reikalingos spyruoklės energija varomos sandarikliai, tačiau tam tikrais darbo profiliais jie yra akivaizdžiai geresnis pasirinkimas. 🎯

Pavaros energija varomi sandarikliai užtikrina maksimalią vertę kintamo slėgio sistemose (veikiančiose žemiau 50 psi), minkšto paleidimo taikymuose, kuriuose reikalingas laipsniškas pagreitis, vakuuminio arba beveik vakuuminio veikimo sąlygomis, tiksliose pozicionavimo sistemose su dažnais slėgio reguliavimais ir procesuose, kuriuose tvarkomi trapūs produktai, reikalaujantys švelnaus pneumatinio valdymo. Didžiausią naudą gauna maisto perdirbimo, farmacijos gamybos, elektronikos surinkimo ir medicinos prietaisų gamybos sektoriai.

Kintamo slėgio reguliavimo sistemos

Kai jūsų procesui reikalingas dinaminis slėgio reguliavimas, būtini spyruokliniai sandarikliai:

- Farmacinė danga: 10–80 psi diapazonas, skirtas delikačiam tablečių tvarkymui

- Maisto produktų pakuotės: 15–60 psi minkštų produktų tvarkymui

- Elektronikos surinkimas: 20–70 psi komponentų montavimui be pažeidimų

- Medicinos prietaisų gamyba: 5–50 psi steriliam, švelniam naudojimui

Lengvas paleidimas ir švelnus judesys

Tai ypač naudinga sistemoms, kurioms reikalingas sklandus pagreitis ir stabdymas:

- Išpilstymo linijos: Laipsniškas slėgio didėjimas apsaugo nuo produkto išsiliejimo

- Kepyklos automatizavimas: Švelnus elgesys su trapiomis kepiniais

- Kosmetikos pakuotės: Švelnus produkto perkėlimas be pažeidimų

- Puslaidininkių tvarkymas: Delikatiškų plokštelių vibracijos nesukeliantis padėties nustatymas

Vakuuminės ir beveik vakuuminės operacijos

Kai kurios specializuotos programos veikia vakuumo sąlygomis arba artimomis sąlygomis:

- Vakuuminis paėmimas ir padėjimas: Neigiamas slėgis komponentų tvarkymui

- Degazavimo sistemos: Aplinkos slėgio mažinimo apdorojimas

- Vakuuminis pakavimas: Sandarumo vientisumas oro evakuacijos metu

- Laboratorijų automatizavimas: Kontroliuojamos atmosferos kameros

Energijos vartojimo efektyvumo iniciatyvos

Neseniai konsultavausi su Sara, tvarumo inžiniere gėrimų išpilstymo gamykloje Oregone. Jos gamykla įgyvendino energijos taupymo iniciatyvas ir norėjo sumažinti darbinį slėgį nuo 90 psi iki 50 psi daugiau nei 200 cilindruose. Tačiau standartinės sandarikliai pernelyg praleisdavo sumažėjus slėgiui, todėl energijos taupymas buvo nereikšmingas.

Mes apskaičiavome, kad perėjimas prie spyruoklinių sandariklių:

- Užtikrinkite patikimą 50 psi veikimą (45% slėgio mažinimas)

- Sumažinti kompresoriaus energijos suvartojimą 38%

- Sutaupykite $127 000 per metus elektros energijos sąnaudų

- Pasiekite ROI vos per 14 mėnesių, nepaisant didesnių sandariklių išlaidų ⚡

Paraiškų atrankos matrica

| Prašymo charakteristika | Standartiniai sandarikliai | Pavasario energijos sandarikliai | Rekomendacija |

|---|---|---|---|

| Nuolatinis slėgis >80 psi | Puikus | Nereikalingas | Standartiniai sandarikliai |

| Kintamas slėgis 40–100 psi | Ribinis | Puikus | Pavasario energija |

| Žemas slėgis <40 psi | Prastas/Nepavykęs | Puikus | Reikalingas spyruoklinis energijos šaltinis |

| Vakuumas iki teigiamo slėgio | Nepavyko | Puikus | Reikalingas spyruoklinis energijos šaltinis |

| Didelis greitis, pastovus slėgis | Geras | Geras | Bet kuris (pagal sąnaudas) |

| Tikslus pozicionavimas | Prastas | Puikus | Pavasario energija |

| Delikatiškas produkto tvarkymas | Ribinis | Puikus | Pavasario energija |

Be strypo cilindro ypatybės

Be strypų cilindrai kelia unikalias problemas, kurias veiksmingai sprendžia spyruoklės energija varomos sandarikliai:

- Ilgi eilių ilgiai: Nuosekli sandarinimo jėga per visą eigą

- Išorinis vežimo sandarinimas: Svarbu vidaus slėgiui palaikyti

- Tikslus padėties nustatymas: Sklandi, nuosekli trintis užtikrina tikslumą

- Atsparumas užterštumui: PTFE apvalkalai atsparūs dalelių prilipimui

„Bepto“ maždaug 35% mūsų be strypo cilindrų sandariklių rinkinių dabar yra su spyruoklėmis, skirtos klientams, kuriems reikalingas kintamas slėgis arba tikslumas. Ši technologija yra pakankamai ištobulinta, kad būtų konkurencinga kainos atžvilgiu daugeliui pagrindinių taikymų. 💼

Kaip pasirinkti ir įdiegti spyruoklinius sandariklius?

Tinkamas pasirinkimas ir montavimas yra labai svarbūs norint pasiekti pranašumus, kuriuos siūlo spyruokliniai sandarikliai. 🔧

Renkantis spyruoklinius sandariklius, reikia suderinti spyruoklės jėgą su minimaliu darbinio slėgio dydžiu (paprastai minimali spyruoklės jėga yra 20–30%), pasirinkti apvalkalo medžiagą, atitinkančią trinties ir cheminių medžiagų reikalavimus, patikrinti griovelių matmenis (dažnai reikia 10–15% gilesnių griovelių nei standartiniams sandarikliams) ir patvirtinti temperatūrinį suderinamumą. Montuojant reikia atidžiai orientuoti spyruoklę, tinkamai sutepti ir vengti spyruoklės pažeidimų montuojant ant sriegių ar kraštų.

Atrankos kriterijų kontrolinis sąrašas

Sistemingai apdorokite šiuos parametrus:

1. Slėgio diapazonas:

- Minimalus darbinis slėgis: _____ psi

- Maksimalus darbinis slėgis: _____ psi

- Reikalinga spyruoklės jėga: 20-30% minimalaus slėgio

- Slėgio ciklų dažnis: _____ ciklų per valandą

2. Eksploatavimo sąlygos:

- Temperatūros diapazonas: nuo _____ iki _____ °C

- Skystosios medžiagos: Oro / Azoto / Kitos: _____

- Užterštumo lygis: Švarus / Vidutinis / Stiprus

- Tepimas: Taip / Ne / Tipas: _____

3. Veiklos reikalavimai:

- Priimtinas nuotėkio greitis: _____ SCFM

- Trinties apribojimai: Maži / Vidutiniai / Nekritiniai

- Ciklo trukmės tikslas: _____ milijonai ciklų

- Padėties nustatymo tikslumas: _____ mm

4. Fiziniai apribojimai:

- Strypo/angos skersmuo: _____ mm

- Esamas griovelio gylis: _____ mm

- Galimybė modifikuoti: Taip / Ne

- Erdvės apribojimai: _____

Groove matmenų reikalavimai

Pavasarinių energijos sandarikliai paprastai reikalauja modifikuotų griovelių matmenų:

| Sandariklio tipas | Standartinis griovelio gylis | Pavasario energija | Gylio padidinimas |

|---|---|---|---|

| Strypo sandariklis (40 mm) | 2,5 mm | 2,8–3,0 mm | +12-20% |

| Stūmoklio sandariklis (40 mm) | 3,0 mm | 3,3–3,5 mm | +10-17% |

| Valytuvo žiedas | 2,0 mm | 2,0 mm | Be pakeitimų |

Kritinis: Prieš užsakydami visada patikrinkite griovelių matmenis. „Bepto“ prie kiekvieno spyruokliniu mechanizmu varomo sandariklio komplekto pateikia išsamius griovelių specifikacijų brėžinius, kad būtų užtikrintas tinkamas montavimas.

Geriausia diegimo praktika

Pavasarį įkraunami sandarikliai reikalauja šiek tiek daugiau dėmesio montavimo metu nei standartiniai sandarikliai:

1 etapas: Pasirengimas

- Nuvalykite visas paviršius (neturi būti dalelių ar nešvarumų)

- Patikrinkite, ar griovelis nėra pažeistas, ar nėra atplaišų ar aštrių kraštų.

- Užtepkite tinkamą tepalą ant sandarinimo apvalkalo ir jungiamųjų paviršių.

- Patikrinkite spyruoklės orientaciją (žr. montavimo schemą).

2 etapas: Įdiegimas

- Naudokite sandarinimo įrengimo movas arba nuožulintus kraštus (privaloma)

- Niekada nenaudokite sandariklio ant sriegių ar aštrių kraštų.

- Apsaugokite spyruoklę nuo deformacijos montavimo metu

- Patikrinkite, ar sandariklis yra visiškai įdėtas į griovelį (vizualiai).

3 etapas: Patikrinimas

- Atlikite žemo slėgio sandarumo bandymą (10–20 psi).

- Ciklo cilindrą per visą eigą 5–10 kartų

- Patikrinkite, ar judesiai yra sklandūs, be trūkčiojimų.

- Atlikite visiško slėgio veikimo bandymą

Įprastos montavimo klaidos, kurių reikia vengti

Aš daugybę kartų mačiau, kaip šios klaidos sukelia ankstyvas gedimas:

❌ Montavimas be tinkamo tepimo: Montavimo metu sugadina striukę

❌ Priešingai nei aštrių sriegių atveju: Žala pavasarį arba plyšusi striukė

❌ Neteisinga spyruoklės orientacija: Sumažina sandarinimo efektyvumą 50%+

❌ Naudojant standartinius griovelius be patikrinimo: Sukelia nepakankamą suspaudimą

❌ Nesuderinamų tepalų maišymas: Sugadina PTFE arba poliuretano apvalkalus

„Bepto“ diegimo palaikymo privalumas

Užsisakydami spyruoklinius sandariklių rinkinius iš „Bepto“, gausite:

- Išsamios montavimo instrukcijos su diagramomis

- Groove matmenų patikrinimo brėžiniai

- Rekomenduojamos tepalų specifikacijos

- Techninės pagalbos karštoji linija, skirta klausimams apie diegimą

- Vaizdo įrengimo instrukcijos (galima rasti mūsų interneto svetainėje)

Marcus farmacijos įmonės poreikiams patenkinti, jo techninės priežiūros komandai surengėme montavimo mokymus vietoje, užtikrinant, kad visi 23 cilindrų sandariklių rinkiniai būtų sumontuoti tinkamai. Keturių valandų mokymai padėjo išvengti montavimo klaidų, kurios galėjo kainuoti tūkstančius dėl sugadintų sandariklių ir prastovų. 📚

Suderinamumas su esamais cilindrais

Geros naujienos: Daugelis standartinių cilindrų gali būti modifikuoti įrengiant spyruoklinius sandariklius, atlikus minimalias modifikacijas arba jų visai neatliekant. Mes tvarkome suderinamumo duomenų bazes:

- Parker be strypo cilindrai (OSP-P, OSP-E serijos)

- Festo be strypo cilindrai (DGC, DGPL serijos)

- SMC be strypo cilindrai (CY1, CY3 serijos)

- Norgren be strypo cilindrai (kelios serijos)

- Bepto cilindrai be strypų (visos serijos, optimizuotos grioveliai)

Susisiekite su mūsų technine komanda ir pateikite cilindro modelio numerį, o mes per 24 valandas patvirtinsime suderinamumą ir pateiksime modernizavimo specifikacijas. 🚀

Išvada

Pavaros energija varomos sandarikliai paverčia žemo slėgio pneumatinės įrangos naudojimą iš probleminio į patikimą, pašalinant standartinių sandariklių konstrukcijų priklausomybę nuo slėgio. Nesvarbu, ar įgyvendinate energiją taupančią slėgio mažinimo sistemą, ar jums reikalingas kintamo slėgio valdymas, ar tvarkote jautrius produktus švelniu pneumatinės įrangos judesiu, pavaros energija varoma technologija užtikrina nuoseklų sandarumo veikimą visame veikimo diapazone. „Bepto“ siūlo ekonomiškus spyruoklinius sandariklius ir techninę pagalbą, kad galėtumėte sėkmingai juos įdiegti savo bešarnyruose cilindruose ir pneumatinėse sistemose.

Dažnai užduodami klausimai apie spyruoklinius sandariklius

Kokiu slėgiu standartiniai sandarikliai paprastai pradeda gedti?

Standartiniai elastomeriniai sandarikliai pradeda smarkiai praleisti esant slėgiui žemiau 40 psi, o slėgiui mažėjant gedimas progresuoja, kol daugumoje konstrukcijų esant slėgiui žemiau 20 psi sandariklis visiškai nustoja sandarinti. Tiksli riba priklauso nuo sandariklio geometrijos, medžiagos kietumo ir suspaudimo santykio, tačiau dauguma inžinierių pastebi našumo sumažėjimą esant 30–40 psi diapazonui. Jei jūsų įrenginys veikia esant mažesniam nei 50 psi slėgiui, reikėtų rimtai apsvarstyti spyruoklinių sandariklių naudojimą.

Ar spyruoklės energija varomi sandarikliai yra brangesni už standartinius sandariklius?

Taip, spyruoklės energija varomi sandarikliai paprastai kainuoja 2,5–4 kartus daugiau nei lygiaverčiai standartiniai sandarikliai, tačiau jų tarnavimo laikas yra 3–5 kartus ilgesnis ir jie gali būti naudojami ten, kur standartiniai sandarikliai netinka. Pavyzdžiui, standartinis stūmoklio sandariklis gali kainuoti $8, o spyruokliniu mechanizmu varomas sandariklis – $28. Tačiau žemo slėgio sistemose spyruokliniu mechanizmu varomas sandariklis gali išsilaikyti daugiau nei 50 000 ciklų, o standartinis sandariklis – tik 10 000 ciklų, todėl bendros nuosavybės išlaidos yra mažesnės. Tikroji vertė yra tai, kad šie sandarikliai gali būti naudojami sistemose, kuriose standartiniai sandarikliai tiesiog neveikia.

Ar spyruoklės energija varomi sandarikliai gali atlaikyti tiek aukštą, tiek žemą slėgį?

Taip, kokybiški spyruokliniai sandarikliai puikiai veikia visame slėgio diapazone nuo vakuumo iki 300–500 psi, derindami spyruoklės jėgą esant žemam slėgiui su slėgio aktyvacija esant aukštam slėgiui. Pavasaris užtikrina bazinę sandarinimo jėgą, o sistemos slėgis didėja, pridedant papildomą jėgą. Dėl to spyruoklės varomos sandarikliai idealiai tinka kintamo slėgio taikymams. „Bepto“ spyruoklės varomi PTFE sandarikliai yra pritaikyti nuolatiniam darbui nuo visiško vakuumo iki 350 psi.

Ar spyruoklės energija varomi sandarikliai reikalauja specialios priežiūros ar keitimo procedūrų?

Ne, spyruoklės energija varomos sandarikliai nereikalauja jokios specialios priežiūros ir keičiami pagal standartines procedūras, tačiau montuojant reikia šiek tiek daugiau atsargumo, kad nebūtų pažeistas spyruoklės elementas. Pakeitimo intervalai paprastai yra 2–4 kartus ilgesni nei standartinių sandariklių, naudojamų lygiaverčiuose taikymuose. Svarbiausias techninės priežiūros aspektas yra suderinamų tepalų naudojimas – PTFE apvalkalai tinka praktiškai visiems pneumatinės sistemos tepalams, o poliuretano apvalkalams reikalingi angliavandenilių neturintys tepalai. Bepto pateikia išsamias techninės priežiūros specifikacijas su kiekvienu sandariklių rinkiniu.

Ar spyruoklės energija varomi sandarikliai veiks mano esamame cilindre be modifikacijų?

Apie 70% atvejais spyruoklės energija varomos sandarikliai gali būti pritaikyti esamiems cilindrams be modifikacijų, tačiau optimaliai veiklai gali prireikti 10–15% gilesnių griovelių. Suderinamumas priklauso nuo esamų griovelių matmenų ir konkrečios spyruoklės energija varomos sandariklio konstrukcijos. “Bepto” siūlo tiek “standartinius griovelių suderinamus” modelius, skirtus lengvai modernizuoti, tiek „optimizuotus griovelių“ modelius, skirtus maksimaliai našumui pasiekti. Pateikite savo cilindro specifikacijas, ir mes rekomenduosime geriausią sprendimą – dažnai galime tiekti modernizavimui suderinamus sandariklius, kurie užtikrina 80–90% našumo pranašumą be jokių modifikacijų.

-

Sužinokite apie politetrafluoretileno (PTFE) chemines savybes ir mažą trintį. ↩

-

Suprasti konsolinių spyruoklių mechaninius principus ir kaip jos taiko kryptinę jėgą. ↩

-

Išnagrinėkite elastomerų medžiagų mokslą ir jų viskoelastines savybes esant slėgiui. ↩

-

Perskaitykite standartinių kubinių pėdų per minutę (SCFM) kaip dujų srauto matavimo vieneto apibrėžimą. ↩

-

Atraskite fizikos dėsnius, lemiančius slydimo-trinties judesį (trintį), ir jo įtaką tikslumui. ↩