Double Rod Cylinders | Deliver Double Thrust & High Anti-Rotation for Stable Linear Motion. Explore our series of double rod cylinders. Their dual-piston-rod design not only delivers twice the output force of a standard cylinder but also offers excellent resistance to side-loads and rotation. This makes them the ideal choice for lifting, pressing, and positioning applications that demand high precision and stability. Select the right model for your precision application now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

Discover the enhanced stability and non-rotating precision of our double rod cylinders. Designed for applications requiring balanced force output and resistance to side loads, these cylinders offer superior performance and reliability for your demanding automation tasks.

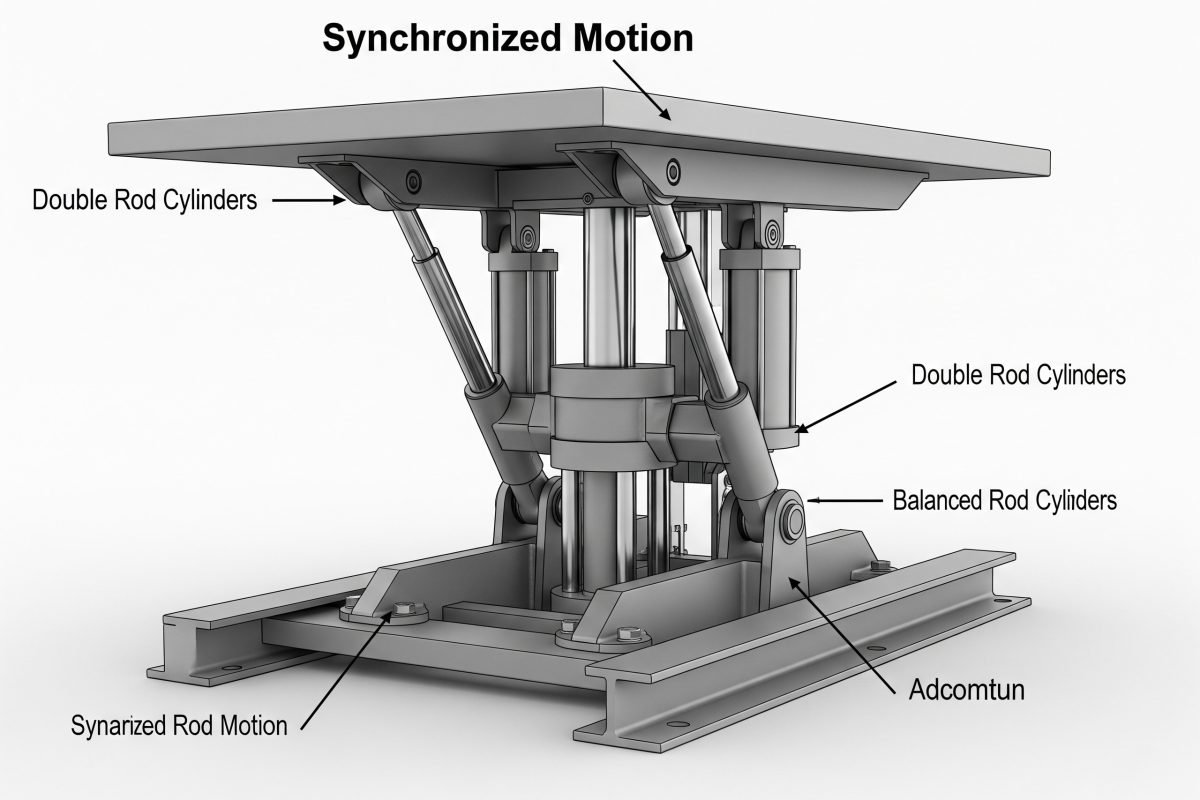

With piston rods extending from both ends, these cylinders provide equal force and speed in both directions of travel, ideal for push-pull applications.

The dual rod design inherently prevents piston rod rotation, ensuring accurate alignment and positioning for tasks requiring non-rotational movement.

Offers increased resistance to side loads and bending moments compared to single rod cylinders, leading to greater stability and longer service life.

Double rod cylinders feature a single piston with two piston rods extending in opposite directions from the cylinder body. This design provides inherent stability and allows for work to be performed at both ends simultaneously or alternately.

High-tensile strength piston rods with hard chrome plating for superior wear resistance and smooth operation.

Utilizing advanced sealing materials and design to minimize friction, prevent leakage, and ensure extended operational life.

Some series offer integrated guide bushings or options for external guides to further enhance stability against side loads and moments.

We offer customization for stroke length, mounting styles, and materials to meet specific application requirements.

Determines the cylinder’s output force.

The travel distance of the piston rods.

The range of air pressure the cylinder is designed for.

Various options like basic, foot, flange, clevis.

Thread type and dimensions for load attachment.

Adjustable air cushioning or fixed bumpers.

The degree to which rod rotation is prevented.

For use with position sensors (magnetic switches).

For detailed parameters, please refer to individual product manuals or consult our technical experts.

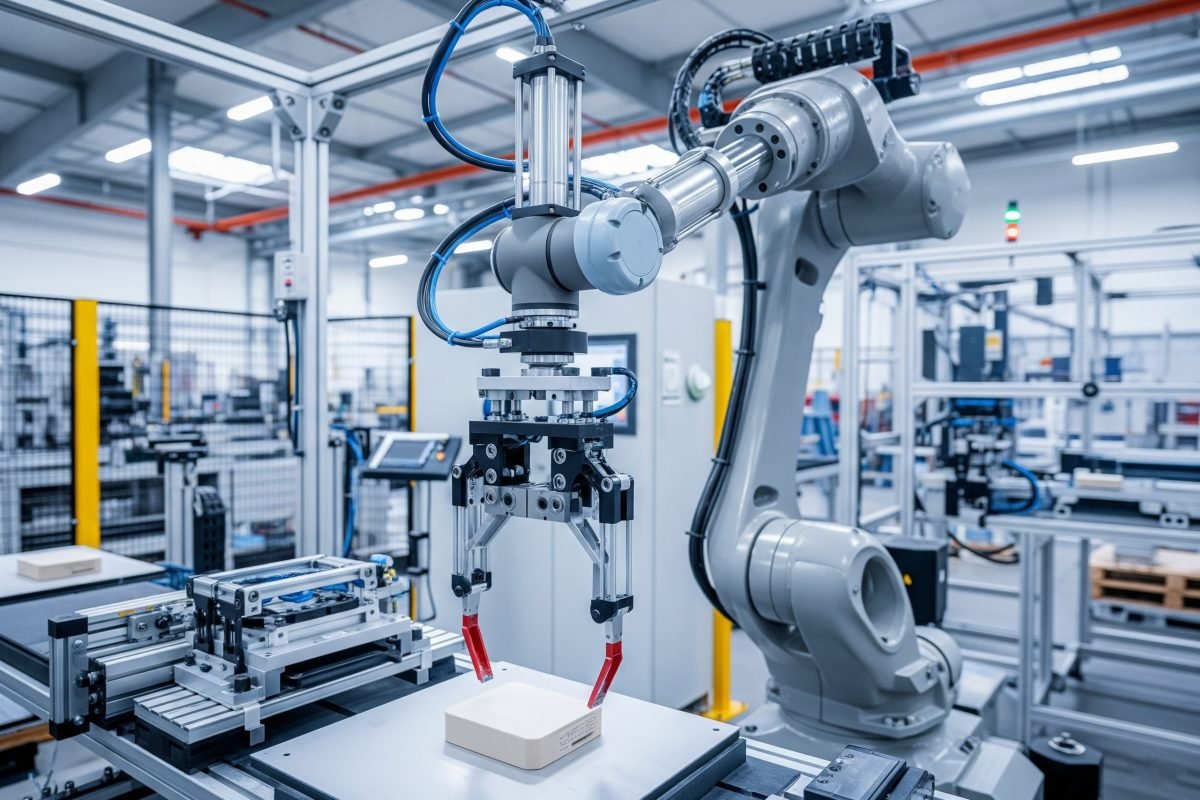

Providing stable, non-rotating linear motion for robotic arms and material handling systems.

Used for diverting, stopping, or positioning items on conveyor belts with enhanced stability.

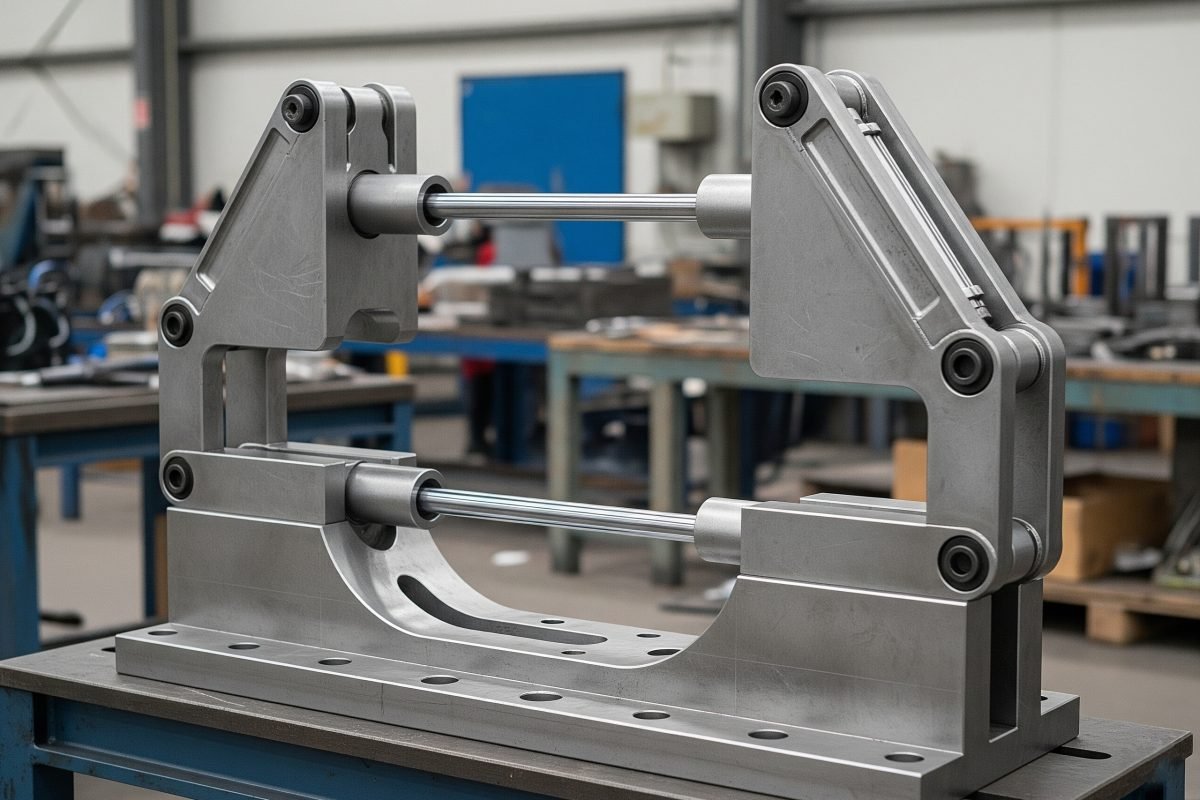

Offering balanced clamping force from two sides, ideal for securing workpieces during machining or assembly.

Providing smooth and controlled motion for opening and closing automated doors, gates, or hatches.

Ensuring precise, non-rotating movement for applicator heads or print heads.

Where two points need to be actuated simultaneously with balanced force, e.g., lifting platforms.

Adhering to proper installation and maintenance practices will maximize the performance and lifespan of your double rod cylinders.

Choose a double rod cylinder when your application requires one or more of the following:

Not exactly. A double rod cylinder has a single piston. The force output is determined by the air pressure acting on the area of this piston.

Since both rods are typically the same diameter, the effective area for extension and retraction is very similar, leading to balanced forces. However, it doesn’t provide “twice the force” of a single rod cylinder of the same bore size. The primary benefit is not doubled force, but rather balanced force, non-rotation, and improved stability.

The stroke length for a double rod cylinder is defined as the total distance the piston travels from one extreme end position to the other. This means it’s the distance one rod end moves relative to the cylinder body when the piston moves fully from one end cap to the other.

It’s important to note that because there are rods extending from both ends, the overall length of the cylinder assembly (body + fully extended rods) will be greater than a single rod cylinder with the same stroke. However, the “working envelope” or the space required for the moving parts might be different depending on how the load is attached and where the cylinder body is fixed.

Controlling double rod cylinders is generally similar to controlling standard double-acting single rod cylinders. You would typically use a 5-port, 2-position (5/2) or 5-port, 3-position (5/3) directional control valve.

Key considerations include:

Standard double rod cylinders typically feature piston rods of the same diameter and equal extension from the center of the piston to achieve balanced performance. This is the most common configuration.

However, for specific applications, customized versions might be possible, though less common:

If you have such a unique requirement, it’s best to discuss it with our engineering team. We can explore the feasibility and potential design implications for a custom solution.

Our double rod cylinders deliver enhanced stability, non-rotating accuracy, and versatile performance for your automation challenges. Explore our range or connect with our pneumatic specialists for expert advice and tailored solutions.