Rodless Cylinders | Save Installation Space & Achieve Long-Stroke Linear Actuation. Explore our rodless cylinders, specially designed for compact spaces and long-stroke applications. Their unique rod-free design maximizes space efficiency and eliminates the piston rod buckling risk associated with traditional cylinders, making them ideal for gantry systems, material handling, and automated production lines. Find your model now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

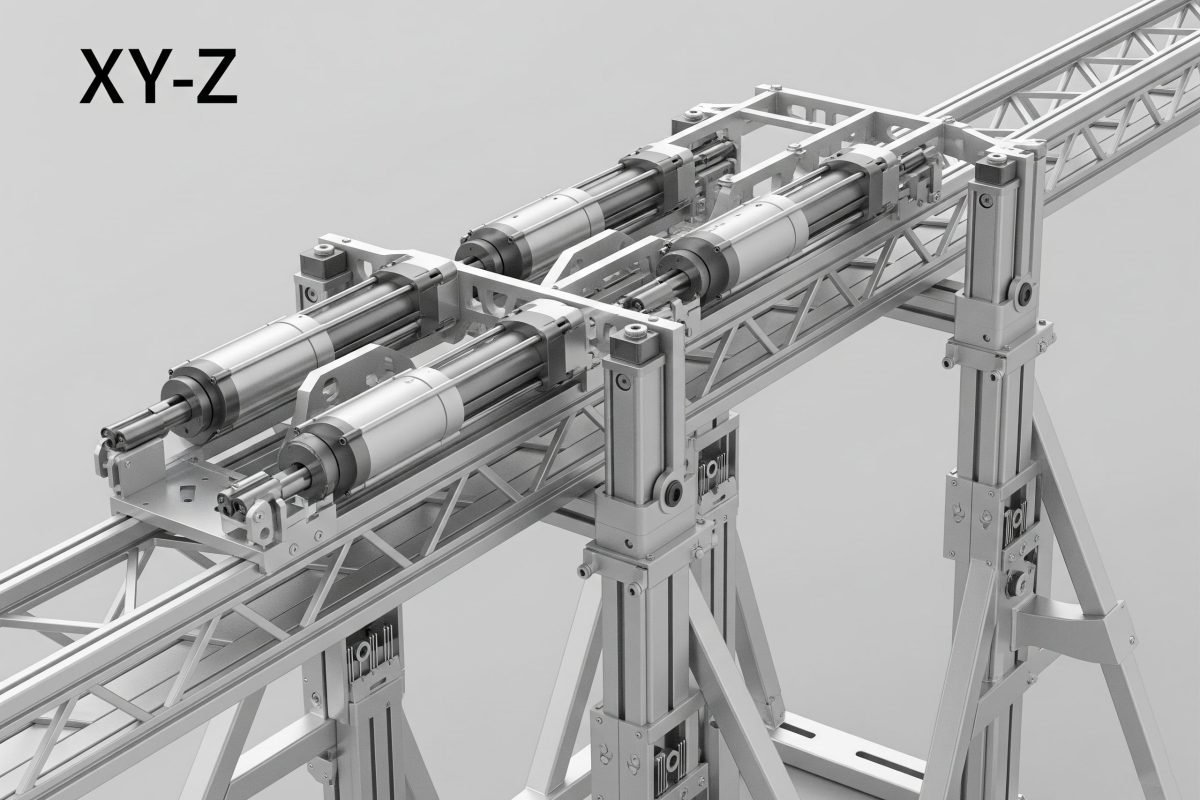

Rodless cylinders, with their unique structural design, offer significant advantages in saving installation space and achieving long-stroke movements. We provide a variety of rodless cylinder types to meet your diverse automation needs, helping to enhance system performance and space utilization.

With no protruding piston rod, the installation length of a rodless cylinder is nearly equal to its effective stroke, significantly saving axial installation space.

The rodless design prevents piston rod bending and sagging in long-stroke applications, easily achieving linear movements of several meters or even longer.

Some rodless cylinders integrate guide units or can be easily combined with external guides, enabling them to handle larger radial loads and moments for smoother motion.

Power is transmitted through a mechanical connection (like a steel band or cable) between the internal piston and the external carriage. They offer high load capacity and robust construction, suitable for various industrial applications.

The internal and external pistons are coupled by strong magnetic force, enabling leak-free power transmission. Ideal for applications requiring high cleanliness or in corrosive environments.

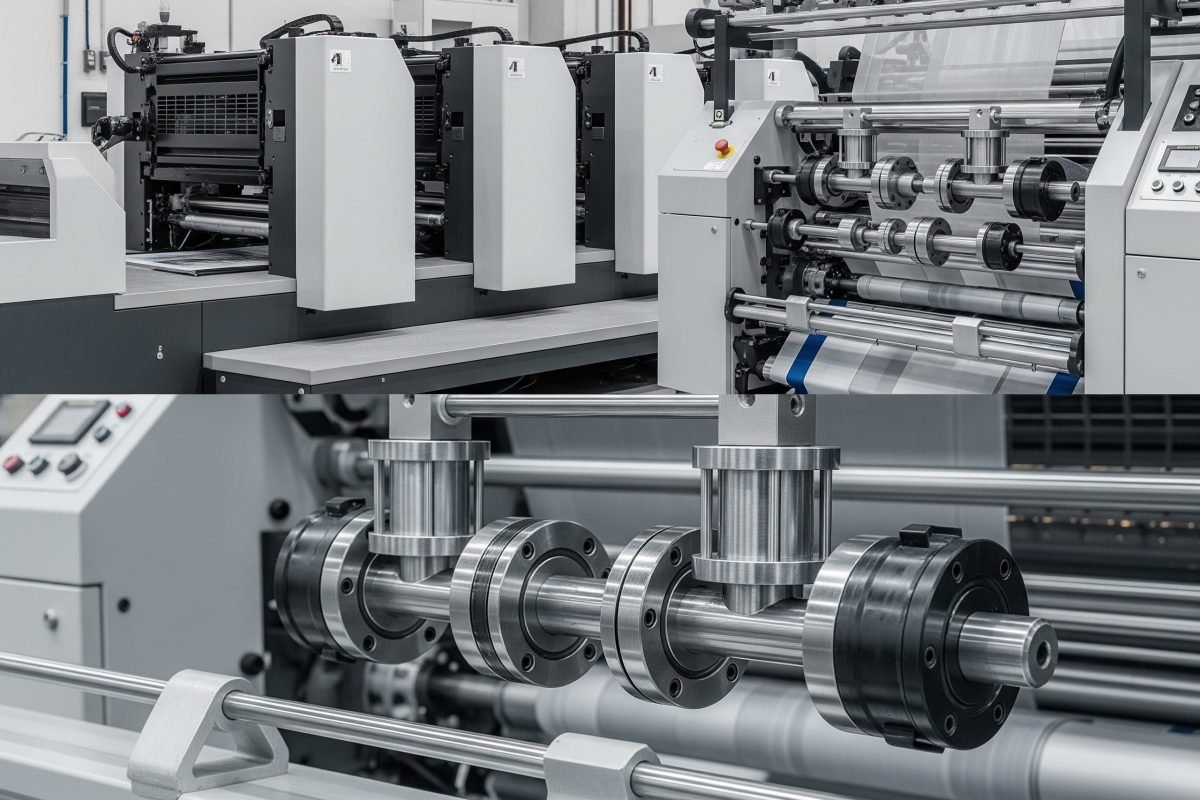

Utilizing advanced CNC machining centers and automated production lines, we strictly control dimensional tolerances and surface finish for high-precision, consistent fittings.

Select series integrate high-precision linear guides or feature special guide designs, ensuring smooth carriage movement, precise guidance, and higher side-load/moment capacity.

Optimized sensor mounting grooves compatible with various magnetic switch models, facilitating precise position detection and automated control for users.

We offer tailored solutions based on customer’s special requirements, including custom strokes, mounting options, high/low-temperature resistant materials, and special environmental protection.

Determines the cylinder’s output force; select based on load requirements.

Choose based on the required linear travel distance; rodless cylinders offer very long strokes.

Consider the direct load on the carriage and any applied moments in various directions.

Select a cylinder that meets the speed range required by the application’s cycle time and efficiency.

Options include pneumatic, elastic, or external shock absorbers to absorb end-of-stroke impact.

Choose appropriate mounting accessories and fixation methods based on equipment structure.

Determine if magnetic switches or other sensors are needed for position detection.

Consider temperature, humidity, dust, corrosiveness, etc., to select suitable materials and protection levels.

For detailed parameters, please refer to individual product manuals or consult our technical experts.

Used in automated warehouses and production lines for horizontal or vertical transport, positioning, and sorting of workpieces.

For long-stroke linear movements in packaging processes such as sealing, labeling, cartoning, and palletizing.

In assembly lines for electronics, automotive, etc., for precise movement, positioning of parts, and switching of test stations.

Used for opening and closing safety doors, protective covers on automated equipment, and driving large sliding doors.

For transverse reciprocating movements in printing presses and textile machines, such as print head movement and fabric traction.

As actuators in X-Y-Z multi-axis motion systems for precise positioning over a wide range.

Always disconnect air and power supplies and release residual system pressure before performing any maintenance to ensure safety.

The main differences lie in their structure and resulting characteristics:

The choice depends on specific application needs:

Loads are mounted directly on the external carriage. Key considerations include:

Improper load mounting can severely affect the performance and lifespan of rodless cylinders.

The stroke accuracy (or repeat positioning accuracy) of rodless cylinders varies by type, brand, and specific model. Generally, high-quality rodless cylinders can achieve good accuracy levels, for example, ±0.1mm to ±0.5mm or better.

Key factors affecting stroke accuracy include:

For high-precision applications, it’s advisable to choose rodless cylinders with high-performance guide units, paired with precise control systems and sensors.

Yes, many rodless cylinders can be installed vertically, but special attention is required:

Safety is paramount when installing rodless cylinders vertically; always implement adequate protective measures.

Our rodless cylinder series offers ideal solutions for your long-stroke, space-sensitive applications. Browse detailed product information now, or contact our pneumatic expert team for personalized selection support.