DNG Series ISO 15552 compliant cylinders with a robust, precise, durable & efficient design for demanding automation. Wide range: 32-200mm bore, 25-1000mm stroke (customizable). Adjustable cushioning: smooth deceleration, less noise/shock, longer life. Std. magnetic piston for easy, precise position sensing with common sensors. ISO 15552 interchangeable for easy system design, upgrades & replacements.

| Bore(mm) | 160 | 200 | 250 | 320 |

| Motion Pattern | Double Action | |||

| Working Medium | Air | |||

| Fixed Type | Normal type FA type FB type CA type CB type LB type TC type | |||

| Working Pressure Range | 0.1~1.0MPa | |||

| Ensured Pressure Resistance | 1.5MPa | |||

| Operating Temperature Range | -5~60℃ | |||

| Operating Speed Range | 50~500mm/s | |||

| Buffer Type | Adjustable Buffer | |||

| Port Size | G3/4″ | G1″ | ||

| Lubrication | Not required (Use Turbine oilISO Vg32 when necessary) | |||

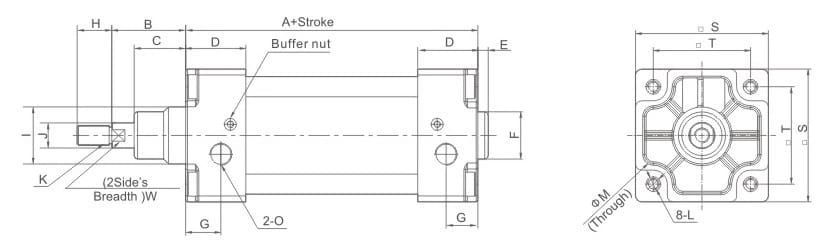

| Bore | A | B | C | D | E | F | G | H | I | J | K | L | M | S | T | O |

| 160 | 180 | 80 | 60 | 50 | 6 | φ65 | 25 | 72 | φ65 | 40 | M36×2 | M16 | φ25dp30 | 180 | 140 | G3/4″ |

| 200 | 180 | 95 | 70 | 50 | 6 | φ75 | 25 | 72 | φ75 | 40 | M36×2 | M16 | φ25dp30 | 220 | 175 | G3/4″ |

| 250 | 200 | 105 | 67 | 52 | 10 | 90 | 31 | 84 | 90 | 50 | M42×2 | M20 | φ30 | 270 | 220 | G1″ |

| 320 | 218 | 120 | 82 | 52 | 10 | 110 | 31 | 96 | 110 | 63 | M48×2 | M24 | φ34 | 340 | 270 | G1″ |

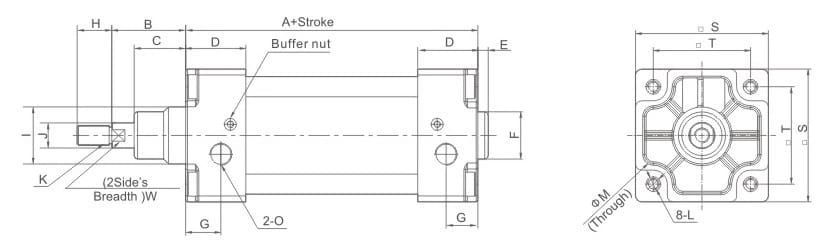

| Bore | A | B | C | D | E | F | G | H | I | J | K | L | M | S | T | O |

| 160 | 180 | 80 | 60 | 50 | 6 | φ65 | 25 | 72 | φ65 | 40 | M36×2 | M16 | φ25dp30 | 180 | 140 | G3/4″ |

| 200 | 180 | 95 | 70 | 50 | 6 | φ75 | 25 | 72 | φ75 | 40 | M36×2 | M16 | φ25dp30 | 220 | 175 | G3/4″ |

| 250 | 200 | 105 | 67 | 52 | 10 | 90 | 31 | 84 | 90 | 50 | M42×2 | M20 | φ30 | 270 | 220 | G1″ |

| 320 | 218 | 120 | 82 | 52 | 10 | 110 | 31 | 96 | 110 | 63 | M48×2 | M24 | φ34 | 340 | 270 | G1″ |