The MA Series Mini Pneumatic Cylinder features a compact, lightweight aluminum body, ideal for space-constrained automation systems. Designed for precise linear motion, it offers smooth operation, fast response, and high durability. Available in multiple bore sizes, it’s perfect for OEM machinery, robotics, and industrial automation.

| Bore(mm) | 16 | 20 | 25 | 32 | 40 | |

| Motion pattern | Double Action or Single Action | |||||

| Working Medium | Air | |||||

| Fixed Type | Normal Type LB/Type FA/Type SDB/Type U/Type | |||||

| Operating Voltage Range | 0.1~0.9MPa | |||||

| Ensured Pressure Resistance | 1.35MPa | |||||

| Operating Temperature Range | -5~70℃ | |||||

| Operating Speed Range | 50~800mm/s | |||||

| Buffer Type | Standard Type | Anti-crash cushion | ||||

| Damping Type | – | Adjustable cushion | ||||

| Pipe Size | M5×0.8 | G1/8″ | ||||

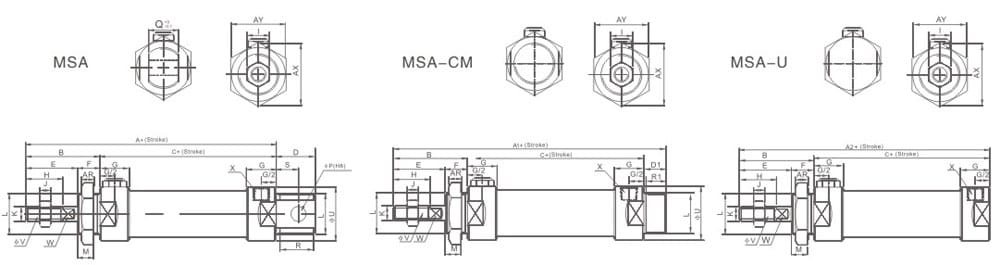

| Bore/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K |

| 16 | 114 | 114 | 98 | 38 | 60 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 | M6×1 |

| 20 | 137 | 128 | 116 | 40 | 76 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 |

| 25 | 141 | 134 | 120 | 44 | 76 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 32 | 147 | 134 | 120 | 44 | 76 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 40 | 149 | 136 | 122 | 46 | 76 | 27 | 14 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12×1.25 |

| Bore/Symbol | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 24 | 27.5 |

| 20 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | ||||

| Bore/Stroke | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | |||||||||

| 16 | 114 | 139 | 128 | 153 | 98 | 123 | 38 | 60 | 85 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 |

| 20 | 137 | 162 | 134 | 159 | 116 | 141 | 40 | 76 | 101 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 |

| 25 | 141 | 166 | 134 | 159 | 120 | 145 | 44 | 76 | 101 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 32 | 147 | 172 | 136 | 161 | 120 | 145 | 44 | 76 | 101 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 40 | 149 | 174 | 122 | 144 | 122 | 147 | 46 | 76 | 101 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 |

| Inside Diameter/Symbol | K | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M6×1 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 25 | 22 |

| 20 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Inside Diameter/Symbol | A | A1 | B | C | E | F | G | H | I | J | K |

| 16 | 136 | 135 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | M6x1 |

| 20 | 156 | 153 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | M8x1.25 |

| 25 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 32 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 40 | 168 | 164 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12x1.25 |

| Inside Diameter/Symbol | L | M | U | V | W | X | AR | AX | AY | T |

| 16 | M16x1.5 | 14 | 21 | 6 | 5 | M5 | 6 | 25 | 22 | 16 |

| 20 | M22x1.5 | 10 | 29 | 9 | 6 | G1/8″ | 7 | 33 | 29 | 19 |

| 25 | M22x1.5 | 12 | 34 | 10 | 8 | G1/8″ | 7 | 33 | 29 | 19 |

| 32 | M24x1.5 | 12 | 39.5 | 12 | 10 | G1/8″ | 8 | 37 | 32 | 21 |

| 40 | M30x2.0 | 12 | 41.6 | 16 | 12 | G1/8″ | 9 | 47 | 41 | 21 |

| NO. | Designation | NO. | Designation |

| 1 | Piston Rod Nut | 2 | Piston Rod |

| 3 | Front Cover Seal Ring | 4 | Oiled Bearing |

| 5 | Front Cover Nut | 6 | Front Cover |

| 7 | Stainless steel tube | 8 | Anti-crash cushion |

| 9 | Piston | 10 | Piston O-Ring |

| 11 | Magnet(Optional) | 12 | Wear Ring |

| 13 | Seal cushion | 14 | Hex socket screw |

| 15 | Back Cover |

| Bore(mm) | Standard Stroke | Max.Stroke | Permissible Stroke |

| 16 | 25 50 75 80 100 125 160 175 200 | 300 | 500 |

| 20 | 25 50 75 80 100 125 160 175 200 250 300 | 500 | 650 |

| 25 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 32 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 40 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

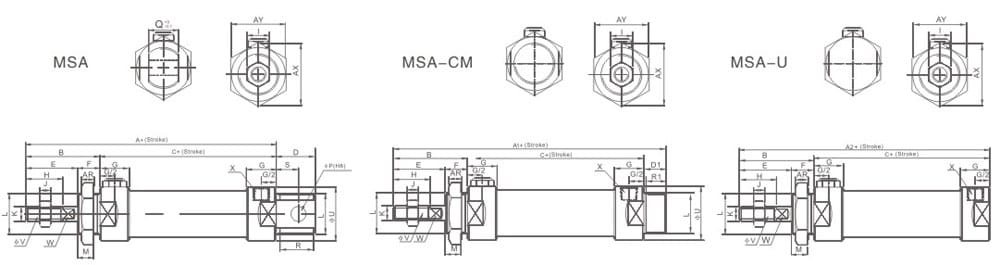

| Bore/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K |

| 16 | 114 | 114 | 98 | 38 | 60 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 | M6×1 |

| 20 | 137 | 128 | 116 | 40 | 76 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 |

| 25 | 141 | 134 | 120 | 44 | 76 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 32 | 147 | 134 | 120 | 44 | 76 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 |

| 40 | 149 | 136 | 122 | 46 | 76 | 27 | 14 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12×1.25 |

| Bore/Symbol | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 24 | 27.5 |

| 20 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | ||||

| Bore/Stroke | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | 0-50 | 51-100 | |||||||||

| 16 | 114 | 139 | 128 | 153 | 98 | 123 | 38 | 60 | 85 | 16 | 16 | 22 | 16 | 10 | 16 | 10 | 5 |

| 20 | 137 | 162 | 134 | 159 | 116 | 141 | 40 | 76 | 101 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 |

| 25 | 141 | 166 | 134 | 159 | 120 | 145 | 44 | 76 | 101 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 32 | 147 | 172 | 136 | 161 | 120 | 145 | 44 | 76 | 101 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 |

| 40 | 149 | 174 | 122 | 144 | 122 | 147 | 46 | 76 | 101 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 |

| Inside Diameter/Symbol | K | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 16 | M6×1 | M16×1.5 | 14 | 6 | 12 | 14 | 14 | 9 | 21 | 6 | 5 | M5 | 6 | 25 | 22 |

| 20 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 27 | 8 | 6 | G1/8″ | 7 | 33 | 29 |

| 25 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 30 | 10 | 8 | G1/8″ | 7 | 33 | 29 |

| 32 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 35 | 12 | 10 | G1/8″ | 8 | 37 | 32 |

| 40 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 41.6 | 16 | 14 | G1/8″ | 9 | 47 | 41 |

| Inside Diameter/Symbol | A | A1 | B | C | E | F | G | H | I | J | K |

| 16 | 136 | 135 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | M6x1 |

| 20 | 156 | 153 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | M8x1.25 |

| 25 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 32 | 164 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 |

| 40 | 168 | 164 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12x1.25 |

| Inside Diameter/Symbol | L | M | U | V | W | X | AR | AX | AY | T |

| 16 | M16x1.5 | 14 | 21 | 6 | 5 | M5 | 6 | 25 | 22 | 16 |

| 20 | M22x1.5 | 10 | 29 | 9 | 6 | G1/8″ | 7 | 33 | 29 | 19 |

| 25 | M22x1.5 | 12 | 34 | 10 | 8 | G1/8″ | 7 | 33 | 29 | 19 |

| 32 | M24x1.5 | 12 | 39.5 | 12 | 10 | G1/8″ | 8 | 37 | 32 | 21 |

| 40 | M30x2.0 | 12 | 41.6 | 16 | 12 | G1/8″ | 9 | 47 | 41 | 21 |

| NO. | Designation | NO. | Designation |

| 1 | Piston Rod Nut | 2 | Piston Rod |

| 3 | Front Cover Seal Ring | 4 | Oiled Bearing |

| 5 | Front Cover Nut | 6 | Front Cover |

| 7 | Stainless steel tube | 8 | Anti-crash cushion |

| 9 | Piston | 10 | Piston O-Ring |

| 11 | Magnet(Optional) | 12 | Wear Ring |

| 13 | Seal cushion | 14 | Hex socket screw |

| 15 | Back Cover |

| Bore(mm) | Standard Stroke | Max.Stroke | Permissible Stroke |

| 16 | 25 50 75 80 100 125 160 175 200 | 300 | 500 |

| 20 | 25 50 75 80 100 125 160 175 200 250 300 | 500 | 650 |

| 25 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 32 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

| 40 | 25 50 75 80 100 125 160 175 200 250 300 350 400 450 500 | 500 | 650 |

Designing and Developing.

We Engineer Pneumatic Excellence - Innovative, Versatile, Empowering.

Our dedicated pneumatic specialists focus on providing premium pneumatic products

to ensure optimal functionality for your systems.

Contact Us

Xuezhai Industrial Zone, Liushi Town, Yueqing City, Zhejiang Province, China

© 2025. All Rights Reserved.Powered by Bepto