Introdução

Os seus cilindros pneumáticos funcionam perfeitamente a pressão total, mas abaixo de 40 psi começam a vazar como peneiras. Você está a tentar implementar sequências de arranque suave ou controlo de pressão variável, mas as suas vedações padrão simplesmente não aguentam baixas pressões. O seu processo requer um manuseamento delicado, mas os seus cilindros não conseguem oferecer a precisão necessária. Este é o desafio da vedação de baixa pressão. 🔧

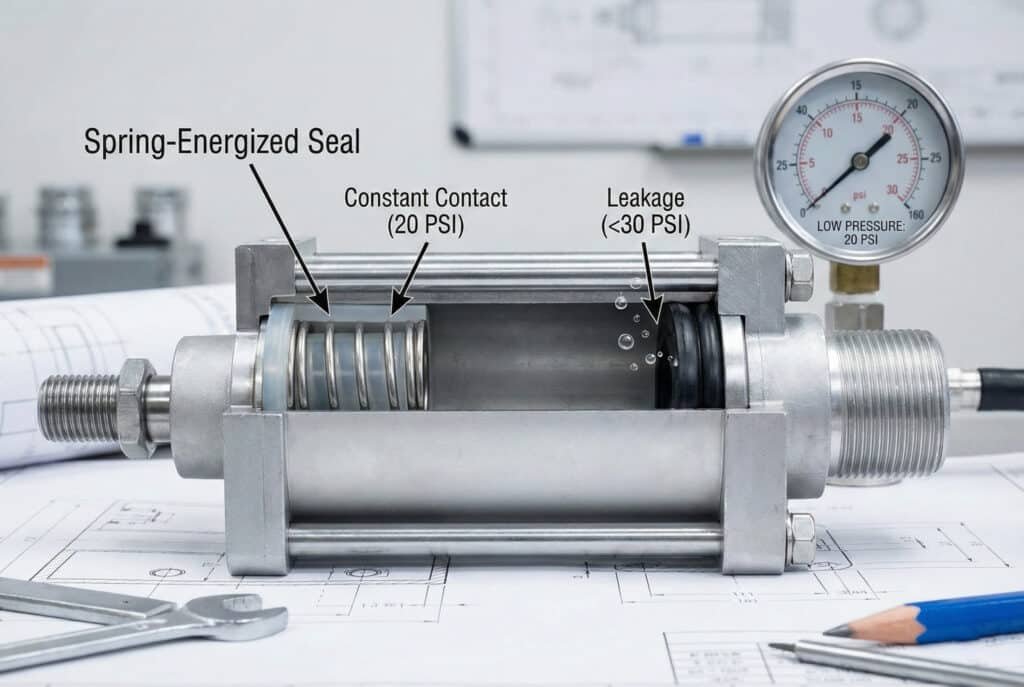

As vedações acionadas por mola resolvem falhas de vedação de baixa pressão usando a força mecânica da mola para manter o contato constante da vedação, independentemente da pressão do sistema. Enquanto as vedações elastoméricas padrão dependem inteiramente da pressão do fluido para ativação e falham abaixo de 30-40 psi, os projetos acionados por mola fornecem vedação confiável em condições de vácuo até mais de 500 psi, tornando-os ideais para aplicações de pressão variável, sistemas de partida suave e processos que exigem manuseio delicado do produto.

No último trimestre, trabalhei com Marcus, um engenheiro de processos numa fábrica de revestimento de comprimidos farmacêuticos em Massachusetts. Os seus tambores de revestimento exigiam um controlo preciso da pressão entre 15 e 80 psi para evitar danos aos comprimidos delicados, mas as vedações padrão dos cilindros apresentavam fugas excessivas na extremidade inferior dessa faixa. A fuga de ar causava flutuações de pressão que resultaram em 8-12% defeitos de revestimento e mais de $60.000 mensais em produtos rejeitados. O seu fornecedor OEM insistia que os cilindros estavam “dentro das especificações”, mas isso não resolvia o seu problema de produção. 💊

Índice

- O que são vedações acionadas por mola e como funcionam?

- Por que é que as vedações padrão falham em baixas pressões?

- Quais aplicações beneficiam mais da tecnologia de vedação energizada por mola?

- Como selecionar e instalar vedações energizadas por mola?

- Conclusão

- Perguntas frequentes sobre vedações energizadas por mola

O que são vedações acionadas por mola e como funcionam?

Compreender a mecânica fundamental das vedações acionadas por mola revela por que elas superam os projetos padrão em aplicações desafiadoras de baixa pressão. ⚙️

As vedações acionadas por mola combinam um elemento de vedação de polímero (normalmente PTFE1 ou poliuretano) com uma mola metálica interna que proporciona uma força radial ou axial constante contra a superfície de vedação. A mola mantém uma pressão de contacto equivalente a 2-5 psi, independentemente da pressão do sistema, garantindo uma vedação fiável desde o vácuo total (0 psi) até toda a gama de funcionamento, enquanto o revestimento de polímero de baixo atrito minimiza o desgaste e o arrasto.

Os componentes básicos do design

Uma vedação acionada por mola consiste em três elementos críticos que funcionam em harmonia:

- Revestimento de vedação: Elemento externo em PTFE, PTFE preenchido ou poliuretano que entra em contacto com a superfície de vedação

- Primavera energizante: Bobina de aço inoxidável, cantiléver2, ou mola em V que fornece força constante

- Geometria da vedação: Perfil usinado com precisão, otimizado para a aplicação

Como funciona a energização da primavera

Ao contrário das vedações ativadas por pressão, que dependem da pressão do sistema para se deformarem e criarem força de vedação, as vedações acionadas por mola funcionam por meio de pré-carga mecânica:

- À pressão zero: A força da mola mantém o contacto da vedação (normalmente equivalente a 2-4 psi)

- A baixa pressão (10-50 psi): Força da mola mais ativação com pressão mínima

- A alta pressão (50-500 psi): Forças combinadas de mola e pressão para uma vedação melhorada

- Durante flutuações de pressão: A mola mantém um contacto consistente, independentemente das variações de pressão.

Tipos de configuração de molas

| Tipo mola | Perfil da força | Melhor aplicação | Gama de pressão | Disponibilidade do Bepto |

|---|---|---|---|---|

| Bobina helicoidal | Força radial uniforme | Vedantes de pistão para uso geral | 0-300 psi | ✓ Padrão |

| Cantilever | Força direcional | Vedantes de haste, vedação unidirecional | 0-200 psi | ✓ Padrão |

| Mola em V | Força elevada, compacto | Aplicações com espaço limitado | 0-500 psi | ✓ Premium |

| Bobina inclinada | Vetor de força angular | Vedação radial/axial combinada | 0-400 psi | ✓ Personalizado |

Combinações de materiais

A seleção do material do revestimento determina o atrito, a resistência ao desgaste e a compatibilidade química:

Casacos de PTFE virgem:

- Coeficiente de atrito mais baixo (0,05-0,10)

- Excelente resistência química

- Intervalo de temperatura: -200 °C a +260 °C

- Ideal para: Ambientes limpos, aplicações de alta velocidade

Casacos com enchimento de PTFE:

- Maior resistência ao desgaste (enchimentos de vidro, carbono ou bronze)

- Atrito moderado (0,08-0,15)

- Melhor estabilidade dimensional

- Ideal para: Condições abrasivas, cargas pesadas

Casacos de poliuretano:

- Resistência superior à abrasão

- Boa flexibilidade a baixas temperaturas

- Intervalo de temperatura: -40 °C a +100 °C

- Ideal para: Aplicações sensíveis ao custo, pressões moderadas

Na Bepto, fabricamos vedações energizadas por mola com os três materiais de revestimento, o que nos permite otimizar o desempenho para a sua aplicação específica de cilindro sem haste e condições operacionais. 🎯

Por que é que as vedações padrão falham em baixas pressões?

A física da vedação ativada por pressão revela limitações fundamentais que a energização por mola supera. 📊

Padrão elastomérico3 As vedações (O-rings, U-cups, V-packings) dependem da pressão do sistema para deformar o material da vedação e criar uma força de vedação contra as superfícies de contato. Abaixo de 30-40 psi, a pressão insuficiente não consegue superar a resistência elástica da vedação, deixando espaços que permitem o vazamento de ar. Essa vedação dependente da pressão cria uma “zona morta” onde a vedação confiável é impossível com projetos convencionais.

O mecanismo de ativação por pressão

As vedações pneumáticas padrão funcionam através de um princípio chamado “ativação por pressão”:

- Pressão do sistema atua na área da superfície da vedação exposta à pressão

- Força hidráulica deforma o elastómero em direção à superfície de vedação

- Pressão de contacto desenvolve-se entre a vedação e a superfície, criando a vedação

- Eficácia da vedação é diretamente proporcional à pressão do sistema

Este mecanismo funciona muito bem em pressões operacionais normais (60-150 psi), mas falha progressivamente à medida que a pressão diminui.

A zona de falha de baixa pressão

Eis o que acontece quando a pressão diminui em designs de vedação padrão:

| Pressão do sistema | Comportamento das focas | Taxa de fuga | Desempenho |

|---|---|---|---|

| Mais de 100 psi | Ativação total, excelente vedação | <0,1 SCFM | Ótimo |

| 60-100 psi | Boa ativação, vedação fiável | 0,1-0,3 SCFM | Bom |

| 40-60 psi | Ativação parcial, vedação marginal | 0,3-1,0 SCFM | Marginal |

| 20-40 psi | Ativação mínima, vedação deficiente | 1,0-5,0 SCFM | Pobres |

| <20 psi | Sem ativação eficaz | >5,0 SCFM | Falha |

Consequências no mundo real

Na aplicação farmacêutica de Marcus em Massachusetts, medimos as taxas reais de fuga em toda a sua faixa de pressão:

- A 80 psi: 0.2 SCFM4 fuga (aceitável)

- A 50 psi: Fuga de 0,8 SCFM (marginal)

- A 30 psi: Fuga de 3,5 SCFM (causando instabilidade de pressão)

- A 15 psi: Fuga superior a 12 SCFM (falha total na vedação)

Este vazamento excessivo a baixas pressões impossibilitou o controle preciso da pressão, causando diretamente defeitos no revestimento.

Desafios adicionais relacionados à baixa pressão

Além do simples vazamento, a operação em baixa pressão cria problemas em cascata:

- Deslizamento irregular5 moção: Forças de separação inconsistentes causam movimentos bruscos

- Erros de posicionamento: As flutuações de pressão impedem paragens precisas

- Aumento do consumo de ar: Os compressores funcionam continuamente para compensar as perdas

- Aceleração do desgaste da vedação: Filme lubrificante inadequado a baixas pressões

- Instabilidade do sistema: Os circuitos de retroalimentação de pressão tornam-se instáveis

Por que a energização da primavera resolve esses problemas

As vedações acionadas por mola eliminam a dependência da pressão, fornecendo pré-carga mecânica:

Força de contacto constante: A mola mantém uma pressão de contacto equivalente a 2-5 psi em todas as pressões do sistema, garantindo uma vedação fiável mesmo com pressão zero.

Desempenho independente da pressão: A eficácia da vedação permanece consistente, independentemente de a pressão do sistema ser de 5 psi ou 500 psi.

Movimento suave: O atrito consistente em todas as pressões elimina o comportamento de deslizamento irregular e permite um posicionamento preciso.

Quando instalamos vedações de PTFE com mola Bepto nos cilindros do tambor de revestimento de Marcus, o vazamento a 15 psi caiu de 12 SCFM para apenas 0,15 SCFM — uma redução de 98,75% que eliminou completamente os seus problemas de controlo de pressão. 📉

Quais aplicações beneficiam mais da tecnologia de vedação energizada por mola?

Nem todos os cilindros precisam de vedações acionadas por mola, mas certos perfis operacionais tornam-nas a escolha claramente superior. 🎯

As vedações acionadas por mola oferecem o máximo valor em sistemas de pressão variável (operando abaixo de 50 psi), aplicações de arranque suave que exigem aceleração gradual, operações a vácuo ou quase vácuo, sistemas de posicionamento de precisão com ajustes frequentes de pressão e processos que lidam com produtos delicados que exigem um controlo pneumático suave. O processamento de alimentos, a fabricação de produtos farmacêuticos, a montagem de componentes eletrónicos e a produção de dispositivos médicos são os setores que mais se beneficiam.

Sistemas de controlo de pressão variável

Quando o seu processo requer ajuste dinâmico da pressão, as vedações acionadas por mola são essenciais:

- Revestimento farmacêutico: Faixa de 10-80 psi para manuseamento delicado de comprimidos

- Embalagem de alimentos: 15-60 psi para manipulação de produtos macios

- Montagem de componentes eletrónicos: 20-70 psi para colocação de componentes sem danos

- Fabricação de dispositivos médicos: 5-50 psi para manuseamento esterilizado e delicado

Aplicações de arranque suave e movimento suave

As aplicações que exigem aceleração e desaceleração suaves beneficiam-se enormemente:

- Linhas de engarrafamento: A pressão gradual evita o derramamento do produto

- Automação de padarias: Manuseamento delicado de produtos de panificação frágeis

- Embalagens de cosméticos: Transferência suave do produto sem danos

- Manuseamento de semicondutores: Posicionamento sem vibração de wafers delicados

Operações a vácuo e quase vácuo

Algumas aplicações especializadas operam em condições de vácuo ou próximas disso:

- Sistema de recolha e colocação a vácuo: Pressão negativa para manuseamento de componentes

- Sistemas de desgaseificação: Processamento com pressão subatmosférica

- Embalagem a vácuo: Integridade da vedação durante a evacuação de ar

- Automatização de laboratórios: Câmaras de atmosfera controlada

Iniciativas de eficiência energética

Recentemente, consultei Sarah, uma engenheira de sustentabilidade numa fábrica de engarrafamento de bebidas no Oregon. A sua fábrica estava a implementar iniciativas de redução de energia e queria diminuir as pressões operacionais de 90 psi para 50 psi em mais de 200 cilindros. No entanto, as vedações padrão apresentavam fugas excessivas com pressões reduzidas, anulando qualquer poupança de energia.

Calculámos que a conversão para vedantes acionados por mola:

- Permite um funcionamento fiável a 50 psi (redução de pressão 45%)

- Reduzir o consumo de energia do compressor em 38%

- Economize $127.000 por ano em custos de eletricidade

- Obtenha ROI em apenas 14 meses, apesar dos custos mais elevados com vedantes ⚡

Matriz de seleção de aplicações

| Característica da aplicação | Vedantes padrão | Vedações acionadas por mola | Recomendação |

|---|---|---|---|

| Pressão constante >80 psi | Excelente | Desnecessário | Vedantes standard |

| Pressão variável 40-100 psi | Marginal | Excelente | Acionado por mola |

| Baixa pressão <40 psi | Insuficiente/Reprovado | Excelente | Energia de mola necessária |

| Vácuo para pressão positiva | Falha | Excelente | Energia de mola necessária |

| Alta velocidade, pressão constante | Bom | Bom | Qualquer um (baseado no custo) |

| Posicionamento de precisão | Pobres | Excelente | Acionado por mola |

| Manuseamento delicado do produto | Marginal | Excelente | Acionado por mola |

Considerações sobre cilindros sem haste

Os cilindros sem haste apresentam desafios únicos que as vedações energizadas por mola resolvem de forma eficaz:

- Comprimentos de curso longos: Força de vedação consistente em todo o percurso

- Vedação externa do carro: Fundamental para manter a pressão interna

- Posicionamento de precisão: O atrito suave e consistente permite precisão

- Resistência à contaminação: Os revestimentos de PTFE resistem à aderência de partículas

Na Bepto, aproximadamente 35% dos nossos kits de vedação para cilindros sem haste agora incluem opções com mola para clientes com requisitos de pressão variável ou precisão. A tecnologia amadureceu a ponto de se tornar competitiva em termos de custo para muitas aplicações convencionais. 💼

Como selecionar e instalar vedações energizadas por mola?

A seleção e instalação adequadas são fundamentais para obter os benefícios de desempenho que as vedações acionadas por mola oferecem. 🔧

A seleção de vedantes acionados por mola requer a correspondência da força da mola com a pressão mínima de operação (normalmente 20-30% de pressão mínima como força da mola), a escolha do material do revestimento para os requisitos de atrito e químicos, a verificação das dimensões da ranhura (geralmente exigindo ranhuras 10-15% mais profundas do que os vedantes padrão) e a confirmação da compatibilidade de temperatura. A instalação exige uma orientação cuidadosa da mola, lubrificação adequada e evitar danos à mola durante a montagem sobre roscas ou bordas.

Lista de verificação dos critérios de seleção

Trabalhe com estes parâmetros de forma sistemática:

1. Faixa de pressão:

- Pressão mínima de funcionamento: _____ psi

- Pressão máxima de operação: _____ psi

- Força de mola necessária: 20-30% de pressão mínima

- Frequência do ciclo de pressão: _____ ciclos/hora

2. Condições de funcionamento:

- Intervalo de temperatura: _____ a _____ °C

- Fluidos: Ar / Nitrogénio / Outros: _____

- Nível de contaminação: Limpo / Moderado / Pesado

- Lubrificação: Sim / Não / Tipo: _____

3. Requisitos de desempenho:

- Taxa de fuga aceitável: _____ SCFM

- Limitações de atrito: Baixa / Moderada / Não crítica

- Meta de vida útil: _____ milhões de ciclos

- Precisão de posicionamento: _____ mm

4. Restrições físicas:

- Diâmetro da haste/furo: _____ mm

- Profundidade da ranhura existente: _____ mm

- Capacidade de modificação disponível: Sim / Não

- Limitações de espaço: _____

Requisitos de dimensão da ranhura

As vedações acionadas por mola normalmente requerem dimensões de ranhura modificadas:

| Tipo de vedação | Profundidade padrão da ranhura | Profundidade energizada por mola | Aumento da profundidade |

|---|---|---|---|

| Vedante da haste (40 mm) | 2,5 mm | 2,8-3,0 mm | +12-20% |

| Vedante do pistão (40 mm) | 3,0 mm | 3,3-3,5 mm | +10-17% |

| Anel do limpador | 2,0 mm | 2,0 mm | Sem alterações |

Crítico: Verifique sempre as dimensões da ranhura antes de fazer o pedido. Na Bepto, fornecemos desenhos detalhados com as especificações da ranhura em todos os kits de vedação acionados por mola para garantir o encaixe adequado.

Melhores práticas de instalação

As vedações acionadas por mola requerem um pouco mais de cuidado durante a instalação do que as vedações padrão:

Passo 1: Preparação

- Limpe bem todas as superfícies (sem partículas ou contaminação)

- Inspecione a ranhura quanto a danos, rebarbas ou arestas afiadas.

- Aplique lubrificante adequado para vedar o revestimento e as superfícies de contato.

- Verifique a orientação da mola (consulte o diagrama de instalação)

Passo 2: Instalação

- Utilize mangas de instalação de vedação ou bordas chanfradas (obrigatório)

- Nunca force a vedação sobre roscas ou bordas afiadas

- Proteja a mola contra deformações durante a instalação

- Confirme se a vedação está totalmente encaixada na ranhura (inspeção visual)

Passo 3: Verificação

- Realize um teste de fuga a baixa pressão (10-20 psi)

- Faça o cilindro completar 5 a 10 ciclos completos.

- Verifique se o movimento é suave, sem aderência

- Realizar teste operacional com pressão total

Erros comuns de instalação a evitar

Já vi esses erros causarem falhas prematuras inúmeras vezes:

❌ Instalação sem lubrificação adequada: Causa danos ao revestimento durante a instalação

❌ Forçar a vedação sobre roscas afiadas: Danos na mola ou rasgos no revestimento

❌ Orientação incorreta da mola: Reduz a eficácia da vedação em 50%+

❌ Utilização de ranhuras padrão sem verificação: Causa compressão inadequada

❌ Mistura de lubrificantes incompatíveis: Degrada revestimentos de PTFE ou poliuretano

A vantagem do suporte à instalação da Bepto

Ao encomendar kits de vedação com mola da Bepto, você recebe:

- Instruções detalhadas de instalação com diagramas

- Desenhos de verificação das dimensões das ranhuras

- Especificações recomendadas para lubrificantes

- Linha direta de suporte técnico para questões relacionadas à instalação

- Guias de instalação em vídeo (disponíveis no nosso site)

Para a aplicação farmacêutica de Marcus, fornecemos formação no local para a sua equipa de manutenção, garantindo a instalação adequada de todos os 23 kits de vedação de cilindros. O investimento de quatro horas de formação evitou erros de instalação que poderiam ter custado milhares em vedações defeituosas e tempo de inatividade. 📚

Compatibilidade com cilindros existentes

Boas notícias: Muitos cilindros padrão podem ser adaptados com vedações acionadas por mola com modificações mínimas ou sem modificações. Mantemos bases de dados de compatibilidade para:

- Cilindros sem haste Parker (séries OSP-P, OSP-E)

- Cilindros sem haste Festo (séries DGC, DGPL)

- Cilindros sem haste SMC (séries CY1, CY3)

- Cilindros sem haste Norgren (várias séries)

- Cilindros sem haste Bepto (todas as séries, ranhuras otimizadas)

Entre em contacto com a nossa equipa técnica com o número do modelo do seu cilindro e confirmaremos a compatibilidade e forneceremos as especificações de adaptação em 24 horas. 🚀

Conclusão

As vedações acionadas por mola transformam aplicações pneumáticas de baixa pressão de problemáticas em confiáveis, eliminando a dependência da pressão dos projetos de vedação padrão. Quer esteja a implementar uma redução de pressão com economia de energia, a necessitar de controlo de pressão variável ou a manusear produtos delicados com movimento pneumático suave, a tecnologia acionada por mola oferece desempenho de vedação consistente em toda a sua faixa de operação. Na Bepto, fornecemos soluções económicas de vedantes acionados por mola com suporte técnico para garantir a implementação bem-sucedida em seus cilindros sem haste e sistemas pneumáticos.

Perguntas frequentes sobre vedações energizadas por mola

A que pressão as vedações padrão normalmente começam a falhar?

As vedações elastoméricas padrão começam a apresentar vazamentos significativos abaixo de 40 psi, com falhas progressivas à medida que a pressão cai, atingindo falha total de vedação abaixo de 20 psi na maioria dos projetos. O limite exato depende da geometria da vedação, da dureza do material e da taxa de compressão, mas a faixa de 30-40 psi é onde a maioria dos engenheiros nota uma degradação no desempenho. Se a sua aplicação opera abaixo de 50 psi, vedações acionadas por mola devem ser seriamente consideradas.

As vedações acionadas por mola são mais caras do que as vedações padrão?

Sim, as vedações energizadas por mola normalmente custam 2,5 a 4 vezes mais do que as vedações padrão equivalentes inicialmente, mas oferecem uma vida útil 3 a 5 vezes maior e permitem aplicações impossíveis com projetos padrão. Por exemplo, uma vedação de pistão padrão pode custar $8, enquanto uma versão com mola custa $28. No entanto, em aplicações de baixa pressão, a vedação com mola pode durar mais de 50.000 ciclos, contra 10.000 ciclos da vedação padrão, proporcionando um melhor custo total de propriedade. O valor real é permitir aplicações que simplesmente não funcionam com vedações padrão.

As vedações acionadas por mola suportam altas pressões tão bem quanto baixas pressões?

Sim, as vedações energizadas por mola de qualidade têm um excelente desempenho em toda a faixa de pressão, do vácuo a 300-500 psi, combinando a força da mola em baixas pressões com a ativação por pressão em altas pressões. A mola fornece a força de vedação básica, enquanto a pressão do sistema adiciona força suplementar à medida que aumenta. Isso torna as vedações acionadas por mola ideais para aplicações de pressão variável. Na Bepto, as nossas vedações de PTFE acionadas por mola são classificadas para operação contínua de vácuo total a 350 psi.

As vedações acionadas por mola requerem procedimentos especiais de manutenção ou substituição?

Não, as vedações acionadas por mola não requerem manutenção especial e são substituídas utilizando procedimentos padrão, embora a instalação exija um pouco mais de cuidado para evitar danificar o elemento de mola. Os intervalos de substituição são normalmente 2 a 4 vezes mais longos do que os vedantes padrão em aplicações equivalentes. A principal consideração de manutenção é a utilização de lubrificantes compatíveis — os revestimentos de PTFE funcionam com praticamente todos os lubrificantes pneumáticos, enquanto os revestimentos de poliuretano requerem opções sem hidrocarbonetos. A Bepto fornece especificações de manutenção detalhadas com cada kit de vedantes.

As vedações acionadas por mola funcionarão no meu cilindro existente sem modificações?

Em aproximadamente 70% dos casos, as vedações acionadas por mola podem ser adaptadas aos cilindros existentes sem modificações, embora o desempenho ideal possa exigir ranhuras 10-15% mais profundas. A compatibilidade depende das dimensões da ranhura existente e do design específico da vedação acionada por mola. Na Bepto, oferecemos designs “compatíveis com ranhuras padrão” para fácil adaptação e designs “otimizados para ranhuras” para desempenho máximo. Forneça as especificações do seu cilindro e recomendaremos a melhor solução — muitas vezes, podemos fornecer vedações compatíveis com adaptações que oferecem 80-90% de benefício de desempenho sem necessidade de modificações.

-

Saiba mais sobre as propriedades químicas e as características de baixo atrito do politetrafluoroetileno (PTFE). ↩

-

Compreender os princípios mecânicos das molas cantilever e como elas aplicam força direcional. ↩

-

Explore a ciência dos materiais dos elastómeros e o seu comportamento viscoelástico sob pressão. ↩

-

Leia a definição de pés cúbicos padrão por minuto (SCFM) como uma medida da taxa de fluxo de gás. ↩

-

Descubra a física por trás do movimento de deslizamento irregular (atrito estático) e como ele afeta o controlo de precisão. ↩