Are you prepared to defend your pneumatic system designs in court? As technical disputes in the fluid power industry become increasingly complex, engineers and technical managers must understand the legal frameworks that govern patent infringement, product liability, and standards compliance. Without this knowledge, even well-designed systems can become the center of costly litigation.

This technical analysis examines three critical areas of legal dispute in pneumatic systems: patent infringement determination using the doctrine of equivalents1 and prosecution history estoppel2, product liability attribution through fault tree analysis and FMEA methodologies, and standards compliance evidence chains that establish due diligence through documented testing, certification, and continuous monitoring. By understanding these frameworks, manufacturers can both defend against unwarranted claims and strengthen their position in legitimate disputes.

Let’s explore the technical aspects of these legal frameworks to help you navigate potential disputes more effectively.

Table of Contents

- How Are Patent Infringement Determinations Made in Pneumatic Technology?

- What Methods Establish Causation in Pneumatic System Liability Cases?

- How to Build an Effective Standards Compliance Evidence Chain

- Conclusion: Implementing Preventive Legal Strategies

- FAQs About Pneumatic System Legal Disputes

How Are Patent Infringement Determinations Made in Pneumatic Technology?

Patent disputes in pneumatic technology often hinge on subtle technical distinctions that can be difficult for non-specialists to evaluate. Understanding the technical frameworks courts use to determine infringement can help manufacturers both avoid inadvertent infringement and defend their own innovations.

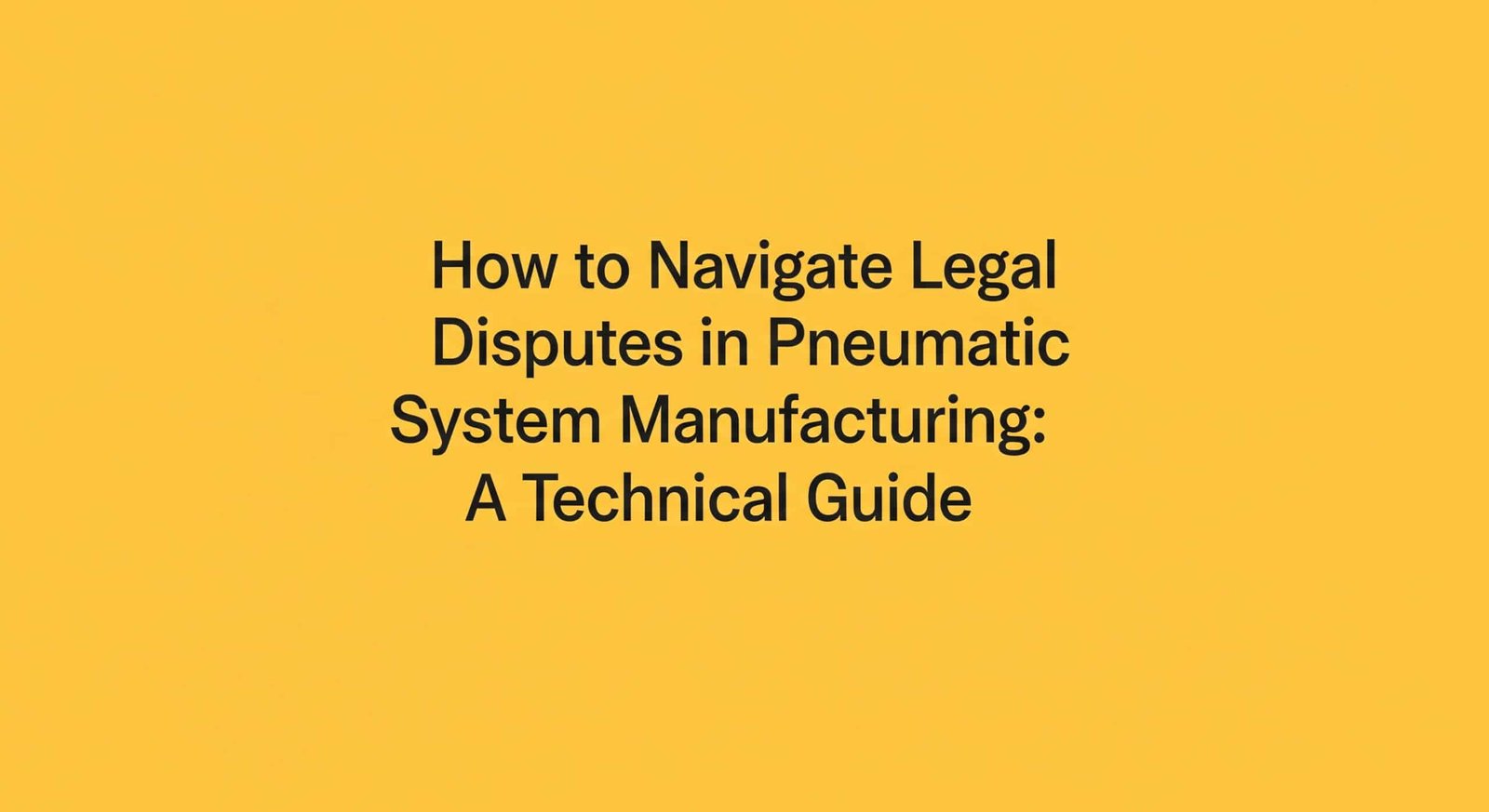

Patent infringement in pneumatic systems is determined through a two-step analysis: claim construction (interpreting the patent’s scope) followed by comparison to the accused device. While literal infringement requires the accused device to contain every element of at least one claim, the doctrine of equivalents extends protection to devices that perform substantially the same function in substantially the same way with substantially the same result. However, prosecution history estoppel can limit this doctrine’s application when claim scope was narrowed during patent examination.

Technical Claim Construction in Pneumatic Patents

Claim construction is the critical first step in any infringement analysis, establishing the precise meaning and scope of the patent claims:

Key Elements in Pneumatic Patent Claim Construction

| Element | Technical Consideration | Legal Significance | Example in Pneumatic Technology |

|---|---|---|---|

| Claim Language | Precise technical terminology | Defines literal scope | “Pressure-compensated flow control valve” has specific technical meaning |

| Specification | Detailed technical descriptions | Provides context for interpretation | Detailed cross-sectional drawings showing internal valve components |

| Prosecution History | Technical arguments made during examination | May limit claim scope | Argument that distinguishes invention from prior art based on specific seal design |

| Ordinary Meaning | Standard industry understanding | Default interpretation absent specific definition | “Piston” has well-understood meaning in fluid power industry |

| Means-Plus-Function | Functional language without structure | Limited to structures disclosed in specification | “Means for maintaining constant flow regardless of pressure” |

A recent case involving pneumatic positioning systems illustrates the importance of technical claim construction. The patent claimed a “pressure-compensated positioning system,” which the court construed to require active pressure sensing and compensation. The accused system used a passive pressure balancing mechanism that achieved similar results but without active sensing. This technical distinction in claim construction was decisive in finding non-infringement.

Doctrine of Equivalents Analysis in Pneumatic Technology

When literal infringement isn’t found, the doctrine of equivalents provides an alternative path to establishing infringement:

The Function-Way-Result Test Applied to Pneumatic Components

| Patent Element | Function | Way | Result | Equivalent Example |

|---|---|---|---|---|

| Pneumatic Seal | Prevent fluid leakage | Creating interference between surfaces | Pressure containment | Different seal material with same interference fit |

| Valve Spool | Control flow direction | Blocking and opening flow paths | Directional control | Different spool geometry achieving same flow pattern |

| Cushioning Mechanism | Decelerate piston at end of stroke | Restricting exhaust flow | Reduced impact force | Alternative flow restriction method |

| Position Feedback | Determine piston location | Sensing piston position | Position data output | Different sensing technology with same accuracy |

| Control Algorithm | Maintain positioning accuracy | Processing feedback signals | Precise positioning | Alternative mathematical approach with same results |

The technical analysis under the doctrine of equivalents requires deep understanding of pneumatic system functionality. For example, in a case involving cushioning mechanisms, the patented design used an adjustable needle valve to restrict exhaust flow, while the accused product used a tapered spear with similar adjustment capability. Though structurally different, the court found equivalence because both performed the same function (flow restriction) in substantially the same way (creating variable orifice) to achieve the same result (controlled deceleration).

Prosecution History Estoppel in Pneumatic Patents

Prosecution history estoppel limits the doctrine of equivalents based on amendments and arguments made during patent prosecution:

Examples of Estoppel in Pneumatic Technology Patents

| Original Claim Element | Amendment/Argument During Prosecution | Resulting Limitation | Estoppel Effect |

|---|---|---|---|

| “Sealing means” | Amended to “elastomeric O-ring seal” | Limited to elastomeric materials | Cannot claim equivalence to metal seals |

| “Valve assembly” | Distinguished from prior art based on specific flow path | Limited to claimed flow path configuration | Cannot claim equivalence to alternative flow paths |

| “Position sensing system” | Argued novelty based on non-contact sensing | Limited to non-contact methods | Cannot claim equivalence to contact sensors |

| “Pressure range of 1-10 MPa” | Narrowed from “0.5-15 MPa” to overcome prior art | Limited to claimed range | Cannot claim equivalence outside specified range |

| “Cylinder with integrated cushioning” | Added “integrated” to overcome prior art | Limited to designs where cushioning is not separable | Cannot claim equivalence to add-on cushioning |

A significant case in the pneumatic industry involved a patent for a “non-contact position feedback system using magnetic coupling.” During prosecution, the applicant amended claims to specify “hall-effect sensors” to overcome prior art using optical sensors. When later asserting the patent against a competitor using magnetostrictive position sensing, the court found prosecution history estoppel prevented application of the doctrine of equivalents, despite the technical similarity in function.

Technical Analysis Framework for Infringement Assessment

When evaluating potential infringement, pneumatic manufacturers should follow this technical analysis framework:

Step-by-Step Technical Infringement Analysis

Claim Mapping

– Identify each element in the independent claims

– Create technical comparison chart mapping each element to accused device

– Identify any missing elements in literal analysis

– Document technical function of each elementTechnical Equivalence Analysis

– For each non-literal element, analyze:

– Function: Technical purpose of the element

– Way: Technical mechanism of operation

– Result: Technical outcome or effect

– Determine if differences are substantial from engineering perspectiveProsecution History Review

– Identify all technical amendments to relevant claims

– Analyze technical arguments made to overcome prior art

– Determine if current technical differences were surrendered

– Evaluate whether amendment was for patentability reasonsPrior Art Comparison

– Identify relevant prior art cited during prosecution

– Analyze technical differences between patent and prior art

– Determine if accused device is more similar to patent or prior art

– Evaluate whether accused device was expressly disclaimed

Case Study: Pneumatic Quick-Connect Coupling Patent Dispute

A recent dispute involved a patented quick-connect coupling with claims requiring “a locking mechanism comprising spring-loaded balls engaged with a circumferential groove.” The accused product used spring-loaded pins engaging with discrete recesses rather than a continuous groove.

Technical Analysis:

Claim Construction:

– “Balls” construed as spherical elements

– “Circumferential groove” construed as continuous channel around circumferenceLiteral Infringement:

– No literal infringement: pins ≠ balls, discrete recesses ≠ circumferential grooveDoctrine of Equivalents:

– Function: Both secure connection against axial separation

– Way: Both use spring-loaded elements engaging with mating features

– Result: Both create secure, releasable connectionProsecution History:

– Original claim: “locking elements engaging with mating features”

– Amended to: “spring-loaded balls engaged with a circumferential groove”

– Amendment made to overcome prior art with “various locking elements”Decision:

– Court found prosecution history estoppel applied

– Specific ball and groove configuration was surrendered during prosecution

– No infringement under doctrine of equivalents

This case demonstrates how technical distinctions in pneumatic designs, even when functionally similar, can be decisive in patent disputes when viewed through the lens of prosecution history.

What Methods Establish Causation in Pneumatic System Liability Cases?

When pneumatic systems are involved in accidents or failures that cause injury or damage, establishing the technical cause is critical for determining liability. Courts rely on systematic engineering analysis methodologies to establish causation chains and apportion responsibility.

Product liability attribution in pneumatic system failures typically employs structured analytical methods including Fault Tree Analysis (FTA)3, Failure Mode and Effects Analysis (FMEA), and root cause analysis using the 5-Why method. These techniques establish causation by systematically evaluating potential failure modes, their effects, and probability of occurrence. Expert testimony then connects these technical findings to specific design decisions, manufacturing processes, maintenance procedures, or user actions to determine liability allocation.

Fault Tree Analysis in Pneumatic System Failure Cases

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis that breaks down a system failure into its contributing factors:

FTA Structure for Common Pneumatic Failures

| Top Event | First-Level Causes | Second-Level Causes | Third-Level Causes | Probability Assessment |

|---|---|---|---|---|

| Catastrophic Cylinder Failure | Overpressurization | Control system failure | Software error | P = 1.2 × 10⁻⁵ |

| Sensor failure | P = 3.5 × 10⁻⁴ | |||

| Relief valve failure | Manufacturing defect | P = 2.1 × 10⁻⁵ | ||

| Contamination | P = 8.7 × 10⁻⁴ | |||

| Material failure | Manufacturing defect | Improper heat treatment | P = 3.2 × 10⁻⁵ | |

| Material impurity | P = 1.8 × 10⁻⁵ | |||

| Design inadequacy | Insufficient safety factor | P = 5.0 × 10⁻⁶ | ||

| Improper material selection | P = 2.4 × 10⁻⁵ | |||

| Improper usage | Exceeding specifications | Inadequate instructions | P = 1.3 × 10⁻³ | |

| Deliberate misuse | P = 3.6 × 10⁻⁴ |

In a recent case involving a pneumatic press that caused serious injury, FTA was crucial in establishing causation. The analysis revealed that while the immediate cause was overpressurization, the root cause was traced to a relief valve contaminated with manufacturing debris. The FTA demonstrated that the manufacturer’s inadequate cleaning procedures and quality control were the primary causes, rather than the system integrator’s design or the operator’s actions.

FMEA Methodology in Liability Attribution

Failure Mode and Effects Analysis (FMEA) evaluates potential failure modes and their impacts:

FMEA Example for Pneumatic Valve Assembly

| Component | Potential Failure Mode | Potential Effects | Severity (1-10) | Potential Causes | Occurrence (1-10) | Current Controls | Detection (1-10) | RPN | Responsibility |

|---|---|---|---|---|---|---|---|---|---|

| Valve Seal | Leakage | System pressure loss, functional failure | 8 | Material degradation | 4 | Material specification | 5 | 160 | Designer |

| Improper installation | 3 | Assembly procedure | 4 | 96 | Assembler | ||||

| Chemical attack | 2 | Usage instructions | 7 | 112 | User | ||||

| Solenoid | Failure to energize | Valve stays in default position | 9 | Coil burnout | 2 | Electrical protection | 3 | 54 | Designer |

| Connection failure | 3 | Quality inspection | 4 | 108 | Manufacturer | ||||

| Power supply issue | 4 | System monitoring | 5 | 180 | System integrator | ||||

| Spool | Sticking/jamming | Valve fails to shift | 7 | Contamination | 5 | Filtration requirements | 6 | 210 | User/Maintainer |

| Excessive wear | 3 | Material selection | 5 | 105 | Designer | ||||

| Manufacturing defect | 2 | Quality control | 4 | 56 | Manufacturer |

FMEA has proven particularly valuable in cases where multiple parties share potential responsibility. In a case involving a pneumatic system failure in an automated production line, the FMEA revealed that while contamination was the immediate cause of a valve failure, the system lacked adequate filtration (designer responsibility) and maintenance procedures failed to include filter inspection (user responsibility). The court used this analysis to apportion liability 70% to the designer and 30% to the user.

Root Cause Analysis Using 5-Why Method

The 5-Why method traces a failure to its fundamental cause through successive questioning:

5-Why Analysis Example: Pneumatic Cylinder Rod Failure

| Level | Question | Answer | Responsible Party |

|---|---|---|---|

| 1 | Why did the system fail? | The cylinder rod broke during operation | Unknown |

| 2 | Why did the rod break? | Material fatigue at the thread root | Unknown |

| 3 | Why did fatigue occur at this location? | Stress concentration due to improper thread design | Designer |

| 4 | Why was the thread improperly designed? | Thread relief was omitted from the design | Designer |

| 5 | Why was the thread relief omitted? | Design standard was not followed | Designer |

| 6 (Additional) | Why wasn’t the design standard followed? | Designer was not trained on company standards | Management |

This method is particularly effective in court because it creates a clear narrative chain that judges and juries can follow. In a case involving a pneumatic cylinder failure that caused property damage, the 5-Why analysis traced the failure to a specific design decision that omitted a critical stress relief feature, clearly establishing designer liability.

Technical Factors in Comparative Negligence Assessment

Many jurisdictions apply comparative negligence principles, requiring technical analysis to apportion responsibility:

Comparative Negligence Factors in Pneumatic System Failures

| Party | Technical Responsibilities | Common Failure Points | Evidence Sources | Typical Liability Range |

|---|---|---|---|---|

| Designer | Safe design within standards | Inadequate safety factors, missing safeguards | Design documentation, risk assessments, calculations | 30-100% |

| Manufacturer | Proper production to specifications | Manufacturing defects, quality control failures | Production records, QC documentation, material certifications | 20-100% |

| Installer | Correct system integration | Improper connections, inadequate testing | Installation procedures, test records, commissioning reports | 10-80% |

| Maintainer | Appropriate maintenance | Neglected maintenance, improper repairs | Maintenance records, repair documentation, inspection reports | 10-70% |

| User | Operation within specifications | Misuse, bypassing safety features | Training records, operating procedures, witness testimony | 0-100% |

A significant case involved a pneumatic lifting system that failed, causing injury. Technical analysis determined that the manufacturer used incorrect heat treatment (30% responsibility), the installer failed to perform pressure testing (20% responsibility), and the user had bypassed a safety valve (50% responsibility). The court apportioned damages according to this technical assessment of comparative negligence.

Expert Witness Technical Analysis Framework

Expert witnesses in pneumatic liability cases typically follow this framework:

Expert Analysis Methodology

System Examination

– Physical examination of failed components

– Non-destructive testing where applicable

– Dimensional analysis and comparison to specifications

– Documentation of physical evidenceDocumentation Review

– Design specifications and calculations

– Manufacturing records and quality control data

– Maintenance and inspection history

– Operating procedures and user manuals

– Applicable standards and regulationsFailure Analysis

– Metallurgical or materials analysis

– Stress analysis and simulation

– Performance testing of exemplar components

– Reconstruction of failure sequenceCausation Determination

– Application of FTA, FMEA, and 5-Why methods

– Evaluation of alternative scenarios

– Probability assessment of contributing factors

– Determination of most likely failure sequenceResponsibility Assessment

– Mapping of technical failures to responsible parties

– Evaluation of standard of care

– Assessment of foreseeability

– Quantification of contribution to failure

Case Study: Pneumatic Clamp System Failure

A pneumatic clamping system in a manufacturing facility failed, causing a workpiece to be ejected and injuring an operator. The technical investigation revealed:

FTA Analysis:

- Top Event: Clamp pressure loss during operation

- Primary Cause: Check valve failure allowing back-flow

- Secondary Causes: Improper valve material for hydraulic fluid, system pressure exceeding valve rating

FMEA Findings:

- Component: Check valve

- Failure Mode: Internal seal degradation

- Effect: Pressure loss during operation

- Cause: Chemical incompatibility with fluid

- Responsibility: Designer specified incorrect material

5-Why Analysis:

- Why was the operator injured? Workpiece ejected from clamp

- Why was the workpiece ejected? Clamp lost pressure during operation

- Why did clamp lose pressure? Check valve failed to maintain pressure

- Why did check valve fail? Internal seal degraded

- Why did seal degrade? Incompatible with hydraulic fluid used

Technical Conclusion:

The system designer specified a standard nitrile-sealed check valve, but the system used phosphate ester hydraulic fluid which is incompatible with nitrile. The designer’s specification was technically incorrect for the application, making them primarily liable. However, the system integrator failed to identify this incompatibility during design review, contributing 30% comparative negligence.

This case demonstrates how technical analysis methodologies provide a structured framework for determining causation and apportioning liability in pneumatic system failures.

How to Build an Effective Standards Compliance Evidence Chain

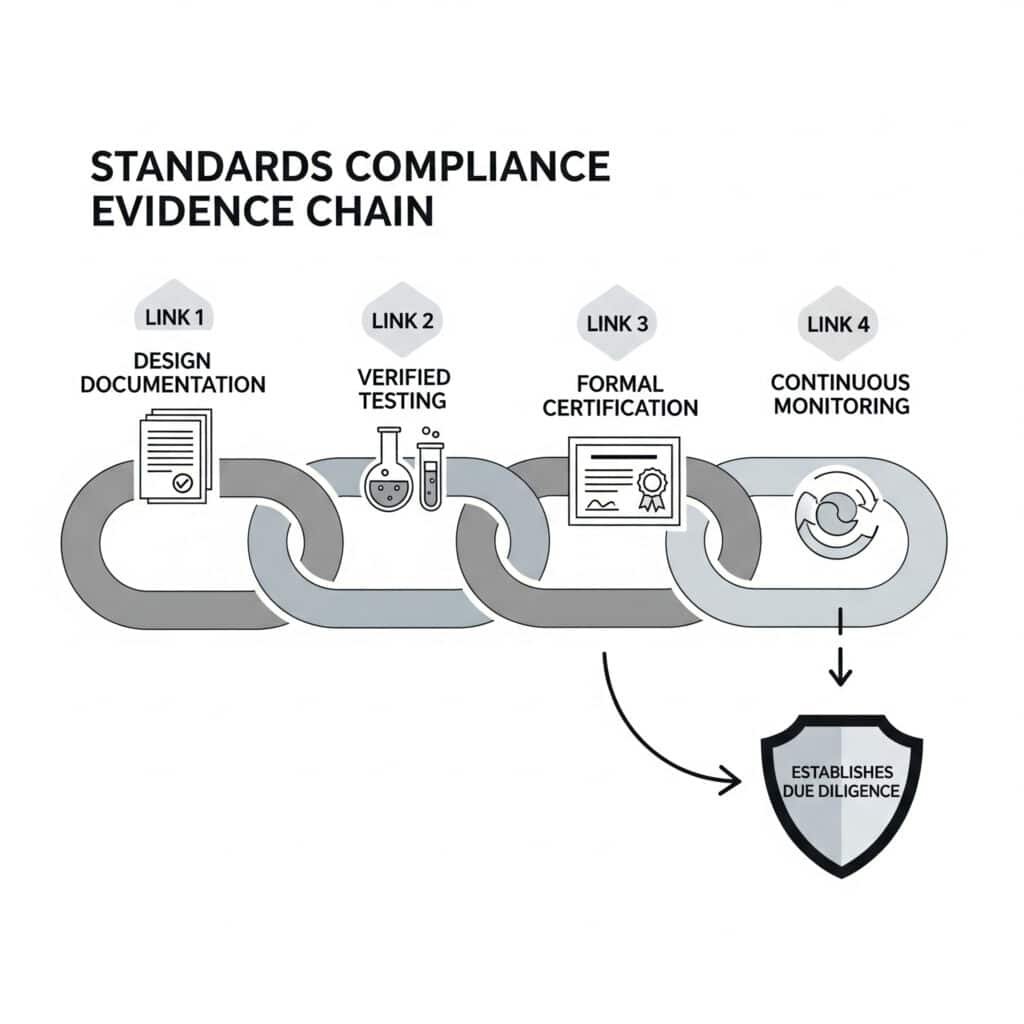

Standards compliance is often the central issue in pneumatic system legal disputes. Manufacturers must not only comply with applicable standards but also maintain a comprehensive evidence chain demonstrating that compliance throughout the product lifecycle.

An effective standards compliance evidence chain for pneumatic systems consists of four key elements: comprehensive documentation of design validation against specific standard requirements, verified testing protocols with calibrated equipment and witnessed procedures, formal certification through accredited third-party assessment, and continuous monitoring systems that track ongoing compliance through the product lifecycle. This chain establishes due diligence and can be decisive in defending against liability claims.

Mapping Pneumatic System Requirements to Standards

The foundation of compliance is a clear mapping of system requirements to specific standards:

Standards Mapping for Pneumatic Systems

| System Aspect | Applicable Standards | Key Requirements | Documentation Required |

|---|---|---|---|

| Pressure Equipment Safety | ISO 4414, ASME B&PV Code | Maximum allowable working pressure, safety factors, pressure testing | Design calculations, material certifications, test reports |

| Control System Safety | ISO 138494, IEC 62061 | Performance Level (PL) or Safety Integrity Level (SIL), fault tolerance | Risk assessment, circuit validation, component certificates |

| Electrical Components | IEC 60204, NFPA 79 | Insulation, grounding, protection against electric shock | Electrical schematics, insulation testing, ground continuity tests |

| Hazardous Environments | ATEX Directive, NEC 500 | Explosion protection methods, temperature classifications | Zone classification, component certifications, installation verification |

| Environmental Conditions | IEC 60529, MIL-STD-810 | Ingress protection, temperature range, vibration resistance | Environmental testing reports, IP certification, climate testing |

A recent legal case involved a pneumatic system that failed in a food processing environment. The manufacturer claimed compliance with ISO 4414 but could not produce documentation showing how specific clause requirements were met in the design. The court ruled that merely claiming compliance without a detailed requirements traceability matrix was insufficient to establish due diligence.

Design Validation Documentation

Design validation forms the first link in the compliance evidence chain:

Design Validation Documentation Requirements

| Validation Element | Documentation Type | Technical Content | Legal Significance |

|---|---|---|---|

| Requirements Traceability | Requirements Matrix | Mapping of each standard clause to design features | Demonstrates comprehensive standards consideration |

| Design Calculations | Engineering Analysis | Safety factors, pressure ratings, cycle life calculations | Proves technical due diligence in design |

| Risk Assessment | ISO 12100 Analysis | Hazard identification, risk estimation, risk reduction measures | Shows foreseeable risks were addressed |

| Design Reviews | Review Reports | Independent verification of design compliance | Establishes peer validation of compliance claims |

| Material Selection | Material Specifications | Compatibility, strength, environmental resistance | Demonstrates appropriate material selection process |

| Simulation Results | FEA/CFD Reports | Stress analysis, flow modeling, thermal analysis | Shows advanced validation of critical parameters |

In a dispute involving a pneumatic system that failed due to material incompatibility, the manufacturer who maintained comprehensive material selection documentation—including compatibility testing and environmental exposure analysis—successfully defended against liability claims by demonstrating thorough due diligence in the design process.

Testing Protocol Verification

Testing protocols provide empirical evidence of compliance:

Testing Evidence Requirements

| Test Type | Protocol Requirements | Documentation Elements | Verification Methods |

|---|---|---|---|

| Prototype Testing | Written test plans referencing standards | Test setup, procedures, acceptance criteria | Independent witness, video documentation |

| Production Testing | Documented test procedures | Pass/fail criteria, test equipment specifications | Statistical process control, calibration records |

| Type Testing | Testing to specific standard requirements | Complete test reports with raw data | Accredited laboratory certification |

| Destructive Testing | Defined failure criteria | Photographic evidence, measurement data | Material analysis reports |

| Field Testing | In-situ test protocols | Environmental conditions, operational parameters | Third-party verification |

| Accelerated Life Testing | Correlation to real-world conditions | Time compression calculations, failure analysis | Statistical validity documentation |

The importance of proper test documentation was highlighted in a case where a manufacturer claimed their pneumatic components were rated for hazardous environments. When a system failure led to an industrial accident, the investigation revealed that while testing had been performed, the test equipment calibration was expired and the test procedures deviated from standard requirements. The court ruled that invalid testing procedures broke the compliance evidence chain.

Certification Documentation

Formal certification provides third-party validation of compliance:

Certification Evidence Requirements

| Certification Type | Issuing Authority | Documentation Required | Maintenance Requirements |

|---|---|---|---|

| Component Certification | Notified Bodies, UL, CSA | Certificates with specific standards reference | Renewal documentation, change management |

| Quality System Certification | ISO 9001 Registrars | Audit reports, non-conformance resolutions | Surveillance audit records, management reviews |

| Product Type Approval | Industry Certification Bodies | Type examination certificates, technical files | Periodic re-certification, modification approvals |

| Personnel Certification | Professional Organizations | Training records, competency assessments | Continuing education documentation |

| Process Certification | Specialized Certification Bodies | Process validation records, capability studies | Process monitoring data, re-validation records |

| Self-Declaration | Manufacturer | Declaration of Conformity with standards list | Technical file maintenance, change control records |

A manufacturer of pneumatic components for medical devices successfully defended against liability claims following a patient injury by producing a comprehensive technical file supporting their CE marking5. The file included detailed certification documentation showing how each essential requirement was met, validated, and maintained through product modifications.

Continuous Monitoring Systems

Ongoing compliance monitoring completes the evidence chain:

Continuous Monitoring Evidence Requirements

| Monitoring Aspect | Monitoring Methods | Documentation Required | Legal Relevance |

|---|---|---|---|

| Product Performance | Field performance tracking | Statistical analysis, trend reports | Demonstrates ongoing compliance verification |

| Customer Feedback | Complaint handling system | Complaint logs, resolution documentation | Shows responsiveness to potential issues |

| Manufacturing Process | Statistical Process Control | Control charts, capability studies | Proves consistent production within specifications |

| Design Changes | Change management system | Impact analysis, re-validation records | Demonstrates compliance maintenance through changes |

| Field Incidents | Incident investigation process | Root cause analysis, corrective actions | Shows due diligence in addressing field issues |

| Regulatory Updates | Standards monitoring process | Gap analysis, implementation plans | Demonstrates awareness of evolving requirements |

In a significant case, a manufacturer of pneumatic control systems for industrial equipment faced liability claims after a system failure. Despite the failure, they successfully limited liability by demonstrating a robust monitoring system that had identified similar potential issues in other installations, implemented corrective actions, and attempted to notify all customers—including the plaintiff who had not responded to recall notices. This evidence of proactive monitoring significantly reduced their liability exposure.

Building a Defensible Technical File

A comprehensive technical file integrates all elements of the compliance evidence chain:

Technical File Structure for Legal Defense

Product Identification and Description

– Detailed technical specifications

– Intended use and limitations

– System boundaries and interfaces

– Component identification and sourcingStandards Compliance Documentation

– Standards applicability assessment

– Clause-by-clause compliance documentation

– Gap analysis and justifications

– Alternative methods where applicableDesign Documentation

– Design calculations and analyses

– Material specifications and justifications

– Risk assessments and mitigations

– Design review recordsVerification and Validation

– Test plans and procedures

– Test reports with raw data

– Simulation reports

– Validation protocols and resultsManufacturing Controls

– Production process specifications

– Quality control procedures

– Inspection methods and criteria

– Non-conformance handlingPost-Market Surveillance

– Field monitoring procedures

– Complaint handling processes

– Incident investigation methods

– Corrective action proceduresChange Management

– Change control procedures

– Impact assessment methods

– Re-validation requirements

– Customer notification processes

Case Study: Pneumatic System Compliance Dispute

A pneumatic control system for an industrial press was involved in a workplace accident resulting in operator injury. The manufacturer faced liability claims based on alleged non-compliance with safety standards.

The Evidence Chain Analysis:

Design Validation:

– Manufacturer maintained comprehensive risk assessment per ISO 12100

– Performance Level determination according to ISO 13849-1 showed PL=d requirement

– Circuit validation documentation demonstrated dual-channel architecture with diagnostics

– Missing: Specific calculation for pneumatic component fault exclusionTesting Evidence:

– Type testing of control system by accredited laboratory

– Fault injection testing documented for electrical components

– Missing: Documented testing of pneumatic component failure modesCertification:

– CE marking with Declaration of Conformity

– ISO 9001 certification for quality management system

– Missing: Specific certification for safety-related pneumatic componentsContinuous Monitoring:

– Field performance tracking system in place

– Previous similar incidents investigated with corrective actions

– Design changes implemented based on field data

– Missing: Evidence that this specific risk was identified and addressed

Court Finding:

The court determined that while the manufacturer had a generally robust compliance system, the specific gap in pneumatic component validation created a broken link in the evidence chain. The manufacturer was found partially liable because they could not demonstrate complete due diligence specific to the failure mode that caused the accident.

This case demonstrates that a compliance evidence chain is only as strong as its weakest link, and that comprehensive documentation across all system aspects is essential for an effective legal defense.

Conclusion: Implementing Preventive Legal Strategies

Understanding the technical aspects of legal frameworks for patent infringement, product liability, and standards compliance enables pneumatic system manufacturers to implement effective preventive strategies. By proactively addressing these areas, companies can both reduce litigation risk and strengthen their position when disputes arise.

Key Preventive Strategies

Patent Risk Management

– Implement systematic freedom-to-operate analyses

– Document design-around decisions with technical rationales

– Maintain comprehensive development records showing independent creation

– Establish clear procedures for handling third-party patent noticesProduct Liability Prevention

– Integrate FMEA and FTA methodologies into design processes

– Implement robust design review procedures with documented risk assessments

– Develop comprehensive user instructions with clear warnings

– Establish incident investigation procedures that preserve evidenceStandards Compliance Management

– Create and maintain standards traceability matrices

– Implement formal design validation processes against standards requirements

– Establish comprehensive testing protocols with proper documentation

– Develop continuous monitoring systems for ongoing compliance

By applying these technical frameworks to legal risk management, pneumatic system manufacturers can significantly reduce their exposure to costly disputes while building stronger defensive positions when litigation does occur.

FAQs About Pneumatic System Legal Disputes

What documentation should be maintained to defend against patent infringement claims?

Maintain comprehensive design development records including: dated design concepts and iterations, alternative designs considered, technical rationale for design decisions, prior art reviewed during development, independent development evidence, and freedom-to-operate analyses. These records should be created contemporaneously with development, properly dated, and preserved in a secure, tamper-evident system. Additionally, maintain records of any patent clearance opinions from qualified counsel and documentation of any design-around efforts if potentially problematic patents were identified.

How can manufacturers effectively document compliance with evolving standards?

Implement a standards monitoring system that tracks relevant standard updates and performs gap analyses when changes occur. Maintain a standards compliance matrix that maps specific product features to standard requirements with explicit documentation of how each requirement is met. For each standard revision, conduct and document a formal impact assessment, implement necessary design or process changes, perform appropriate validation, and update the technical file accordingly. Preserve all versions of this documentation to demonstrate compliance with the standards applicable at the time of manufacture.

What is the most effective way to apportion liability in complex pneumatic system failures?

The most effective approach combines multiple technical analysis methodologies. Begin with a comprehensive Fault Tree Analysis (FTA) to identify all potential contributing factors. Follow with Failure Mode and Effects Analysis (FMEA) to evaluate the relative impact of each factor. Apply the 5-Why method to trace each significant factor to its root cause. Then map these technical findings to specific responsibilities based on design decisions, manufacturing processes, installation procedures, maintenance actions, and user operations. This multi-method approach provides a defensible technical basis for liability apportionment that can withstand legal scrutiny.

-

Provides a legal explanation of the doctrine of equivalents, a U.S. patent law principle that allows courts to find a party liable for patent infringement even if the infringing device does not fall within the literal scope of a patent claim. ↩

-

Details the legal principle of prosecution history estoppel (or file wrapper estoppel), which prevents a patent owner from using the doctrine of equivalents for claim elements that were narrowed during patent prosecution to overcome prior art. ↩

-

Offers a comprehensive overview of Fault Tree Analysis (FTA), a top-down, deductive failure analysis in which a system’s failure is traced back to its root causes through a series of logical steps. ↩

-

Explains the ISO 13849 standard, which provides safety requirements and guidance on the principles for the design and integration of safety-related parts of control systems, including the determination of Performance Levels (PL). ↩

-

Describes the CE marking, a mandatory conformity marking for certain products sold within the European Economic Area (EEA), which certifies that the product meets EU health, safety, and environmental protection requirements. ↩