Industrial equipment breakdowns cost companies thousands daily. Air slides seem simple but play crucial roles in automation systems. Many engineers struggle to understand their full potential and miss opportunities for efficiency improvements.

Air slides are pneumatic actuators that create linear motion using compressed air, primarily used for material handling, positioning, and automation in manufacturing processes where smooth, long-stroke movement is essential.

Last month, I helped a German automotive engineer named Klaus Weber replace his failing air slide system. His production line was down for three days, costing €50,000 in lost revenue. The original supplier couldn’t deliver replacement parts for six weeks, but we provided a compatible solution within 48 hours.

Table of Contents

- How Do Air Slides Create Linear Motion?

- What Are the Main Types of Air Slides Available?

- Where Are Air Slides Most Commonly Used?

- How Do Air Slides Compare to Other Pneumatic Actuators?

- What Are the Key Benefits of Using Air Slides?

- Conclusion

- FAQs About Air Slides

How Do Air Slides Create Linear Motion?

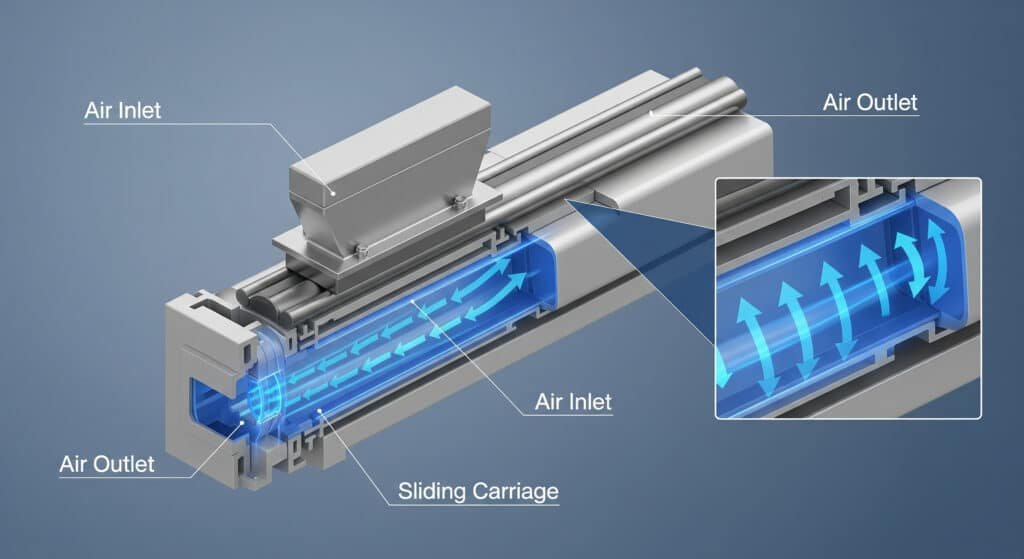

Air slides work through compressed air pressure differences. The system uses pneumatic force to move loads along predetermined paths. Understanding this mechanism helps engineers select appropriate solutions for their applications.

Air slides use compressed air chambers to generate pushing or pulling forces, moving materials horizontally or at slight angles through controlled pneumatic pressure differentials.

Basic Working Principle

Air slides operate on simple pressure dynamics. Compressed air enters one chamber while the opposite chamber vents to atmosphere. This pressure difference creates the driving force that moves the load carrier along guide rails.

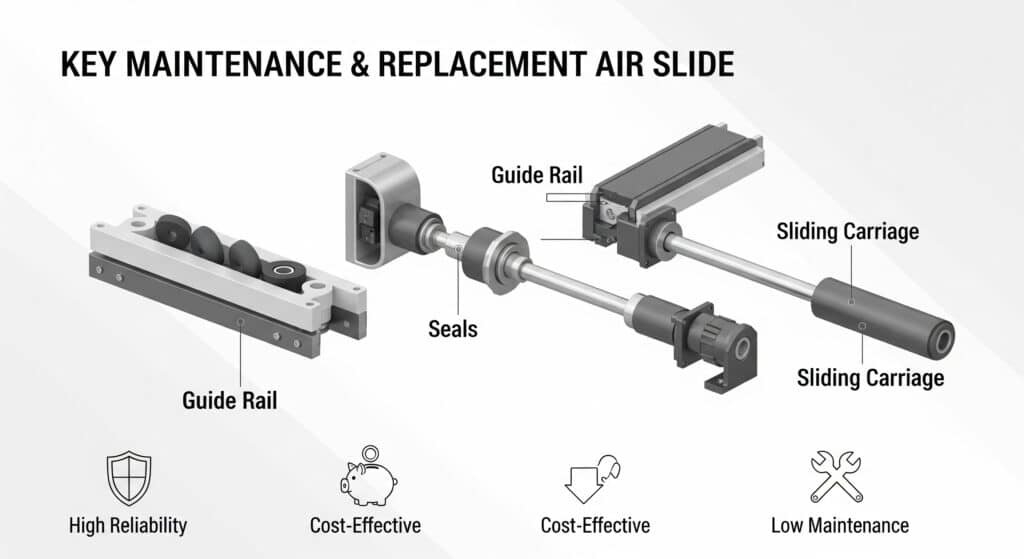

The mechanism includes several critical components working together:

| Component | Function | Material Options | Typical Lifespan |

|---|---|---|---|

| Air Chamber | Houses compressed air | Aluminum/Steel | 10-15 years |

| Piston/Diaphragm | Converts pressure to motion | Rubber/Plastic/Metal | 5-8 years |

| Guide Rails | Direct movement path | Steel/Aluminum | 15-20 years |

| Seals | Prevent air leakage | Nitrile/Viton1 | 2-5 years |

| Mounting Hardware | Secure installation | Steel/Stainless Steel | 20+ years |

Pressure Requirements and Force Calculations

Most air slides operate between 80-120 PSI for optimal performance. Higher pressures increase force output but also accelerate wear rates. I recommend starting with 90 PSI for most applications and adjusting based on load requirements.

The force calculation follows a straightforward formula: Force = Pressure × Effective Area. A 4-inch diameter slide at 100 PSI generates approximately 1,256 pounds of force. However, friction losses typically reduce actual output by 15-20%.

Speed Control Methods

Air slides offer multiple speed control options:

- Flow Control Valves: Restrict air flow for slower movements

- Pressure Regulators: Reduce driving pressure for gentler operation

- Cushioning Systems: Provide soft stops at stroke ends

- Variable Orifices: Allow real-time speed adjustment during operation

What Are the Main Types of Air Slides Available?

Different applications require specific air slide designs. Each type offers unique advantages for particular industrial needs. Selecting the wrong type can lead to premature failure and increased maintenance costs.

The three main types are diaphragm air slides, piston air slides, and rodless pneumatic cylinders, each designed for specific load capacities, stroke lengths, and movement requirements.

Diaphragm Air Slides

Diaphragm slides use flexible membranes instead of rigid pistons. They work exceptionally well for lighter loads and provide smooth, quiet operation that’s ideal for sensitive environments.

These units typically handle loads up to 500 pounds. The diaphragm design eliminates internal friction between moving parts, extending service life significantly compared to piston-based systems.

Advantages of Diaphragm Design:

- Zero internal friction

- Self-lubricating operation

- Excellent for food-grade applications

- Minimal maintenance requirements

- Quiet operation under 65 decibels

Limitations:

- Limited to lighter loads

- Shorter stroke lengths (typically under 6 feet)

- Less precise positioning capability

- Diaphragm replacement requires complete disassembly

Piston Air Slides

Piston-based systems handle heavier loads and provide more precise positioning control. They use traditional cylinder technology with specialized mounting configurations optimized for horizontal movement.

These systems excel in applications requiring loads from 500 to 5,000 pounds. The rigid piston design allows for better force transmission and more accurate positioning feedback systems.

Rodless Pneumatic Cylinder Applications

Rodless pneumatic cylinders offer the longest stroke lengths available in pneumatic systems. I’ve installed units with 20-foot strokes for conveyor applications. These systems eliminate the space requirements of traditional rod cylinders while providing excellent force output.

The magnetic coupling design in rodless cylinders prevents air leakage while maintaining smooth operation. This technology is particularly valuable in clean room environments2 where contamination control is critical.

Where Are Air Slides Most Commonly Used?

Air slides serve multiple industries with diverse applications. Manufacturing facilities rely on them for automation and material handling tasks that require reliable, repeatable motion.

Air slides are primarily used in conveyor systems, sorting equipment, packaging machinery, and assembly line automation where smooth linear motion with long stroke capability is required.

Manufacturing Applications

Assembly lines use air slides for part positioning and product movement between workstations. The automotive industry particularly benefits from their reliability and speed in high-volume production environments.

I recently supplied air slides to a Canadian manufacturer named Sarah Mitchell in Ontario. Her packaging line needed gentle product handling for fragile electronics components. The original European supplier quoted 12 weeks delivery, but we provided a superior replacement solution in just one week.

Specific Manufacturing Uses:

- Component feeding systems

- Product indexing and positioning

- Quality control station movement

- Automated assembly processes

- Paint line conveyor systems

Material Handling Systems

Warehouses and distribution centers increasingly rely on air slides for automated sorting and movement systems. These applications benefit from the long stroke capability and smooth operation characteristics.

Common material handling applications include:

- Package sorting and diverting

- Conveyor direction changes and transfers

- Load positioning for automated storage

- Palletizing and depalletizing operations

- Cross-docking facility automation

Food and Pharmaceutical Industries

Food processing and pharmaceutical manufacturing require specialized air slide designs that meet strict hygiene standards. Stainless steel construction and FDA-approved sealing materials3 are essential.

These industries use air slides for:

- Product conveying between processing stages

- Packaging line automation

- Clean room material transfer

- Sterile environment applications

How Do Air Slides Compare to Other Pneumatic Actuators?

Air slides offer specific advantages over traditional pneumatic cylinders and electric actuators. Understanding these differences helps engineers make informed equipment selection decisions that optimize both performance and cost.

Air slides provide smoother operation and longer stroke lengths compared to standard pneumatic cylinders, but offer less precise positioning than servo-driven electric systems.

Detailed Comparison Analysis

| Feature | Air Slides | Standard Cylinders | Electric Actuators | Hydraulic Systems4 |

|---|---|---|---|---|

| Stroke Length | Up to 20+ feet | Limited to 8 feet | Up to 12 feet | Up to 15 feet |

| Speed Control | Good (flow control) | Excellent (servo valves) | Excellent (variable speed) | Excellent (proportional) |

| Positioning Accuracy | ±0.1 inch | ±0.05 inch | ±0.001 inch | ±0.02 inch |

| Maintenance Frequency | Every 6 months | Every 3 months | Every 12 months | Every 2 months |

| Initial Cost | $500-3000 | $200-1500 | $1500-8000 | $2000-10000 |

| Operating Cost | Low (compressed air) | Low (compressed air) | Medium (electricity) | High (hydraulic fluid) |

| Environmental Impact | Clean operation | Clean operation | Very clean | Potential leaks |

Performance Considerations in Detail

Air slides excel in applications requiring long, smooth movements with moderate speed control. They consume significantly less compressed air than multiple short-stroke cylinders performing equivalent functions.

The trade-off involves positioning precision and response time. Electric actuators provide superior accuracy and programmable motion profiles but cost 3-5 times more initially and require complex control systems with specialized programming knowledge.

Reliability and Maintenance Factors

Air slides typically operate 2-3 years between major maintenance intervals. The simple design with fewer moving parts reduces failure points compared to complex servo systems.

Standard pneumatic cylinders require more frequent seal replacement due to rod wear and contamination exposure. Air slides eliminate rod-related maintenance issues entirely.

What Are the Key Benefits of Using Air Slides?

Air slides provide multiple operational advantages that make them attractive for many industrial applications. These benefits often justify the initial investment through reduced operating costs and improved reliability.

Key benefits include long stroke capability, smooth operation, low maintenance requirements, cost-effectiveness, and excellent reliability in harsh industrial environments.

Economic Advantages

Air slides offer excellent return on investment through several factors:

Cost Savings Analysis:

- Reduced Downtime: Fewer mechanical failures mean less production interruption

- Lower Maintenance Costs: Simple design requires minimal specialized service

- Energy Efficiency: Optimized air consumption reduces utility costs

- Longer Service Life: Robust construction extends replacement intervals

Operational Benefits

The smooth, consistent motion of air slides improves product quality in manufacturing applications. This is particularly important for fragile products or precision assembly operations.

Air slides also provide excellent force-to-weight ratios, making them ideal for applications where mounting space is limited but high force output is required.

Environmental and Safety Advantages

Air slides operate using clean compressed air, making them suitable for food processing and pharmaceutical applications. They produce no harmful emissions and operate quietly compared to hydraulic alternatives.

The fail-safe design5 of most air slide systems ensures safe operation even during power failures or air supply interruptions.

Conclusion

Air slides provide reliable, cost-effective linear motion solutions for industrial applications requiring smooth, long-stroke movement with moderate positioning requirements and excellent durability.

FAQs About Air Slides

What is an air slide used for?

Air slides move materials and products along predetermined paths using compressed air pressure, commonly used in conveyor systems, manufacturing automation, and material handling applications where smooth linear motion is essential.

How much weight can an air slide handle?

Air slide capacity ranges from 50 pounds for lightweight diaphragm types to over 5,000 pounds for heavy-duty piston designs, depending on air pressure, slide diameter, and mounting configuration.

What’s the difference between air slides and pneumatic cylinders?

Air slides provide longer stroke lengths up to 20+ feet and smoother operation than standard cylinders, while pneumatic cylinders offer more precise positioning and faster response times for shorter movements.

How do you maintain an air slide system?

Regular maintenance includes checking air pressure monthly, lubricating moving parts every six months, inspecting seals annually for wear, and cleaning guide rails quarterly to prevent contamination buildup.

Can air slides work vertically?

Yes, air slides can operate vertically but require 20-30% higher air pressure to overcome gravity loads and should include safety mechanisms like mechanical locks to prevent load dropping during power loss.

What air pressure do air slides need?

Most air slides operate optimally between 80-120 PSI, with 90 PSI being the recommended starting point for most applications, though specific requirements depend on load weight and desired speed.

-

Review a detailed comparison of the chemical resistance and temperature ratings for these common sealing materials. ↩

-

Learn about the official ISO standards that classify and govern clean room environments. ↩

-

Access the U.S. Food and Drug Administration’s official regulations regarding materials safe for food contact. ↩

-

Understand the basic principles of hydraulic systems, which use incompressible fluids to transfer force. ↩

-

Explore the engineering principle of fail-safe design and its importance for industrial safety. ↩