Vanne de régulation à bouton mécanique | Actionnée mécaniquement pour contrôler le débit d'air pour la détection et le positionnement automatisés. Découvrez notre gamme de vannes boutons mécaniques. Elles sont actionnées par contact avec des éléments externes de la machine, tels que des cames ou des déclencheurs, pour déplacer automatiquement le flux d'air sans intervention manuelle. Elles sont idéales pour la détection des pièces, la limitation de la course et le séquençage sur les lignes de production. Sélectionnez maintenant la vanne mécanique adaptée à votre processus automatisé.

Besoin de produits pour votre projet ?

Nous comprenons que la recherche de sources d'approvisionnement peut être un défi.

Remplissez le formulaire avec vos articles spécifiques - n'hésitez pas à indiquer des composants uniques ou difficiles à trouver - soumettez votre demande et obtenez les solutions sur mesure que vous recherchez ! Oubliez les offres génériques ; nous sommes spécialisés dans la compréhension de vos besoins exacts et dans l'obtention de résultats qui vous vont comme un gant.

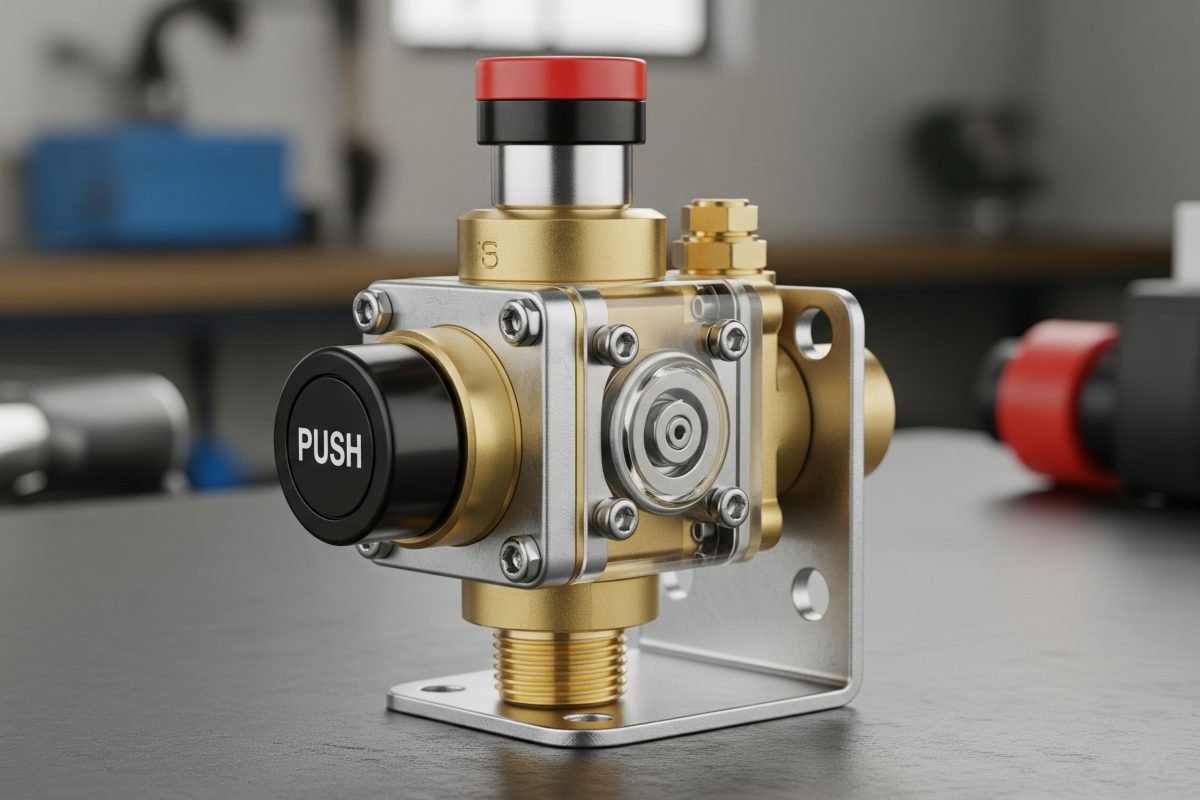

Faites l'expérience d'un contrôle pneumatique direct et fiable grâce à notre gamme de vannes à bouton mécaniques. Conçues pour durer et être faciles à utiliser, ces vannes assurent un actionnement manuel positif pour une variété d'applications industrielles, garantissant la sécurité et un fonctionnement précis lorsque vous en avez le plus besoin.

Offre un actionnement immédiat et positif par le biais de boutons-poussoirs, de boutons ou de leviers, permettant aux opérateurs de contrôler directement les circuits pneumatiques.

Construit avec des matériaux durables et des mécanismes simples pour une longue durée de vie et des performances constantes, même dans des environnements industriels exigeants.

Parfait pour les commandes manuelles, les arrêts d'urgence et les circuits de verrouillage de sécurité où une intervention directe de l'opérateur est nécessaire.

Les vannes de commande à bouton mécanique sont actionnées par une force physique appliquée à un bouton, un levier, un bouton ou une pédale. Cette action mécanique directe déplace le tiroir ou le clapet de la vanne, redirigeant le flux d'air pour contrôler les actionneurs pneumatiques ou les fonctions du système. Ils sont appréciés pour leur simplicité et leur fiabilité, car ils fonctionnent sans alimentation électrique.

Boutons, leviers et composants internes très résistants, conçus pour une durée de vie élevée et une résistance à l'usure en milieu industriel.

De nombreux modèles sont dotés de positions de détente claires, offrant un retour d'information tactile et garantissant que la vanne reste dans l'état sélectionné jusqu'à ce qu'elle soit modifiée intentionnellement.

Ils comprennent des boutons affleurants, étendus, à tête champignon (pour les arrêts d'urgence) et masqués pour répondre aux différents besoins opérationnels et de sécurité.

Conçu pour un montage facile sur panneau pour les consoles de commande ou pour un montage direct sur les machines.

Par exemple, 3/2 NF, 3/2 NO, 5/2, 5/3 (à détente ou à ressort).

Bouton poussoir (différents styles), levier, bouton de sélection, rouleau, poussoir.

Tailles courantes telles que M5, G1/8″, G1/4″.

Pression maximale que la soupape peut supporter en toute sécurité.

Indique la capacité de débit d'air de la vanne.

Force nécessaire pour actionner le bouton ou le levier.

Généralement de l'aluminium, du laiton ou des plastiques durables.

Montage sur panneau (col fileté) ou trous de montage sur le corps.

Pour les paramètres détaillés, veuillez vous référer aux manuels des produits individuels ou à l'adresse suivante consulter nos experts techniques.

Permettre aux opérateurs de contrôler manuellement des parties d'un système automatisé lors de l'installation, de la maintenance ou en cas d'urgence.

Utilisé dans les systèmes de commande bimanuelle ou dans le cadre de la protection des machines pour assurer la sécurité de l'opérateur.

Fournir une entrée directe pour le démarrage, l'arrêt ou la sélection des fonctions dans les machines pneumatiques.

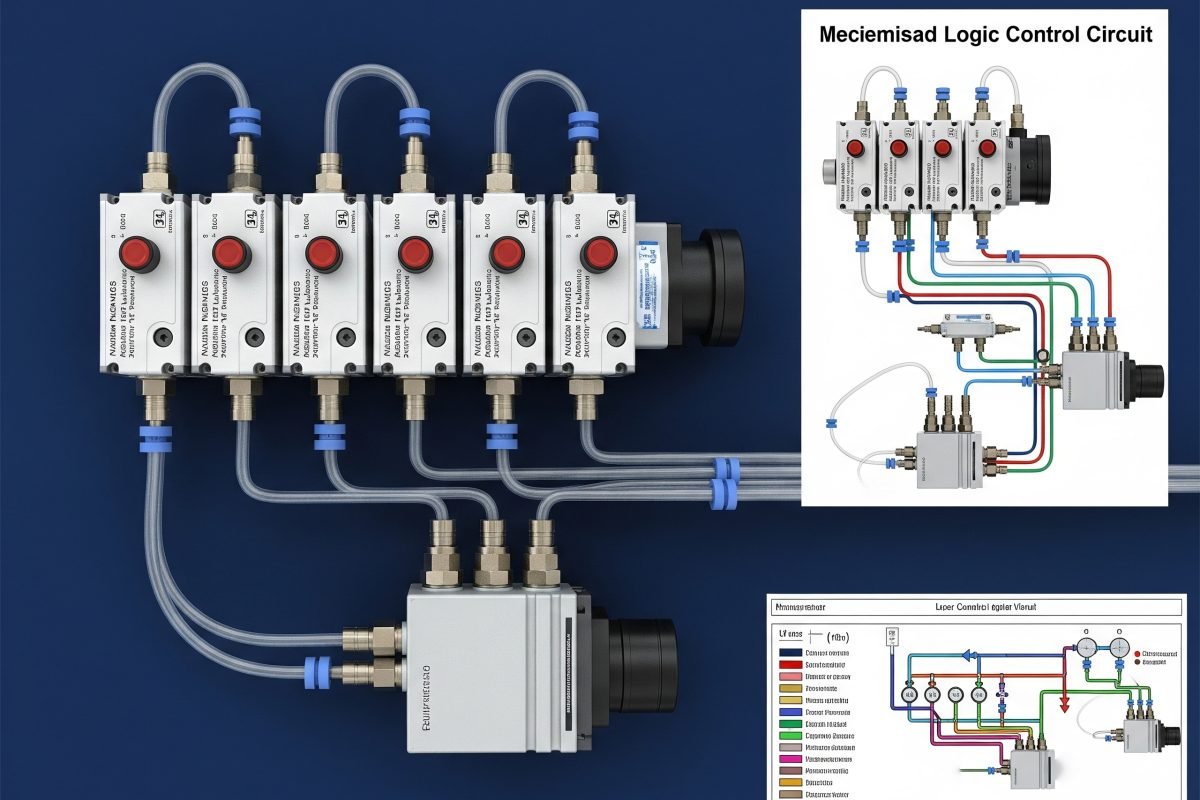

Utilisés comme éléments d'entrée dans les systèmes de contrôle purement pneumatiques où les signaux électriques ne sont pas souhaités.

Pour le déclenchement manuel de séquences d'essai ou d'opérations de serrage/débridage sur les bancs d'essai.

Pour la commande de base marche/arrêt ou directionnelle de petits appareils et outils pneumatiques.

Il faut toujours dépressuriser le système pneumatique avant d'effectuer des travaux d'entretien ou d'essayer de démonter une vanne.

Le principal avantage est le suivant simplicité et indépendance par rapport à l'énergie électrique. Les vannes boutons mécaniques sont actionnées par une force physique directe, ce qui les rend très efficaces :

Il s'agit de la manière dont la vanne maintient sa position après l'actionnement :

Choisissez selon que vous avez besoin que la vanne reste actionnée ou qu'elle revienne automatiquement.

La force de fonctionnement requise varie considérablement en fonction de la conception de la soupape, de sa taille, de la force du ressort interne (pour les types à ressort de rappel) et de la pression d'air à laquelle elle est soumise.

Les petites valves ou celles dont le tiroir est équilibré requièrent généralement moins de force. Les vannes plus grandes ou celles fonctionnant à des pressions plus élevées peuvent nécessiter une force plus importante. Les fiches techniques des produits précisent généralement la force ou la plage de fonctionnement typique pour chaque modèle. Pour les boutons-poussoirs, cette force est souvent exprimée en newtons (N) ou en livres-force (lbf).

Bien que les vannes boutons mécaniques soient robustes, leur adaptation à des taux de cycles très élevés dépend de la conception et de l'application spécifiques.

Pour les cadences extrêmement élevées ou les processus entièrement automatisés, les électrovannes sont généralement préférées. Les vannes-boutons mécaniques conviennent parfaitement aux applications nécessitant une intervention manuelle délibérée, des fonctions de sécurité ou lorsque la commande électrique n'est pas possible.

Les options de montage les plus courantes pour les vannes de régulation à bouton mécanique sont les suivantes :

Les options de montage spécifiques sont détaillées dans la documentation technique du produit.

Pour les applications exigeant une intervention manuelle fiable et des performances robustes, nos vannes de commande à bouton mécanique constituent un choix de confiance. Explorez notre gamme diversifiée ou contactez nos spécialistes en vannes pour trouver la solution parfaite à vos besoins.

Concevoir et développer.

Nous concevons l'excellence pneumatique - innovante, polyvalente, performante.

Nos spécialistes en pneumatique se concentrent sur la fourniture de produits pneumatiques de qualité supérieure.

afin de garantir une fonctionnalité optimale de vos systèmes.

A propos de

Nous contacter

Zone industrielle de Xuezhai, ville de Liushi, ville de Yueqing, province de Zhejiang, Chine

© 2025. Tous droits réservés.Powered by Bepto