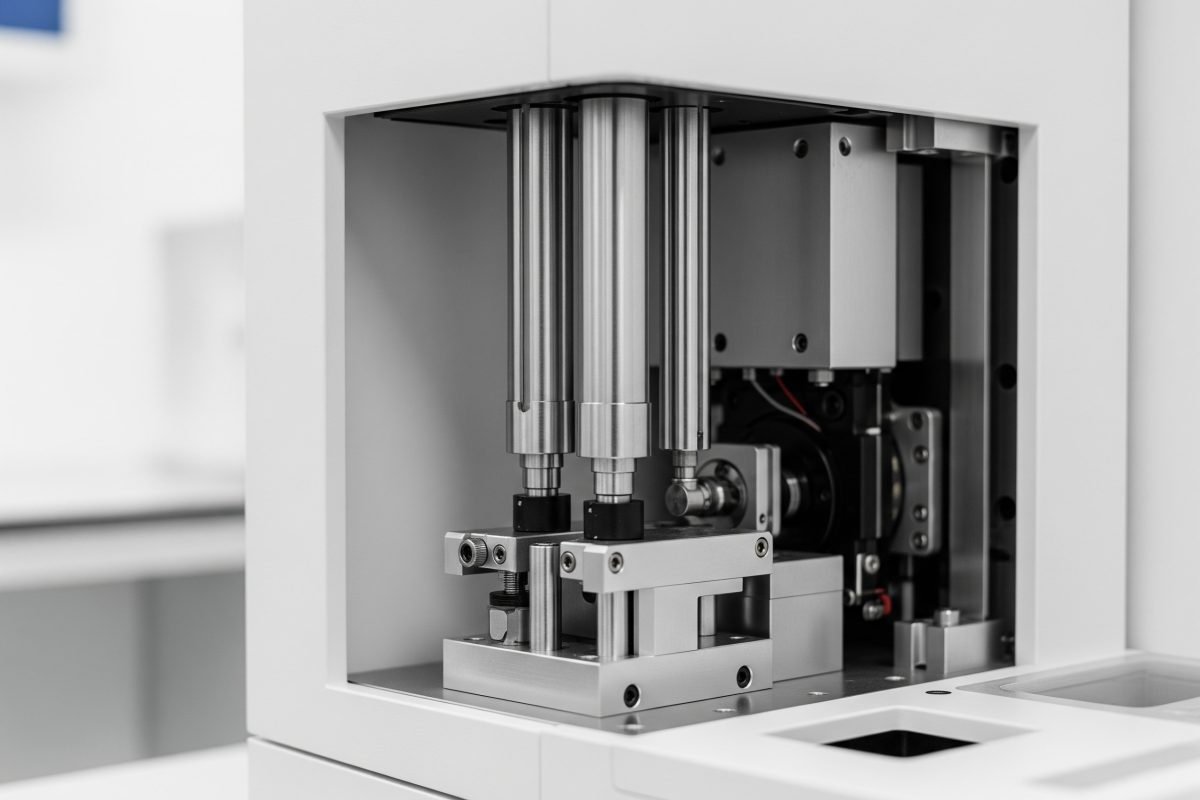

Cylindres de guidage compacts offrant un guidage de haute précision et une capacité anti-charges latérales pour les tâches de précision. Découvrez nos vérins de guidage compacts conçus pour un assemblage et un positionnement de précision. Leur structure de tige de guidage intégrée offre une précision anti-rotation et une résistance aux charges latérales exceptionnelles sur une courte course, ce qui en fait le choix idéal pour les applications où l'espace est limité et les exigences de stabilité élevées. Sélectionnez dès maintenant le modèle adapté à votre tâche de précision.

Besoin de produits pour votre projet ?

Nous comprenons que la recherche de sources d'approvisionnement peut être un défi.

Remplissez le formulaire avec vos articles spécifiques - n'hésitez pas à indiquer des composants uniques ou difficiles à trouver - soumettez votre demande et obtenez les solutions sur mesure que vous recherchez ! Oubliez les offres génériques ; nous sommes spécialisés dans la compréhension de vos besoins exacts et dans l'obtention de résultats qui vous vont comme un gant.

Nos vérins de guidage compacts intègrent de manière transparente l'actionnement pneumatique linéaire avec des mécanismes de guidage robustes. Ils offrent un contrôle de mouvement précis, stable et peu encombrant, ce qui les rend idéaux pour les tâches d'automatisation exigeantes où la précision et l'encombrement minimal sont essentiels.

Le guide et le corps du vérin intégrés réduisent considérablement la longueur totale et l'encombrement de l'installation, ce qui est parfait pour les espaces restreints.

Les mécanismes de guidage robustes offrent une excellente résistance aux charges latérales et aux moments, ce qui garantit la stabilité dans des conditions difficiles.

Ils garantissent un mouvement linéaire précis et sans rotation, ce qui les rend idéaux pour les applications critiques de précision.

Utilise des roulements linéaires de haute qualité ou des tiges de guidage robustes pour une rectitude exceptionnelle de la course et un jeu minimal, garantissant un mouvement précis.

Le cylindre et l'unité de guidage sont parfaitement intégrés, ce qui réduit la taille globale et simplifie l'assemblage de la machine pour nos clients.

Les matériaux résistants à l'usure et la construction robuste garantissent une longue durée de vie, même dans des conditions industrielles exigeantes.

Il offre différents points de montage sur de multiples surfaces, ce qui permet une grande souplesse de conception pour une intégration aisée des machines.

Par exemple, Ø12, Ø16, Ø20, Ø25, Ø32, Ø40, Ø50, Ø63 mm.

Des options standard et personnalisées sont disponibles pour répondre aux besoins de déplacement des applications.

Par exemple, guide à roulement à billes, guide à palier lisse (douille), guide à double tige.

Force maximale perpendiculaire à la direction du mouvement que le guide peut supporter.

Capacité à résister aux moments de tangage, de lacet et de roulis.

Précision du positionnement pour les tâches répétitives.

Plage de pression pneumatique standard, par exemple 0,1-1,0 MPa.

Disponibilité d'un piston magnétique et d'encoches de montage du capteur pour la détection de la position.

Pour les paramètres détaillés, veuillez vous référer aux manuels des produits individuels ou à l'adresse suivante consulter nos experts techniques.

Pour la manipulation et le transfert précis de petites pièces dans l'assemblage électronique, l'emballage et la fabrication légère.

Transport, arrêt ou déviation de composants à faible course sur des lignes automatisées où l'espace est limité.

Dans les équipements d'essai, les stations d'inspection et les petites machines automatisées nécessitant un placement linéaire précis.

Maintien en toute sécurité de pièces de petite et moyenne taille dans des espaces restreints pendant les processus d'assemblage ou d'usinage.

Actionner de petits outils, des gabarits ou des montages avec un mouvement précis et guidé dans des systèmes automatisés.

Pour des mouvements compacts et précis dans les instruments d'analyse, les équipements de diagnostic et les systèmes de manipulation d'échantillons.

Une installation correcte et un entretien régulier sont essentiels à la longévité et aux performances optimales des vérins de guidage compacts.

Les principaux avantages sont les suivants intégration et gain de place:

Pour sélectionner la capacité de charge correcte, vous devez tenir compte de toutes les forces et de tous les moments agissant sur la plaque de montage du vérin ou sur l'outil :

Consultez le catalogue du produit pour le modèle spécifique. Vous y trouverez des tableaux ou des graphiques indiquant les charges et les moments statiques et dynamiques maximaux admissibles. Veillez à ce que les charges calculées pour l'application soient bien en deçà de ces limites, en incluant un facteur de sécurité adéquat.

Les mécanismes de guidage les plus courants sont les suivants

Le choix du type de guidage influe sur la précision, la capacité de charge, la vitesse et le coût du vérin.

En général, oui, les vérins de guidage compacts peuvent être montés en les orientations horizontales, verticales ou inclinées. La plupart des fabricants prévoient des trous de montage sur plusieurs surfaces du corps du vérin ou des plaques d'extrémité pour faciliter une installation flexible.

Cependant, il est important de prendre en compte :

Les exigences en matière de lubrification dépendent du type de mécanisme de guidage utilisé :

Toujours se référer à la manuel du produit spécifique au fabricant pour obtenir des instructions de lubrification détaillées, y compris le type de lubrifiant, la quantité et l'intervalle de re-lubrification. Une lubrification correcte est essentielle pour obtenir les performances et la durée de vie attendues du mécanisme de guidage.

Nos vérins de guidage compacts offrent le mélange idéal de précision, de stabilité et d'efficacité en termes d'espace pour vos tâches d'automatisation les plus difficiles. Explorez notre gamme complète de produits ou contactez nos spécialistes de l'actionnement pour obtenir des conseils d'experts et des solutions sur mesure.