robust solutions for secure workholding with high clamping force and a reliable toggle-lock action. Specifically designed for angled applications or with an angular clamping arm, they ensure precise workpiece stabilization in welding, assembly, and machining fixtures. Durable construction for demanding industrial automation tasks.

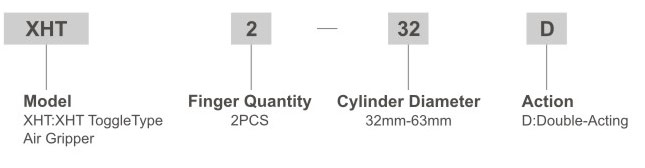

| Modello | MHT2-32D | MHT2-40D | MHT2-50D | MHT2-63D |

| Dimensione del foro | 32 | 40 | 50 | 63 |

| Modello di movimento | Doppio effetto | |||

| Fluido | Aria | |||

| Intervallo di tensione operativa | 0.1~0.6 MPa | |||

| Temperatura ambiente e del fluido | 5~60℃ | |||

| Lubrificazione | Non richiesto | |||

| Finger opening angle (Total) | -3°~28° | -3°~27° | -2°~23° | -2°~23° |

| Weight (kg) | 0.80 | 1.09 | 1.93 | 2.8 |

| Effective gripping force (N.m) at 0.5 Mpa | 12.4 | 36.0 | 63.0 | 106 |

| Foro (mm) | A | B | C | D | E | F | G | H | I |

| 32 | 8 | 12 | 28 | 41.6 | 42 | 32 | 8 | 16 | 5.5 |

| 40 | 8 | 12 | 28 | 42 | 48 | 37 | 10 | 18 | 7 |

| 50 | 10 | 16 | 35 | 52.5 | 54 | 40 | 10 | 22 | 8 |

| 63 | 10 | 17 | 35 | 53.2 | 60 | 45 | 11 | 24 | 10 |

| Foro (mm) | J | K | L | M | N | O | EE | P |

| 32 | 48 | 123.6 | 50 | 68 | Open:28°,Closed:-3° | Doble Sides:4-M6/Thread:Dep 10 | 18 | 22 |

| 40 | 54.5 | 136.5 | 60 | 74 | Open:27°,Closed:-3° | Doble Sides:4-M8/Thread:Dep 10 | 24 | 29 |

| 50 | 60.5 | 157 | 80 | 100 | Open:23°,Closed:-2° | Doble Sides:4-M10/Thread:Dep 12 | 30 | 36 |

| 63 | 66 | 169.2 | 90 | 104 | Open:23°,Closed:-2° | Doble Sides:4-M12/Thread:Dep 17 | 36 | 40 |

| Foro (mm) | Q | R | S | T | U | V | W | X |

| 32 | 34±0.2 | 46 | 34±0.2 | 4.5 | 45 | 72 | 86 | 4-M6/Thread:Dep 10 |

| 40 | 40±0.2 | 53 | 40±0.2 | 5 | 52 | 82 | 96 | 4-M8/Thread:Dep 10 |

| 50 | 50±0.2 | 66 | 50±0.2 | 7 | 64 | 110 | 124 | 4-M8/Thread:Dep 14 |

| 63 | 60±0.2 | 80 | 60±0.2 | 7 | 77 | 116 | 132 | 4-M10/Thread:Dep 18 |

| Foro (mm) | Y | Z | A1 | B1 | C1 | D1 | E1 | F1 |

| 32 | 20 | 30 | 7.5 | 34 | Finger Open:Rc(PT)1/8 | Finger Closed:Rc(PT)1/8 | 4-M6/Thread:Dep 5.1 | 4-M6/Thread:Dep 15 |

| 40 | 20 | 35.5 | 8 | 40 | Finger Open:Rc(PT)1/8 | Finger Closed:Rc(PT)1/8 | 4-M8/Thread:Dep 6.8 | 4-M8/Thread:Dep 12 |

| 50 | 25 | 39.5 | 10.5 | 52 | Finger Open:Rc(PT)1/4 | Finger Closed:Rc(PT)1/4 | 4-M10/Thread:Dep 8.6 | 4-M10/Thread:Dep 12 |

| 63 | 25 | 40.5 | 10.5 | 50 | Finger Open:Rc(PT)1/4 | Finger Closed:Rc(PT)1/4 | 4-M12/Thread:Dep 10.4 | 4-M12/Thread:Dep 10 |

| Bore Size | Track Mouth |

| 32 | D-A72L D-A80L

D-A73L D-F79L D-A76L D-J79L |

| 40 | |

| 50 | |

| 63 | |

|

Note:Magnetism switch model can refer to magnetism switch series ①Fit for grip heavy equipment ②Toggle structure unless lost the pressure suddenly the gripper still can work ③Magnet inside,can install magnetism switch |

|

| Foro (mm) | A | B | C | D | E | F | G | H | I |

| 32 | 8 | 12 | 28 | 41.6 | 42 | 32 | 8 | 16 | 5.5 |

| 40 | 8 | 12 | 28 | 42 | 48 | 37 | 10 | 18 | 7 |

| 50 | 10 | 16 | 35 | 52.5 | 54 | 40 | 10 | 22 | 8 |

| 63 | 10 | 17 | 35 | 53.2 | 60 | 45 | 11 | 24 | 10 |

| Foro (mm) | J | K | L | M | N | O | EE | P |

| 32 | 48 | 123.6 | 50 | 68 | Open:28°,Closed:-3° | Doble Sides:4-M6/Thread:Dep 10 | 18 | 22 |

| 40 | 54.5 | 136.5 | 60 | 74 | Open:27°,Closed:-3° | Doble Sides:4-M8/Thread:Dep 10 | 24 | 29 |

| 50 | 60.5 | 157 | 80 | 100 | Open:23°,Closed:-2° | Doble Sides:4-M10/Thread:Dep 12 | 30 | 36 |

| 63 | 66 | 169.2 | 90 | 104 | Open:23°,Closed:-2° | Doble Sides:4-M12/Thread:Dep 17 | 36 | 40 |

| Foro (mm) | Q | R | S | T | U | V | W | X |

| 32 | 34±0.2 | 46 | 34±0.2 | 4.5 | 45 | 72 | 86 | 4-M6/Thread:Dep 10 |

| 40 | 40±0.2 | 53 | 40±0.2 | 5 | 52 | 82 | 96 | 4-M8/Thread:Dep 10 |

| 50 | 50±0.2 | 66 | 50±0.2 | 7 | 64 | 110 | 124 | 4-M8/Thread:Dep 14 |

| 63 | 60±0.2 | 80 | 60±0.2 | 7 | 77 | 116 | 132 | 4-M10/Thread:Dep 18 |

| Foro (mm) | Y | Z | A1 | B1 | C1 | D1 | E1 | F1 |

| 32 | 20 | 30 | 7.5 | 34 | Finger Open:Rc(PT)1/8 | Finger Closed:Rc(PT)1/8 | 4-M6/Thread:Dep 5.1 | 4-M6/Thread:Dep 15 |

| 40 | 20 | 35.5 | 8 | 40 | Finger Open:Rc(PT)1/8 | Finger Closed:Rc(PT)1/8 | 4-M8/Thread:Dep 6.8 | 4-M8/Thread:Dep 12 |

| 50 | 25 | 39.5 | 10.5 | 52 | Finger Open:Rc(PT)1/4 | Finger Closed:Rc(PT)1/4 | 4-M10/Thread:Dep 8.6 | 4-M10/Thread:Dep 12 |

| 63 | 25 | 40.5 | 10.5 | 50 | Finger Open:Rc(PT)1/4 | Finger Closed:Rc(PT)1/4 | 4-M12/Thread:Dep 10.4 | 4-M12/Thread:Dep 10 |

| Bore Size | Track Mouth |

| 32 | D-A72L D-A80L

D-A73L D-F79L D-A76L D-J79L |

| 40 | |

| 50 | |

| 63 | |

|

Note:Magnetism switch model can refer to magnetism switch series ①Fit for grip heavy equipment ②Toggle structure unless lost the pressure suddenly the gripper still can work ③Magnet inside,can install magnetism switch |

|