Handbediende kleppen | regelen handmatig de luchtstroom voor een directe, betrouwbare werking. Bekijk ons assortiment handbediende kleppen, waaronder hefboom-, drukknop- en kneveltypes. Ze hebben geen externe voeding nodig en regelen de richting van de luchtstroom door directe menselijke actie, waardoor ze de ideale keuze zijn voor het instellen van apparatuur, noodstops en eenvoudige pneumatische circuits en de meest intuïtieve en betrouwbare besturingsmethode bieden. Selecteer nu de juiste handbediende klep voor uw toepassing.

Producten nodig voor je project?

We begrijpen dat sourcing een uitdaging kan zijn.

Vul het formulier in met uw specifieke items - aarzel niet om zelfs unieke of moeilijk te vinden onderdelen te vermelden - dien uw aanvraag in en ontvang de precies op maat gemaakte oplossingen die u zoekt! Vergeet algemene aanbiedingen; wij zijn gespecialiseerd in het begrijpen van uw exacte behoeften en het leveren van resultaten die passen als een handschoen

Ons assortiment handbediende kleppen biedt directe, betrouwbare controle over uw pneumatische systemen. Deze kleppen zijn ontworpen met het oog op eenvoud, duurzaamheid en nauwkeurige werking en zijn essentieel voor toepassingen waarbij interventie door de operator, systeeminstelling, isolatie of veiligheidsvergrendeling vereist is.

Biedt onmiddellijke tactiele feedback en duidelijke visuele indicatie van de klepstatus voor betrouwbare handmatige bediening.

Ze zijn ontworpen voor duurzaamheid zonder dat er elektrische voeding nodig is, waardoor ze ideaal zijn voor verschillende omgevingen en veiligheidskritische toepassingen.

Geschikt voor systeemisolatie, handmatig overschrijven, stromingsrichtingregeling en eenvoudige aan/uit-bediening in diverse pneumatische circuits.

Robuuste handbediende hendelventielen met betrouwbare richtingsregeling voor pneumatische actuators. Verkrijgbaar in verschillende poortconfiguraties en posities.

Veelzijdige handbediende regelafsluiters, inclusief handschuifafsluiters (HV) en roterende handafsluiters (K34), voor eenvoudige aan/uit- of richtingsregeling.

Compacte en duurzame handbediende hendelventielen met nauwkeurige handbediening voor diverse pneumatische toepassingen, eenvoudig te bedienen.

Handbediende afsluitkleppen met vergrendelingsmogelijkheid, ontworpen om stroomafwaartse luchtdruk veilig te isoleren en te ontluchten tijdens onderhoud (LOTO).

Handgrepen, hendels en knoppen zijn ontworpen voor een comfortabele grip en eenvoudige bediening, waardoor de operator minder snel vermoeid raakt.

Veel modellen hebben duidelijke visuele aanwijzingen of arrêteringen om duidelijk de huidige klepstand aan te geven (open, gesloten of specifiek pad).

Gemaakt van hoogwaardige metalen of speciale polymeren voor uitstekende duurzaamheid en weerstand tegen industriële omgevingen.

Opties zoals vergrendelbare handgrepen (bijv. VHS-serie) of bewaakte actuators om onbedoelde bediening te voorkomen en de veiligheid op de werkplek te verbeteren.

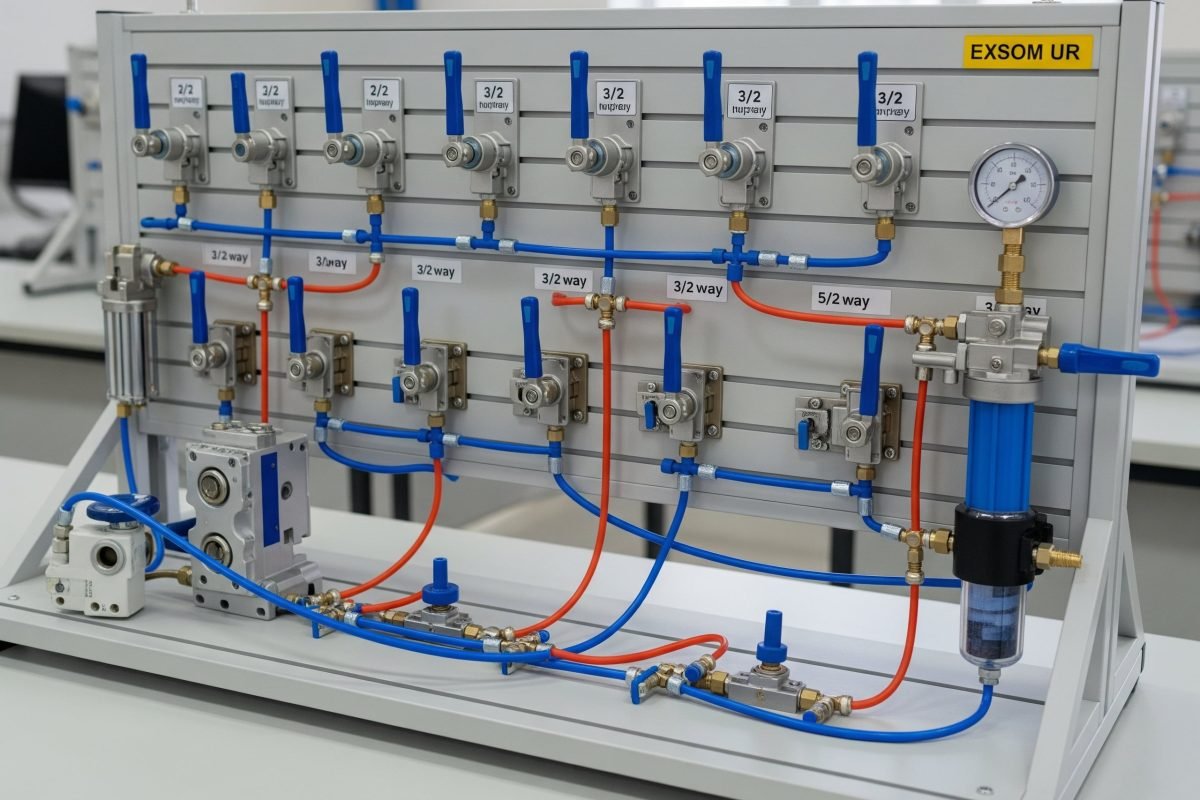

Bijv. 2/2, 3/2, 4/2, 5/2, 5/3; aantal stabiele posities (2 of 3).

Handhendel, drukknop, draaiknop, handschuif, voetpedaal.

Bijvoorbeeld M5, G1/8″, G1/4″, G3/8″, G1/2″, NPT.

Maximale werkdruk waarvoor de klep geschikt is.

Geeft de capaciteit van het ventiel aan om lucht door te laten.

Veerretour (kortstondig) of vastgezet (vastgezette positie).

Bijv. aluminiumlegering, messing behuizing; NBR, Viton afdichtingen.

Paneelbevestiging, bevestigingsgaten voor carrosserie, enz.

Raadpleeg voor gedetailleerde parameters de afzonderlijke producthandleidingen of raadpleeg onze technische experts.

Handmatig isoleren van delen van een pneumatisch circuit voor onderhoud, reparatie of instelling (bijv. VHS-serie lock-outkleppen).

Een handmatige manier om een geautomatiseerd systeem of onderdeel te bedienen bij stroomuitval of om te testen.

Voor directe bediening van pneumatisch gereedschap, klemmen, persen of andere apparaten door de operator (bijv. 4R/3R, SH-serie handbediende hendelafsluiters).

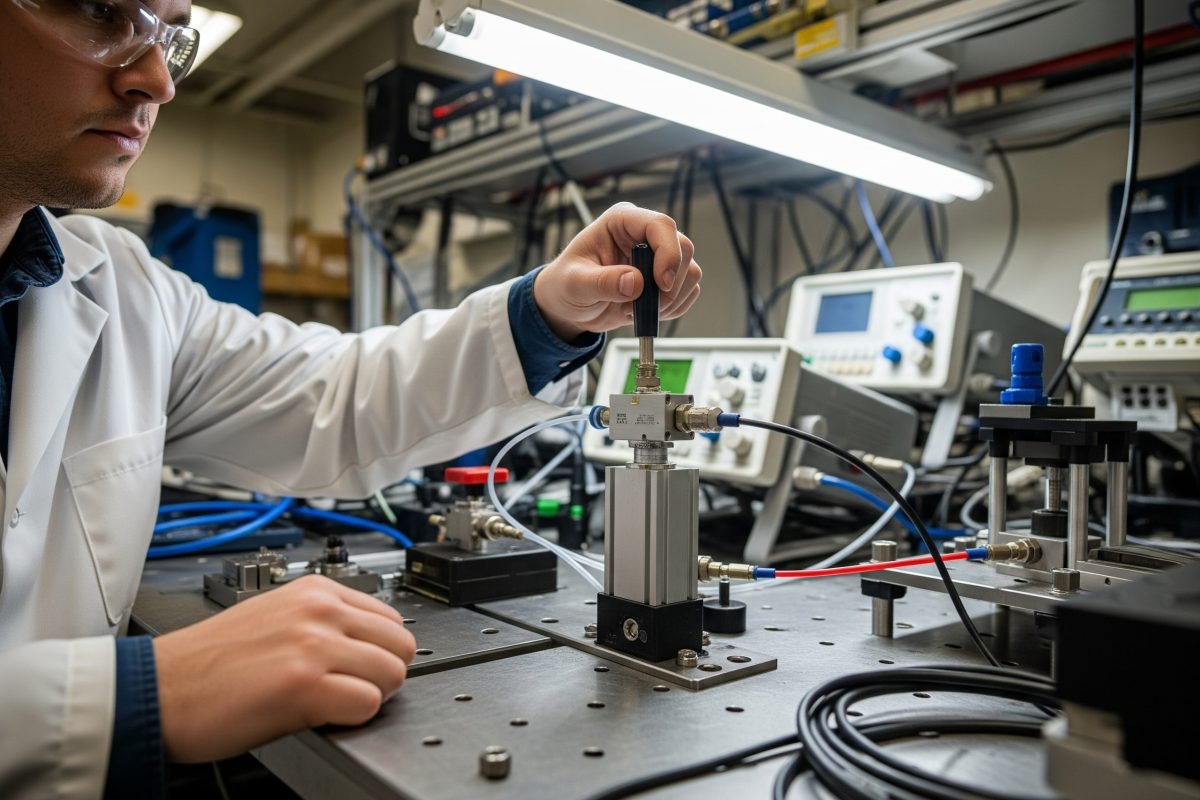

Handmatig de luchttoevoer regelen voor het testen van pneumatische onderdelen of het bedienen van armaturen.

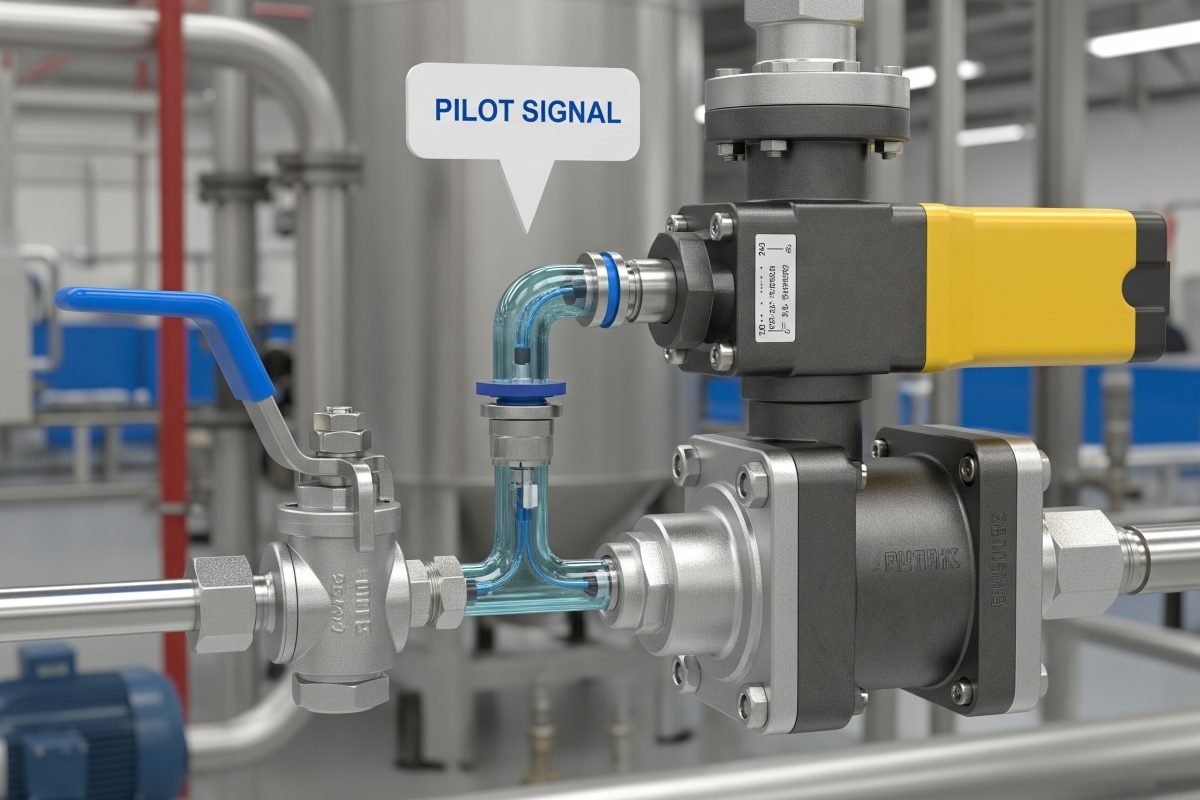

Handmatig initiëren van een pneumatisch signaal om grotere, luchtgestuurde kleppen in een besturingsvolgorde aan te sturen.

Ideaal voor het demonstreren van pneumatische basisprincipes en het bouwen van eenvoudige besturingscircuits.

Maak het systeem altijd drukloos voordat u handbediende kleppen installeert of onderhoud uitvoert.

Handbediende kleppen hebben de voorkeur in situaties die vereisen:

De termen verwijzen naar het aantal poorten en stroompaden:

Het kiezen van de juiste poortgrootte is cruciaal om te zorgen voor voldoende luchtstroom naar je pneumatische apparaat. Overweeg:

Productinformatiebladen vermelden de beschikbare poortmaten (bijv. G1/4, G1/2) en de bijbehorende gegevens over de stroomsnelheid.

Een veiligheidsafsluiter, zoals onze VHS-serie, is een essentieel veiligheidsonderdeel dat wordt gebruikt in pneumatische systemen. Het primaire doel is om isoleer een deel van het pneumatische systeem van de luchttoevoer en ontlucht eventuele opgesloten stroomneerwaartse luchtdruk. Dit zorgt ervoor dat machines of apparatuur spanningsloos zijn en niet onverwacht in werking kunnen treden tijdens onderhoud, service of reiniging.

Belangrijkste functies en gebruiksmogelijkheden zijn onder andere:

Handbediende kleppen zijn over het algemeen robuust en vereisen minimaal onderhoud, vooral bij gebruik met schone, droge lucht. Periodieke controles kunnen echter een lange levensduur garanderen:

Als een klep moeilijk te bedienen is of voortdurend lekt, kan dit duiden op slijtage of vervuiling van de inwendige afdichting en is mogelijk onderhoud of vervanging nodig.

Voor een directe, betrouwbare pneumatische besturing waarop u kunt rekenen, kunt u ons aanbod aan handbediende kleppen bekijken, inclusief gespecialiseerde handbediende hendel-, knop- en veiligheidsvergrendelingsopties. Vind de perfecte klep voor uw toepassing of neem contact op met onze experts voor persoonlijk advies.