Minicilinders maken precisiebewegingen in compacte ruimten mogelijk en optimaliseren ontwerpen op kleine schaal. Ontdek onze serie minicilinders, ontworpen voor toepassingen waar de ruimte beperkt is. Door hun lichte, compacte constructie zijn ze de ideale actuators voor zeer nauwkeurige taken zoals elektronica-assemblage, medische apparatuur en handling van kleine onderdelen. Ze leveren uitstekende prestaties en betrouwbaarheid in de kleinste ruimte. Vind nu de juiste maat voor uw toepassing.

Producten nodig voor je project?

We begrijpen dat sourcing een uitdaging kan zijn.

Vul het formulier in met uw specifieke items - aarzel niet om zelfs unieke of moeilijk te vinden onderdelen te vermelden - dien uw aanvraag in en ontvang de precies op maat gemaakte oplossingen die u zoekt! Vergeet algemene aanbiedingen; wij zijn gespecialiseerd in het begrijpen van uw exacte behoeften en het leveren van resultaten die passen als een handschoen

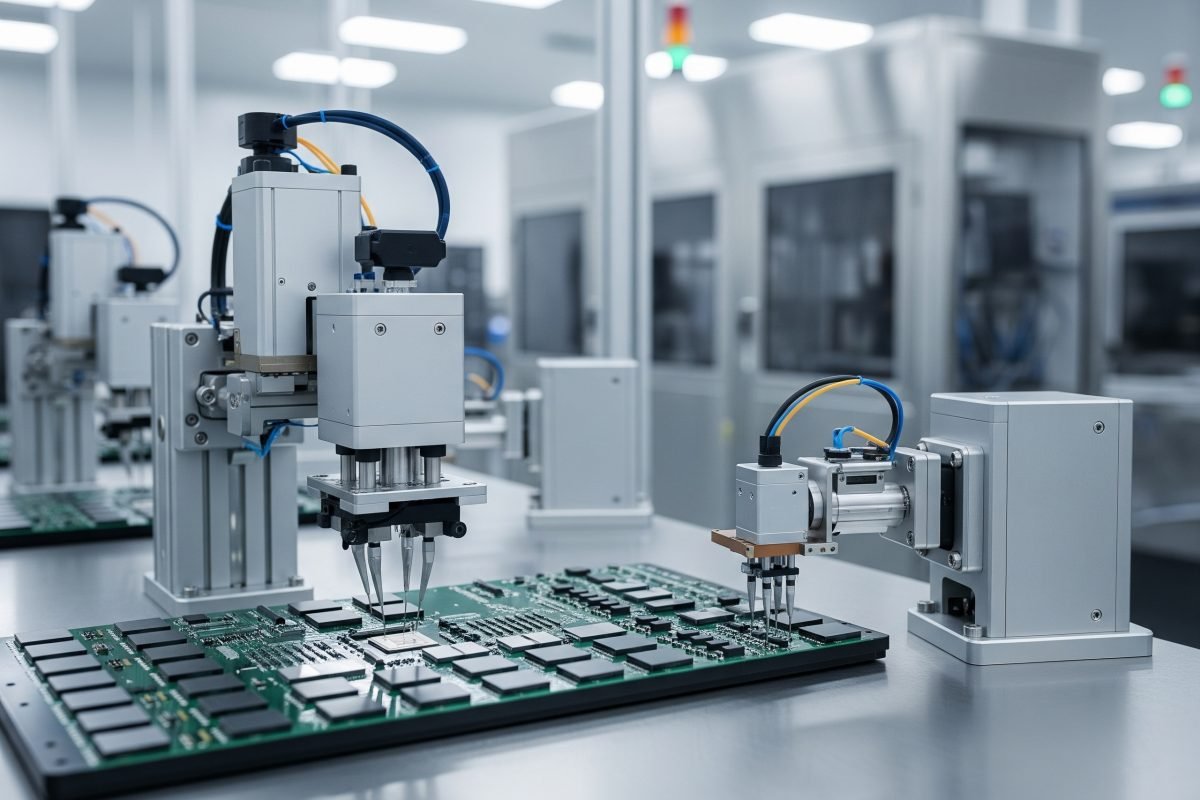

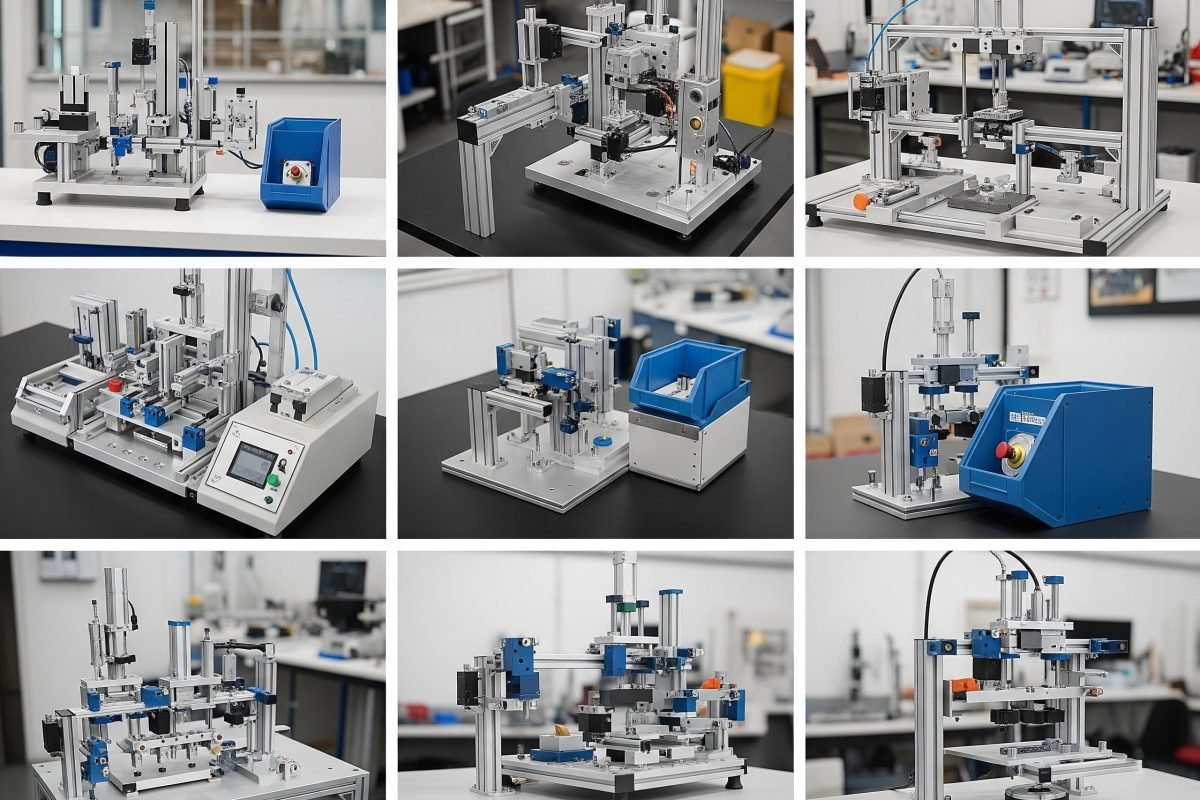

Onze serie minicilinders is vakkundig ontworpen voor compacte ruimtes en lichte toepassingen. Met hun kleine formaat, precieze besturing en snelle respons zijn ze de ideale keuze voor industrieën zoals elektronica, medische toepassingen en kleinschalige automatisering, waardoor u fijnere, efficiëntere geautomatiseerde bewerkingen kunt uitvoeren.

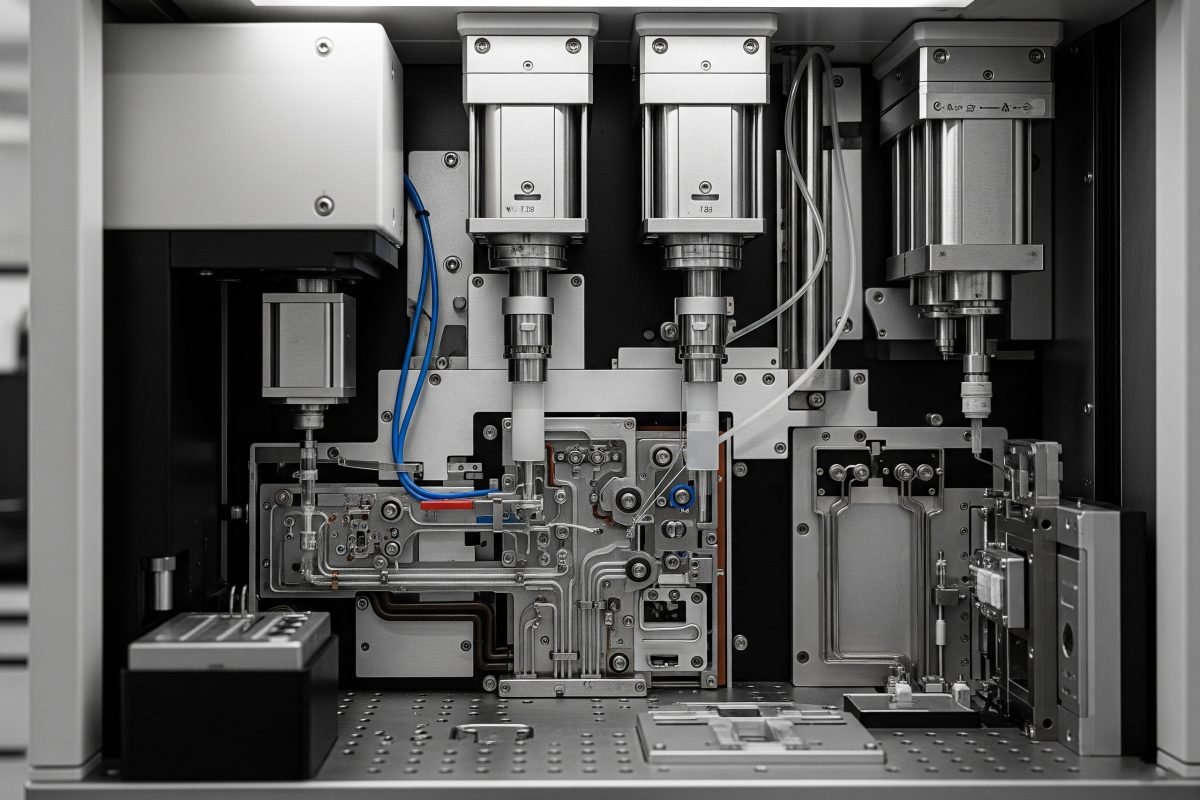

Door de kleine boring en het geminiaturiseerde algemene ontwerp zijn ze perfect voor apparatuur en toepassingen met extreem beperkte installatieruimte.

Dankzij hun kleine interne volume wordt lucht snel gevuld en afgevoerd, waardoor minicilinders uitstekende dynamische responskenmerken en hoge werkfrequenties hebben.

Hoge fabricageprecisie maakt nauwkeurige uitvoer van kleine slagen en krachten mogelijk, geschikt voor delicate en verfijnde operationele taken.

Minicilinders, ook wel pencilinders of kleine cilinders genoemd, verwijzen meestal naar cilinders met een kleine boring (bijvoorbeeld van Ø4 mm tot ongeveer Ø25 mm). Ze zijn de ideale keuze voor lichte belastingen, korte slagen en hoogfrequente bewerkingen.

Door gebruik te maken van zeer nauwkeurige bewerkingsapparatuur en strikte tolerantiecontrole worden de maatnauwkeurigheid en consistente werking gegarandeerd.

Gebouwd met hoogwaardige, slijtvaste materialen voor zuigerstangen en afdichtingen, gecombineerd met geoptimaliseerde smeringsoplossingen om de levensduur aanzienlijk te verlengen.

Ze bieden verschillende afgeleide modellen, zoals geleide, niet-roterende en dubbelstangs versies om te voldoen aan complexere toepassingseisen.

We bieden snelle en flexibele aanpassingsdiensten voor speciale slaglengtes, montagematen of materiaalvereisten.

bijv. Ø4, Ø6, Ø8, Ø10, Ø12, Ø16, Ø20, Ø25 mm.

Van een paar millimeter tot meer dan honderd, aanpasbaar.

Gewoonlijk 0,1~0,7 MPa of 0,1~1,0 MPa.

Enkelwerkend (veerretour/verlenging), dubbelwerkend.

Meestal elastische bumpers aan beide uiteinden of geen demping.

Kleine draadmaten zoals M3, M5, G1/8.

Optionele magnetische zuiger voor positiebepaling met magnetische schakelaars.

Standaardreeks, met aanpasbare versies die bestand zijn tegen hoge/lage temperaturen.

Raadpleeg voor gedetailleerde parameters de afzonderlijke producthandleidingen of raadpleeg onze technische experts.

Picken-en-plaatsen van chips, precisieassemblage van kleine onderdelen, bediening van testtasters, enz.

Monstername, reagentia doseren, kleppen schakelen, kleine pompen bedienen, enz.

Desktop assemblagemachines, kleine sorteersystemen, educatieve labapparatuur, enz.

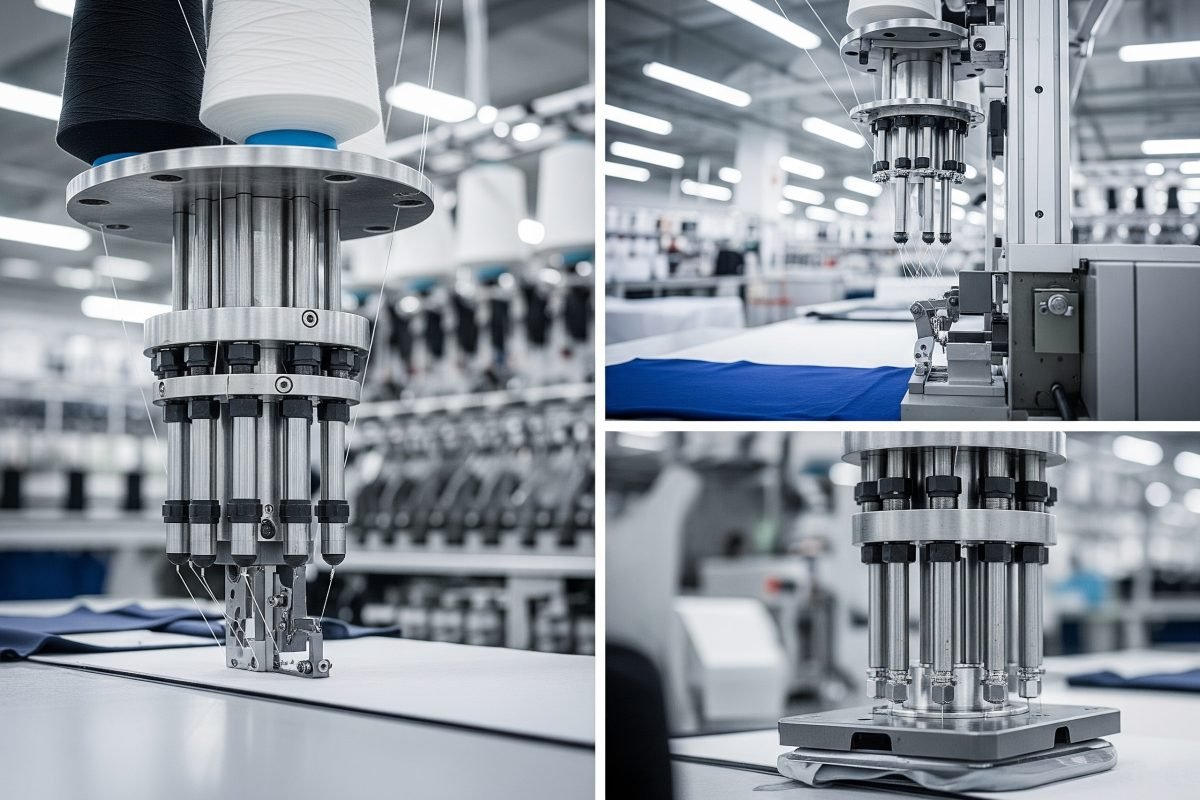

Voor het verwisselen van garen, snijden van draden, kleine persbewegingen en andere delicate bewegingen.

Hulpwerkzaamheden bij het verpakken van kleine artikelen, labelen, sealen, enz.

Kleine experimentele platforms bouwen, robotmodellen, geautomatiseerde onderwijsdemonstraties, enz.

Een juiste installatie en adequaat onderhoud verlengen de levensduur van minicilinders aanzienlijk.

Door hun kleine boring hebben minicilinders een relatief kleine uitgaande kracht. Zo heeft een minicilinder Ø10 mm bij een werkdruk van 0,5 MPa een theoretische uitgaande kracht (uitschuiven) van ongeveer 39 Newton (ca. 4 kgf).

Bereken bij het selecteren de werkelijke belasting, het bewegingstype (duwen of trekken) en de vereiste veiligheidsfactor. Over het algemeen wordt aanbevolen dat de theoretische uitgangskracht van de cilinder ten minste 1,5 tot 2 keer de werkelijke belasting is. Voor grotere belastingen kunt u cilinders met grotere boringen of andere soorten actuators overwegen.

Enkelwerkende minicilinders: Hebben één luchtpoort; luchtdruk drijft de zuiger in één richting aan, terwijl een veer of externe belasting de zuiger terugleidt. Types zijn onder andere veerretour (lucht uittrekken, veer intrekken) en veeruitbreiding (lucht intrekken, veer uittrekken).

Dubbelwerkende minicilinders: Hebben twee luchtpoorten die het in- en uitschuiven regelen via luchtdruk.

Ja, vanwege hun precieze interne structuur en kleine spelingen hebben minicilinders meestal hogere luchtzuiverheidseisen dan grotere cilinders. Verontreinigingen zoals vocht, olie en stof in perslucht kunnen gemakkelijk klepspoelen doen vastlopen, afdichtingen doen slijten of storingen veroorzaken.

Aanbevelingen:

Schone lucht is essentieel voor een langdurige, stabiele en betrouwbare werking van minicilinders.

Standaard minicilinders (vooral pennencilinders met een rond lichaam) zijn voornamelijk ontworpen voor axiale belastingen. Door hun dunne zuigerstangen en beperkte geleidingslengte is hun vermogen om zijwaartse belastingen of momenten te weerstaan zeer beperkt.

Aanzienlijke zijwaartse belastingen of momenten kunnen leiden tot:

Voor toepassingen met zijwaartse belasting wordt aanbevolen:

Houd bij het kiezen van een magneetschakelaar voor een minicilinder rekening met de volgende punten:

Vanwege de beperkte afmetingen kan het selecteren en installeren van magneetschakelaars voor minicilinders kritischer zijn dan voor standaardcilinders. Raadpleeg onze selectiegidsen voor accessoires of technische ondersteuning raadplegen.

Onze minicilinders, met hun uitzonderlijke compactheid, hoge precisie en snelle respons, bieden een krachtige ondersteuning voor de miniaturisatie van uw apparatuur en prestatieverbetering. Bekijk nu onze productseries of neem contact op met ons pneumatische expertteam voor professioneel selectieadvies en oplossingen op maat.