Rotary Actuators | Convert Air Pressure into Rotary Motion for Angular Positioning & Flipping. Explore our series of rotary actuators that provide precise angular control, including rack & pinion and vane types. They are the ideal choice for valve control, material diverting, and part-flipping tasks in automation, offering high torque and high repeatability in a compact footprint. Select the right model for your rotary application now.

Need products for your project?

We understand sourcing can be challenging.

Fill out the form with your specific items – don’t hesitate to list even unique or hard-to-find components – submit your inquiry, and get the precisely tailored solutions you’re looking for! Forget generic offerings; we specialize in understanding your exact needs and delivering results that fit like a glove

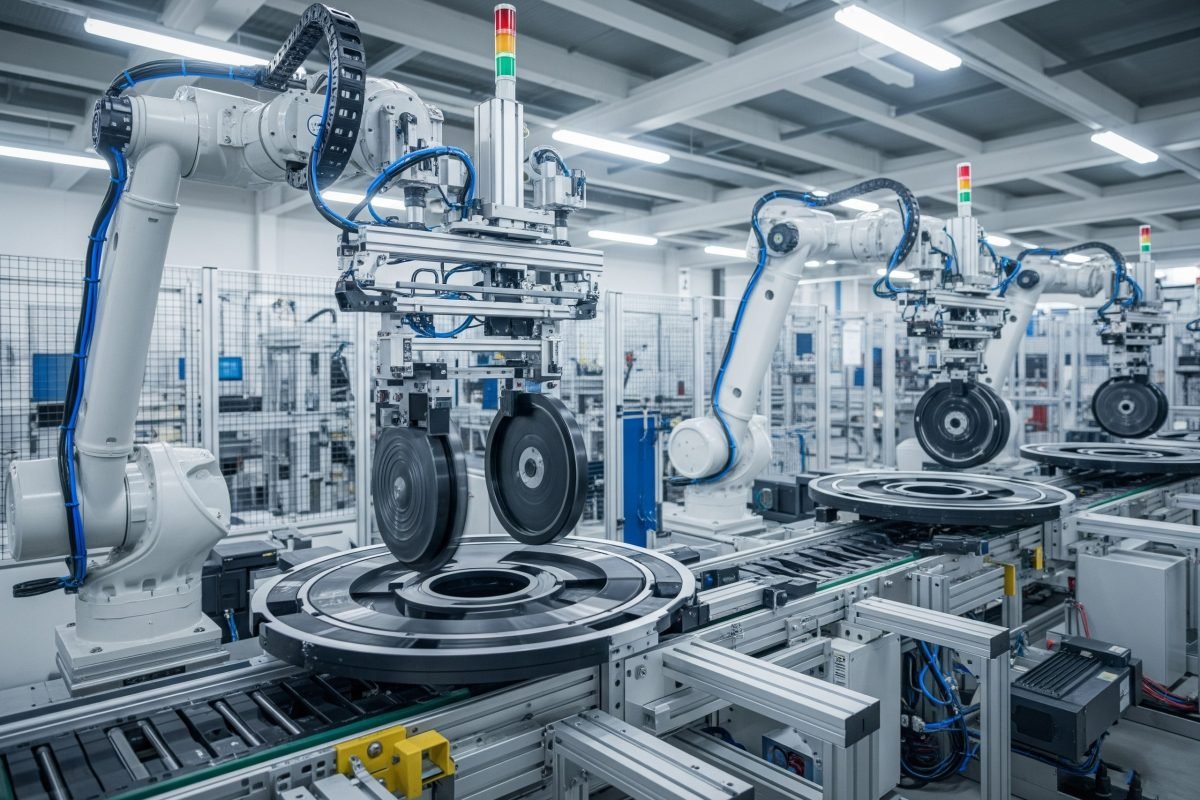

Our rotary actuator series converts pneumatic energy into precise rotary or oscillating motion, providing reliable torque output and angle control for your automation systems. Whether for valve actuation, material diverting, or precision positioning, our diverse range of rotary actuators meets your needs.

Offers accurate rotational angle control, with adjustable angles in some models, meeting various positioning and indexing requirements.

Optimized design achieves high torque output within a compact size, saving installation space while providing robust power.

Utilizes high-quality bearings and seals to ensure smooth rotational movement, excellent durability, and extended service life.

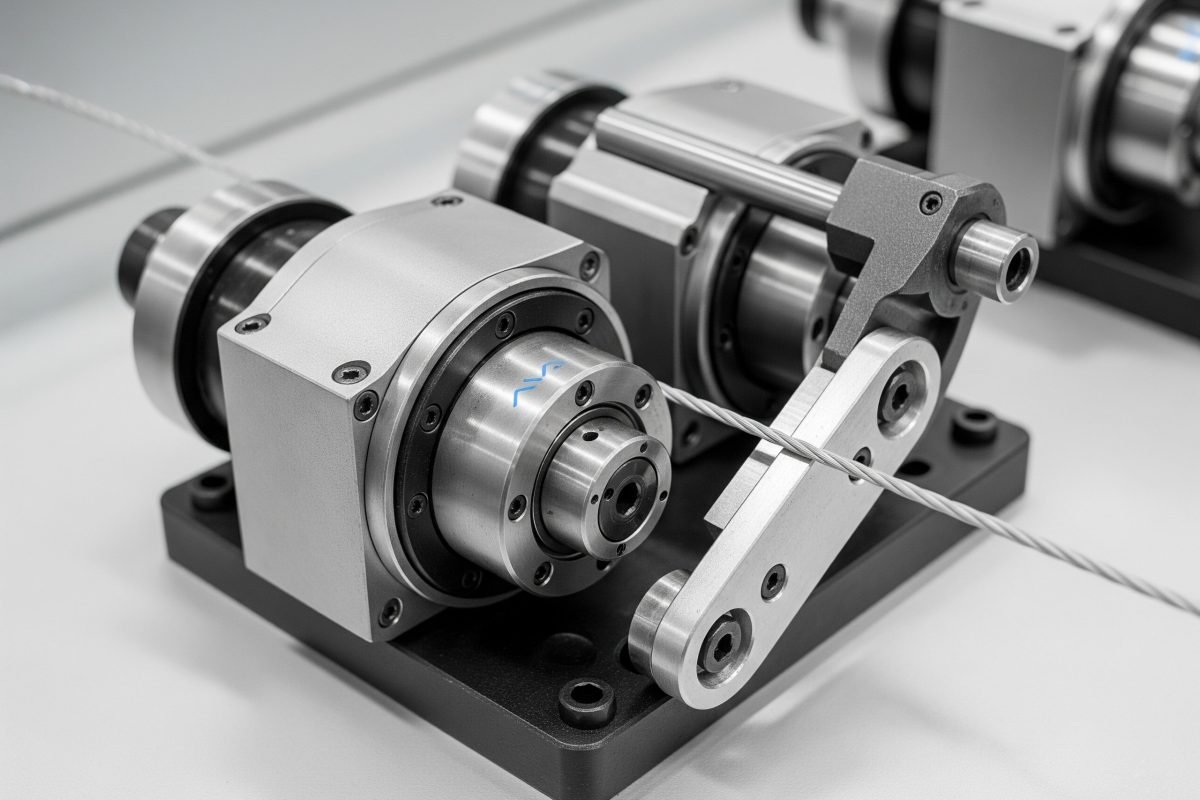

Linear motion of the cylinder piston drives a rack, which in turn rotates a pinion to achieve rotary output. Simple structure, capable of providing large torque and rotation angles (typically 90°, 180°, customizable).

Air pressure drives a vane to rotate within the cylinder body. Very compact structure with no external moving parts. Typically used for smaller torque and specific angle oscillations.

For rack & pinion types, we use high-precision gear machining processes to ensure smooth engagement, minimal backlash, and high rotational accuracy.

Utilizing imported or high-quality bearings and wear-resistant seals to guarantee output shaft rigidity, actuator sealing performance, and extended service life.

Some models are equipped with convenient and reliable rotation angle adjustment screws or mechanisms, allowing users to precisely set the swing angle within a certain range.

Offering various standard mounting holes and output shaft connection methods for easy integration with different equipment and actuators.

E.g., 0-90°, 0-180°, 0-270°; some models offer adjustable angles.

Maximum torque the output shaft can deliver at a specific air pressure, usually in N·m.

For rack & pinion type, refers to piston bore; vane type has equivalent parameters.

Allowable minimum and maximum operating air supply pressure.

Time to complete a specified rotation or maximum allowable operating frequency.

Air cushioning, rubber bumpers, or external hydraulic shock absorbers.

Radial and axial load capacity of the output shaft.

E.g., M5, G1/8, G1/4.

For detailed parameters, please refer to individual product manuals or consult our technical experts.

Driving ball valves, butterfly valves, and other rotary valves for opening/closing in fluid control systems.

Changing workpiece orientation, sorting, or achieving 90°/180° flips on automated production lines.

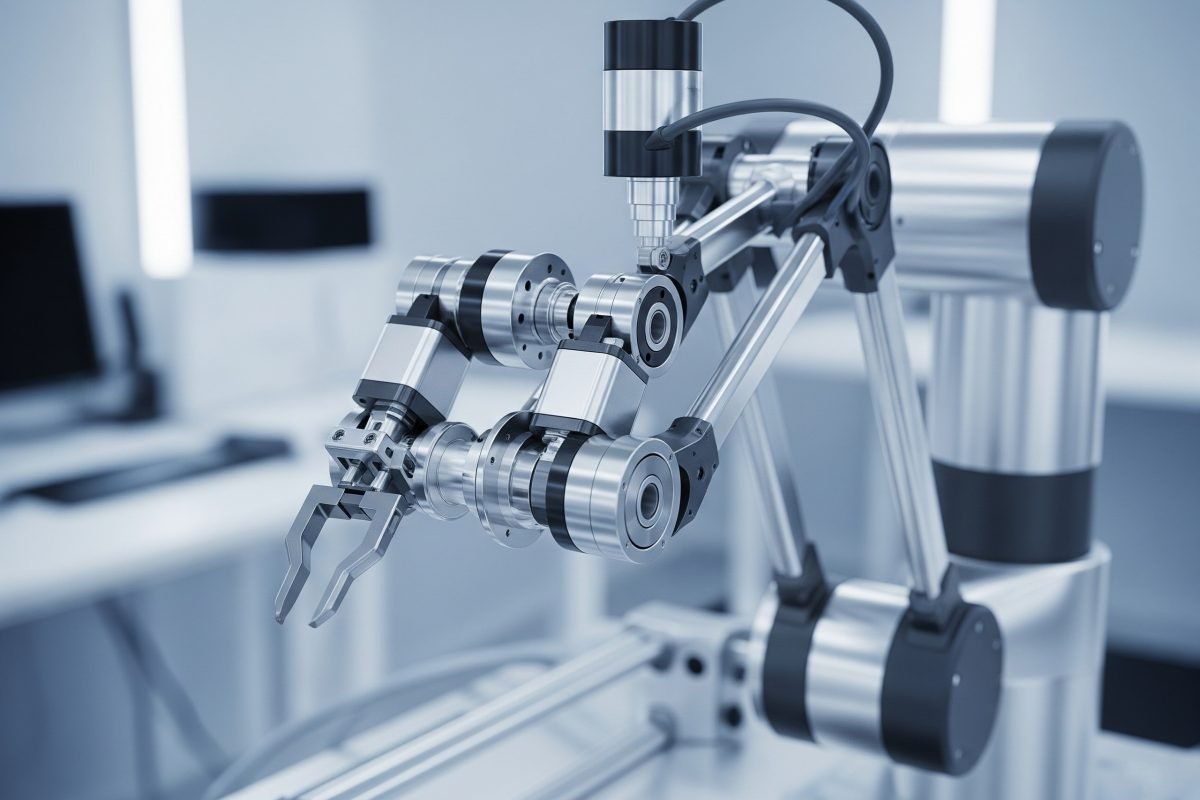

Serving as joint actuators for small robots or manipulators to achieve flexible rotary movements.

Driving indexing tables or small rotary worktables for precise angular indexing and positioning.

Used for opening, closing, or adjusting the angle of various flaps, gates, and diverter plates.

Used in film, paper, and cable winding equipment for tension adjustment or dancer arm control.

Proper installation and adequate maintenance are key to the long-term reliable operation of rotary actuators.

Output torque is a critical parameter when selecting a rotary actuator. You need to:

If calculations are complex or you’re unsure, please contact our technical support with your load parameters and operating conditions for assistance.

Rack & Pinion Type Rotary Actuators:

Vane Type Rotary Actuators:

The choice depends on the specific application requirements for torque, angle, space, precision, noise, etc.

Some models of rotary actuators (especially rack & pinion types) are designed with an angle adjustment feature.

If highly precise or widely variable rotation angle control is needed, it might require an external sensor and control system (like a servo motor + gearbox) or a dedicated programmable rotary actuator. Please specify your angle control needs when selecting.

Yes, rotary actuators have high coaxiality requirements during installation, especially between their output shaft and the shaft of the driven component.

Precise installation is a crucial prerequisite for ensuring the performance and lifespan of rotary actuators.

Rotary actuators can be used for reciprocating oscillation, but their high-speed performance is limited by several factors:

For very high-speed reciprocating oscillation applications, a careful evaluation of load characteristics is necessary. Select an appropriate rotary actuator model and control scheme, and consider additional cushioning and heat dissipation measures. Please consult our engineers for professional advice.

With precise angle control, reliable torque output, and diverse structural options, our rotary actuator series provides efficient rotary power for your automation equipment. Explore our products now, or contact our pneumatic expert team for professional selection advice and customized solutions.