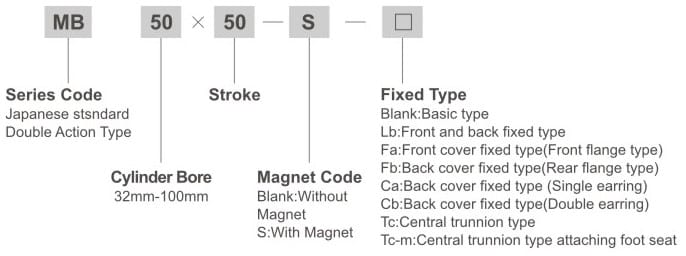

Premium ISO 15552 tie-rod cylinders for tough industrial tasks. Get exceptional durability & precise performance by accurately configuring your exact solution—bores (Ø32-Ø320mm), custom strokes, materials, magnetic pistons, high-temp seals & rod ends—all via our intuitive ordering code system. Standard adjustable cushioning ensures smooth motion. Universally interchangeable.

| Cylinder diameter | 32 | 40 | 50 | 63 | 80 | 100 |

| Working Medium | Air | |||||

| Action type | Double acting | |||||

| Proof pressure | 15.3kgf/cm2(1.5Mpa) | |||||

| Max.pressure | 10.2kgf/cm2(1.0Mpa) | |||||

| Min.pressure | 0.5kgf/cm2(0.05Mpa) | |||||

| Environment and fluid temp | -10~+60℃ | |||||

| Piston veocity | 50~1000mm/s | |||||

| Buffering | Air buffering | |||||

| Stroke tolerance | ~0~250+10 , 251~1000+14 , 1001~1500+18 | |||||

| Rc(PT)Joint size | G1/8″ | G1/4″ | G3/8″ | G1/2″ | ||

| Bore(mm) | Standard Stroke |

| 32 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500 |

| 40 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500 |

| 50 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500,600 |

| 63 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500,600 |

| 80 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500,600,700,750 |

| 100 | 25,50,75,100,125,150,175,200, 250,300,350,400,450,500,600,700,750 |

|

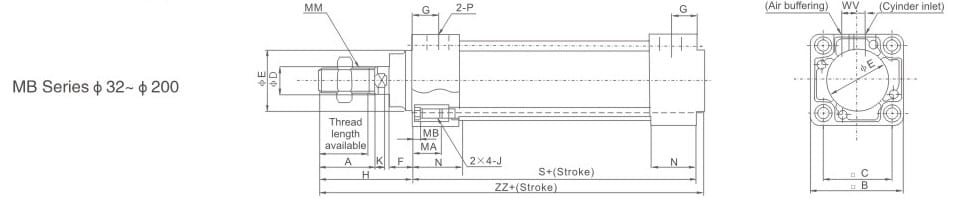

Diameter |

Stroke range | Thread length available | A | □B | □C | φD | φE | F | G | MA | MB | J | K | MM | N | P | S | V | W | H | ZZ |

|

32 |

~500 | 19.5 | 22 | 46 | 32.5 | 12 | 30 | 13 | 13 | 16 | 4 | M6×1.0 | 6 | M10×1.25 | 27 | 1/8 | 84 | 4 | 6.5 | 47 | 135 |

|

40 |

~500 | 27 | 30 | 52 | 38 | 16 | 35 | 13 | 14 | 16 | 4 | M6×1.0 | 6 | M14×1.5 | 27 | 1/4 | 84 | 4 | 9 | 51 | 139 |

| 50 | ~600 | 32 | 35 | 65 | 46.5 | 20 | 40 | 14 | 15.5 | 16 | 5 | M8×1.25 | 7 | M18×1.5 | 31.5 | 1/4 | 94 | 5 | 10.5 | 58 |

156 |

|

63 |

~600 | 32 | 35 | 75 | 56.5 | 20 | 45 | 14 | 16.5 | 16 | 5 | M8×1.25 | 7 | M18×1.5 | 31.5 | 3/8 | 94 | 9 | 12 | 58 | 156 |

|

80 |

~750 | 37 | 40 | 95 | 72 | 25 | 45 | 20 | 19 | 16 | 5 | M10×1.5 | 10 | M22×1.5 | 38 | 3/8 | 114 | 11.5 | 14 | 72 |

190 |

| 100 | ~750 | 37 | 40 | 114 | 89 | 30 | 55 | 20 | 19 | 16 | 5 | M10×1.5 | 10 | M26×1.5 | 38 | 1/2 | 114 | 17 | 15 | 72 |

190 |

|

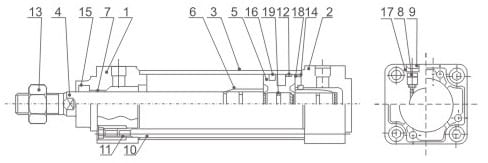

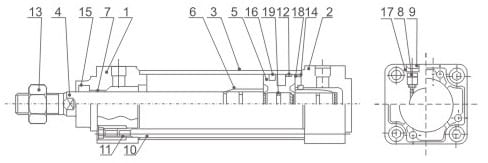

NO. |

Designation | NO. | Designation | NO. | Designation |

|

1 |

Front cover | 6 | Buffe ring | 11 | Tie rod nut |

|

2 |

Back Cover | 7 | Bearing | 12 | Wear ring |

| 3 | Barrel | 8 | Cushion Screw | 13 |

Piston rod nut |

| 4 | Piston rod | 9 | Cushion Seal | 14 |

Buffe seal ring |

| 5 | Piston | 10 | Tie rod | 15 |

Piston O-ring |

|

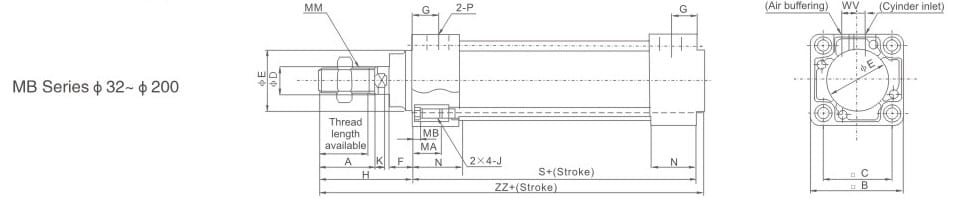

Diameter |

Stroke range | Thread length available | A | □B | □C | φD | φE | F | G | MA | MB | J | K | MM | N | P | S | V | W | H | ZZ |

|

32 |

~500 | 19.5 | 22 | 46 | 32.5 | 12 | 30 | 13 | 13 | 16 | 4 | M6×1.0 | 6 | M10×1.25 | 27 | 1/8 | 84 | 4 | 6.5 | 47 | 135 |

|

40 |

~500 | 27 | 30 | 52 | 38 | 16 | 35 | 13 | 14 | 16 | 4 | M6×1.0 | 6 | M14×1.5 | 27 | 1/4 | 84 | 4 | 9 | 51 | 139 |

| 50 | ~600 | 32 | 35 | 65 | 46.5 | 20 | 40 | 14 | 15.5 | 16 | 5 | M8×1.25 | 7 | M18×1.5 | 31.5 | 1/4 | 94 | 5 | 10.5 | 58 |

156 |

|

63 |

~600 | 32 | 35 | 75 | 56.5 | 20 | 45 | 14 | 16.5 | 16 | 5 | M8×1.25 | 7 | M18×1.5 | 31.5 | 3/8 | 94 | 9 | 12 | 58 | 156 |

|

80 |

~750 | 37 | 40 | 95 | 72 | 25 | 45 | 20 | 19 | 16 | 5 | M10×1.5 | 10 | M22×1.5 | 38 | 3/8 | 114 | 11.5 | 14 | 72 |

190 |

| 100 | ~750 | 37 | 40 | 114 | 89 | 30 | 55 | 20 | 19 | 16 | 5 | M10×1.5 | 10 | M26×1.5 | 38 | 1/2 | 114 | 17 | 15 | 72 |

190 |

|

NO. |

Designation | NO. | Designation | NO. | Designation |

|

1 |

Front cover | 6 | Buffe ring | 11 | Tie rod nut |

|

2 |

Back Cover | 7 | Bearing | 12 | Wear ring |

| 3 | Barrel | 8 | Cushion Screw | 13 |

Piston rod nut |

| 4 | Piston rod | 9 | Cushion Seal | 14 |

Buffe seal ring |

| 5 | Piston | 10 | Tie rod | 15 |

Piston O-ring |