Are you experiencing positioning inaccuracies, unexpected vibrations, or premature component failures in your pneumatic systems? These common problems often stem from a frequently overlooked factor: material elastic deformation. Many engineers focus solely on pressure and flow requirements while neglecting how component elasticity affects real-world performance.

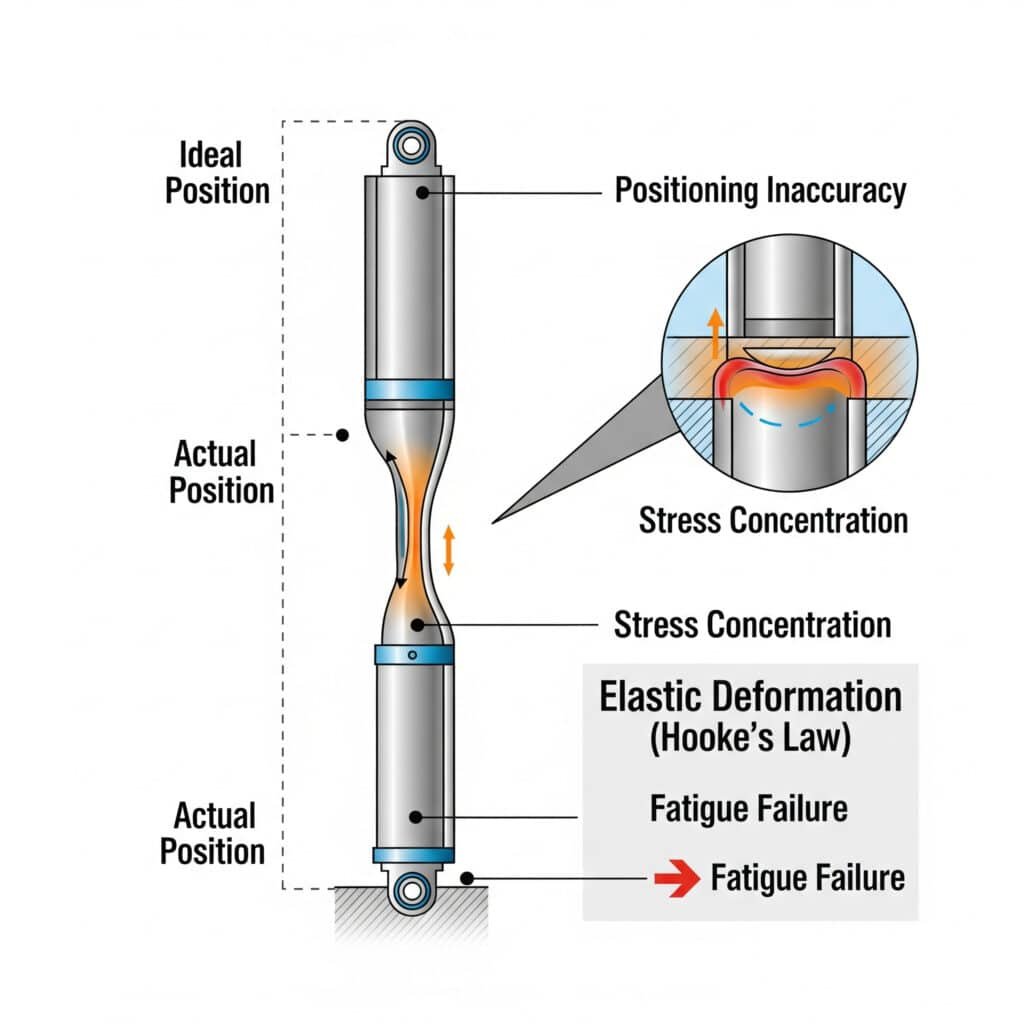

Elastic deformation in pneumatic systems causes positioning errors, dynamic response variations, and stress concentration that can lead to premature failures. These effects are governed by Hooke’s Law1, Poisson’s ratio2 relationships, and plastic deformation thresholds that determine whether deformation is temporary or permanent. Understanding these principles can improve positioning accuracy by 30-60% and extend component life by 2-3 times.

In my 15+ years at Bepto working with pneumatic systems across various industries, I’ve seen countless cases where understanding and accounting for material elasticity has transformed problematic systems into reliable, precise operations. Let me share what I’ve learned about identifying and managing these often-neglected effects.

Table of Contents

- How Does Hooke’s Law Actually Apply to Pneumatic Cylinder Performance?

- Why Is Poisson’s Ratio Critical for Pneumatic Seal and Component Design?

- When Does Elastic Deformation Become Permanent Damage?

- Conclusion

- FAQs About Material Elasticity in Pneumatic Systems

How Does Hooke’s Law Actually Apply to Pneumatic Cylinder Performance?

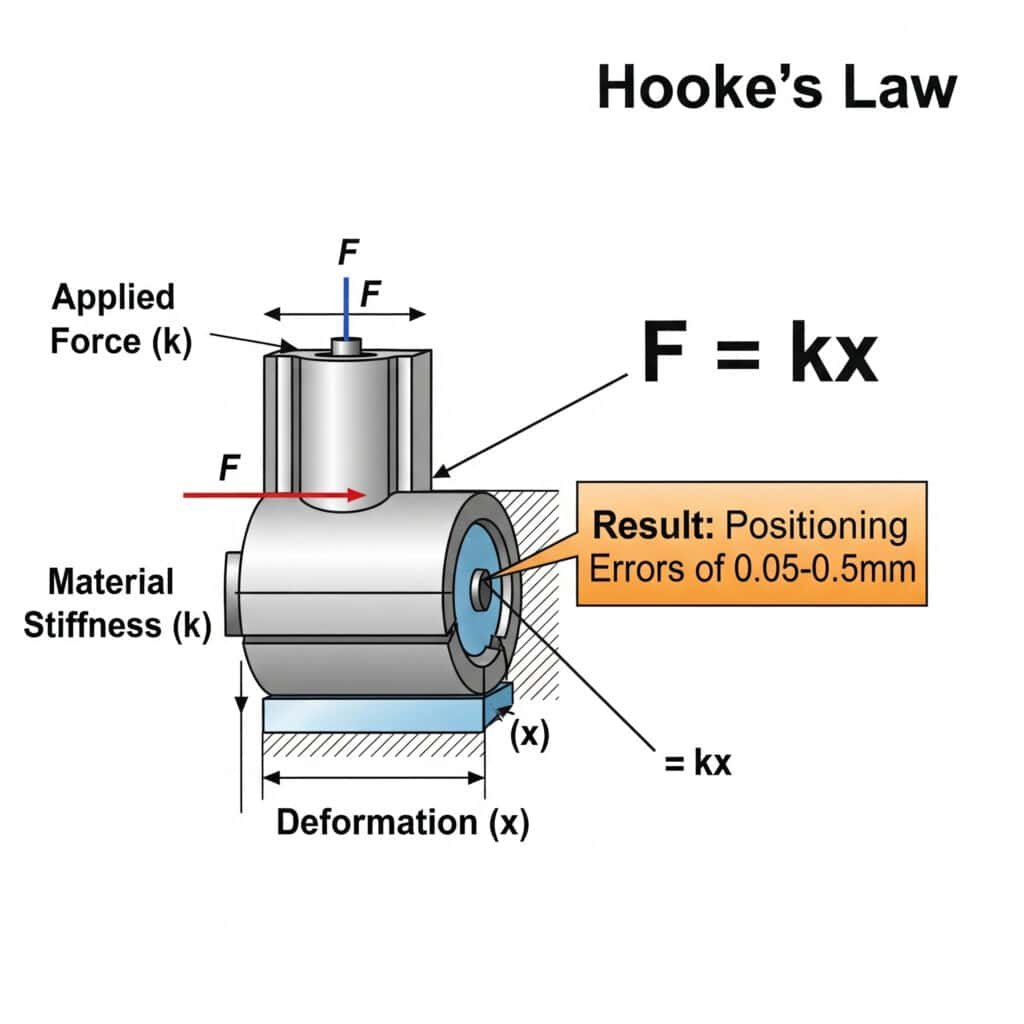

Hooke’s Law may seem like a basic physics principle, but its implications for pneumatic cylinder performance are profound and frequently misunderstood.

Hooke’s Law governs elastic deformation in pneumatic cylinders through the equation F = kx, where F is the applied force, k is the material stiffness, and x is the resulting deformation. In pneumatic systems, this deformation affects positioning accuracy, dynamic response, and energy efficiency. For a typical rodless cylinder, elastic deformation can cause positioning errors of 0.05-0.5mm depending on load and material properties.

Understanding how Hooke’s Law applies to pneumatic systems has practical implications for design and troubleshooting. Let me break this down into actionable insights.

Quantifying Elastic Deformation in Pneumatic Components

The elastic deformation in different pneumatic components can be calculated using:

| Component | Deformation Equation | Example |

|---|---|---|

| Cylinder Barrel | δ = PD²L/(4Et) | For 40mm bore, 3mm wall, 6 bar: δ = 0.012mm |

| Piston Rod | δ = FL/(AE) | For 16mm rod, 500mm length, 1000N: δ = 0.16mm |

| Mounting Brackets | δ = FL³/(3EI) | For cantilever mount, 1000N: δ = 0.3-0.8mm |

| Seals | δ = Fh/(AE) | For 2mm seal height, 50 Shore A: δ = 0.1-0.2mm |

Where:

- P = pressure

- D = diameter

- L = length

- E = elastic modulus3

- t = wall thickness

- A = cross-sectional area

- I = moment of inertia

- h = height

- F = force

Hooke’s Law in Real Pneumatic Applications

The elastic deformation in pneumatic systems manifests in several ways:

- Positioning errors: Deformation under load causes the actual position to differ from the intended position

- Dynamic response variations: Elastic elements act as springs, affecting system natural frequency

- Force transmission inefficiency: Energy is stored in elastic deformation rather than producing useful work

- Stress concentration: Non-uniform deformation creates stress hotspots that can lead to fatigue failure

I recently worked with Lisa, a precision automation engineer at a medical device manufacturer in Massachusetts. Her rodless cylinder-based assembly system was experiencing inconsistent positioning accuracy, with errors varying based on load position.

Analysis revealed that the aluminum profile supporting the rodless cylinder was deflecting according to Hooke’s Law, with the maximum deflection occurring at the center of travel. By calculating the expected deflection using F = kx and reinforcing the mounting structure to increase stiffness (k), we improved positioning accuracy from ±0.3mm to ±0.05mm—a critical improvement for their precision assembly process.

Material Selection Impact on Elastic Deformation

Different materials exhibit vastly different elastic behavior:

| Material | Elastic Modulus (GPa) | Relative Stiffness | Common Applications |

|---|---|---|---|

| Aluminum | 69 | Baseline | Standard cylinder barrels, profiles |

| Steel | 200 | 2.9× stiffer | Heavy-duty cylinders, piston rods |

| Stainless Steel | 190 | 2.75× stiffer | Corrosion-resistant applications |

| Bronze | 110 | 1.6× stiffer | Bushings, wear components |

| Engineering Plastics | 2-4 | 17-35× more flexible | Lightweight components, seals |

| Elastomers | 0.01-0.1 | 690-6900× more flexible | Seals, cushioning elements |

Practical Strategies to Manage Elastic Deformation

To minimize the negative impacts of elastic deformation:

- Increase component stiffness: Use materials with higher elastic modulus or optimize geometry

- Pre-load components: Apply initial force to take up elastic deformation before operation

- Compensate in control systems: Adjust target positions based on known deformation characteristics

- Distribute loads evenly: Minimize stress concentrations that cause localized deformation

- Consider temperature effects: Elastic modulus typically decreases with increasing temperature

Why Is Poisson’s Ratio Critical for Pneumatic Seal and Component Design?

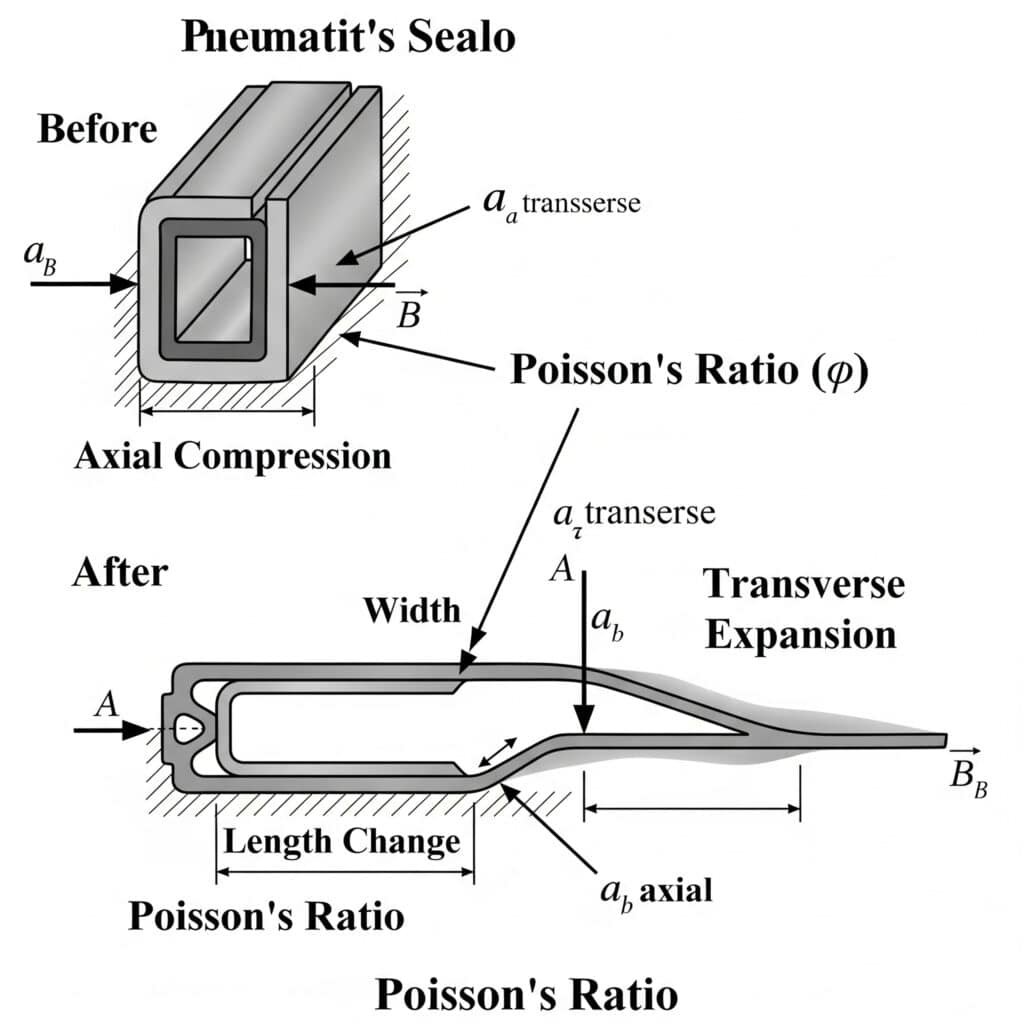

Poisson’s ratio may seem like an obscure material property, but it significantly impacts pneumatic system performance, particularly for seals, cylinder barrels, and mounting components.

Poisson’s ratio describes how materials expand perpendicular to the direction of compression, according to the equation εtransverse = -ν × εaxial, where ν is Poisson’s ratio. In pneumatic systems, this affects seal compression behavior, pressure-induced expansion, and stress distribution. Understanding these effects is crucial for preventing leakage, ensuring proper fit, and avoiding premature component failure.

Let’s explore how Poisson’s ratio impacts pneumatic system design and performance.

Poisson’s Ratio Impact Parameters for Common Materials

Different materials exhibit different Poisson’s ratio values, affecting their behavior under load:

| Material | Poisson’s Ratio (ν) | Volumetric Change | Application Implications |

|---|---|---|---|

| Aluminum | 0.33 | Moderate volume conservation | Good balance of properties for cylinders |

| Steel | 0.27-0.30 | Better volume conservation | More predictable deformation under pressure |

| Brass/Bronze | 0.34 | Moderate volume conservation | Used in valve components, bushings |

| Engineering Plastics | 0.35-0.40 | Less volume conservation | Greater dimensional changes under load |

| Elastomers (Rubber) | 0.45-0.49 | Near-perfect volume conservation | Critical for seal design and function |

| PTFE (Teflon) | 0.46 | Near-perfect volume conservation | Low friction seals with high expansion |

Practical Effects of Poisson’s Ratio in Pneumatic Components

Poisson’s ratio impacts pneumatic systems in several key ways:

- Seal compression behavior: When compressed axially, seals expand radially by an amount determined by Poisson’s ratio

- Pressure vessel expansion: Pressurized cylinders expand both longitudinally and circumferentially

- Component fit under load: Parts under compression or tension change dimensions in all directions

- Stress distribution: Poisson effect creates multi-axial stress states even under simple loading

Case Study: Solving Seal Leakage Through Poisson’s Ratio Analysis

Last year, I worked with Marcus, a maintenance manager at a food processing plant in Oregon. His rodless cylinders were experiencing persistent air leakage despite regular seal replacement. The leakage was particularly bad during pressure spikes and at higher operating temperatures.

Analysis revealed that the seal material had a Poisson’s ratio of 0.47, causing significant radial expansion when compressed axially. During pressure spikes, the cylinder bore also expanded due to its own Poisson’s ratio effect. The combination created temporary gaps that allowed air leakage.

By switching to a composite seal with a slightly lower Poisson’s ratio (0.43) and higher elastic modulus, we reduced the radial expansion under compression. This simple change, based on understanding Poisson’s ratio effects, reduced air leakage by 85% and extended seal life from 3 months to over a year.

Calculating Dimensional Changes Using Poisson’s Ratio

To predict how components will change dimensions under load:

| Dimension | Calculation | Example |

|---|---|---|

| Axial Strain | εaxial = σ/E | For 10MPa stress in aluminum: εaxial = 0.000145 |

| Transverse Strain | εtransverse = -ν × εaxial | With ν = 0.33: εtransverse = -0.0000479 |

| Diameter Change | ΔD = D × εtransverse | For 40mm bore: ΔD = -0.00192mm (compression) |

| Length Change | ΔL = L × εaxial | For 200mm cylinder: ΔL = 0.029mm (extension) |

| Volume Change | ΔV/V = εaxial + 2εtransverse | ΔV/V = 0.000145 – 2(0.0000479) = 0.000049 (0.0049%) |

Optimizing Seal Design Using Poisson’s Ratio

Understanding Poisson’s ratio is crucial for seal design:

- Compression set resistance: Materials with lower Poisson’s ratio typically have better compression set resistance

- Extrusion resistance: Higher Poisson’s ratio materials expand more into gaps under compression

- Temperature sensitivity: Poisson’s ratio often increases with temperature, affecting seal performance

- Pressure response: Under pressure, seal material compression and cylinder bore expansion both depend on Poisson’s ratio

When Does Elastic Deformation Become Permanent Damage?

Understanding the boundary between elastic and plastic deformation is crucial for preventing permanent damage to pneumatic components and ensuring long-term reliability.

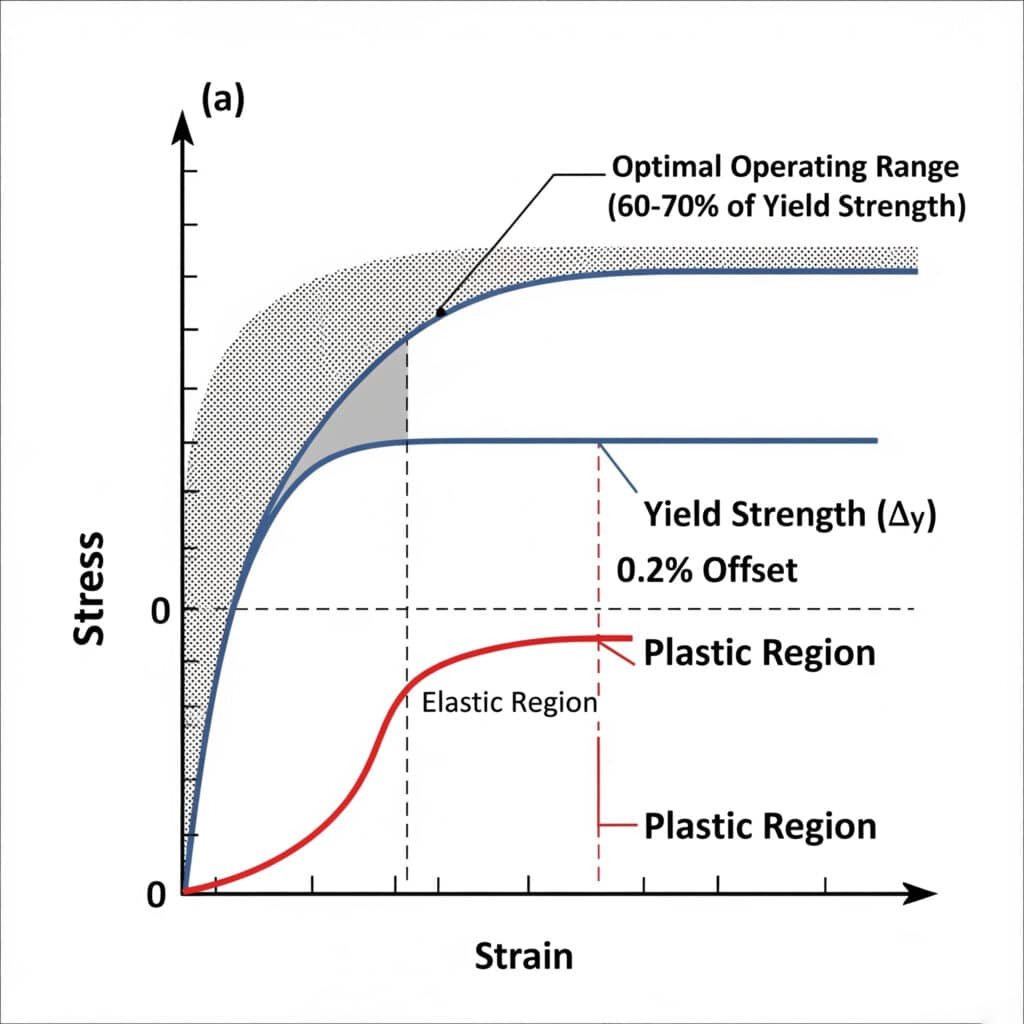

The transition from elastic to plastic deformation occurs at the yield strength4 of a material, typically 0.2% offset from perfect elasticity. For pneumatic components, this threshold varies from 35-500 MPa depending on material. Exceeding this limit causes permanent deformation, altered performance characteristics, and potential failure. Experimental data shows that operating at 60-70% of yield strength maximizes component life while maintaining elastic recovery.

Let’s explore the practical implications of this elastic-plastic boundary for pneumatic system design and maintenance.

Experimental Plastic Deformation Thresholds for Common Materials

Different materials transition from elastic to plastic behavior at different stress levels:

| Material | Yield Strength (MPa) | Typical Safety Factor | Safe Working Stress (MPa) |

|---|---|---|---|

| Aluminum 6061-T6 | 240-276 | 1.5 | 160-184 |

| Aluminum 7075-T6 | 460-505 | 1.5 | 307-337 |

| Mild Steel | 250-350 | 1.5 | 167-233 |

| Stainless Steel 304 | 205-215 | 1.5 | 137-143 |

| Brass (70/30) | 75-150 | 1.5 | 50-100 |

| Engineering Plastics | 35-100 | 2.0 | 17.5-50 |

| PTFE (Teflon) | 10-15 | 2.5 | 4-6 |

Signs of Exceeding Elastic Limits in Pneumatic Systems

When components exceed their elastic limits, several observable symptoms appear:

- Permanent deformation: Components don’t return to original dimensions when unloaded

- Hysteresis: Different behavior during loading vs. unloading cycles

- Drift: Gradual dimensional changes over multiple cycles

- Surface marks: Visible stress patterns or discoloration

- Changed performance: Altered friction, sealing, or alignment characteristics

Case Study: Preventing Bracket Failure Through Elastic Limit Analysis

I recently helped Robert, an automation engineer at an automotive parts manufacturer in Michigan. His rodless cylinder mounting brackets were failing after 3-6 months of operation, despite being sized according to standard load calculations.

Laboratory testing revealed that while the brackets weren’t failing immediately, they were experiencing stresses beyond their elastic limit during pressure spikes and emergency stops. Each event caused a small amount of plastic deformation that accumulated over time, eventually leading to fatigue failure.

By redesigning the brackets with a larger safety margin below the elastic limit and adding reinforcement at stress concentration points, we extended the bracket life from 6 months to over 3 years—a 6× improvement in durability.

Experimental Methods to Determine Elastic Limits

To determine the elastic limits of components in your specific application:

- Strain gauge testing: Apply incremental loads and measure strain recovery

- Dimensional inspection: Measure components before and after loading

- Cycle testing: Apply repeated loads and monitor for dimensional changes

- Finite Element Analysis (FEA)5: Model stress distributions to identify potential problem areas

- Material testing: Perform tensile/compression tests on material samples

Factors That Reduce Elastic Limits in Real Applications

Several factors can lower the elastic limit compared to published material specifications:

| Factor | Impact on Elastic Limit | Mitigation Strategy |

|---|---|---|

| Temperature | Decreases with increasing temperature | Derate by 0.5-1% per °C above room temperature |

| Cyclic Loading | Decreases with number of cycles | Use fatigue strength (30-50% of yield) for cyclic applications |

| Corrosion | Surface degradation lowers effective strength | Use corrosion-resistant materials or protective coatings |

| Manufacturing Defects | Stress concentrations at defects | Implement quality control and inspection procedures |

| Stress Concentrations | Local stresses can be 2-3× nominal stress | Design with generous fillets and avoid sharp corners |

Practical Guidelines for Staying Within Elastic Limits

To ensure your pneumatic components remain within their elastic limits:

- Apply appropriate safety factors: Typically 1.5-2.5 depending on application criticality

- Consider all loading cases: Include dynamic loads, pressure spikes, and thermal stresses

- Identify stress concentrations: Use FEA or stress visualization techniques

- Implement condition monitoring: Regular inspection for signs of plastic deformation

- Control operating conditions: Manage temperature, pressure spikes, and impact loads

Conclusion

Understanding the principles of material elastic deformation—from Hooke’s Law applications to Poisson’s ratio effects and plastic deformation thresholds—is essential for designing reliable, efficient pneumatic systems. By applying these principles to your rodless cylinder applications and other pneumatic components, you can improve positioning accuracy, extend component life, and reduce maintenance costs.

FAQs About Material Elasticity in Pneumatic Systems

How much elastic deformation is normal in a pneumatic cylinder?

In a properly designed pneumatic cylinder, elastic deformation typically ranges from 0.01-0.2mm under normal operating conditions. This includes barrel expansion, rod elongation, and seal compression. For precision applications, total elastic deformation should be limited to 0.05mm or less. For standard industrial applications, deformations up to 0.1-0.2mm are generally acceptable as long as they’re consistent and predictable.

How does temperature affect the elastic properties of pneumatic components?

Temperature significantly impacts elastic properties. For most metals, elastic modulus decreases by approximately 0.03-0.05% per °C temperature increase. For polymers and elastomers, the effect is much greater, with elastic modulus decreasing by 0.5-2% per °C. This means that a pneumatic system operating at 60°C might experience 20-30% more elastic deformation than the same system at 20°C, particularly in seal components and plastic parts.

What’s the relationship between pressure and cylinder barrel expansion?

Cylinder barrel expansion follows Hooke’s Law and is directly proportional to pressure and barrel diameter, and inversely proportional to wall thickness. For a typical aluminum cylinder with a 40mm bore and 3mm wall thickness, each 1 bar pressure increase causes approximately 0.002mm radial expansion. This means a standard 6 bar system experiences about 0.012mm radial expansion—small but significant for precision applications and seal design.

How do I calculate the stiffness of a pneumatic cylinder mounting arrangement?

Calculate mounting stiffness by determining the effective spring constant (k) of the mounting system. For a cantilever mount, k = 3EI/L³, where E is elastic modulus, I is moment of inertia, and L is lever length. For a typical aluminum profile (40×40mm) supporting a rodless cylinder with a 300mm cantilever, the stiffness is approximately 2500-3500 N/mm. This means a 100N force would cause 0.03-0.04mm deflection at the end of the cantilever.

What’s the impact of Poisson’s ratio on pneumatic seal performance?

Poisson’s ratio directly affects how seals behave under compression. When a seal with Poisson’s ratio of 0.47 (typical for NBR rubber) is compressed by 10% in the axial direction, it expands approximately 4.7% in the radial direction. This expansion is essential for creating sealing force against the cylinder wall. Materials with lower Poisson’s ratios expand less under compression and typically require higher compression percentages to achieve effective sealing.

How can I determine if a pneumatic component has experienced plastic deformation?

Check for these five signs of plastic deformation: 1) The component doesn’t return to its original dimensions when pressure or load is removed (measure with precision calipers or indicators), 2) Visible distortion, particularly at stress concentration points like corners and mounting holes, 3) Surface marks or discoloration along stress paths, 4) Changed operating characteristics such as increased friction or binding, and 5) Progressive dimensional changes over time, which indicates ongoing deformation beyond the elastic range.

-

Provides a detailed explanation of Hooke’s Law, the fundamental principle of physics that describes the linear relationship between the force applied to a spring-like object and its resulting extension or compression. ↩

-

Describes the concept of Poisson’s ratio, an important material property that quantifies the tendency of a material to expand or contract in directions perpendicular to the direction of loading. ↩

-

Offers a clear definition of Elastic Modulus (also known as Young’s Modulus), a key mechanical property that measures a solid material’s stiffness and its resistance to being deformed elastically. ↩

-

Explains the meaning of yield strength, the critical stress level at which a material begins to deform plastically, meaning it will no longer return to its original shape after the load is removed. ↩

-

Provides an overview of Finite Element Analysis (FEA), a powerful computational tool used by engineers to simulate how a product or component reacts to real-world forces, vibration, heat, and other physical effects. ↩