Are you struggling to justify the investment in premium pneumatic components when procurement keeps pushing for lower-cost alternatives? Many engineering and maintenance professionals face significant challenges when trying to demonstrate the true financial impact of their cylinder selection decisions beyond the initial purchase price.

Comprehensive lifecycle cost analysis1 for rodless cylinders reveals that initial purchase price typically represents only 12-18% of total ownership costs, with energy consumption (35-45%) and maintenance expenses (25-40%) constituting the majority of lifetime expenses – making premium cylinders with higher efficiency and reliability up to 42% less expensive over a 10-year operational period.

I recently worked with a food processing plant that was hesitant to upgrade their pneumatic systems due to a 65% higher initial cost for premium components. After implementing the lifecycle cost analysis methods I’ll outline below, they discovered their “economical” cylinders were actually costing them an additional $327,000 annually in energy and maintenance expenses. Let me show you how to uncover similar insights in your operation.

Table of Contents

- How Can You Create an Accurate Initial Cost Comparison Matrix?

- What’s the Most Practical Method for Calculating Energy Efficiency Costs?

- Which Approaches Best Predict Long-Term Maintenance Costs?

- Conclusion

- FAQs About Rodless Cylinder Lifecycle Cost Analysis

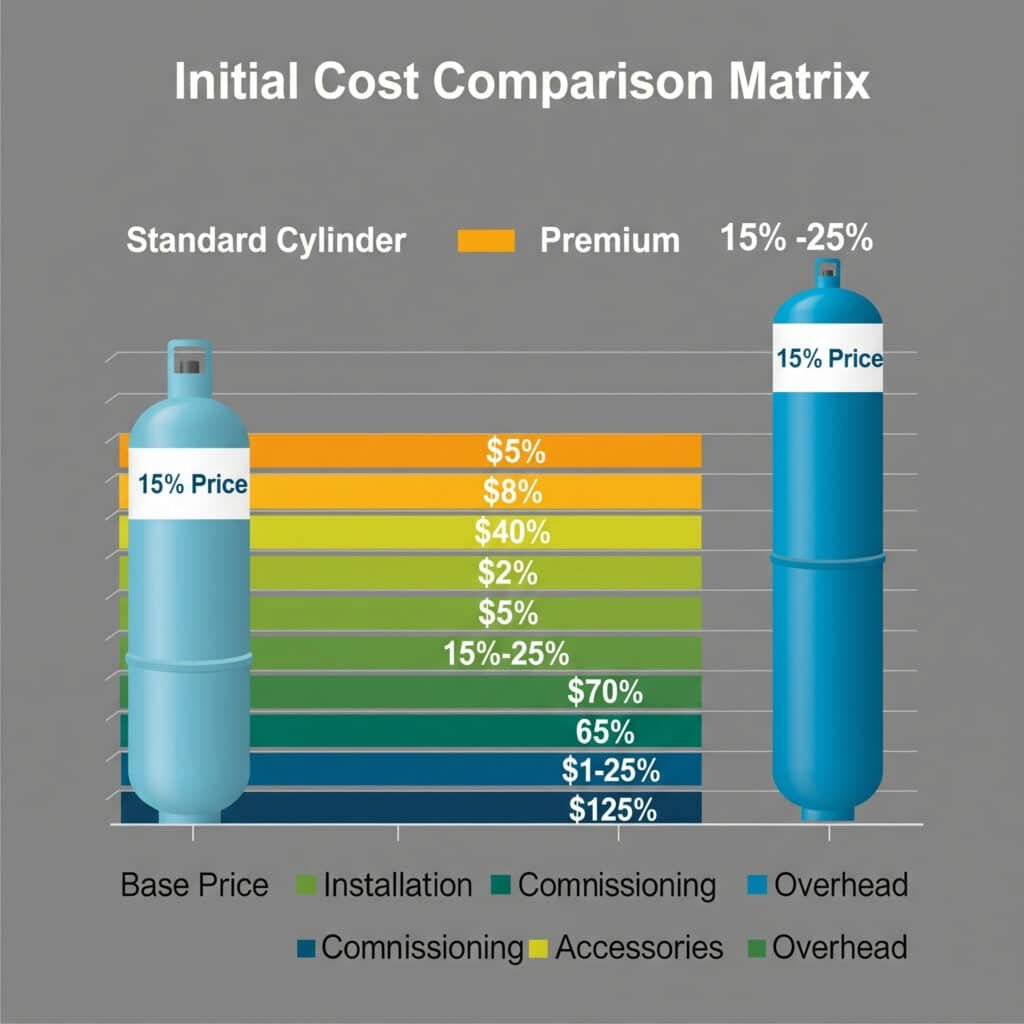

How Can You Create an Accurate Initial Cost Comparison Matrix?

Initial cost comparison matrices provide the foundation for any comprehensive lifecycle analysis, but must go beyond simple purchase price examination.

An accurate initial cost comparison matrix for rodless cylinders must incorporate not only base component pricing but also quantify installation expenses, commissioning requirements, accessory costs, and procurement overhead – revealing that premium cylinders often reduce initial implementation costs by 15-25% despite higher purchase prices.

Having developed procurement strategies for pneumatic systems across multiple industries, I’ve found that most organizations significantly underestimate the true initial costs by focusing exclusively on component purchase prices. The key is developing a comprehensive matrix that captures all relevant expenses from selection through commissioning.

Comprehensive Initial Cost Framework

A properly constructed initial cost comparison matrix includes these essential components:

1. Direct Component Cost Analysis

The baseline component costs must be thoroughly examined:

| Cost Category | Standard Components | Premium Components | Evaluation Approach |

|---|---|---|---|

| Base Cylinder | Lower unit cost | Higher unit cost | Direct quote comparison |

| Required Accessories | Often sold separately | Often included | Itemized accessory list |

| Mounting Hardware | Basic options | Comprehensive options | Application-specific requirements |

| Connection Components | Standard fittings | Optimized fittings | Complete pneumatic circuit analysis |

| Control Components | Basic functionality | Advanced features | Control system integration assessment |

| Spare Parts Package | Limited initial spares | Comprehensive spares | Operational risk assessment |

Implementation considerations:

- Request detailed, itemized quotes from multiple suppliers

- Ensure like-for-like comparison of complete systems

- Account for quantity discounts and package pricing

- Consider lead time impact on project scheduling

2. Installation and Implementation Cost Analysis

Installation expenses often vary significantly between options:

Installation Labor Requirements

– Mounting complexity assessment

– Connection and integration time estimation

– Specialized skill requirements

– Installation tool and equipment needs

– Access requirements and constraintsSystem Integration Expenses

– Control system programming requirements

– Interface adaptation needs

– Communication protocol compatibility

– Software configuration complexity

– Testing and validation proceduresDocumentation and Training Needs

– Required technical documentation

– Operator training requirements

– Maintenance personnel training

– Specialized knowledge transfer

– Ongoing support requirements

3. Commissioning2 and Startup Cost Evaluation

Commissioning costs can vary dramatically between different cylinder options:

Adjustment and Calibration Requirements

– Initial setup complexity

– Calibration procedure requirements

– Specialized tool needs

– Technical expertise requirements

– Validation and verification proceduresTesting and Qualification Expenses

– Performance testing requirements

– Reliability validation procedures

– Compliance verification needs

– Documentation requirements

– Third-party certification costsProduction Ramp-Up Impact

– Learning curve considerations

– Initial production efficiency impact

– Startup waste and quality issues

– Productivity during commissioning

– Time to full production capability

Real-World Application: Manufacturing Plant Expansion

One of my most comprehensive initial cost analyses was for a manufacturing plant expansion in Germany. Their requirements included:

- Comparison of three different rodless cylinder technologies

- Evaluation of five potential suppliers

- Integration with existing automation systems

- Compliance with strict internal standards

We developed a comprehensive comparison matrix that revealed surprising results:

| Cost Category | Economy Option | Mid-Range Option | Premium Option |

|---|---|---|---|

| Base Component Cost | €156,000 | €217,000 | €284,000 |

| Installation Expenses | €87,000 | €62,000 | €43,000 |

| Commissioning Costs | €112,000 | €76,000 | €51,000 |

| Administrative Overhead | €42,000 | €38,000 | €32,000 |

| Total Initial Cost | €397,000 | €393,000 | €410,000 |

The key insight was that while the premium option had an 82% higher component cost, the total initial cost was only 3.3% higher than the economy option due to significantly reduced installation, commissioning, and administrative expenses. This challenged their procurement-driven decision process that had historically focused exclusively on component pricing.

What’s the Most Practical Method for Calculating Energy Efficiency Costs?

Energy consumption represents the largest operational expense for most pneumatic systems, making accurate efficiency calculations essential for lifecycle cost analysis.

The most practical energy efficiency calculation for rodless cylinders combines basic air consumption measurement with duty cycle analysis and system efficiency factors – revealing that premium cylinders typically reduce energy costs by 25-40% compared to standard alternatives through reduced air consumption, lower operating pressures, and improved system efficiency.

Having conducted energy audits for pneumatic systems across diverse industries, I’ve found that most organizations significantly underestimate energy costs by using simplified calculations that fail to account for real-world operating conditions. The key is developing a practical approach that captures all relevant factors affecting consumption.

Practical Energy Cost Calculation Approach

An effective energy cost calculation includes these key elements:

1. Basic Air Consumption Measurement

Start with straightforward air consumption measurement:

Cycle Consumption Testing

– Measure air consumption per cycle (liters)

– Test at actual operating pressure

– Include both extension and retraction

– Account for any mid-position stopsConversion to Standard Conditions

– Convert to standard conditions (ANR)3

– Account for actual operating pressure

– Consider temperature effects

– Establish comparable baseline metricsSimple Calculation Method

– Air consumption per cycle (L)

– Cycles per hour

– Operating hours per day

– Operating days per year

2. Efficiency Factor Incorporation

Account for key efficiency factors:

Cylinder Efficiency Considerations

– Seal design and friction impact

– Bearing design efficiency

– Material and construction quality

– Operating pressure requirementsSystem Efficiency Factors

– Valve selection and sizing

– Supply line sizing and routing

– Connection and fitting quality

– Control system efficiencyPractical Efficiency Comparison

– Relative efficiency ratings

– Percentage improvement metrics

– Comparative testing results

– Real-world performance data

3. Energy Cost Calculation

Calculate actual costs using a straightforward approach:

Annual Consumption Calculation

– Daily consumption: Consumption per cycle × Cycles per hour × Hours per day

– Annual consumption: Daily consumption × Operating days per year

– Adjusted consumption: Annual consumption ÷ System efficiencyEnergy Cost Conversion

– Conversion factor: kWh per 1,000 liters of compressed air

– Energy cost: Adjusted consumption × Conversion factor × Cost per kWh

– Annual energy cost: Energy cost × (1 + Inflation factor)Lifecycle Projection

– Simple multiplication for estimated lifecycle

– Basic present value calculation

– Consideration of energy price trends

– Comparative analysis between options

Real-World Application: Automotive Component Manufacturing

One of my most practical energy efficiency analyses was for an automotive component manufacturer in Mexico. Their requirements included:

- Comparison of three different rodless cylinder technologies

- Evaluation across multiple operating pressures

- Analysis of various duty cycles

- Projection of 10-year energy costs

We implemented a practical analysis approach:

Consumption Measurement

– Installed flow meters on supply lines

– Measured consumption at actual operating pressure

– Tested with typical production loads

– Recorded cycles per hour during normal operationEfficiency Evaluation

– Compared cylinder designs and specifications

– Evaluated operating pressure requirements

– Measured system efficiency factors

– Determined overall efficiency ratingsCost Calculation

– Energy cost: $0.112/kWh

– Conversion factor: 0.12 kWh per 1,000 liters

– Annual operating hours: 7,920

– 10-year projection with 3.5% annual energy inflation

The results revealed dramatic differences:

| Metric | Economy Cylinder | Mid-Range Cylinder | Premium Cylinder |

|---|---|---|---|

| Air Consumption per Cycle | 3.8 L | 2.9 L | 2.2 L |

| Operating Pressure Required | 6.5 bar | 5.8 bar | 5.2 bar |

| System Efficiency | 43% | 56% | 67% |

| Annual Energy Cost | $12,840 | $8,760 | $6,240 |

| 10-Year Energy Cost | $147,800 | $100,900 | $71,880 |

The key insight was that the premium cylinder, despite costing $1,850 more initially, would save $75,920 in energy costs over its lifecycle compared to the economy option. This 41:1 return on the incremental investment transformed their procurement approach from price-based to value-based decision making.

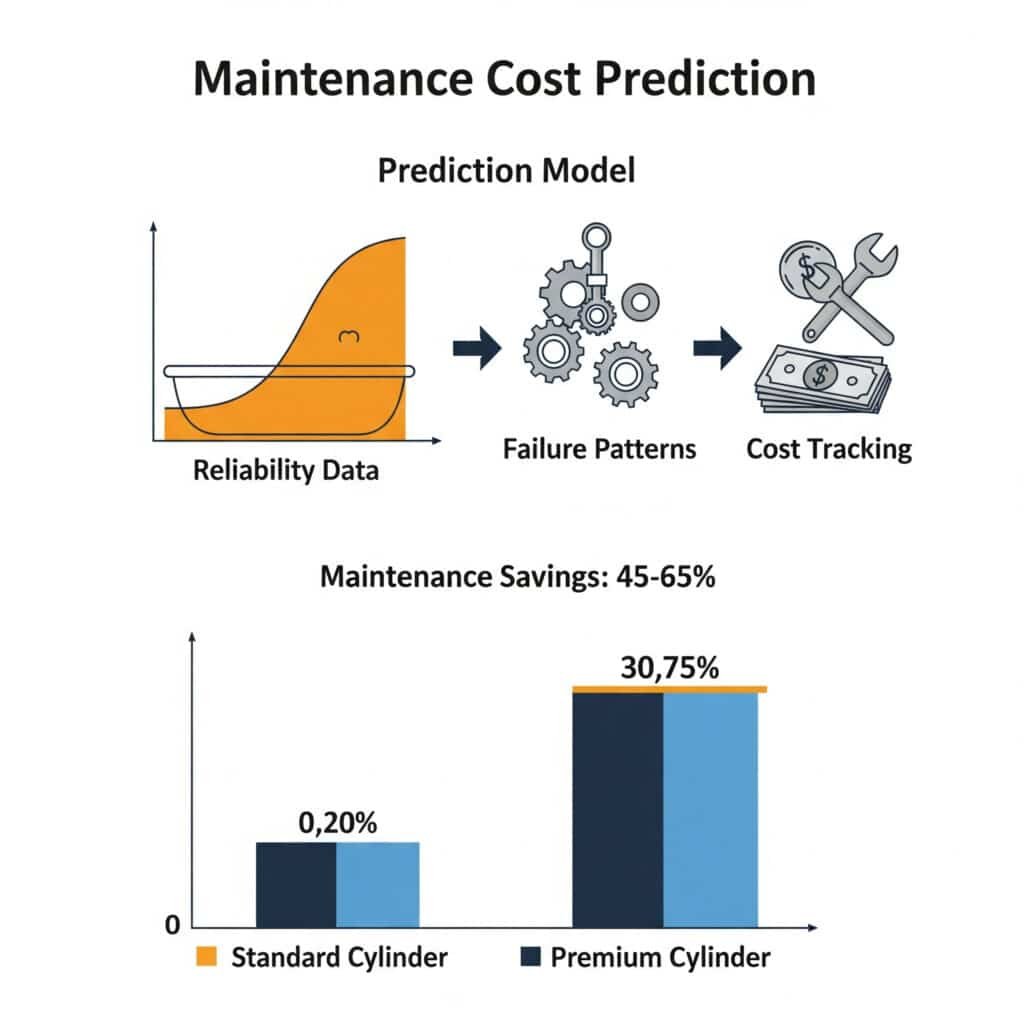

Which Approaches Best Predict Long-Term Maintenance Costs?

Maintenance expenses often represent the most unpredictable aspect of lifecycle costs, making practical prediction approaches essential for informed decision-making.

The most effective maintenance cost prediction approaches for rodless cylinders combine reliability data analysis, failure pattern recognition, and comprehensive cost tracking – revealing that premium cylinders typically reduce maintenance costs by 45-65% through extended service intervals, reduced failure rates, and simplified maintenance procedures.

Having developed maintenance strategies for pneumatic systems across multiple industries, I’ve found that most organizations significantly underestimate lifetime maintenance costs by failing to account for both direct and indirect expenses. The key is implementing a practical prediction approach that captures all relevant cost factors.

Practical Maintenance Cost Prediction Approach

An effective maintenance cost prediction model includes these key elements:

1. Reliability Data Analysis

Start with straightforward reliability assessment:

Failure Frequency Analysis

– Track mean time between failures (MTBF)4

– Calculate failure rates

– Identify common failure modes

– Compare reliability across optionsService Life Evaluation

– Determine typical service life

– Identify key limiting factors

– Compare manufacturer specifications

– Validate with real-world experienceMaintenance Interval Comparison

– Document recommended service intervals

– Compare actual maintenance frequency

– Identify preventive maintenance requirements

– Evaluate service complexity

2. Direct Maintenance Cost Tracking

Capture all direct maintenance expenses:

Labor Cost Analysis

– Track maintenance hours per event

– Document skill level requirements

– Calculate labor cost per intervention

– Project annual labor expensesParts and Materials Expenses

– List required replacement components

– Document consumable materials

– Calculate average parts cost per repair

– Project annual parts expensesExternal Service Requirements

– Identify specialized service needs

– Document contractor costs

– Calculate annual service expenses

– Include emergency service provisions

3. Indirect Cost Evaluation

Account for often-overlooked indirect costs:

Production Impact Assessment

– Calculate downtime cost per hour

– Document average repair duration

– Determine production loss per failure

– Project annual production impactQuality and Scrap Considerations

– Identify quality impact of degradation

– Calculate scrap and rework costs

– Document customer impact

– Project annual quality-related expensesInventory and Administrative Overhead

– Determine spare parts inventory requirements

– Calculate inventory carrying costs5

– Document administrative overhead

– Project annual overhead expenses

Real-World Application: Manufacturing Plant Comparison

One of my most practical maintenance cost analyses was for a manufacturing plant comparing three different rodless cylinder options. Their requirements included:

- Projection of 12-year maintenance costs

- Evaluation across multiple maintenance strategies

- Analysis of direct and indirect costs

- Consideration of production impact

We implemented a practical analysis approach:

Reliability Assessment

– Collected historical failure data

– Calculated average MTBF for each option

– Identified common failure modes

– Projected failure frequencyDirect Cost Analysis

– Documented average repair time

– Calculated typical parts costs

– Determined maintenance labor rates

– Projected annual direct maintenance expensesIndirect Cost Evaluation

– Calculated production impact per failure

– Determined quality-related costs

– Assessed inventory requirements

– Projected total maintenance impact

The results revealed dramatic differences:

| Metric | Economy Cylinder | Mid-Range Cylinder | Premium Cylinder |

|---|---|---|---|

| MTBF (operating hours) | 4,200 | 7,800 | 12,500 |

| Average Repair Time | 4.8 hours | 3.2 hours | 2.5 hours |

| Parts Cost per Repair | $720 | $890 | $1,150 |

| Annual Direct Maintenance Cost | $9,850 | $5,620 | $3,480 |

| Annual Production Impact Cost | $42,300 | $18,700 | $9,200 |

| 12-Year Maintenance Cost | $625,800 | $291,840 | $152,160 |

The key insight was that the premium cylinder, despite having 60% higher parts costs per repair, would save $473,640 in maintenance costs over 12 years compared to the economy option. The majority of these savings came from reduced production impact rather than direct maintenance expenses, highlighting the importance of considering the complete cost picture.

Conclusion

Comprehensive lifecycle cost analysis for rodless cylinder systems reveals that initial purchase price is often the least significant factor in total ownership costs. By creating accurate initial cost comparison matrices, implementing practical energy efficiency calculations, and developing effective maintenance cost prediction approaches, organizations can make truly informed decisions that optimize long-term financial performance.

The most important insight from my experience implementing these analyses across multiple industries is that premium pneumatic components almost always deliver the lowest total lifecycle cost despite higher initial prices. The combination of reduced energy consumption, lower maintenance requirements, and decreased production impact typically results in 30-50% lower total ownership costs over a 10-year period.

FAQs About Rodless Cylinder Lifecycle Cost Analysis

What is the typical payback period for premium rodless cylinders compared to economy options?

The typical payback period for premium rodless cylinders ranges from 8-18 months in most industrial applications. Energy savings usually provide the fastest return, with reduced maintenance costs contributing over longer periods. In high-duty cycle applications (>60% utilization) or operations with high downtime costs (>$1,000/hour), the payback period can be as short as 3-6 months. The key to accurate payback calculation is including all cost factors, particularly the often-overlooked production impact of reduced reliability.

How do you account for energy cost variations in lifecycle cost analysis?

To account for energy cost variations in lifecycle cost analysis, I recommend using a combination of historical trend analysis and sensitivity modeling. Start with your current energy costs as a baseline, then apply a projected inflation rate based on historical data for your region (typically 2-5% annually). Create multiple scenarios with different inflation rates to understand the sensitivity of your results. For operations in multiple locations, perform separate analyses using local energy costs. Remember that energy efficiency improvements become even more valuable as energy costs rise.

What are the most commonly overlooked costs in rodless cylinder lifecycle analysis?

The most commonly overlooked costs in rodless cylinder lifecycle analysis include: production losses during unplanned downtime (often 5-10x the direct repair costs), quality impacts from degrading performance (typically 2-5% of production value), inventory carrying costs for spare parts (10-25% of parts value annually), and administrative overhead for maintenance management (15-30% of direct maintenance costs). Additionally, many analyses fail to account for the cost of technical support, troubleshooting time, and the learning curve associated with new equipment implementation.

How do you compare cylinders with different expected lifespans in lifecycle analysis?

To compare cylinders with different expected lifespans, use a consistent analysis period equal to the longest expected life or a common multiple of the different lifespans. Include replacement costs for shorter-lived components at appropriate intervals. Calculate the net present value (NPV) of all costs using a discount rate that reflects your organization’s cost of capital (typically 8-12%). This approach allows fair comparison by accounting for the timing of expenses and the time value of money. For example, if comparing cylinders with 5-year vs. 10-year lifespans, use a 10-year analysis period and include replacement costs for the 5-year option.

What data should be collected to improve the accuracy of maintenance cost predictions?

To improve maintenance cost prediction accuracy, collect these key data points: detailed failure records (date, operating hours, failure mode, cause), repair information (time, parts, labor hours, skill level required), maintenance history (preventive maintenance activities, findings, adjustments), operating conditions (pressure, temperature, cycle rate, load), and production impact (downtime duration, production loss, quality impact). Track this data for at least 12 months to capture seasonal variations. The most valuable insights often come from comparing similar equipment in different applications or operating conditions to identify key performance factors.

-

Provides a detailed explanation of Lifecycle Cost Analysis or Total Cost of Ownership (TCO), a financial principle that includes the initial purchase price of an asset plus all direct and indirect operating and maintenance costs over its lifespan. ↩

-

Explains the commissioning phase of a project, which is the systematic process of ensuring that all systems and components are designed, installed, tested, operated, and maintained according to the operational requirements of the owner. ↩

-

Details the difference between ANR (conditions normales de référence), the European standard for “normal” reference conditions (0°C, 1013.25 mbar), and SCFM (Standard Cubic Feet per Minute), the common North American standard. ↩

-

Offers a clear definition of Mean Time Between Failures (MTBF), a key reliability metric that represents the predicted elapsed time between inherent failures of a mechanical or electronic system during normal system operation. ↩

-

Describes inventory carrying costs (or holding costs), which are the total expenses related to storing unsold inventory, including storage space, labor, insurance, and the cost of obsolescence or damage. ↩