Engineers frequently struggle with pipe surface area calculations when sizing pneumatic tubing systems for rodless cylinders. Incorrect surface area estimates lead to inadequate heat dissipation and flow capacity issues.

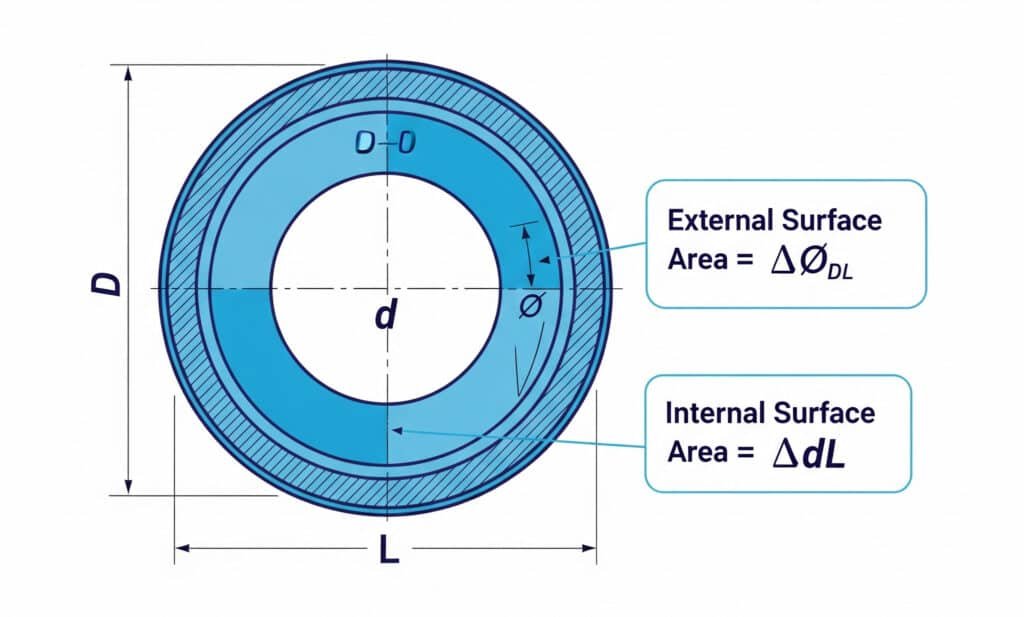

Pipe surface area equals πDL for external surface or πdL for internal surface, where D is outer diameter, d is inner diameter, and L is pipe length, critical for heat transfer and coating calculations.

Last week, I helped Stefan, a system designer from Austria, whose pneumatic tubing overheated because he miscalculated surface area for heat dissipation requirements in his high-pressure rodless cylinder installation.

Table of Contents

- What is Pipe Surface Area in Pneumatic Systems?

- How Do You Calculate External Pipe Surface Area?

- How Do You Calculate Internal Pipe Surface Area?

- Why is Pipe Surface Area Important for Pneumatic Applications?

What is Pipe Surface Area in Pneumatic Systems?

Pipe surface area represents the cylindrical surface area of pneumatic tubing and piping, essential for heat transfer calculations, coating requirements, and flow analysis in rodless cylinder systems.

Pipe surface area is the curved cylindrical surface measured as circumference times length, calculated separately for internal and external surfaces using respective diameters.

Surface Area Definition

Geometric Components

- Cylindrical surface: Curved pipe wall area

- External surface: Outside diameter-based calculation

- Internal surface: Inside diameter-based calculation

- Linear measurement: Length along pipe centerline

Key Measurements

- Outer diameter (D): External pipe dimension

- Inner diameter (d): Internal bore dimension

- Pipe length (L): Straight-line distance

- Wall thickness: Difference between outer and inner radii

Surface Area Types

| Surface Type | Formula | Application | Purpose |

|---|---|---|---|

| External | A = πDL | Heat dissipation | Cooling calculations |

| Internal | A = πdL | Flow analysis | Pressure drop, friction |

| End areas | A = π(D²-d²)/4 | Pipe ends | Connection calculations |

| Total surface | External + Internal + Ends | Complete analysis | Comprehensive design |

Common Pneumatic Pipe Sizes

Standard Tubing Dimensions

- 6mm OD, 4mm ID: External area = 18.8 mm²/mm length

- 8mm OD, 6mm ID: External area = 25.1 mm²/mm length

- 10mm OD, 8mm ID: External area = 31.4 mm²/mm length

- 12mm OD, 10mm ID: External area = 37.7 mm²/mm length

- 16mm OD, 12mm ID: External area = 50.3 mm²/mm length

Industrial Pipe Standards

- 1/4″ NPT1: 13.7mm OD typical

- 3/8″ NPT: 17.1mm OD typical

- 1/2″ NPT: 21.3mm OD typical

- 3/4″ NPT: 26.7mm OD typical

- 1″ NPT: 33.4mm OD typical

Surface Area Applications

Heat Transfer Analysis

I calculate pipe surface area for:

- Heat dissipation: Cooling compressed air systems

- Thermal expansion: Pipe length changes

- Insulation requirements: Energy conservation

- Temperature control: System thermal management

Coating and Treatment

Surface area determines:

- Paint coverage: Material quantity requirements

- Corrosion protection: Coating application area

- Surface preparation: Cleaning and treatment costs

- Maintenance planning: Recoating schedules

Pneumatic System Considerations

Rodless Cylinder Connections

- Supply lines: Main air feed piping

- Return lines: Exhaust air routing

- Control lines: Pilot air connections

- Sensor lines: Pressure monitoring tubing

System Integration

- Manifold connections: Multiple cylinder feeds

- Distribution networks: Plant-wide air systems

- Filtration systems: Clean air delivery

- Pressure regulation: Control system piping

Material Impact on Surface Area

Pipe Materials

- Steel: Standard industrial applications

- Stainless steel: Corrosive environments

- Aluminum: Lightweight installations

- Plastic/Nylon: Clean air applications

- Copper: Specialized requirements

Wall Thickness Effects

- Thin wall: Larger internal diameter, more internal area

- Standard wall: Balanced internal/external area

- Heavy wall: Smaller internal diameter, less internal area

- Custom thickness: Application-specific requirements

How Do You Calculate External Pipe Surface Area?

External pipe surface area calculation uses the outer diameter and pipe length to determine the curved cylindrical surface area for heat transfer and coating applications.

Calculate external pipe surface area using A = πDL, where D is the outer diameter and L is the pipe length, providing the total outside surface area.

External Surface Area Formula

Basic Formula

A = πDL

- A: External surface area

- π: 3.14159 (mathematical constant)

- D: Outer diameter of pipe

- L: Length of pipe

Formula Components

- Circumference: πD (distance around pipe)

- Length factor: L (pipe length)

- Surface generation: Circumference × length

- Unit consistency: All dimensions in same units

Step-by-Step Calculation

Measurement Process

- Measure outer diameter: Use calipers for accuracy

- Measure pipe length: Straight-line distance

- Verify units: Ensure consistent measurement system

- Apply formula: A = πDL

- Check result: Verify reasonable magnitude

Calculation Example

For 12mm OD pipe, 2000mm length:

- Outer diameter: D = 12mm

- Pipe length: L = 2000mm

- Surface area: A = π × 12 × 2000

- Result: A = 75,398 mm² = 0.075 m²

External Surface Area Table

| Outer Diameter | Length | Circumference | Surface Area | Area per Meter |

|---|---|---|---|---|

| 6mm | 1000mm | 18.85mm | 18,850 mm² | 18.85 cm²/m |

| 8mm | 1000mm | 25.13mm | 25,133 mm² | 25.13 cm²/m |

| 10mm | 1000mm | 31.42mm | 31,416 mm² | 31.42 cm²/m |

| 12mm | 1000mm | 37.70mm | 37,699 mm² | 37.70 cm²/m |

| 16mm | 1000mm | 50.27mm | 50,265 mm² | 50.27 cm²/m |

Practical Applications

Heat Dissipation Calculations

- Cooling requirements: Surface area for heat transfer

- Ambient temperature: Environmental heat exchange

- Air flow effects: Convective cooling enhancement

- Insulation needs: Thermal protection requirements

Coating Coverage

- Paint quantity: Material requirements calculation

- Application costs: Labor and material estimation

- Coverage rates: Manufacturer specifications

- Waste factors: Allow for application losses

Multiple Pipe Calculations

System Totals

For complex pneumatic systems:

- List all pipe sections: Diameter and length

- Calculate individual areas: Each pipe segment

- Sum total area: Add all surface areas

- Apply safety factors: Account for fittings and connections

Example System Calculation

- Main line: 16mm × 10m = 0.503 m²

- Branch lines: 12mm × 15m = 0.565 m²

- Control lines: 8mm × 5m = 0.126 m²

- Total system: 1.194 m²

Advanced Calculations

Curved Pipe Sections

- Bend radius: Affects surface area calculation

- Arc length: Use curved length, not straight-line

- Complex geometry: CAD software for accuracy

- Approximation methods: Straight-line segments

Tapered Pipes

- Variable diameter: Use average diameter

- Conical sections: Specialized geometric formulas

- Stepped diameters: Calculate each section separately

- Transition areas: Include in total calculation

Measurement Tools

Diameter Measurement

- Calipers: Most accurate for small pipes

- Tape measure: Wrap around for large pipes

- Pi tape2: Direct diameter reading

- Ultrasonic: Non-contact measurement

Length Measurement

- Steel tape: Straight runs

- Measuring wheel: Long distances

- Laser distance: High accuracy

- CAD software: Design-based calculations

Common Calculation Errors

Measurement Mistakes

- Diameter confusion: Inner vs outer diameter

- Unit inconsistency: Mixing mm, cm, inches

- Length errors: Curved vs straight distance

- Precision loss: Insufficient decimal places

Formula Errors

- Missing π: Forgetting mathematical constant

- Wrong diameter: Using radius instead of diameter

- Area vs circumference: Formula confusion

- Unit conversion: Improper scaling

When I helped Rachel, a project engineer from New Zealand, calculate coating requirements for her pneumatic distribution system, she initially used inner diameter instead of outer diameter, underestimating paint requirements by 40% and causing project delays.

How Do You Calculate Internal Pipe Surface Area?

Internal pipe surface area calculation uses the inner diameter to determine the surface area in contact with flowing air, critical for pressure drop and flow analysis.

Calculate internal pipe surface area using A = πdL, where d is the inner diameter and L is the pipe length, representing the surface area exposed to airflow.

Internal Surface Area Formula

Basic Formula

A = πdL

- A: Internal surface area

- π: 3.14159 (mathematical constant)

- d: Inner diameter of pipe

- L: Length of pipe

Relationship to Flow

- Contact surface: Area touching flowing air

- Friction effects: Surface roughness impact

- Pressure drop: Related to internal surface area

- Flow resistance: Larger area = less resistance per unit flow

Internal vs External Comparison

Area Differences

| Pipe Size | External Area | Internal Area | Difference | Wall Impact |

|---|---|---|---|---|

| 10mm OD, 8mm ID | 31.4 cm²/m | 25.1 cm²/m | 20% less | Moderate |

| 12mm OD, 8mm ID | 37.7 cm²/m | 25.1 cm²/m | 33% less | Significant |

| 16mm OD, 12mm ID | 50.3 cm²/m | 37.7 cm²/m | 25% less | Moderate |

Wall Thickness Effects

- Thin wall: Internal area close to external area

- Thick wall: Significant difference between areas

- Standard ratios: Typical wall thickness relationships

- Custom applications: Specialized wall thickness requirements

Flow Analysis Applications

Pressure Drop Calculations

ΔP = f × (L/d) × (ρv²/2)

- Surface roughness: Internal area affects friction factor

- Reynolds number3: Flow regime determination

- Friction losses: Proportional to internal surface area

- System efficiency: Minimize pressure losses

Heat Transfer Analysis

- Convective cooling: Internal surface for heat exchange

- Temperature effects: Air temperature changes

- Thermal boundary layer: Surface area impact

- System thermal management: Cooling requirements

Measurement Considerations

Inner Diameter Measurement

- Bore gauges: Direct internal measurement

- Calipers: For accessible pipe ends

- Ultrasonic: Wall thickness measurement method

- Specification sheets: Manufacturer data

Calculation Accuracy

- Measurement precision: ±0.1mm typical requirement

- Surface roughness: Affects effective area

- Manufacturing tolerances: Standard pipe variations

- Quality control: Verification methods

Pneumatic System Applications

Flow Capacity Analysis

I use internal surface area for:

- Flow rate calculations: Maximum capacity determination

- Velocity analysis: Speed of air movement

- Turbulence assessment: Flow regime evaluation

- System optimization: Pipe sizing decisions

Contamination Control

- Particle deposition: Surface area for accumulation

- Cleaning requirements: Internal surface treatment

- Filter effectiveness: Downstream protection

- Maintenance scheduling: Cleaning intervals

Complex Pipe Systems

Multiple Diameters

For systems with varying pipe sizes:

- Segment identification: List each pipe section

- Individual calculations: A = πdL for each segment

- Total internal area: Sum all segments

- Weighted averages: For overall system analysis

System Example

- Main trunk: 20mm ID × 50m = 3.14 m²

- Distribution: 12mm ID × 100m = 3.77 m²

- Branch lines: 8mm ID × 200m = 5.03 m²

- Total internal: 11.94 m²

Surface Roughness Considerations

Roughness Effects

- Smooth pipes: Theoretical internal area applies

- Rough surfaces: Effective area may be larger

- Corrosion impact: Surface degradation over time

- Material selection: Affects long-term performance

Roughness Values

- Drawn tubing: 0.0015mm typical

- Seamless pipe: 0.045mm typical

- Welded pipe: 0.045mm typical

- Plastic tubing: 0.0015mm typical

Advanced Internal Area Calculations

Non-Circular Cross-Sections

- Square ducts: Use hydraulic diameter4

- Rectangular ducts: Perimeter-based calculations

- Oval pipes: Elliptical area formulas

- Custom shapes: Specialized geometric analysis

Variable Diameter Pipes

- Tapered sections: Use average diameter

- Stepped changes: Calculate each section

- Transition zones: Include in analysis

- Complex geometry: CAD-based calculations

Quality Control and Verification

Measurement Verification

- Multiple measurements: Check consistency

- Reference standards: Compare with specifications

- Cross-sectional analysis: Cut samples if needed

- Dimensional inspection: Quality assurance

Calculation Checks

- Formula verification: Confirm correct application

- Unit consistency: Check all measurements

- Reasonableness: Compare with similar systems

- Documentation: Record all calculations

When I worked with Ahmed, a maintenance engineer from UAE, his compressed air system showed excessive pressure drop. Recalculating internal surface area revealed 30% more area than expected due to pipe corrosion, requiring system rebalancing and pipe replacement scheduling.

Why is Pipe Surface Area Important for Pneumatic Applications?

Pipe surface area directly affects heat transfer, pressure drop, coating requirements, and overall system performance in pneumatic installations supporting rodless cylinders.

Pipe surface area determines heat dissipation capacity, friction losses, material requirements, and maintenance costs, making accurate calculations essential for optimal pneumatic system design.

Heat Transfer Applications

Cooling Requirements

- Compressed air cooling: Heat dissipation after compression

- Temperature control: Maintaining optimal operating temperatures

- Thermal expansion: Managing pipe length changes

- System efficiency: Energy conservation through proper cooling

Heat Transfer Calculations

Q = hA(T₁ – T₂)

- Q: Heat transfer rate

- h: Heat transfer coefficient

- A: Pipe surface area

- T₁ – T₂: Temperature difference

Pressure Drop Analysis

Flow Resistance

ΔP = f × (L/D) × (ρv²/2)

- Surface area impact: Affects friction factor

- Internal roughness: Surface condition effects

- Flow velocity: Related to pipe internal area

- System pressure: Overall efficiency impact

Friction Loss Factors

| Surface Condition | Roughness | Friction Impact | Area Consideration |

|---|---|---|---|

| Smooth drawn | 0.0015mm | Minimal | Theoretical area |

| Standard pipe | 0.045mm | Moderate | Actual measured area |

| Corroded pipe | 0.5mm+ | Significant | Increased effective area |

| Coated interior | Variable | Depends on coating | Modified area calculation |

Material and Coating Requirements

Coverage Calculations

- Paint quantity: External surface area × coverage rate

- Primer requirements: Base coat material needs

- Protective coatings: Corrosion resistance applications

- Insulation materials: Thermal protection coverage

Cost Estimation

- Material costs: Proportional to surface area

- Labor requirements: Application time estimates

- Maintenance scheduling: Recoating intervals

- Lifecycle costs: Total ownership expenses

System Performance Impact

Flow Capacity

- Maximum flow rates: Limited by internal area and pressure drop

- Velocity constraints: Avoid excessive speeds

- Noise generation: High velocities cause noise

- Energy efficiency: Optimize for minimum losses

Response Time

- System volume: Internal area × length affects response

- Pressure wave propagation: Speed through system

- Control accuracy: Dynamic response characteristics

- Cycle time: Overall system performance

Maintenance Considerations

Cleaning Requirements

- Internal surface area: Determines cleaning time and materials

- Access methods: Pigging5, chemical cleaning

- Contamination removal: Particle and oil deposits

- System downtime: Maintenance scheduling impact

Inspection Needs

- Corrosion monitoring: External surface assessment

- Wall thickness: Ultrasonic testing requirements

- Leak detection: Surface area affects inspection time

- Replacement planning: Condition-based maintenance

Design Optimization

Pipe Sizing

Surface area considerations for:

- Heat dissipation: Adequate cooling capacity

- Pressure drop: Minimize flow losses

- Material costs: Balance performance vs cost

- Installation space: Physical constraints

- Maintenance access: Service requirements

System Integration

- Manifold design: Multiple connections

- Support structures: Thermal expansion allowance

- Insulation systems: Energy conservation

- Safety systems: Emergency shutdown considerations

Economic Analysis

Initial Costs

- Pipe materials: Larger diameter = more surface area = higher cost

- Coating systems: Surface area directly affects material needs

- Installation labor: More complex for larger systems

- Support structures: Additional hardware requirements

Operating Costs

- Energy consumption: Pressure drop affects compressor power

- Maintenance frequency: Surface area affects service requirements

- Replacement schedules: Wear related to surface exposure

- Efficiency losses: System performance degradation

Real-World Applications

Rodless Cylinder Systems

- Supply manifolds: Multiple cylinder connections

- Control circuits: Pilot air distribution

- Exhaust systems: Return air handling

- Sensor networks: Pressure monitoring lines

Industrial Examples

- Packaging machinery: High-speed pneumatic systems

- Assembly lines: Multiple actuator coordination

- Material handling: Conveyor pneumatic controls

- Process automation: Integrated pneumatic networks

Performance Monitoring

Key Indicators

- Pressure drop measurements: System efficiency

- Temperature monitoring: Heat dissipation effectiveness

- Flow rate analysis: Capacity utilization

- Energy consumption: Overall system efficiency

Troubleshooting Guidelines

- Excessive pressure drop: Check internal surface condition

- Overheating: Verify heat dissipation capacity

- Slow response: Analyze system volume and flow restrictions

- High energy use: Optimize pipe sizing and routing

When I optimized the pneumatic distribution system for Marcus, a plant engineer from Sweden, proper surface area calculations revealed that increasing main line diameter by 25% would reduce pressure drop by 40% and cut compressor energy consumption by 15%, paying for the upgrade in 18 months through energy savings.

Conclusion

Pipe surface area equals πDL (external) or πdL (internal) using diameter and length measurements. Accurate calculations ensure proper heat transfer, coating coverage, and flow analysis for optimal pneumatic system performance.

FAQs About Pipe Surface Area

How do you calculate pipe surface area?

Calculate external pipe surface area using A = πDL where D is outer diameter and L is length. For internal surface area, use A = πdL where d is inner diameter. A 12mm OD, 2m pipe has external area = π × 12 × 2000 = 75,398 mm².

What’s the difference between internal and external pipe surface area?

External surface area uses outer diameter for heat transfer and coating calculations. Internal surface area uses inner diameter for flow analysis and pressure drop calculations. External area is always larger due to pipe wall thickness.

Why is pipe surface area important in pneumatic systems?

Pipe surface area affects heat dissipation, pressure drop calculations, coating requirements, and maintenance costs. Accurate surface area calculations ensure proper system cooling, flow capacity, and material quantity estimates for pneumatic installations.

How does surface area affect pneumatic system performance?

Larger internal surface area reduces flow resistance and pressure drop. External surface area determines heat dissipation capacity and cooling effectiveness. Both factors directly impact system efficiency, energy consumption, and operating costs.

What tools help calculate pipe surface area accurately?

Use digital calipers for diameter measurement and steel tape for length. Online calculators, engineering software, and spreadsheet formulas provide quick calculations. Always verify measurements and use consistent units throughout calculations.

-

Learn about the National Pipe Thread (NPT) standard, including thread taper and dimensions for industrial pipes and fittings. ↩

-

See a guide on how Pi tapes work and why they provide highly accurate direct diameter measurements of cylindrical objects. ↩

-

Understand the definition and significance of the Reynolds number for predicting flow regimes (laminar vs. turbulent) in fluid dynamics. ↩

-

Explore the concept of hydraulic diameter and how it is used to analyze fluid flow in non-circular pipes and channels. ↩

-

Review the industrial process of pipeline pigging for cleaning, inspection, and maintenance operations. ↩