Every plant manager I consult with faces the same dilemma: pneumatic systems consume massive amounts of energy, but traditional efficiency measures barely make a dent in costs. You’ve tried basic leak detection, maybe upgraded some components, yet your energy bills remain stubbornly high while corporate sustainability targets loom unmet. This inefficiency drains your operational budget and threatens your company’s environmental commitments.

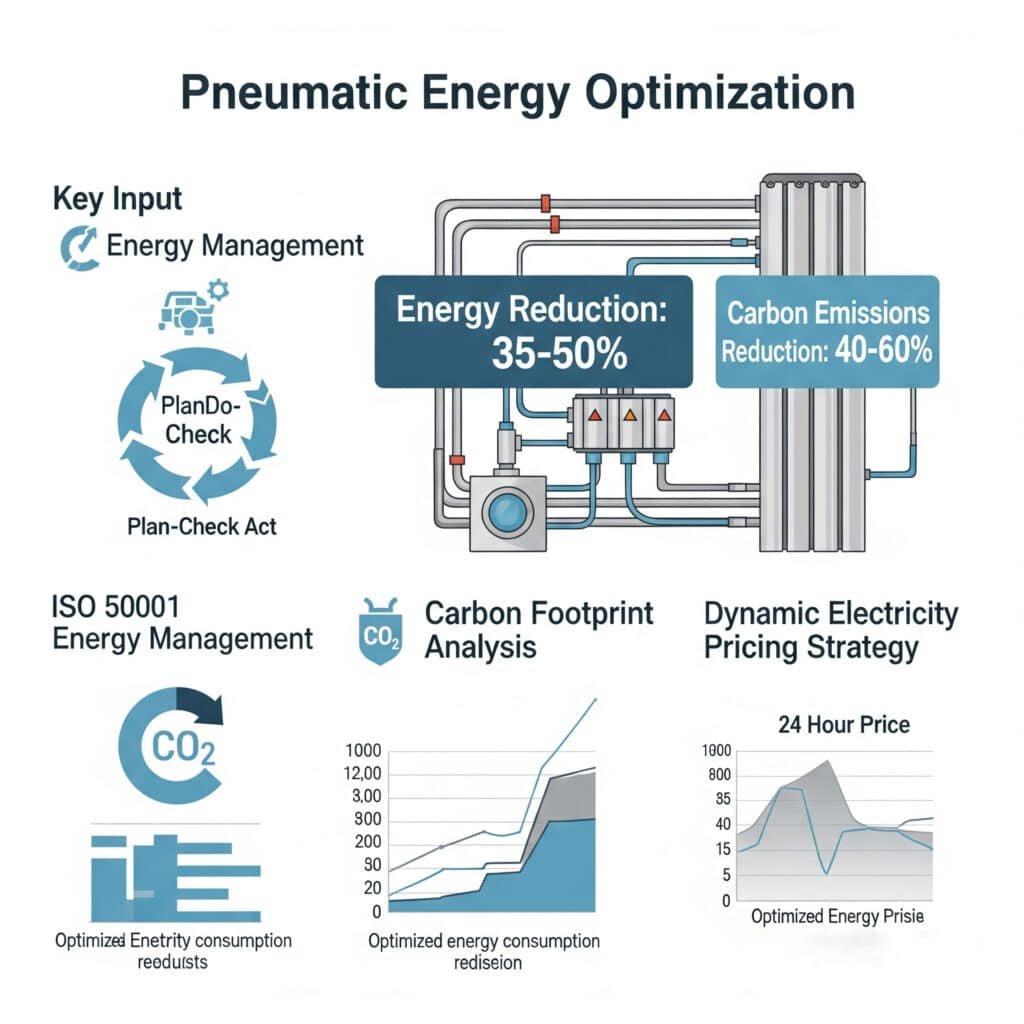

The most effective pneumatic energy optimization combines ISO 500011-compliant energy management systems, comprehensive carbon footprint analysis, and dynamic electricity pricing strategies. This integrated approach typically reduces energy consumption by 35-50% while decreasing carbon emissions by 40-60% compared to conventional systems.

Last month, I worked with a manufacturing facility in Michigan that had been struggling with excessive pneumatic system energy costs despite multiple improvement attempts. After implementing our integrated energy evaluation approach, they reduced compressed air energy consumption by 47% and documented a 52% reduction in system carbon footprint. Their payback period was just 7.3 months, and they’re now on track to meet their 2025 sustainability targets ahead of schedule.

Table of Contents

- ISO 50001 Energy Efficiency Rating Implementation Pathway

- Pneumatic System Carbon Footprint Calculation Tools

- Peak-Valley Electricity Pricing Strategy Matching Model

- Conclusion

- FAQs About Pneumatic Energy Optimization

How Do You Implement ISO 50001 to Maximize Energy Savings in Pneumatic Systems?

Many organizations attempt ISO 50001 implementation as a checkbox exercise, missing the substantial energy and cost savings potential. This surface-level approach results in certification without meaningful efficiency improvements.

Effective ISO 50001 implementation for pneumatic systems requires a structured six-phase approach that begins with comprehensive baseline energy assessment, establishes system-specific KPIs, and creates continuous improvement cycles with clear accountability. The most successful implementations achieve energy intensity reductions of 6-8% annually for the first five years.

Six-Phase ISO 50001 Implementation Pathway for Pneumatic Systems

| Implementation Phase | Key Activities | Typical Timeline | Critical Success Factors | Expected Outcomes |

|---|---|---|---|---|

| 1. Energy Baseline Assessment | Comprehensive energy mapping, data collection system setup, performance benchmarking | 4-6 weeks | Accurate measurement systems, historical data availability, system boundary definition | Detailed energy consumption baseline, key improvement opportunities identified |

| 2. Management System Development | Energy policy creation, roles assignment, documentation structure, training program | 6-8 weeks | Executive sponsorship, clear responsibilities, integrated approach with existing systems | Documented EnMS framework, trained personnel, management commitment |

| 3. Performance Indicators & Targets | KPI development, target setting, monitoring systems, reporting structures | 3-4 weeks | Relevant metrics selection, achievable but challenging targets, automated data collection | System-specific KPIs, SMART objectives, monitoring dashboard |

| 4. Improvement Plan Creation | Opportunity prioritization, project planning, resource allocation, implementation scheduling | 4-6 weeks | ROI-based prioritization, cross-functional input, realistic timelines | Documented improvement roadmap, resource commitments, clear milestones |

| 5. Implementation & Operation | Project execution, training delivery, operational control, communication systems | 3-6 months | Project management discipline, change management, ongoing communication | Completed improvement projects, operational controls, competent personnel |

| 6. Performance Evaluation & Improvement | Monitoring system operation, management review, corrective actions, continuous improvement | Ongoing | Data-driven decision making, regular reviews, accountability for results | Sustained performance improvement, adaptive management system |

Pneumatic-Specific ISO 50001 Implementation Strategy

To maximize energy savings in pneumatic systems through ISO 50001, focus on these critical elements:

Energy Performance Indicators (EnPIs) for Pneumatic Systems

Develop these pneumatic-specific performance indicators:

Specific Power Consumption (SPC)

Measure energy input per unit of compressed air output:

– kW/m³/min (or kW/cfm) at specified pressure

– Baseline typical values: 6-8 kW/m³/min for systems <100 kW

– Target values: 5-6 kW/m³/min through optimization

– Best-in-class: <4.5 kW/m³/min with advanced technologySystem Efficiency Ratio (SER)

Calculate the ratio of useful pneumatic energy to electrical input:

– Percentage of input energy converted to useful work

– Baseline typical values: 10-15% for unoptimized systems

– Target values: 20-25% through system improvements

– Best-in-class: >30% with comprehensive optimizationLeak Loss Percentage (LLP)

Quantify energy wasted through leakage:

– Percentage of total production lost to leaks

– Baseline typical values: 25-35% in average systems

– Target values: 10-15% with regular maintenance

– Best-in-class: <8% with advanced monitoringPressure Drop Ratio (PDR)

Measure distribution system efficiency:

– Pressure drop as percentage of generation pressure

– Baseline typical values: 15-20% in typical systems

– Target values: 8-10% with distribution improvements

– Best-in-class: <5% with optimized pipingPart-Load Efficiency Factor (PLEF)

Evaluate compressor performance during variable demand:

– Efficiency relative to full-load at various operating points

– Baseline typical values: 0.6-0.7 for fixed-speed systems

– Target values: 0.8-0.9 with control optimization

– Best-in-class: >0.9 with VSD and advanced controls

Energy Management Action Plan for Pneumatic Systems

Develop a structured action plan addressing these key areas:

Generation Optimization

Focus on the compressed air production system:

Compressor Technology Evaluation

– Assess current vs. best available technology

– Evaluate variable speed drive (VSD)2 retrofit opportunities

– Analyze multi-compressor control strategies

– Consider heat recovery potentialPressure Optimization

– Establish minimum required pressure for each application

– Implement pressure zoning for different requirements

– Evaluate pressure reduction potential (each 1 bar reduction saves ~7% energy)

– Consider pressure/flow controllers

Distribution Efficiency

Address the delivery network:

Piping System Assessment

– Map and analyze the distribution network

– Identify undersized piping sections causing pressure drops

– Evaluate loop systems vs. dead-end configurations

– Optimize pipe sizing for minimal pressure dropLeak Management Program

– Implement regular ultrasonic leak detection

– Establish leak tagging and repair protocols

– Install zone isolation valves

– Consider permanent leak monitoring systems

End-Use Optimization

Improve how compressed air is used:

Application Appropriateness Review

– Identify inappropriate uses of compressed air

– Evaluate alternative technologies for each application

– Eliminate open blowing applications

– Optimize air consumption in remaining applicationsControl System Enhancement

– Implement point-of-use pressure regulation

– Add automatic shut-off valves for unused sections

– Consider intelligent flow controllers

– Evaluate engineered nozzles for blowing applications

Monitoring and Measurement System Design

Implement these critical measurement capabilities:

Core Measurement Points

– Power input (kW) to compressor system

– Compressed air output (flow rate)

– System pressure at key points

– Dew point (for air quality)

– Operating hours and load profilesAdvanced Monitoring Capabilities

– Real-time specific power consumption

– Leak rate estimation during non-production

– Pressure drop across distribution sections

– Temperature monitoring for efficiency analysis

– Automated performance reporting

Case Study: Automotive Components Manufacturer

A tier-one automotive supplier in Tennessee struggled with excessive energy consumption in their pneumatic systems despite previous improvement efforts. Their compressed air system accounted for 27% of plant electricity use, and they faced corporate mandates to reduce energy intensity by 15% within two years.

We implemented ISO 50001 with a pneumatic-specific focus:

Phase 1: Baseline Assessment Results

- System consumed 4.2 million kWh annually

- Specific power consumption: 7.8 kW/m³/min

- Leak loss percentage: 32%

- Average pressure: 7.2 bar

- System efficiency ratio: 12%

Phase 2-3: Management System and KPIs

- Established compressed air management team

- Developed pneumatic-specific EnPIs

- Set targets: 25% energy reduction in 18 months

- Implemented weekly performance review process

- Created operator-level awareness program

Phase 4-5: Improvement Plan and Implementation

Prioritized projects based on ROI:

| Improvement Project | Energy Saving Potential | Implementation Cost | Payback Period | Implementation Timeline |

|---|---|---|---|---|

| Leak detection and repair program | 12-15% | $28,000 | 2.1 months | Months 1-3 |

| Pressure reduction (7.2 to 6.5 bar) | 5-7% | $12,000 | 1.8 months | Month 2 |

| Compressor control system upgrade | 8-10% | $45,000 | 5.2 months | Months 3-4 |

| Distribution system optimization | 4-6% | $35,000 | 6.8 months | Months 4-6 |

| End-use efficiency improvements | 8-12% | $52,000 | 5.0 months | Months 5-8 |

| Heat recovery implementation | N/A (thermal energy) | $65,000 | 11.2 months | Months 7-9 |

Phase 6: Results After 18 Months

- Energy consumption reduced to 2.6 million kWh (38% reduction)

- Specific power consumption improved to 5.3 kW/m³/min

- Leak loss percentage reduced to 8%

- System pressure stabilized at 6.3 bar

- System efficiency ratio improved to 23%

- ISO 50001 certification achieved

- Annual cost savings of $168,000

- Carbon emissions reduced by 1,120 tons annually

Implementation Best Practices

For successful ISO 50001 implementation in pneumatic systems:

Integration with Existing Systems

Maximize efficiency by integrating with:

- Quality management systems (ISO 9001)

- Environmental management systems (ISO 14001)

- Asset management systems (ISO 55001)

- Existing maintenance programs

- Production management systems

Technical Documentation Requirements

Develop these critical documents:

- Compressed air system map with measurement points

- Energy flow diagrams for pneumatic systems

- Standard operating procedures for energy-efficient operation

- Maintenance procedures with energy impact considerations

- Energy performance verification protocols

Training and Competence Development

Focus training on these key roles:

- System operators: efficient operation practices

- Maintenance personnel: energy-focused maintenance

- Production staff: appropriate use of compressed air

- Management: energy performance review and decision-making

- Engineering: energy-efficient design principles

How Do You Calculate the True Carbon Footprint of Your Pneumatic System?

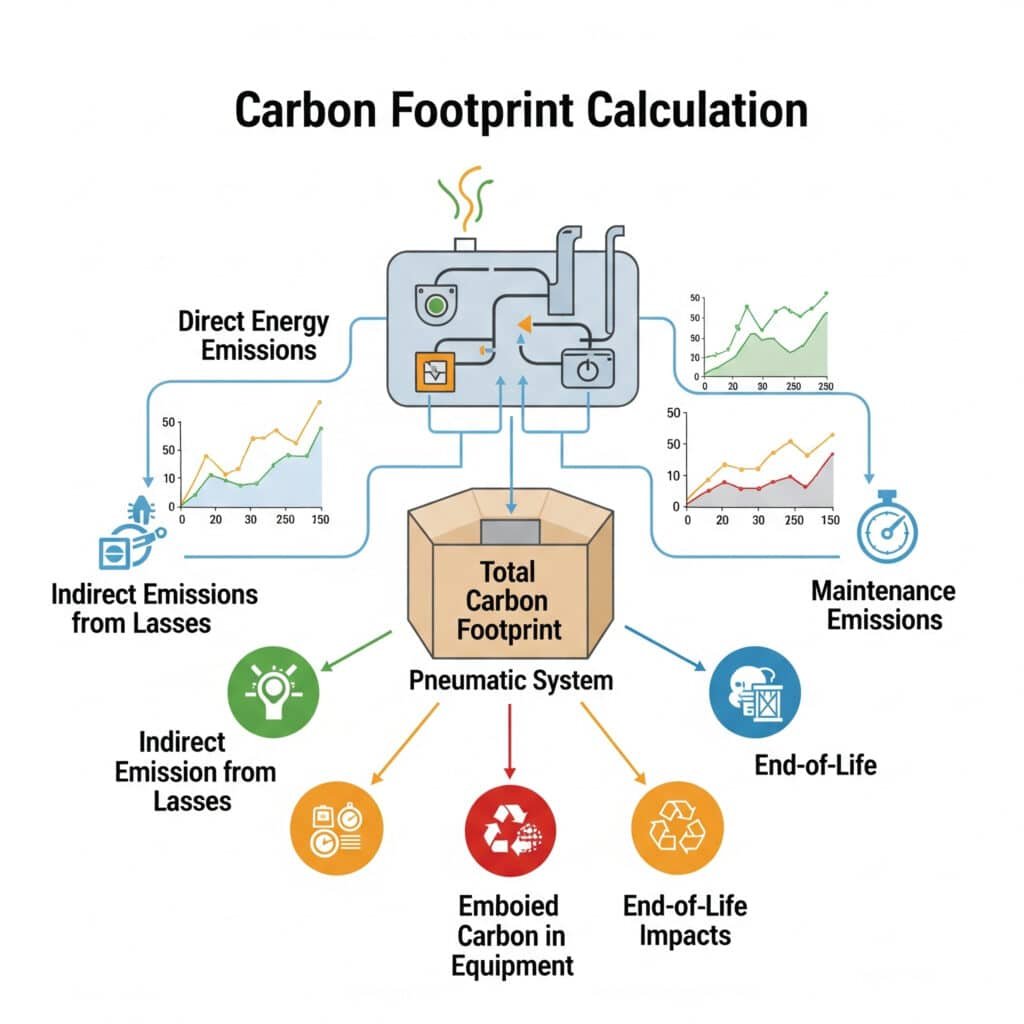

Many organizations significantly underestimate the carbon impact of their pneumatic systems, focusing only on direct electricity consumption while missing significant emission sources throughout the system lifecycle.

Comprehensive carbon footprint calculation for pneumatic systems must include direct energy emissions, indirect emissions from system losses, embodied carbon in equipment, maintenance-related emissions, and end-of-life impacts. The most accurate assessments use dynamic models that account for varying load profiles, electricity grid carbon intensity fluctuations, and system degradation over time.

Comprehensive Carbon Footprint Calculation Methodology

After developing carbon assessments for hundreds of industrial pneumatic systems, I’ve created this comprehensive calculation framework:

| Emission Category | Calculation Approach | Typical Contribution | Data Requirements | Key Reduction Opportunities |

|---|---|---|---|---|

| Direct Energy Consumption | kWh × Grid Emission Factor | 65-75% | Power monitoring, grid emission factors | Efficiency improvements, renewable energy |

| System Losses | Loss percentage × Total Emissions | 15-25% | Leak rates, pressure drops, inappropriate uses | Leak management, system optimization |

| Equipment Embodied Carbon | LCA data × System Components | 5-10% | Equipment specifications, LCA databases | Longer equipment life, proper sizing |

| Maintenance Activities | Activity-based calculation | 2-5% | Maintenance records, travel data | Predictive maintenance, local service |

| End-of-Life Impact | Material-based calculation | 1-3% | Component materials, disposal methods | Recyclable materials, refurbishment |

Carbon Footprint Calculation Tool Development

To accurately assess pneumatic system carbon footprint, I recommend developing a calculation tool with these key components:

Core Calculation Engine

Build a model incorporating these elements:

Direct Energy Emissions Calculation

Calculate emissions from electricity consumption:

– E₁ = P × t × EF

– Where:

– E₁ = Emissions from direct energy (kgCO₂e)

– P = Power consumption (kW)

– t = Operating time (hours)

– EF = Grid emission factor3 (kgCO₂e/kWh)System Loss Emissions

Quantify emissions from system inefficiencies:

– E₂ = E₁ × (L₁ + L₂ + L₃)

– Where:

– E₂ = Emissions from system losses (kgCO₂e)

– L₁ = Leak loss percentage (decimal)

– L₂ = Pressure drop loss percentage (decimal)

– L₃ = Inappropriate use percentage (decimal)Equipment Embodied Carbon

Calculate lifecycle emissions of equipment:

– E₃ = Σ(C_i × M_i) / L

– Where:

– E₃ = Annualized embodied emissions (kgCO₂e/year)

– C_i = Carbon intensity of material i (kgCO₂e/kg)

– M_i = Mass of material i in system (kg)

– L = Expected system lifetime (years)Maintenance-Related Emissions

Assess emissions from maintenance activities:

– E₄ = (T × D × EF_t) + (P_m × EF_p)

– Where:

– E₄ = Maintenance emissions (kgCO₂e)

– T = Technician visits per year

– D = Average travel distance (km)

– EF_t = Transport emission factor (kgCO₂e/km)

– P_m = Parts replaced (kg)

– EF_p = Parts production emission factor (kgCO₂e/kg)End-of-Life Emissions

Calculate disposal and recycling impacts:

– E₅ = Σ(M_i × (1-R_i) × EF_d_i – M_i × R_i × EF_r_i) / L

– Where:

– E₅ = Annualized end-of-life emissions (kgCO₂e/year)

– M_i = Mass of material i (kg)

– R_i = Recycling rate for material i (decimal)

– EF_d_i = Disposal emission factor for material i (kgCO₂e/kg)

– EF_r_i = Recycling credit for material i (kgCO₂e/kg)

Dynamic Modeling Capabilities

Enhance accuracy with these advanced features:

Load Profile Integration

Account for varying system demand:

– Create typical daily/weekly load profiles

– Map seasonal variations in demand

– Incorporate production schedule impacts

– Calculate weighted average emissions based on profilesGrid Carbon Intensity Variations

Reflect changing electricity emissions:

– Incorporate time-of-day emission factors

– Account for seasonal grid variations

– Consider regional grid differences

– Project future grid decarbonizationSystem Degradation Modeling

Account for efficiency changes over time:

– Model compressor efficiency degradation

– Incorporate increasing leak rates without maintenance

– Account for filter pressure drop increases

– Simulate maintenance intervention effects

Reporting and Analysis Features

Include these output capabilities:

Emissions Breakdown Analysis

– Category-based emissions allocation

– Component-level carbon contribution

– Temporal analysis (daily/monthly/annual)

– Comparative benchmarkingReduction Opportunity Identification

– Sensitivity analysis for key parameters

– “What-if” scenario modeling

– Marginal abatement cost curve generation

– Prioritized reduction opportunity listTarget Setting and Tracking

– Science-based target alignment

– Progress tracking against baseline

– Projection modeling for future emissions

– Reduction achievement verification

Case Study: Food Processing Facility Carbon Assessment

A food processing plant in California needed to accurately assess their pneumatic system carbon footprint as part of their corporate sustainability initiative. Their initial calculations considered only direct electricity consumption, significantly underestimating their true impact.

We developed a comprehensive carbon footprint assessment:

System Characteristics

- Seven compressors totaling 450 kW installed capacity

- Average load: 65% of capacity

- Operating schedule: 24/6 with reduced weekend operation

- California grid emission factor: 0.24 kgCO₂e/kWh

- System age: 3-12 years for different components

Carbon Footprint Results

| Emission Source | Annual Emissions (tCO₂e) | Percentage of Total | Key Contributing Factors |

|---|---|---|---|

| Direct Energy Consumption | 428.5 | 71.2% | 24-hour operation, aging compressors |

| System Losses | 132.8 | 22.1% | 28% leak rate, excessive pressure |

| Equipment Embodied Carbon | 24.6 | 4.1% | Multiple compressor replacements |

| Maintenance Activities | 9.2 | 1.5% | Frequent emergency repairs, part replacements |

| End-of-Life Impact | 6.7 | 1.1% | Limited recycling program |

| Total Annual Carbon Footprint | 601.8 | 100% |

Emission Reduction Opportunities

Based on the detailed assessment, we identified these key reduction opportunities:

| Reduction Measure | Potential Annual Savings (tCO₂e) | Implementation Cost | Cost per tCO₂e Avoided | Implementation Complexity |

|---|---|---|---|---|

| Comprehensive leak repair program | 98.4 | $42,000 | $71/tCO₂e | Medium |

| Pressure optimization (7.8 to 6.5 bar) | 45.2 | $15,000 | $55/tCO₂e | Low |

| VSD compressor replacement | 85.7 | $120,000 | $233/tCO₂e | High |

| Heat recovery implementation | 32.1 | $65,000 | $337/tCO₂e | Medium |

| Renewable energy procurement (25%) | 107.1 | $18,000/year | $168/tCO₂e | Low |

| Predictive maintenance program | 22.5 | $35,000 | $259/tCO₂e | Medium |

Results after implementing the top three measures:

- Carbon footprint reduced by 229.3 tCO₂e (38.1%)

- Additional 10.2% reduction from improved maintenance

- Total reduction achieved: 48.3% within 18 months

- Annual cost savings of $87,500

- Payback period of 2.0 years for all implemented measures

Implementation Best Practices

For accurate carbon footprint assessment of pneumatic systems:

Data Collection Methodology

Ensure comprehensive data gathering:

- Install permanent power monitoring on compressors

- Conduct regular leak assessments with ultrasonic detection

- Document all maintenance activities and parts

- Maintain detailed equipment inventory with specifications

- Record operating schedules and production patterns

Emission Factor Selection

Use appropriate emission factors:

- Obtain location-specific grid emission factors

- Update factors annually as grid composition changes

- Use manufacturer-specific LCA data when available

- Apply appropriate uncertainty ranges to calculations

- Document all emission factor sources and assumptions

Verification and Reporting

Ensure calculation credibility:

- Implement internal verification procedures

- Consider third-party verification for public reporting

- Align with recognized standards (GHG Protocol, ISO 14064)

- Maintain transparent calculation documentation

- Regularly validate assumptions against actual performance

How Do You Match Compressed Air Operation to Electricity Pricing for Maximum Savings?

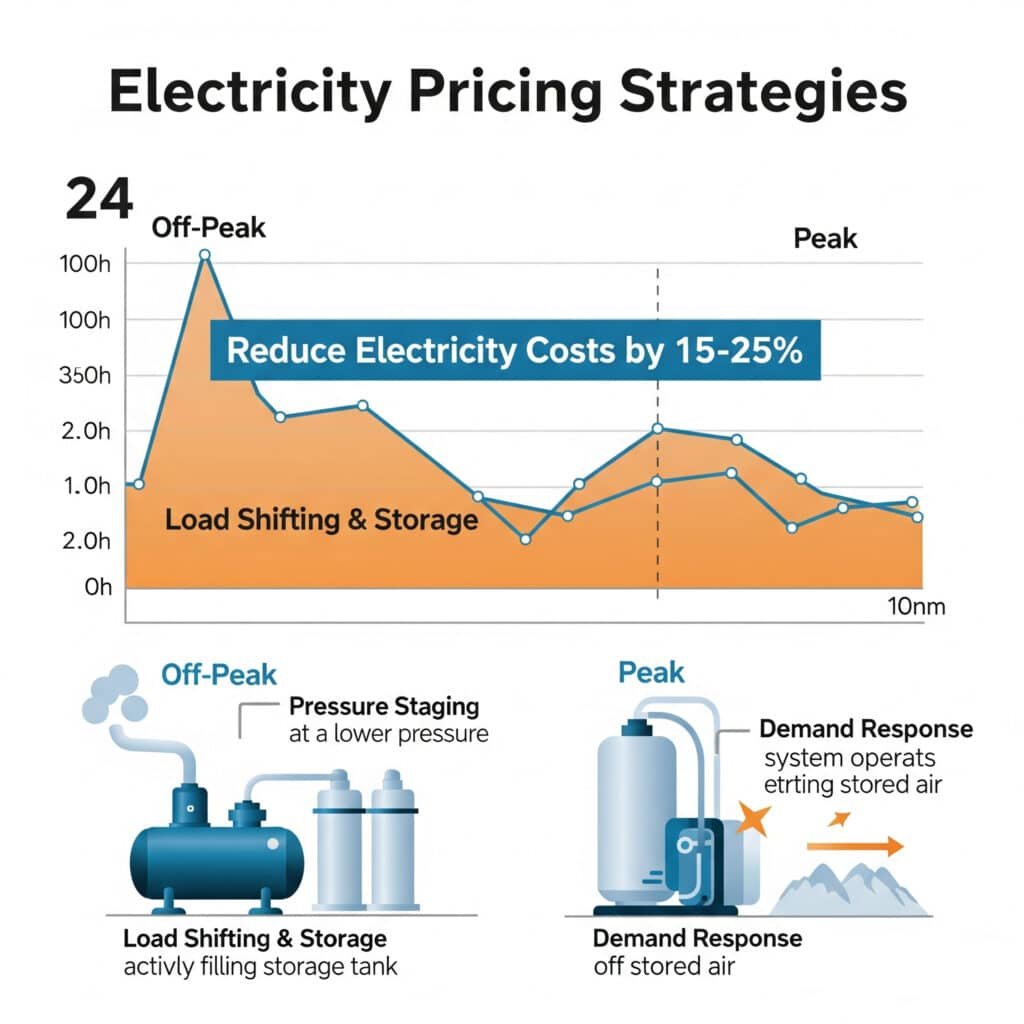

Most pneumatic systems operate without consideration for electricity pricing4 variations, missing significant cost-saving opportunities. This disconnect between operation and energy costs results in unnecessarily high operating expenses.

Effective peak-valley electricity pricing strategies for pneumatic systems combine load shifting for compressor operation, pressure staging aligned with price periods, storage optimization for peak avoidance, and demand response capability. The most successful implementations reduce electricity costs by 15-25% without impacting production requirements.

Comprehensive Electricity Pricing Strategy Model

Based on implementing energy cost optimization for hundreds of pneumatic systems, I’ve developed this strategic framework:

| Strategy Component | Implementation Approach | Typical Savings | Requirements | Limitations |

|---|---|---|---|---|

| Load Shifting | Schedule compression during low-cost periods | 10-15% | Storage capacity, flexible production | Limited by production needs |

| Pressure Staging | Adjust system pressure based on price periods | 5-8% | Multi-pressure capability, control system | Minimum pressure requirements |

| Storage Optimization | Size receivers to bridge peak price periods | 8-12% | Adequate storage space, investment capacity | Capital constraints |

| Demand Response5 | Reduce pneumatic consumption during grid events | 3-5% + incentives | Automated controls, production flexibility | Critical process constraints |

| Tariff Optimization | Select optimal rate structure for usage pattern | 5-15% | Detailed consumption data, utility options | Available tariff structures |

Electricity Pricing Strategy Matching Model

To develop an optimal electricity pricing strategy for pneumatic systems, I recommend this structured approach:

Phase 1: Load and Price Profile Analysis

Begin with comprehensive understanding of both demand and pricing:

Pneumatic Load Profiling

Document system demand patterns:

– Collect compressed air flow data at 15-minute intervals

– Create typical daily/weekly/seasonal demand profiles

– Identify base, average, and peak demand levels

– Categorize demand by production requirement (critical vs. deferrable)

– Quantify minimum pressure requirements by applicationElectricity Pricing Structure Analysis

Understand all applicable tariff components:

– Time-of-use periods and rates

– Demand charge structure and calculation method

– Seasonal variations in pricing

– Available rider programs and incentives

– Demand response program opportunitiesCorrelation Analysis

Map the relationship between demand and pricing:

– Overlay pneumatic demand profile with electricity pricing

– Calculate current cost distribution across price periods

– Identify high-impact periods (high demand during high prices)

– Quantify potential savings from ideal alignment

– Assess technical feasibility of load shifting

Phase 2: Strategy Development

Create a customized strategy based on analysis results:

Load Shifting Opportunity Assessment

Identify operations that can be rescheduled:

– Non-critical compressed air applications

– Batch processes with flexible timing

– Preventive maintenance activities

– Testing and quality control operations

– Ancillary systems with deferrable demandPressure Optimization Modeling

Develop multi-level pressure strategies:

– Map minimum pressure requirements by application

– Design staged pressure reduction during peak pricing

– Calculate energy savings from each pressure reduction step

– Assess production impact of pressure modifications

– Develop implementation requirements and controlsStorage Capacity Optimization

Design optimal storage solution:

– Calculate required storage volume for peak avoidance

– Determine optimal receiver pressure ranges

– Evaluate distributed vs. centralized storage options

– Assess control system requirements for storage management

– Develop charging/discharging strategies aligned with pricingDemand Response Capability Development

Create grid-responsive reduction capability:

– Identify non-critical loads for curtailment

– Establish automated response protocols

– Determine maximum reduction potential

– Assess production impact of curtailment

– Calculate economic value of participation

Phase 3: Implementation Planning

Develop a detailed execution plan:

Control System Requirements

Specify necessary control capabilities:

– Real-time electricity pricing data integration

– Automated pressure adjustment controls

– Storage management algorithms

– Load shedding automation

– Monitoring and verification systemsInfrastructure Modifications

Identify required physical changes:

– Additional storage receiver capacity

– Pressure zone separation equipment

– Control valve installations

– Monitoring system enhancements

– Backup systems for critical applicationsOperational Procedure Development

Create new standard operating procedures:

– Peak period operation guidelines

– Manual intervention protocols

– Emergency override procedures

– Monitoring and reporting requirements

– Staff training materialsEconomic Analysis

Complete detailed financial assessment:

– Implementation costs for all components

– Projected savings by strategy element

– Payback period calculation

– Net present value analysis

– Sensitivity analysis for key variables

Case Study: Chemical Manufacturing Facility

A specialty chemical manufacturer in Texas faced rapidly increasing electricity costs due to their 24/7 operation and the introduction of more aggressive time-of-use pricing by their utility. Their compressed air system, with 750 kW of installed capacity, represented 28% of their electricity consumption.

We developed a comprehensive electricity pricing strategy:

Initial Assessment Findings

- Electricity rate structure:

– On-peak (1pm-7pm weekdays): $0.142/kWh + $18.50/kW demand

– Mid-peak (8am-1pm, 7pm-11pm): $0.092/kWh + $5.20/kW demand

– Off-peak (11pm-8am, weekends): $0.058/kWh, no demand charge - Pneumatic system operation:

– Relatively consistent demand (450-550 kW)

– Operating pressure: 7.8 bar throughout facility

– Minimal storage capacity (2 m³ receivers)

– No pressure zoning or control

– Critical processes requiring continuous operation

Strategy Development

We created a multi-faceted approach:

| Strategy Element | Implementation Details | Expected Savings | Implementation Cost |

|---|---|---|---|

| Pressure Staging | Reduce pressure to 6.8 bar during on-peak periods for non-critical areas | $42,000/year | $28,000 |

| Storage Expansion | Add 15 m³ of receiver capacity to bridge peak periods | $65,000/year | $75,000 |

| Production Scheduling | Shift batch operations to off-peak periods where possible | $38,000/year | $12,000 |

| Leak Repair Program | Prioritize repairs in areas operating during peak periods | $35,000/year | $30,000 |

| Tariff Optimization | Switch to alternative rate rider with lower peak charges | $28,000/year | $5,000 |

Implementation Results

After implementing the strategy:

- Peak period pneumatic demand reduced by 32%

- Overall energy consumption reduced by 18%

- Annual electricity cost savings of $187,000 (22.5%)

- Payback period of 9.3 months

- No impact on production output or quality

- Additional benefit: reduced compressor maintenance costs

Advanced Implementation Techniques

For maximum benefit from electricity pricing strategies:

Automated Price Response Systems

Implement intelligent control systems:

- Real-time pricing data integration via API

- Predictive algorithms for demand forecasting

- Automated pressure and flow adjustments

- Dynamic storage management

- Machine learning optimization over time

Multi-Resource Optimization

Coordinate pneumatic systems with other energy systems:

- Integrate with thermal energy storage strategies

- Coordinate with facility-wide demand management

- Align with on-site generation operation

- Complement battery storage systems

- Optimize within overall energy management system

Contractual Optimization

Leverage utility programs and contract structures:

- Negotiate custom tariff structures where available

- Participate in demand response programs

- Explore interruptible rate options

- Evaluate peak load contribution management

- Consider third-party energy supply options

Implementation Best Practices

For successful electricity pricing strategy implementation:

Cross-Functional Collaboration

Ensure involvement from key stakeholders:

- Production planning and scheduling

- Maintenance and engineering

- Finance and procurement

- Quality assurance

- Executive sponsorship

Phased Implementation Approach

Reduce risk through staged deployment:

- Begin with no/low-risk applications

- Implement monitoring before control changes

- Conduct limited trials before full deployment

- Build on successful elements incrementally

- Document and address concerns promptly

Continuous Optimization

Maintain long-term performance:

- Regular strategy review and adjustment

- Ongoing monitoring and verification

- Periodic recommissioning of systems

- Updates for changing production requirements

- Adaptation to evolving utility rate structures

Conclusion

Effective pneumatic system energy optimization requires a comprehensive approach that combines ISO 50001-compliant energy management systems, accurate carbon footprint calculation, and strategic electricity pricing alignment. By implementing these methodologies, organizations can typically reduce energy costs by 35-50% while making significant progress toward sustainability goals.

The most successful companies approach pneumatic energy optimization as a continuous journey rather than a one-time project. By establishing robust management systems, accurate measurement tools, and dynamic operating strategies, you can ensure your pneumatic systems deliver optimal performance at minimum energy cost and environmental impact.

FAQs About Pneumatic Energy Optimization

What is the typical payback period for comprehensive pneumatic energy optimization?

The typical payback period for comprehensive pneumatic energy optimization ranges from 8 to 18 months, depending on the initial system efficiency and electricity costs. The fastest returns usually come from leak management (2-4 months payback) and pressure optimization (3-6 months payback), while infrastructure investments like storage expansion or compressor replacements typically pay back in 12-24 months. Companies with electricity costs above $0.10/kWh generally see faster returns.

How accurately can carbon footprint calculations predict actual emissions?

When properly implemented, comprehensive carbon footprint calculations for pneumatic systems can achieve accuracy within ±8-12% of actual emissions. The greatest uncertainties typically come from variations in grid emission factors (which can fluctuate seasonally) and from estimating embodied carbon in equipment. Direct energy emissions calculations are typically the most accurate component (±3-5%) when based on actual metered data, while maintenance-related emissions often have the highest uncertainty (±15-20%).

Which industries typically benefit most from peak-valley electricity pricing strategies?

Industries with high compressed air consumption and operational flexibility gain the most from electricity pricing strategies. Food and beverage manufacturers typically achieve savings of 18-25% through storage optimization and production scheduling. Chemical processing facilities can reduce costs by 15-22% through pressure staging and strategic maintenance timing. Metal fabrication operations often see 20-30% cost reductions by shifting non-critical compressed air operations to off-peak periods. The key factor is the ratio of deferrable to non-deferrable compressed air demand.

Can ISO 50001 implementation be justified for smaller compressed air systems?

Yes, ISO 50001 implementation can be economically justified for compressed air systems as small as 50-75 kW in capacity, though the approach should be scaled appropriately. For systems in this range, a streamlined implementation focusing on core elements (baseline establishment, performance indicators, improvement plans, and regular review) typically yields annual savings of $8,000-$15,000 with implementation costs of $10,000-$20,000, resulting in payback periods of 12-24 months. The key is integrating the energy management approach with existing business systems rather than creating a standalone program.

How do renewable energy purchases affect pneumatic system carbon footprint calculations?

Renewable energy purchases directly reduce the grid emission factor used in carbon footprint calculations, but proper accounting depends on the type of purchase

-

Provides an overview of the ISO 50001 standard, which specifies the requirements for establishing, implementing, maintaining, and improving an energy management system (EnMS), enabling an organization to follow a systematic approach in achieving continual improvement of energy performance. ↩

-

Explains how a Variable Speed Drive (VSD) controls the speed of an electric motor to match the demand of the load, significantly reducing energy consumption in applications with varying loads, such as air compressors. ↩

-

Describes the grid emission factor, a value that quantifies the amount of greenhouse gas emissions (in kg of CO₂ equivalent) produced per unit of consumed electricity (kWh) for a specific electrical grid, which varies by location and time. ↩

-

Details the principles of Time-of-Use (TOU) or peak-valley electricity tariffs, where the price for electricity varies based on the time of day and season, encouraging consumers to shift energy use to off-peak hours. ↩

-

Provides an explanation of demand response programs, which are initiatives by electric utilities that offer incentives to consumers for voluntarily reducing their electricity usage during periods of peak demand to help maintain grid stability. ↩