Katup Kontrol Udara | Gunakan Sinyal Udara untuk Mengontrol Aliran untuk Otomasi Non-Listrik yang Aman. Jelajahi rangkaian katup kontrol yang digerakkan oleh udara. Katup ini menggunakan sinyal udara bertekanan rendah untuk menggeser spul katup utama, mengendalikan jalur aliran tanpa daya listrik. Hal ini menjadikannya pilihan yang secara inheren aman dan andal untuk lingkungan berbahaya seperti pabrik kimia atau pertambangan, atau dalam aplikasi dengan kelembapan tinggi. Temukan katup yang tepat untuk sistem kontrol non-listrik Anda sekarang.

Butuh produk untuk proyek Anda?

Kami memahami bahwa mencari sumber daya bisa menjadi tantangan.

Isi formulir dengan item spesifik Anda - jangan ragu untuk mencantumkan komponen yang unik atau sulit ditemukan - kirimkan pertanyaan Anda, dan dapatkan solusi yang sesuai dengan yang Anda cari! Lupakan penawaran umum; kami mengkhususkan diri dalam memahami kebutuhan Anda dan memberikan hasil yang sesuai dengan keinginan Anda

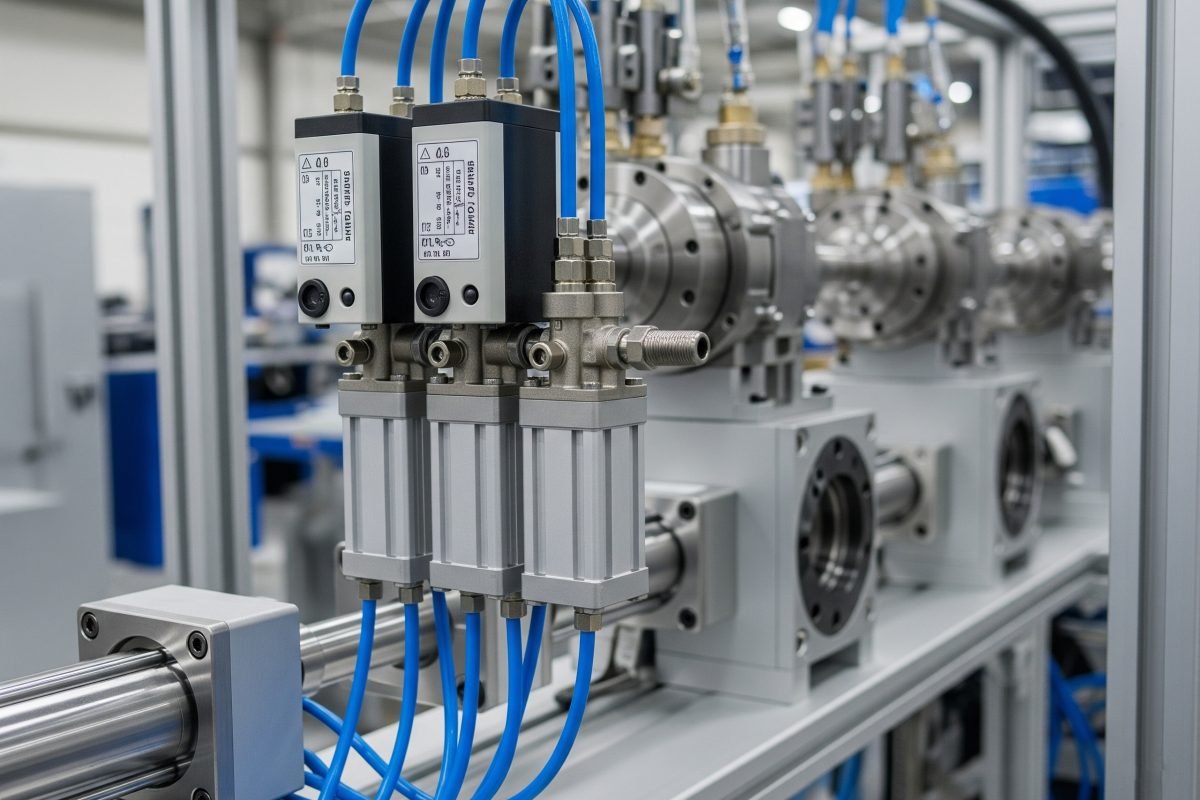

Katup kontrol udara kami dirancang secara ahli untuk mengarahkan dan mengelola aliran udara dalam sistem pneumatik Anda dengan keandalan yang luar biasa. Ideal untuk aplikasi yang membutuhkan aktuasi non-listrik yang kuat, katup ini memastikan pengoperasian yang lancar dan kontrol yang tepat untuk berbagai tugas otomasi industri.

Dioperasikan dengan sinyal udara (dioperasikan oleh pilot), menawarkan kinerja yang dapat diandalkan, terutama di lingkungan di mana aktuasi listrik tidak disukai atau tidak memungkinkan.

Dibuat untuk umur panjang, katup kontrol udara kami tahan terhadap kondisi industri yang menuntut, memastikan pengoperasian yang konsisten dan perawatan yang minimal.

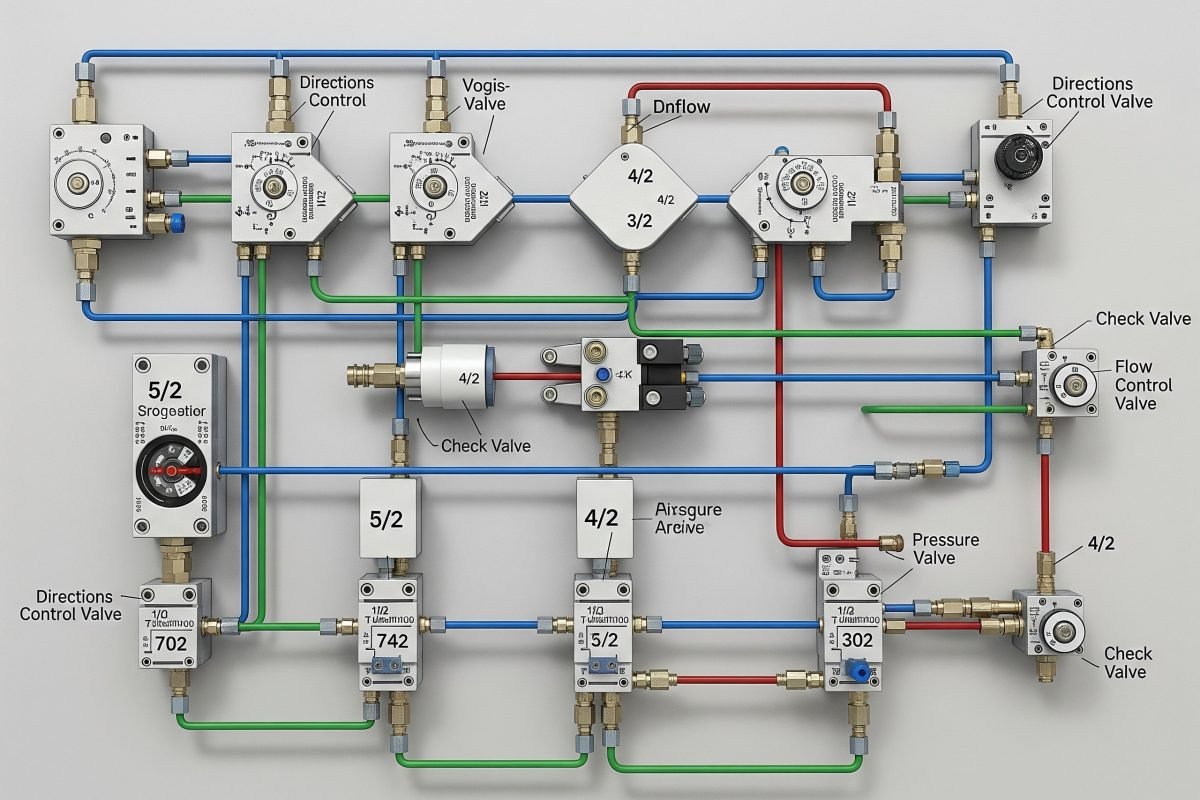

Tersedia dalam berbagai konfigurasi (misalnya, 3/2, 5/2, 5/3 arah) untuk mengatur arah aliran udara secara tepat untuk aktuator kerja tunggal dan ganda.

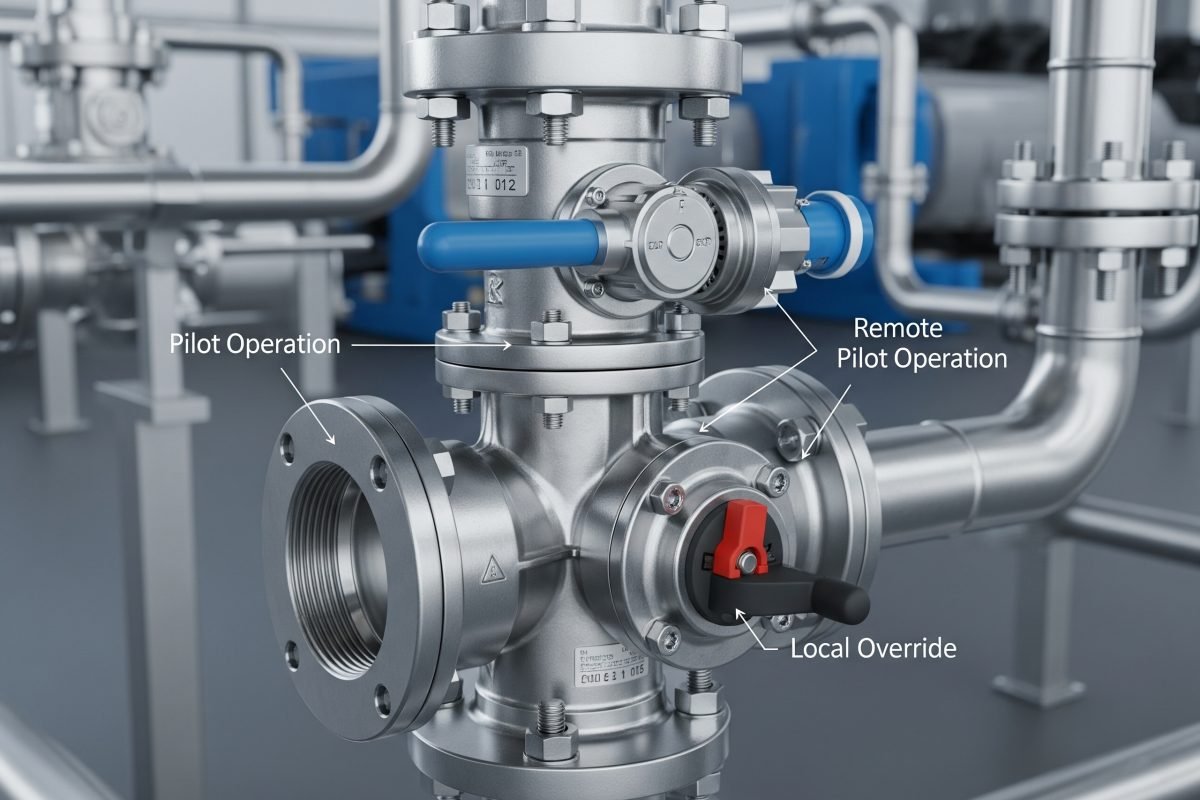

Katup kontrol udara, terutama jenis yang dioperasikan pilot, menggunakan sejumlah kecil tekanan udara (sinyal pilot) untuk menggeser spul atau poppet internal yang lebih besar. Tindakan ini mengalihkan aliran udara utama melalui port yang berbeda, mengendalikan pengoperasian silinder pneumatik, aktuator, atau perangkat lain. Metode ini memungkinkan kontrol yang kuat tanpa input listrik langsung pada katup itu sendiri.

Dirancang dengan jalur aliran internal yang dioptimalkan untuk memberikan aliran udara maksimum (Cv/Kv) dengan penurunan tekanan minimal, memastikan pengoperasian aktuator yang efisien.

Kumparan yang dikerjakan dengan mesin presisi dan seal berkualitas tinggi yang tahan aus memastikan masa pakai operasional yang lama dan kinerja yang konsisten.

Didesain untuk beroperasi secara andal di berbagai suhu lingkungan dan media, cocok untuk berbagai lingkungan industri.

Banyak seri yang menawarkan basis bermacam-macam untuk perakitan ringkas beberapa katup, menyederhanakan pemipaan dan pemasangan.

Misalnya, 3/2, 5/2, 5/3 (tengah tertutup, knalpot tengah, tekanan tengah).

Ukuran ulir port inlet, outlet, dan exhaust (mis., G1/8, G1/4, G1/2).

Pilot udara tunggal, pilot udara ganda.

Jangkauan untuk suplai udara utama dan sinyal udara pilot.

Menunjukkan kapasitas katup untuk mengalirkan udara.

Waktu yang dibutuhkan katup untuk bergeser setelah aplikasi sinyal pilot.

Biasanya paduan aluminium untuk kekuatan dan ketahanan korosi yang baik.

Bodi porting atau manifold dapat dipasang.

Untuk parameter terperinci, silakan merujuk ke manual produk individual atau berkonsultasi dengan pakar teknis kami.

Mengarahkan aliran udara untuk mengontrol gerakan (memanjangkan/memendekkan, memutar) silinder pneumatik dan aktuator putar.

Komponen integral dalam mesin pengemasan, jalur perakitan, sistem penanganan material, dan aplikasi robotik.

Digunakan dalam berbagai proses manufaktur untuk menyortir, mengalihkan, menjepit, dan tugas otomatis lainnya.

Ideal untuk digunakan di area yang mudah meledak atau rawan debu di mana komponen listrik menimbulkan risiko.

Dapat digunakan untuk membangun sirkuit kontrol pneumatik murni untuk fungsi pengurutan atau logika tertentu.

Pengoperasian pilot memungkinkan aktuasi jarak jauh, sementara penggantian manual menawarkan kontrol lokal yang nyaman.

Selalu turunkan tekanan dan hilangkan energi sistem sebelum melakukan pemasangan, pemeliharaan, atau pemecahan masalah.

Perbedaan utamanya adalah metode aktuasi:

Meskipun keduanya mengontrol aliran udara, namun cara aktivasi dan lingkungan aplikasi tipikal dapat berbeda secara signifikan.

Notasi ini menjelaskan fungsi katup:

Sebagai contoh:

Tekanan pilot minimum adalah yang tekanan udara terendah yang diperlukan di port pilot untuk menggeser spool katup utama secara andal. Nilai ini khusus untuk setiap model katup dan biasanya tercantum dalam lembar data teknisnya.

Sangat penting untuk memastikan tekanan sinyal pilot Anda memenuhi atau melampaui persyaratan minimum ini. Jika tekanan pilot terlalu rendah, katup mungkin tidak bergeser sepenuhnya, mungkin bergeser dengan lamban, atau mungkin tidak bergeser sama sekali, yang menyebabkan kerusakan sistem. Tekanan pilot minimum juga dapat bervariasi tergantung pada tekanan saluran utama pada beberapa desain katup.

Ya, banyak katup kontrol udara dirancang untuk pemasangan bermacam-macam. Manifold adalah blok dasar dengan saluran suplai dan pembuangan yang umum, memungkinkan beberapa katup dipasang secara kompak berdampingan.

Manfaat pemasangan manifold meliputi:

Untuk memaksimalkan masa pakai katup kontrol udara:

Untuk kontrol arah yang kuat dan andal, katup kontrol udara kami menawarkan kinerja yang Anda butuhkan. Jelajahi rangkaian produk kami untuk menemukan yang paling sesuai untuk aplikasi Anda, atau hubungi spesialis pneumatik kami untuk mendapatkan panduan dan solusi ahli.